Patents

Literature

41results about How to "Improve one-time assembly pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

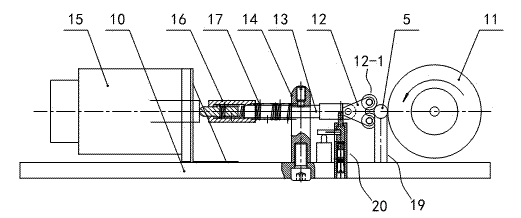

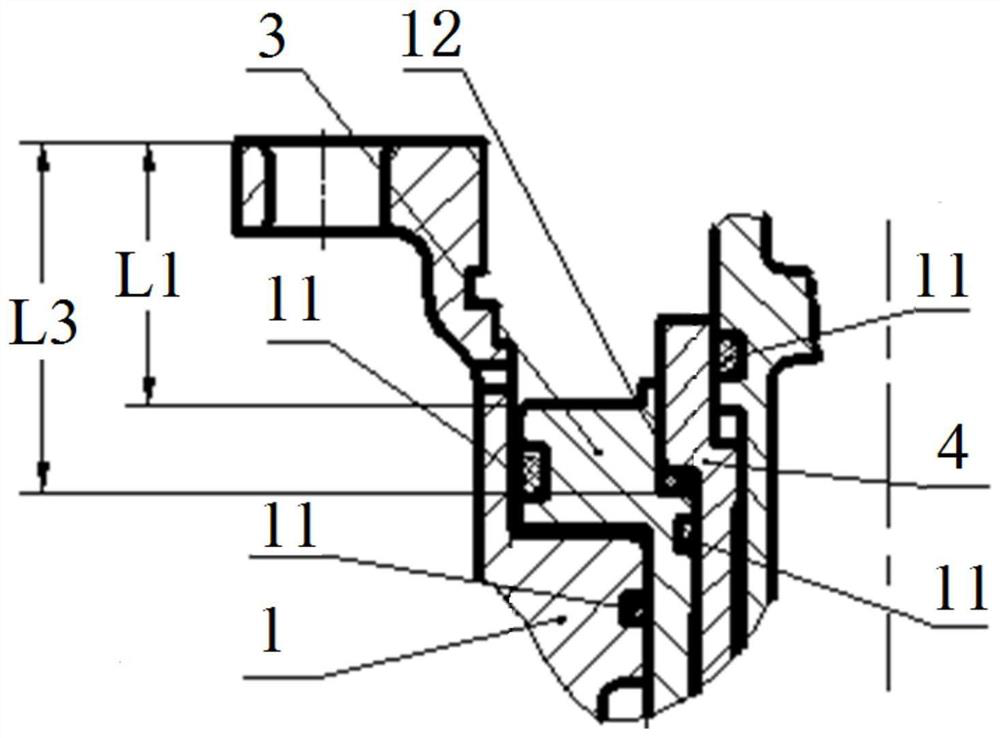

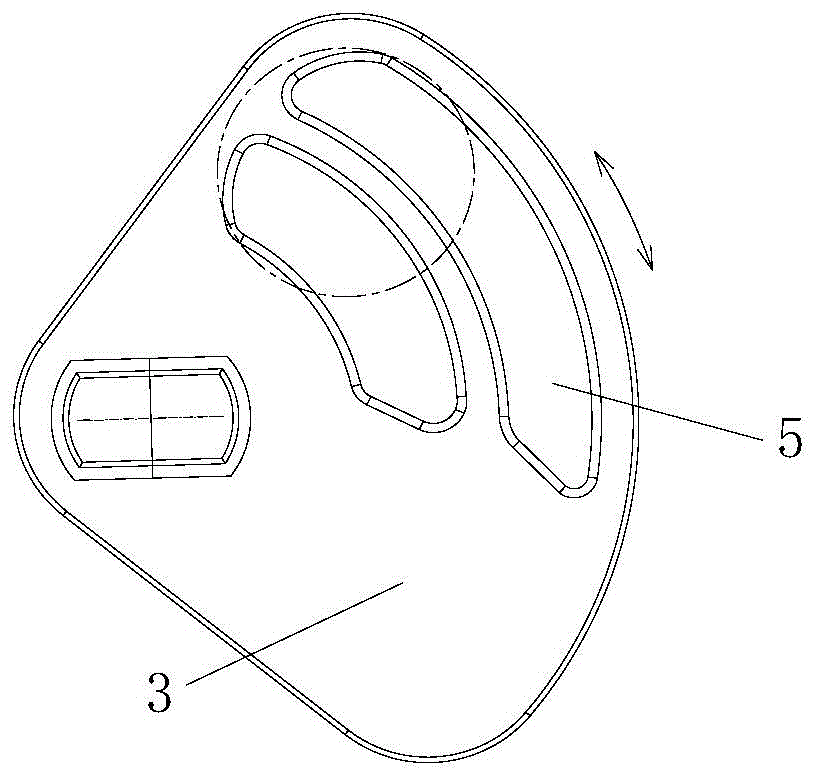

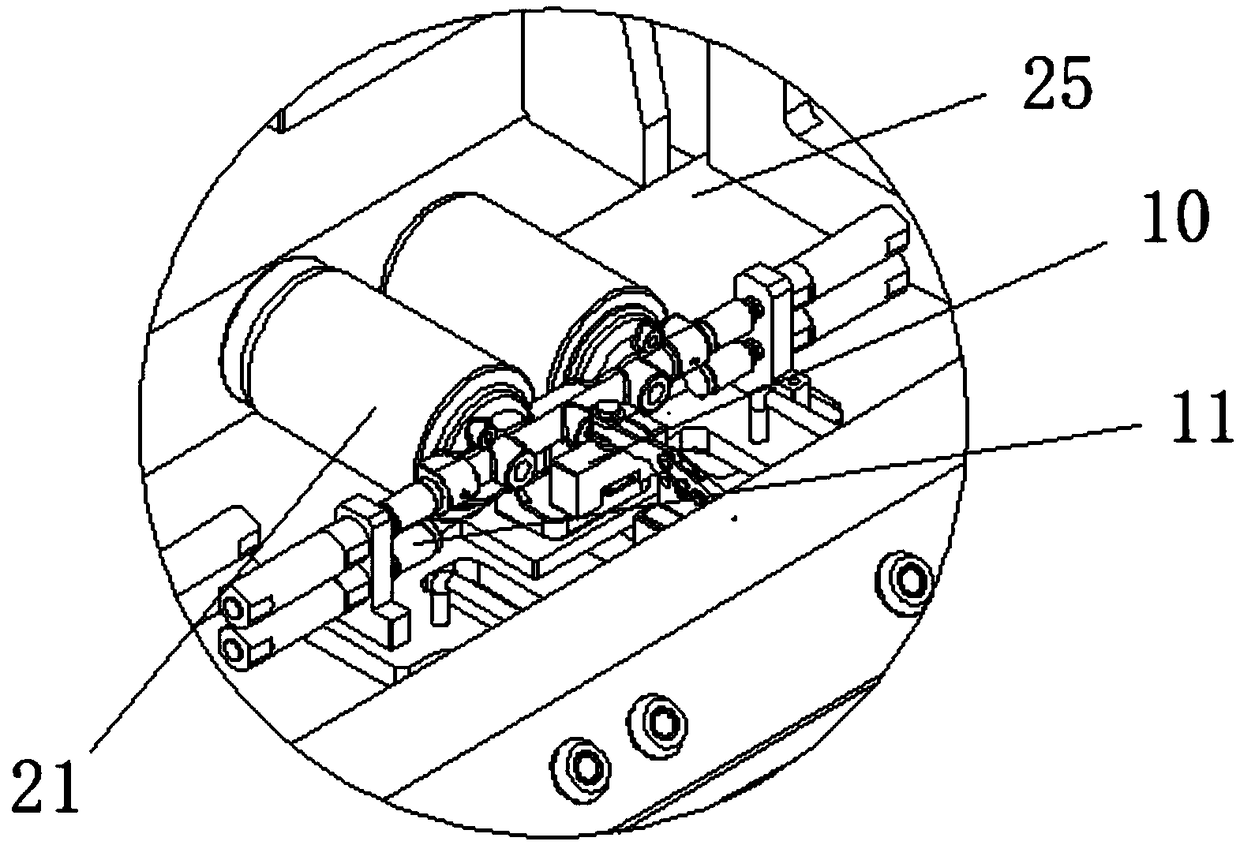

Device for rapidly detecting size parameters of cylinder type excircle shape

InactiveCN105387817AHigh dimensional consistencyImprove one-time assembly pass rateUsing optical meansObservational errorGrating

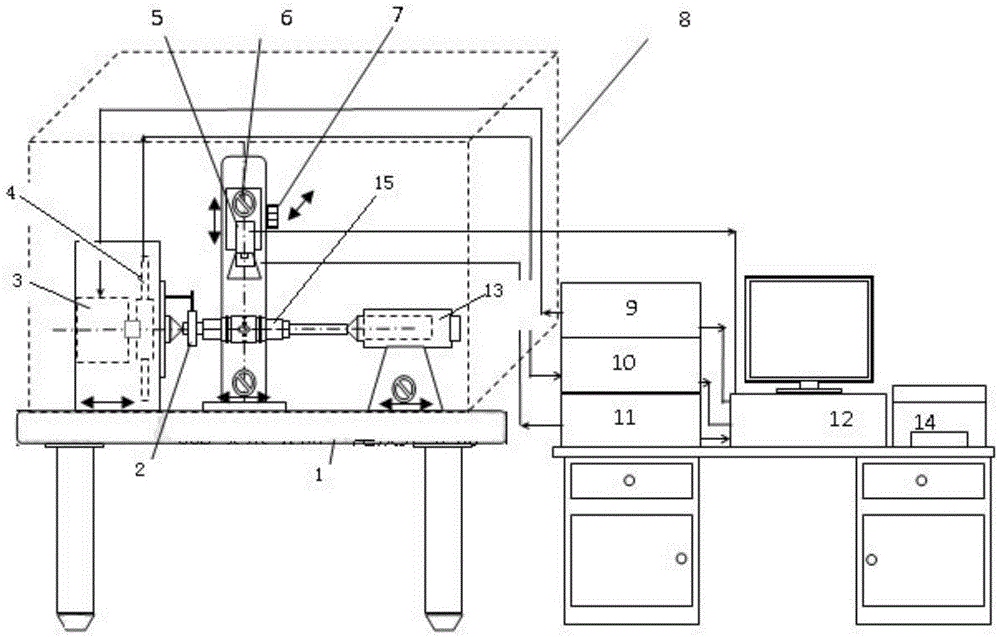

The invention discloses a device for rapidly detecting size parameters of a cylinder type excircle shape, and aims at providing the rapid detection device simple in structure, high in measuring efficiency and capable of improving the measuring precision. A CCD camera (5) whose lens just faces a clamped detected workpiece (2) is arranged over the clamped detected workpiece, the CCD camera (5) collects images of the clamped detected workpiece which is driven by a servo motor to rotate, the collected calibration position size of each groove is converted into a digital signal, the digital signal is transmitted to a circular grating (4) fixed on a main shaft of the servo motor, the angular displacement of the detected workpiece, namely a moving object, is obtained, a linear array photosensitive tube calculates the position size of each groove via a computer image processing software system input by a reading head device, parameters including the width, the position accuracy and the verticality of the calibration groove of the detected workpiece are displayed and printed. The device can be used to overcome the disadvantages that errors of manual measurement influence test results a lot and cause low measuring efficiency.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

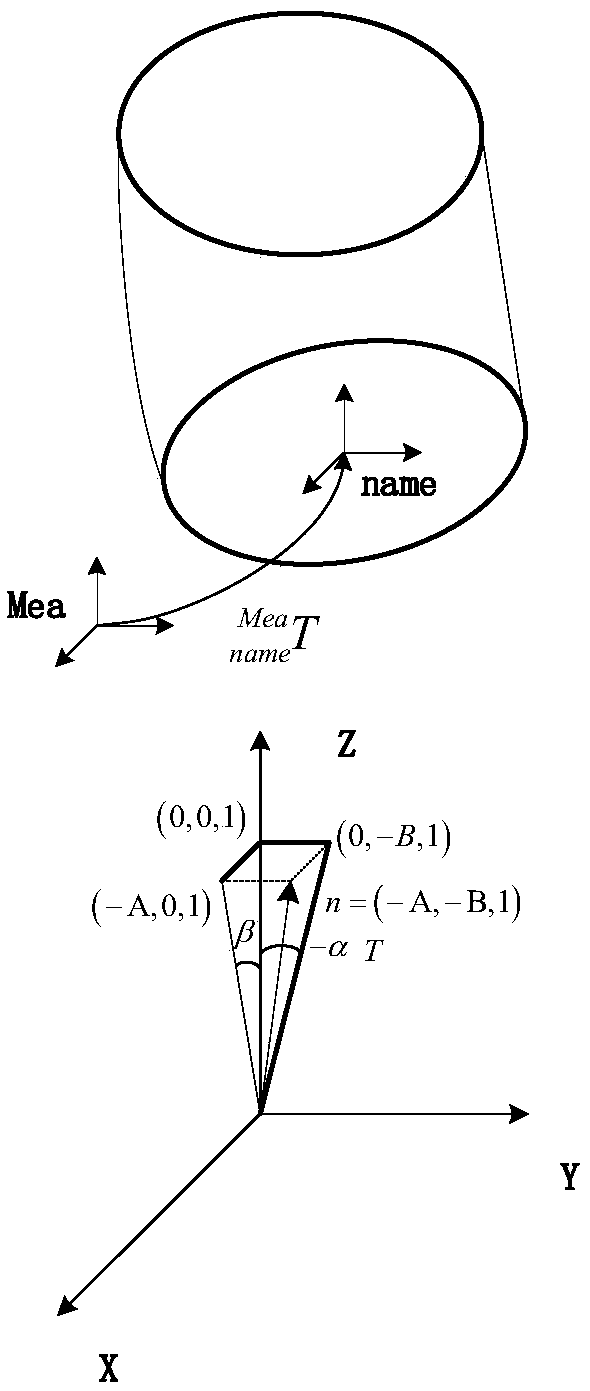

Self-adaptive adjustment method and system based on digital twinborn body

PendingCN111046549AImprove one-time assembly pass rateImprove assembly and debugging efficiencyDesign optimisation/simulationReal-time dataSimulation

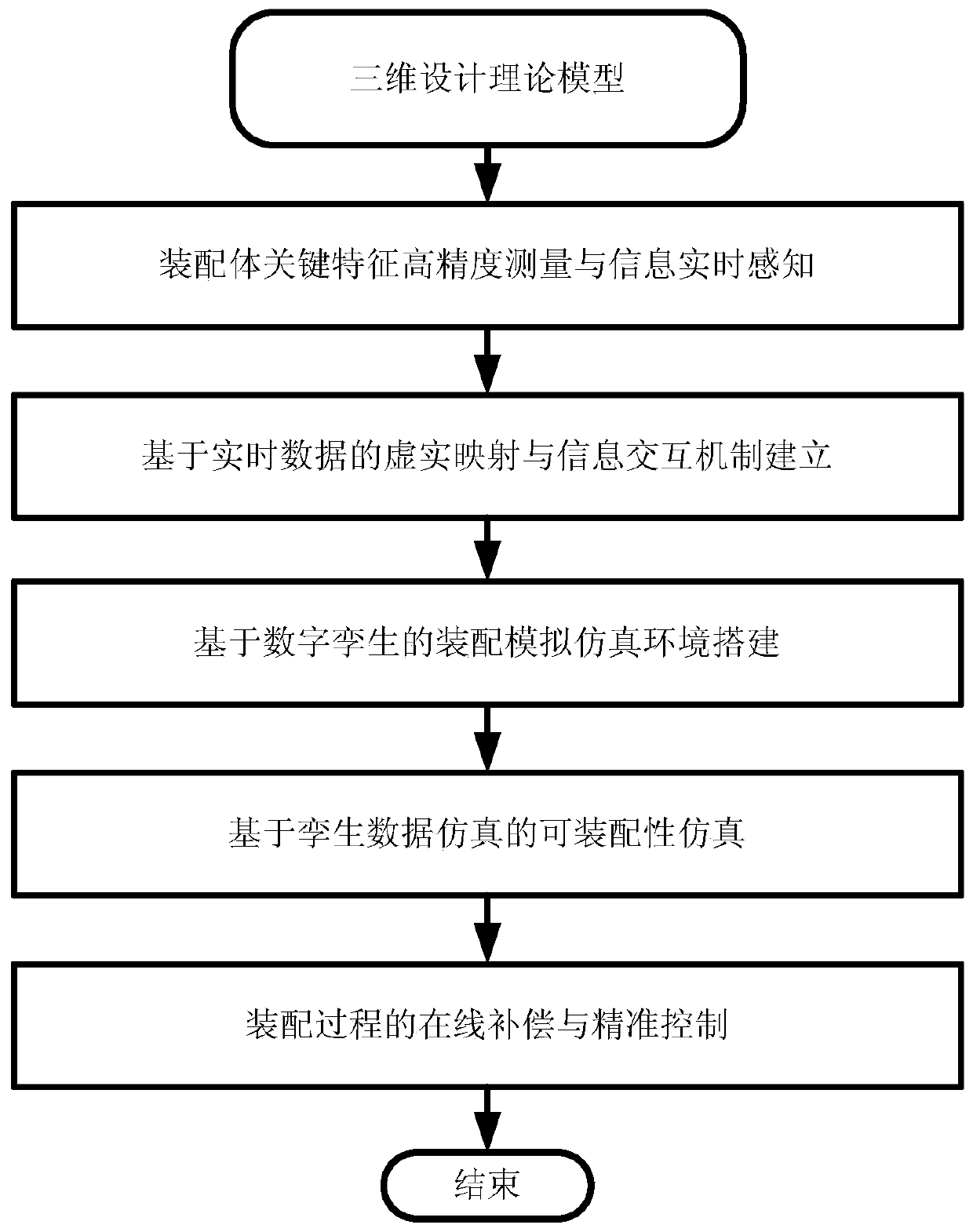

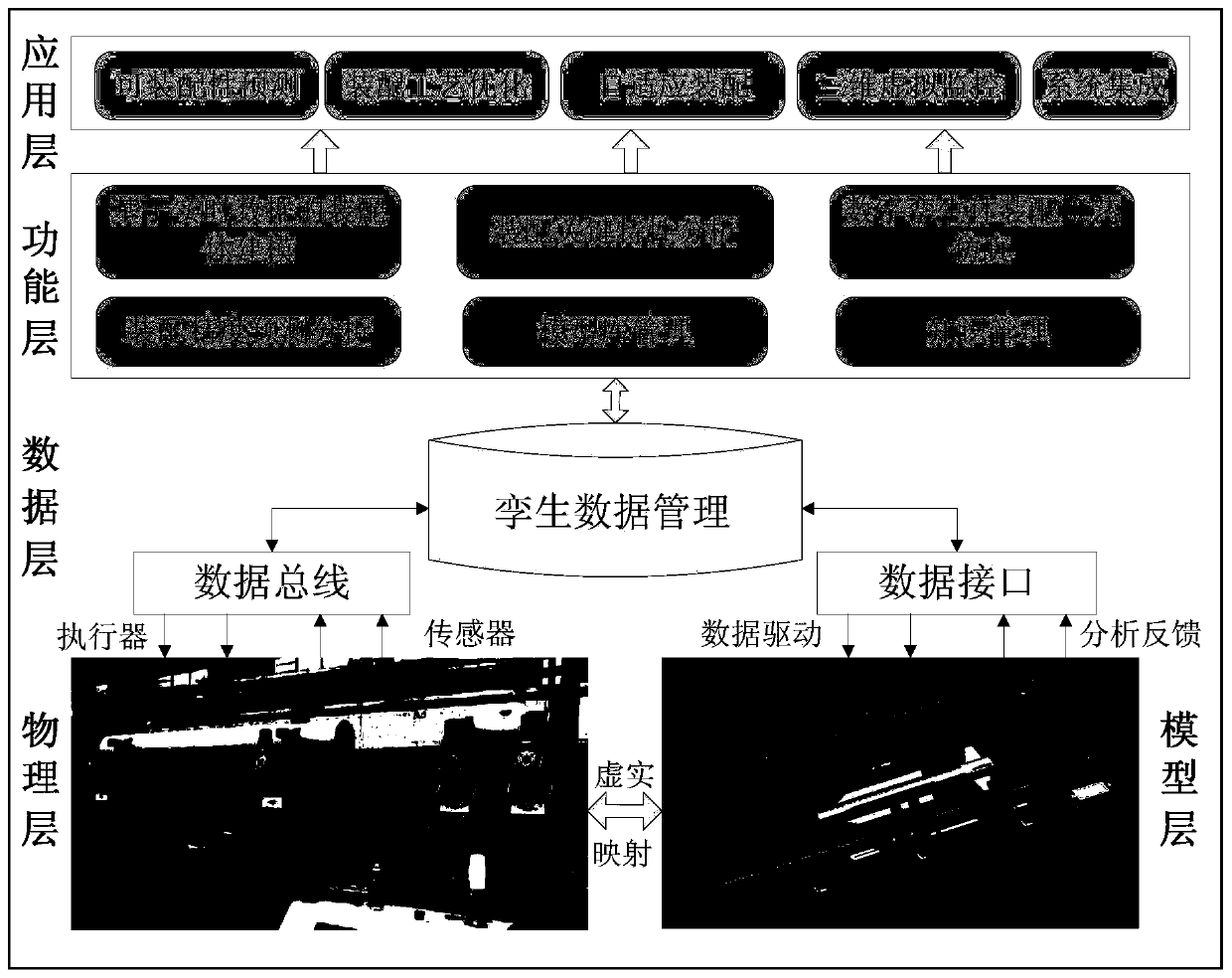

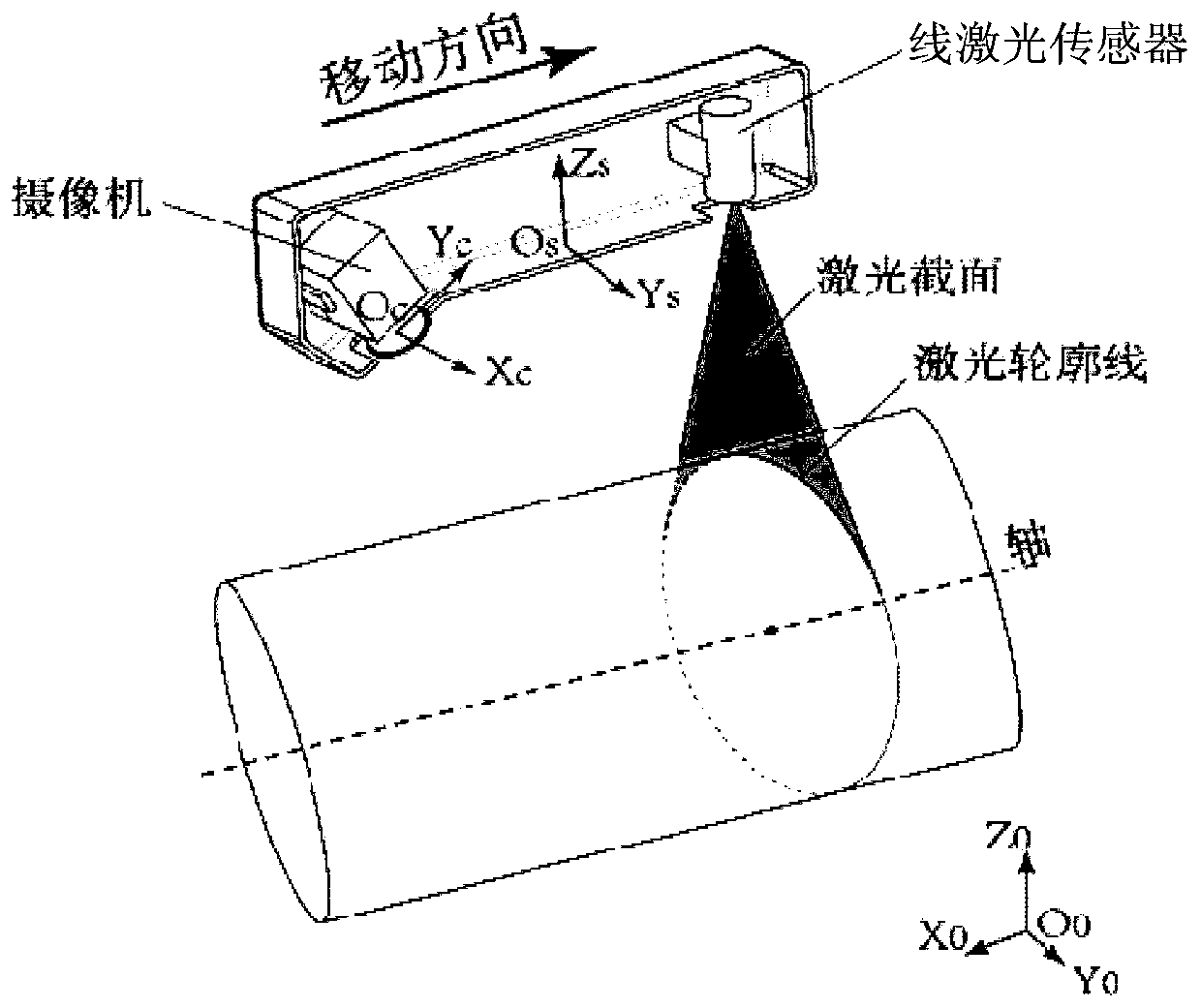

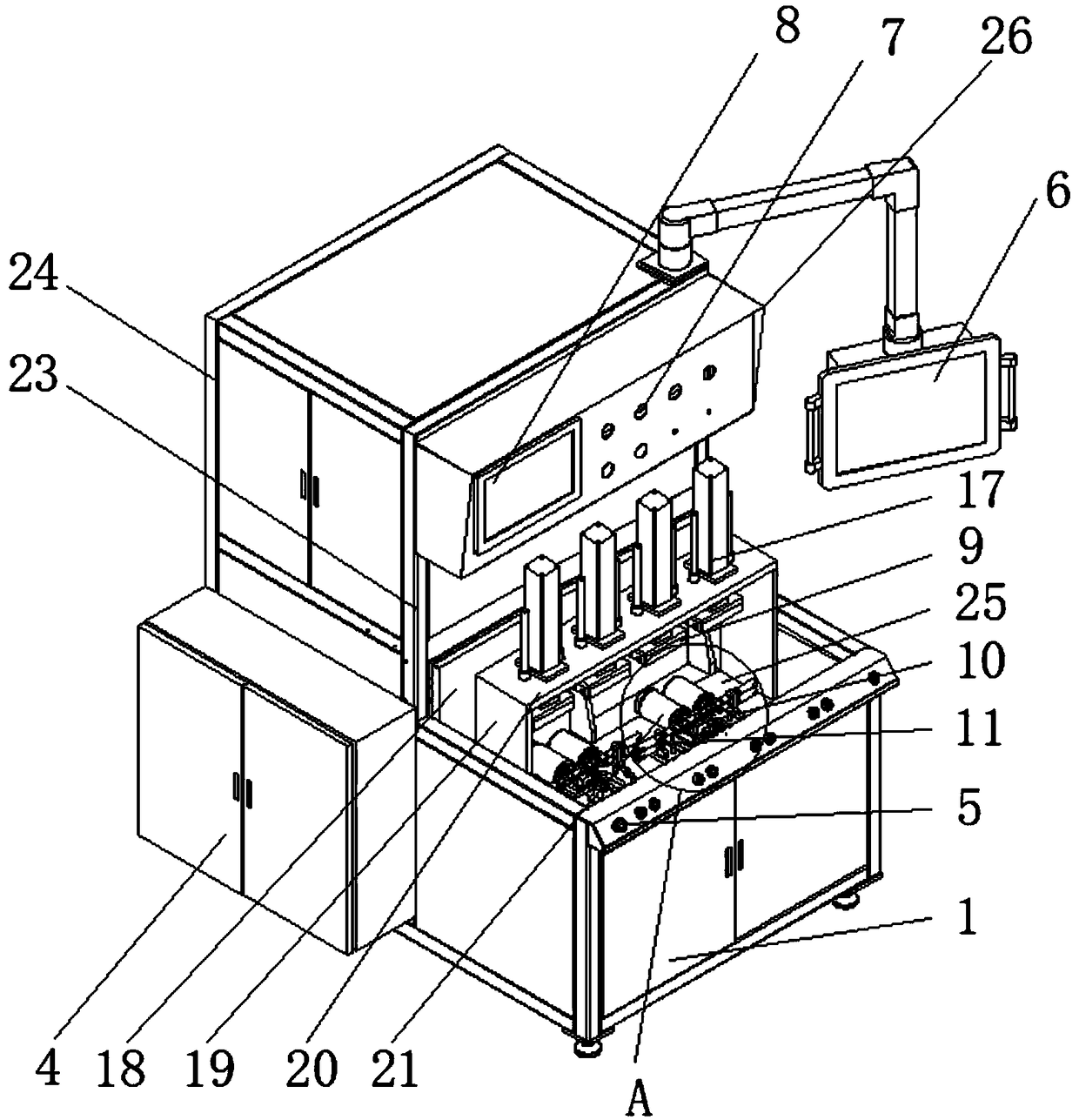

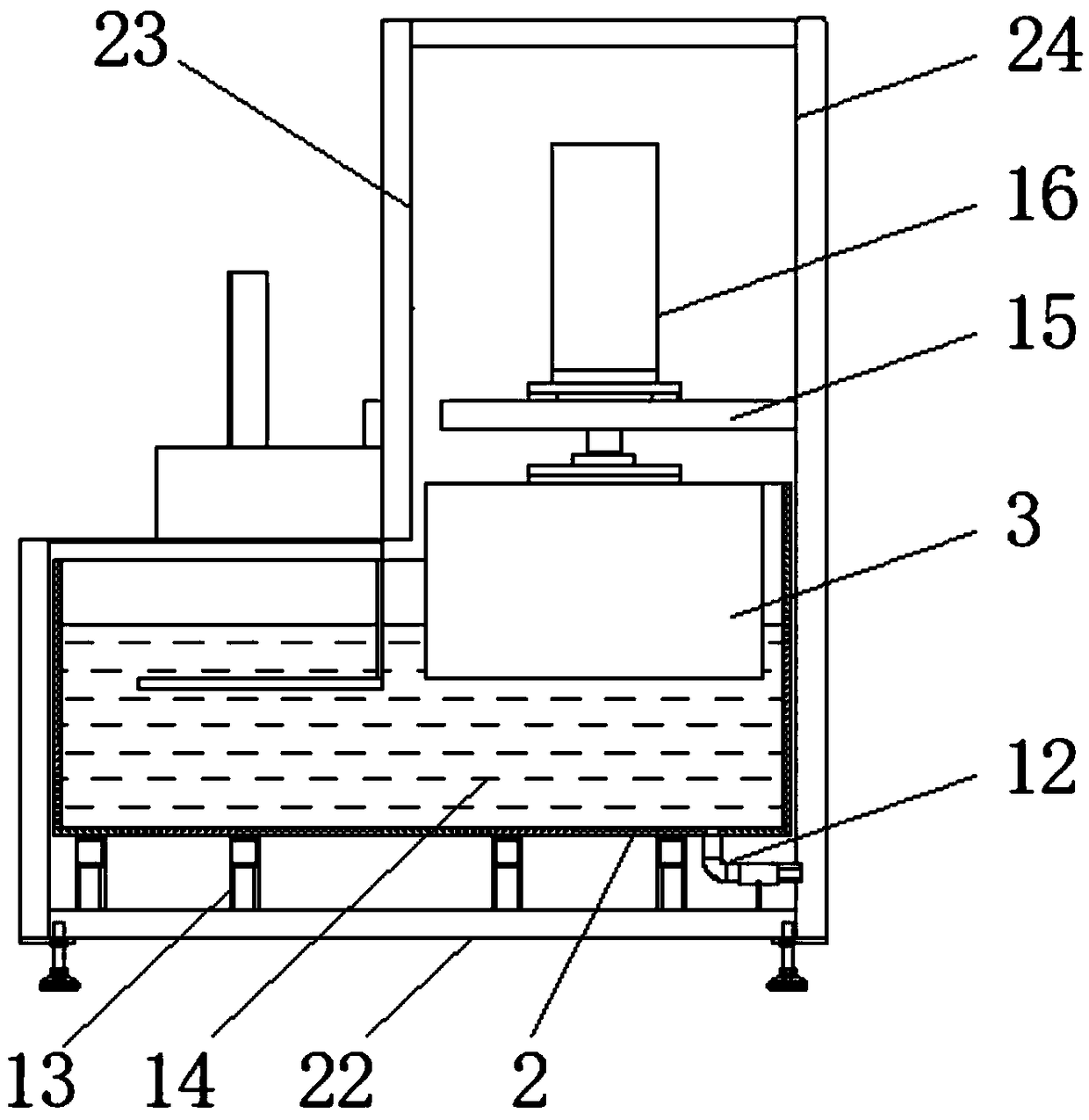

According to the self-adaptive adjustment method and system based on the digital twinborn body, a line laser sensor and a camera are used for carrying out digital measurement on the outline and end face positioning pin of a cylindrical assembly body, and the axis of the cylindrical assembly body and the axis of a pin hole are fitted out; by adjusting the position of the cylindrical assembly body,the axes of the assembly body are controlled to be consistent, and self-adaptive assembly and adjustment are achieved based on digital twinning body virtual monitoring. Techniques by means of digitaltwinning, an assembly analog simulation environment based on virtual-real fusion is constructed; the manufacturing system Internet of Things serves as a carrier, interconnection and intercommunicationbetween the physical world and the information world in the assembling process are achieved, and through virtual-real mapping and information interaction based on real-time data, precise simulation,monitoring, diagnosis, prediction and control over the states and behaviors of aerospace precise complex product parts, equipment and the assembling process are achieved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

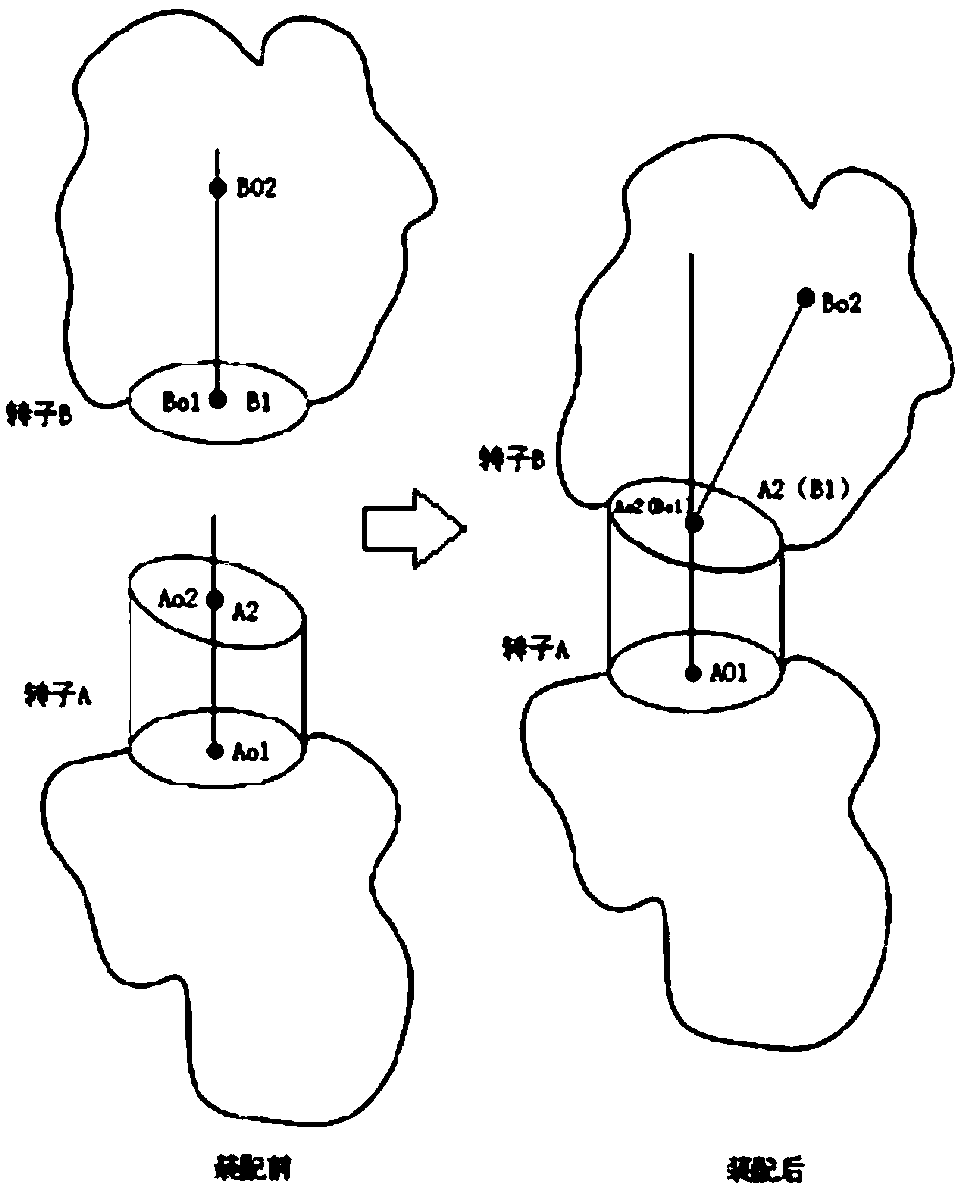

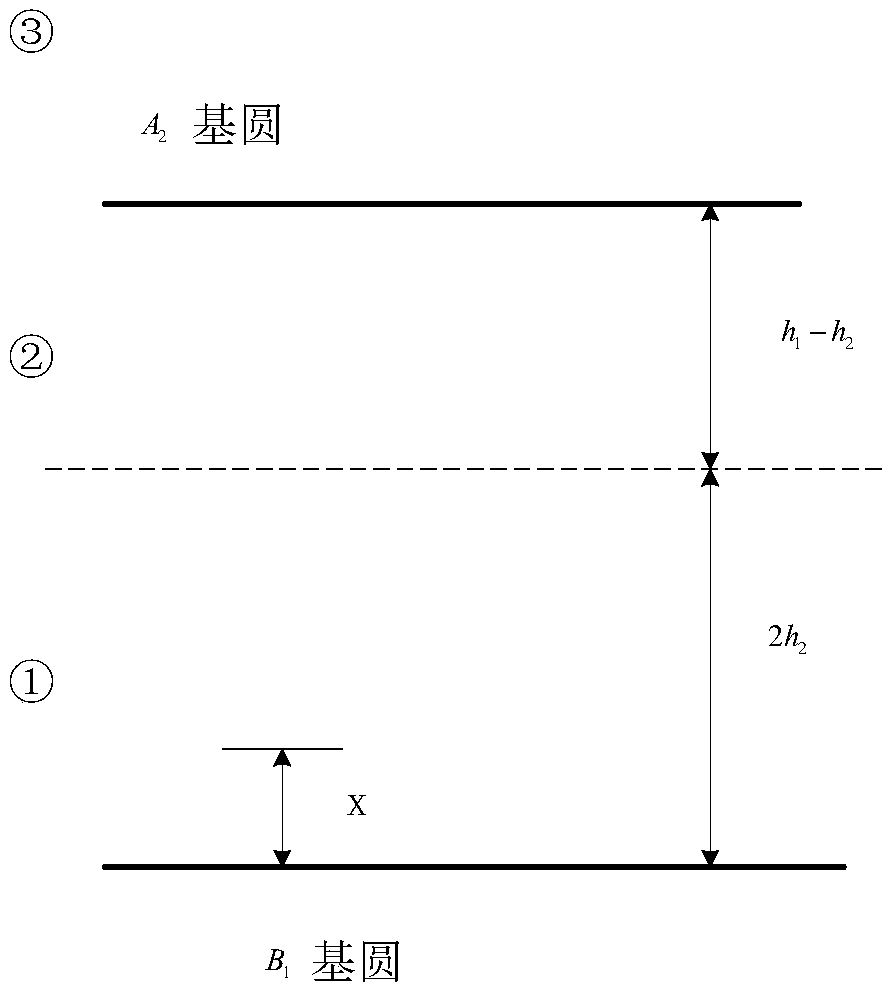

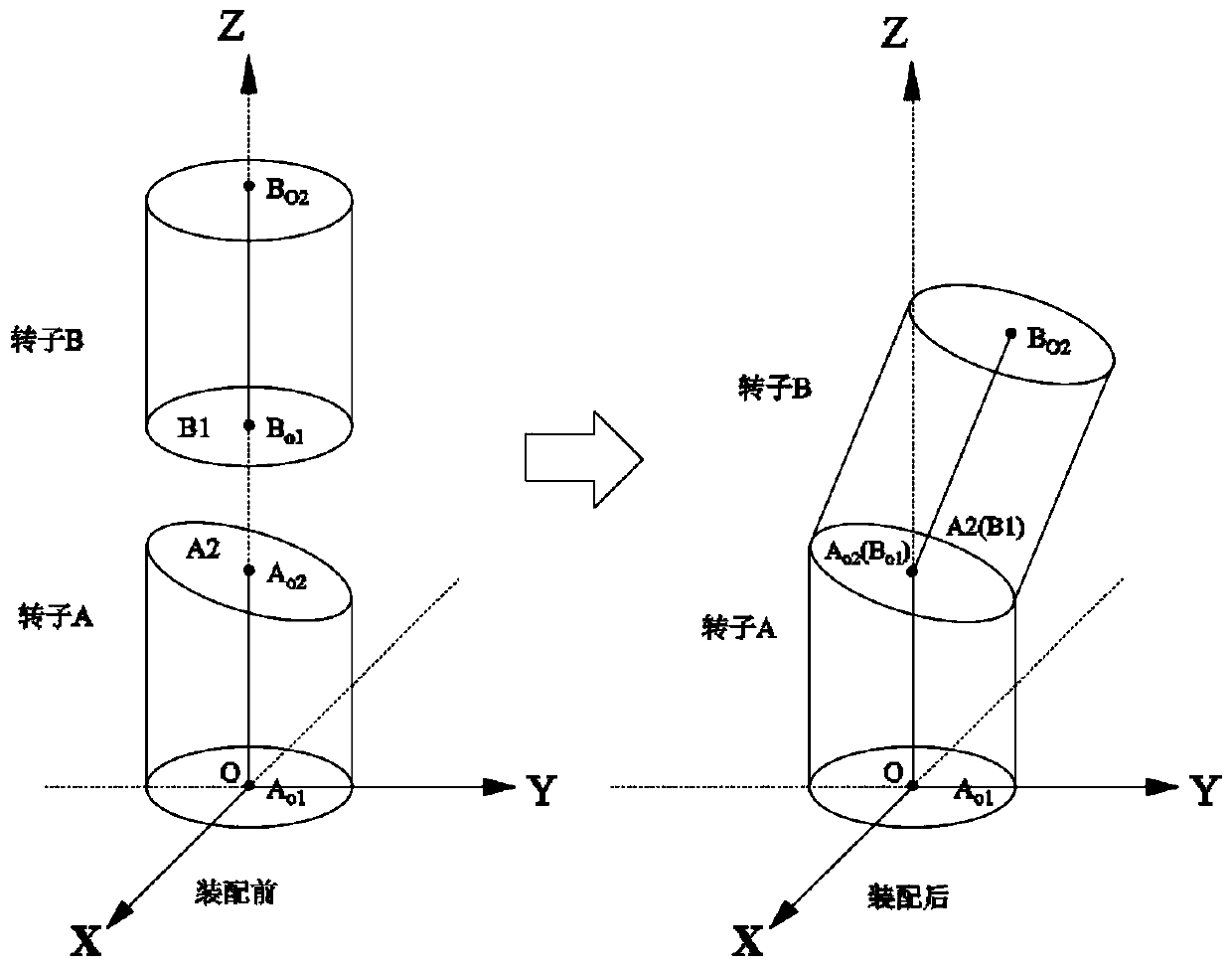

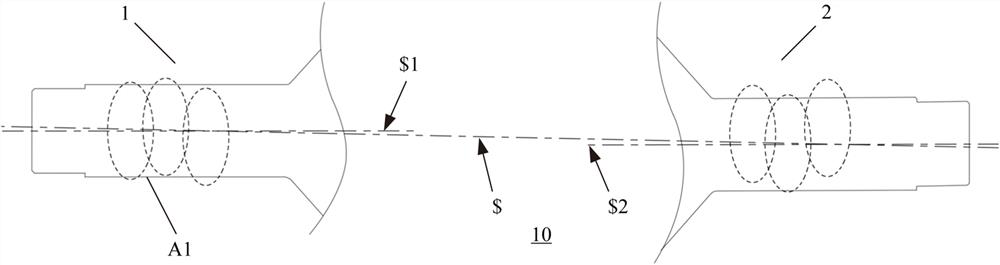

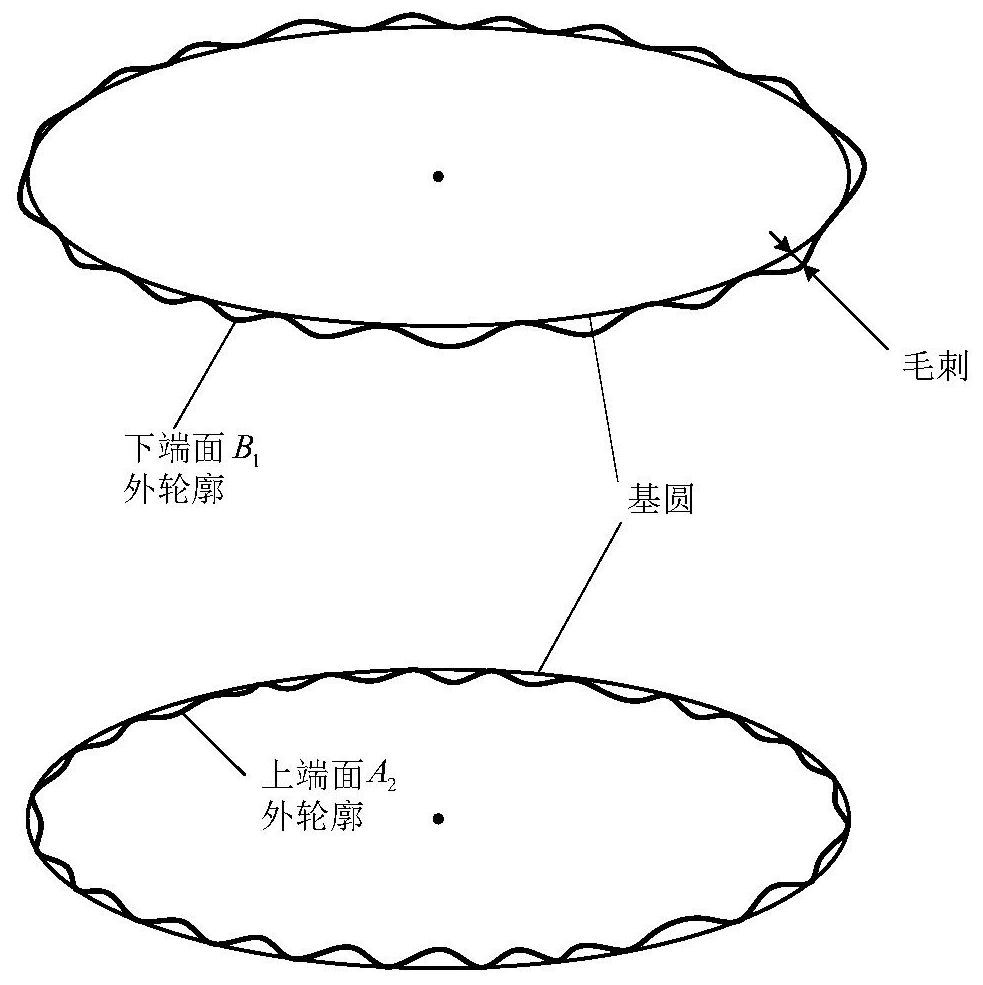

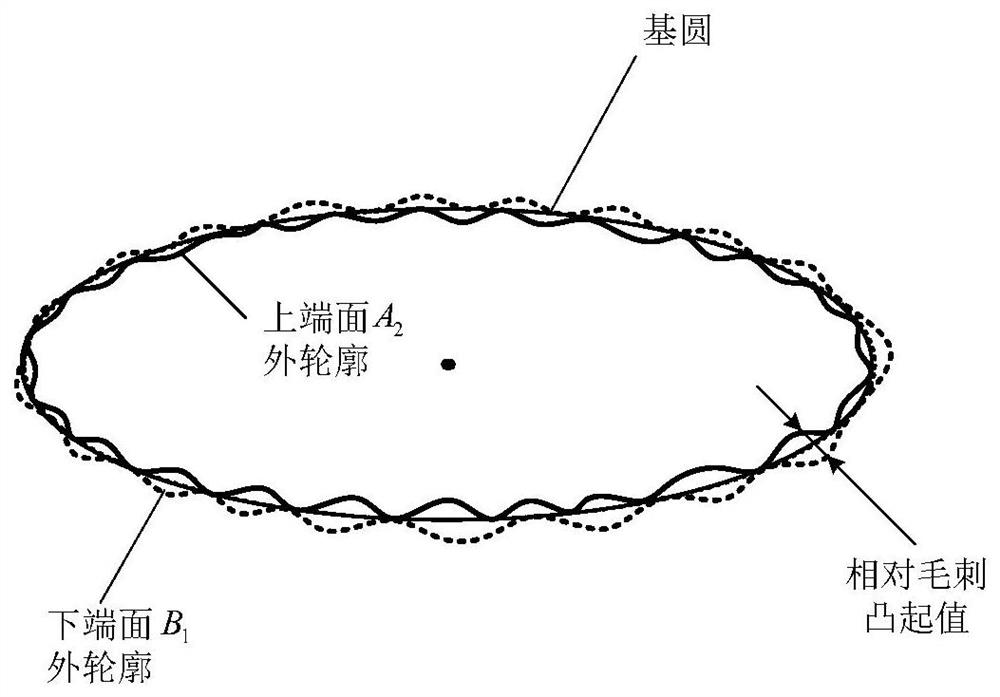

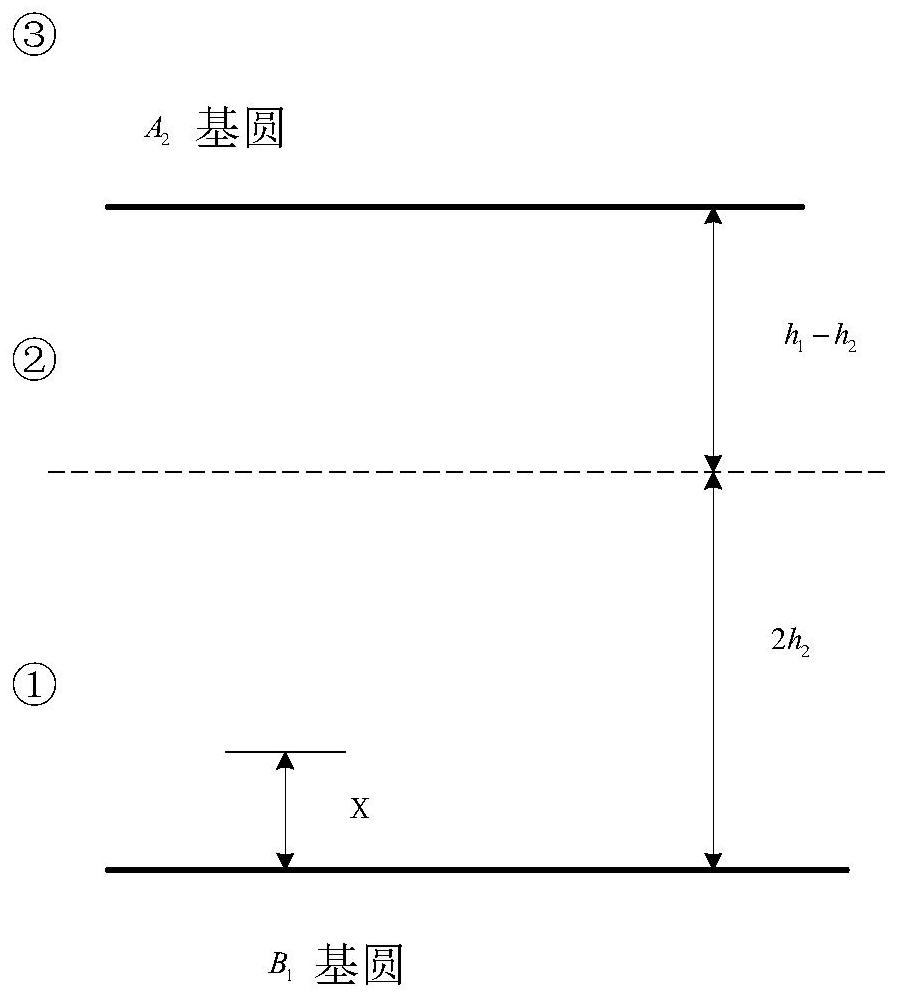

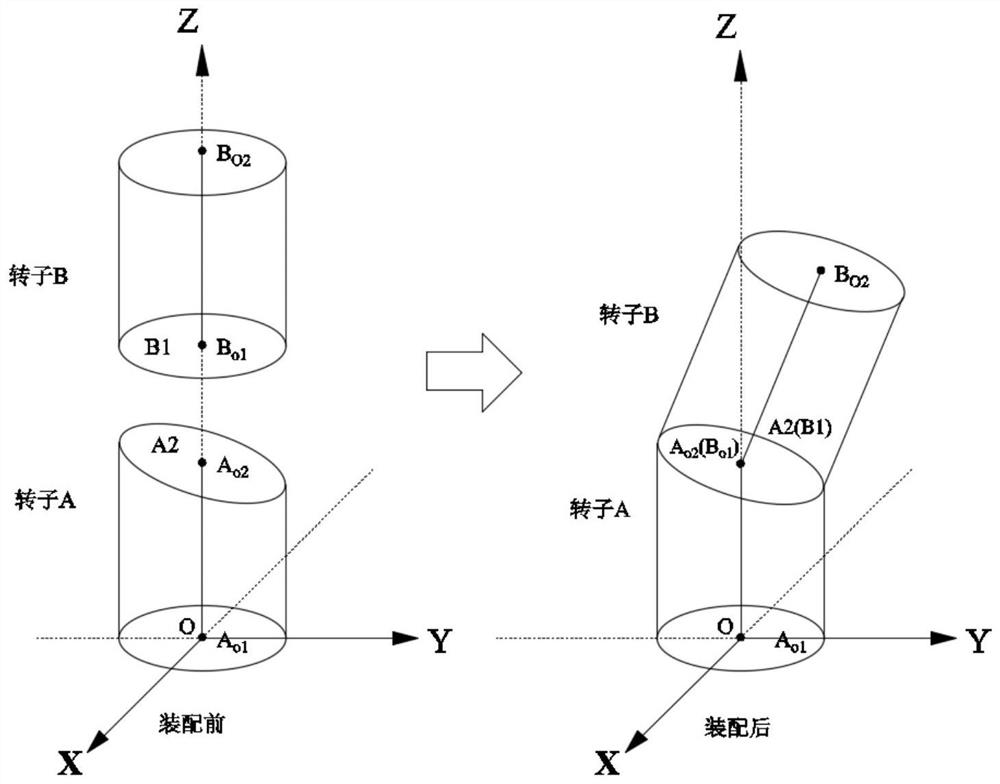

Method for calculating rotor assembly axis deflection based on end-skip measurement

ActiveCN109117460AReduce the number of repeated disassembly and assemblyImprove one-time assembly pass rateComplex mathematical operationsAviationTransformation algorithm

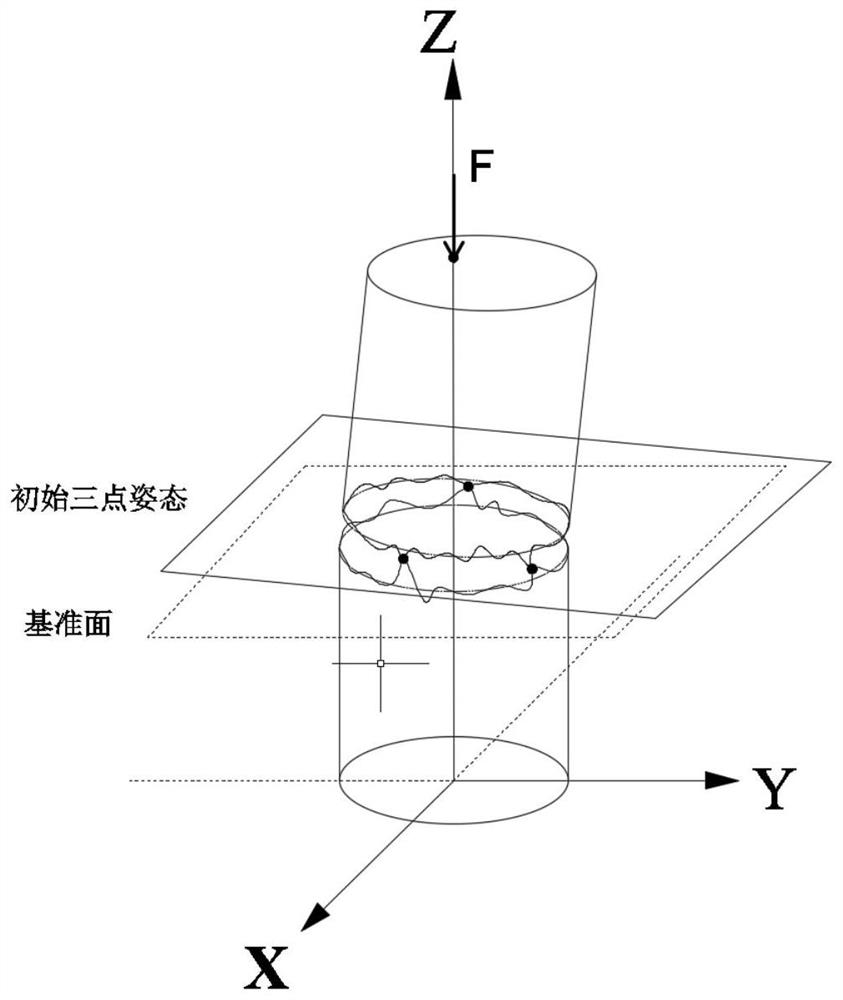

The invention relates to a method for calculating rotor assembly axis deflection based on end-skip measurement, which comprises three parts: calculation of three contact points, triangle judgment criterion and homogeneous coordinate transformation algorithm of deflection matrix. The three-point contact calculation mainly includes the characterization of initial measurement data, the determinationof contact point, the determination of deflection direction and the characterization method. The triangle criterion is used to judge whether the three points are in conformity with the reality, and the principle of determination, calculation method and the determination process of abandoned points are described in detail. The homogeneous coordinate transformation algorithm of deflection matrix includes the matrix representation of inclination direction and size, the calculation method and matrix representation of the overall axis deflection of the final assembly result, etc. Based on the measured end-skip data in production practice, the method realizes the prediction of axis deviation before assembly, improves the coaxiality of the assembled rotor, and greatly improves the pass rate of one-time assembly, which has important practical guiding significance for the axis prediction, assembly phase adjustment and optimization in the assembly process of aero-engine rotor parts.

Owner:DALIAN UNIV OF TECH

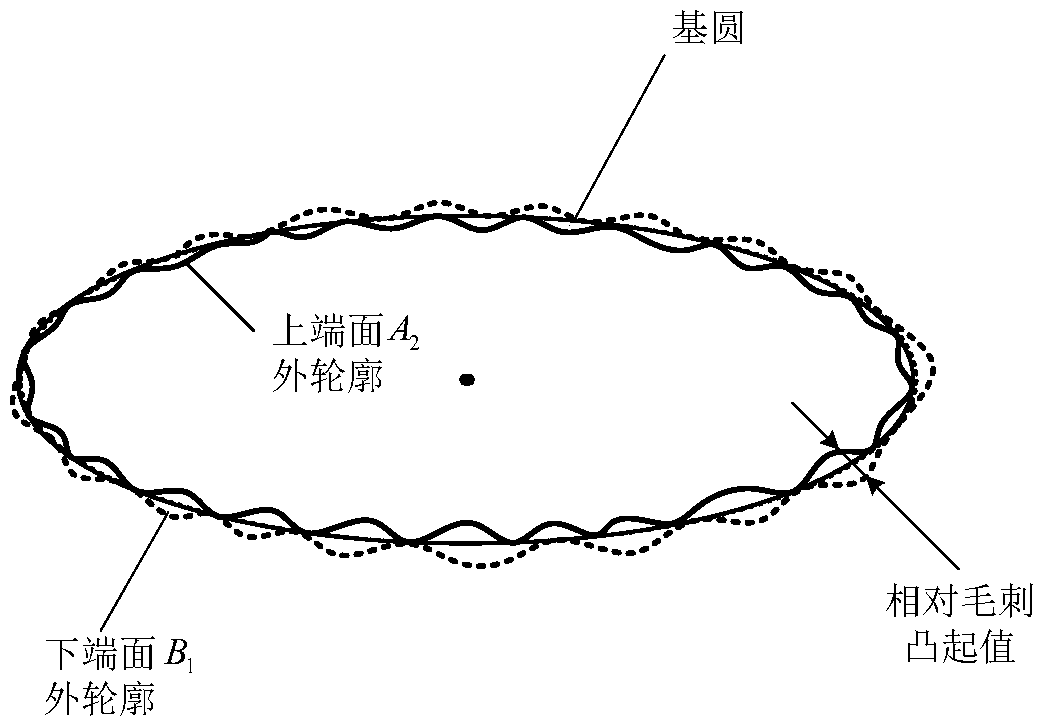

Method for calculating rotor assembly axis eccentricity based on radial skip measurement

ActiveCN109117461AReduce the number of repeated disassembly and assemblyImprove one-time assembly pass rateComplex mathematical operationsContact forceComputer science

The invention relates to a method for calculating the eccentricity of a rotor assembly axis based on radial skip measurement, which comprises the matrix representation of each point data and the calculation of relative skip value, the establishment of an equivalent spring model and the calculation of each point contact force under an ideal state, and the direction and magnitude of the eccentricity. The calculation of relative runout value of each point and the calculation of assembly interference of each point according to the diameter jump data of two stopper fitting surfaces; Based on the assumption of elastic deformation, the spring equivalent model is established to analyze the relationship between force and displacement in each stage of the contact process, and then the non-uniform contact force at each point is obtained by the non-uniform interference. The determination of eccentricity is based on the equivalent model of spring and the equilibrium equation of state to determine the size of the eccentricity. Based on the measured diameter skip data in production practice, the method realizes the prediction of axis eccentricity before assembly, improves the coaxiality of rotorafter assembly, and has important practical guiding significance for the axis prediction, assembly phase adjustment and optimization in the assembly process of aero-engine rotor parts.

Owner:DALIAN UNIV OF TECH

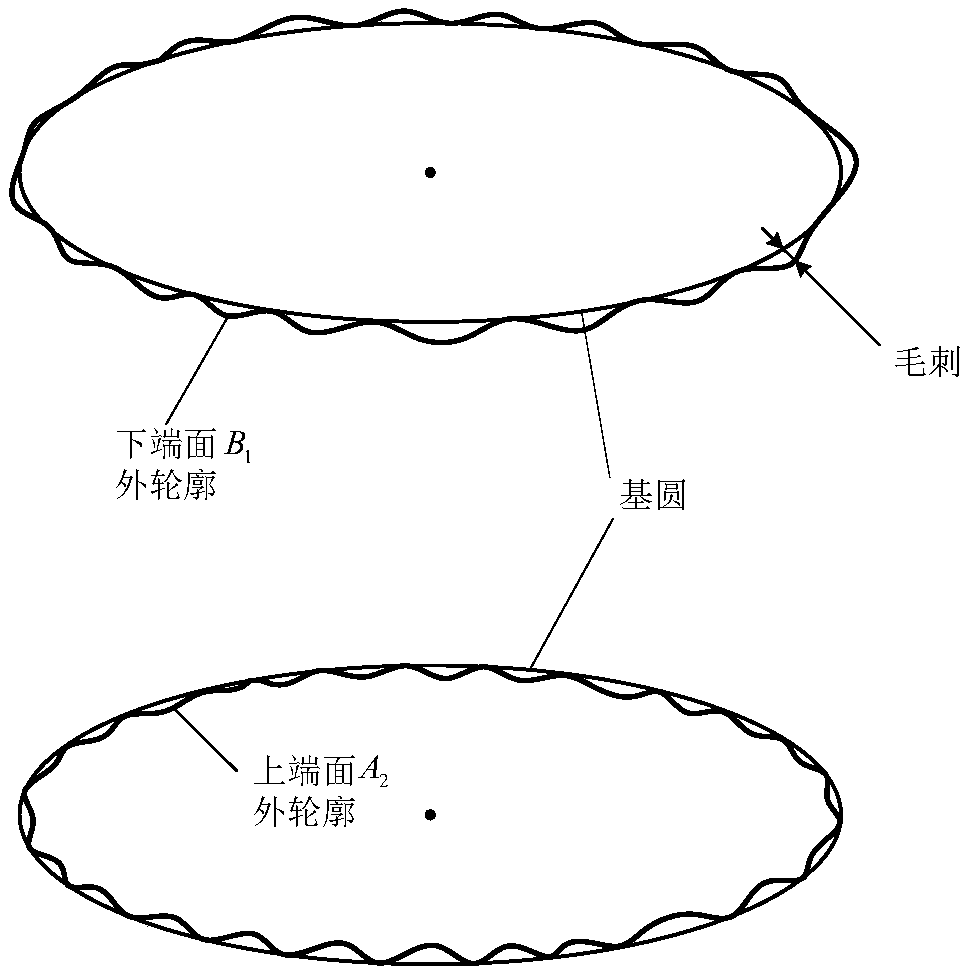

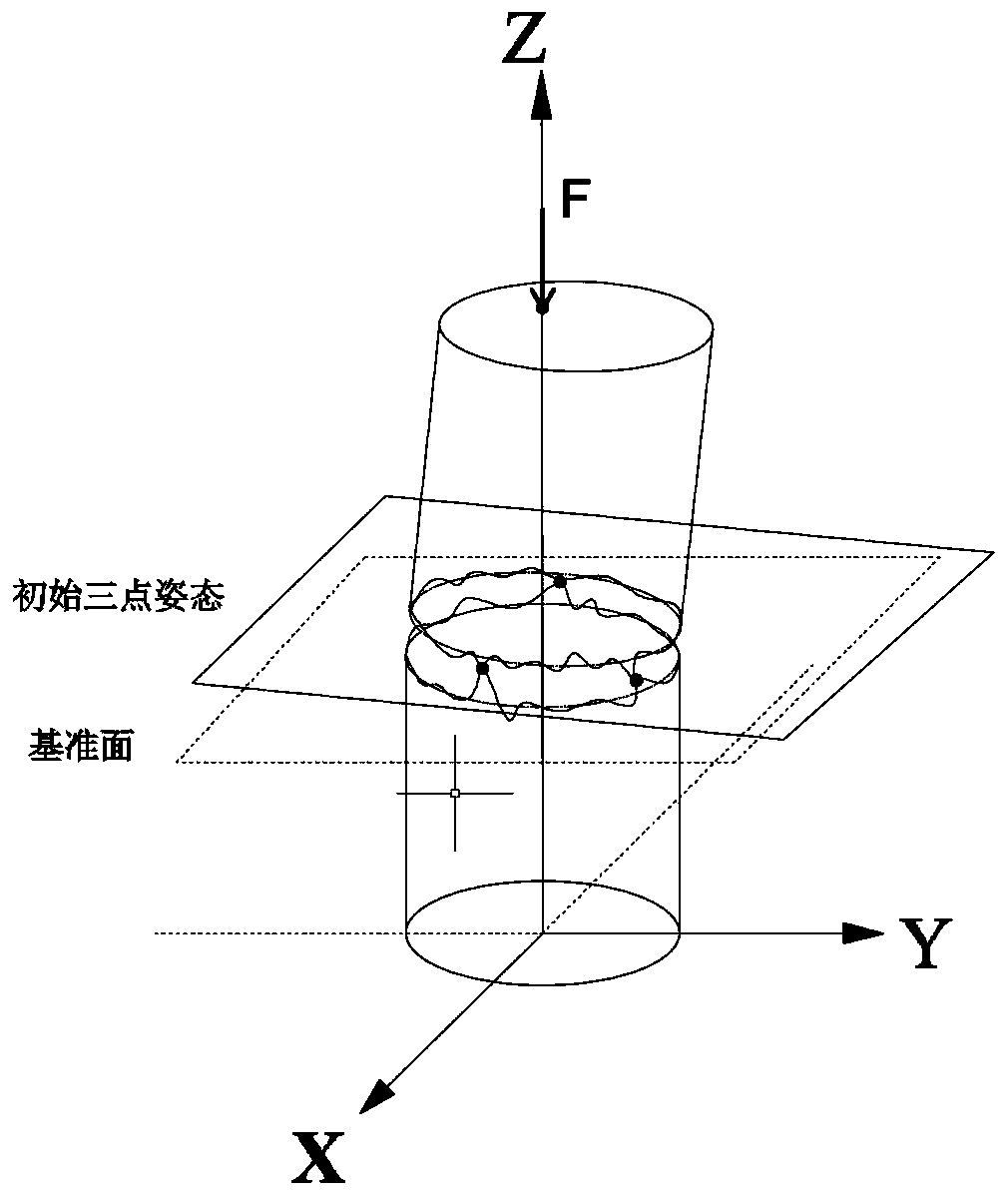

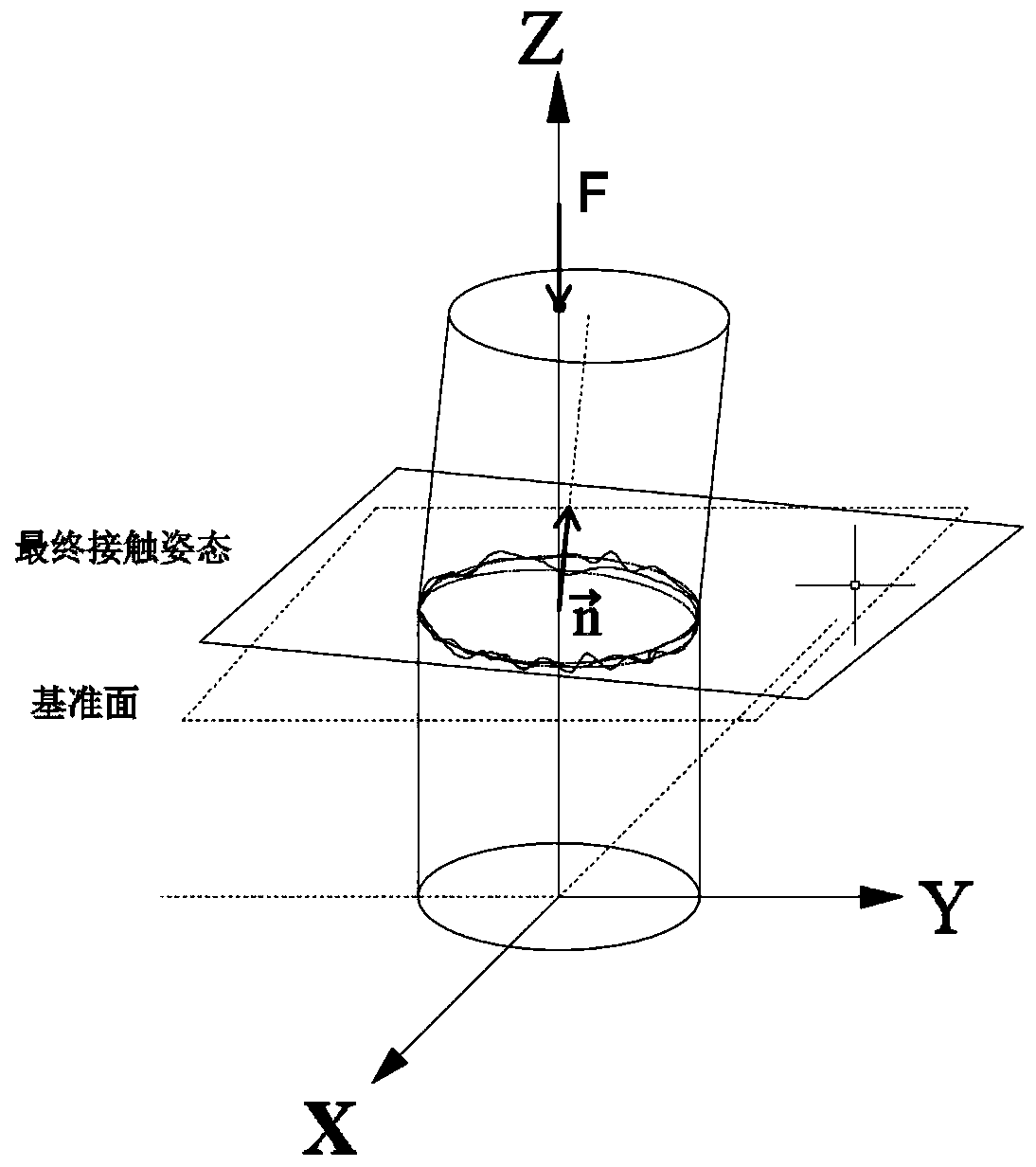

Elastic algorithm for calculating rotor assembly pose based on end jump measurement

ActiveCN110083906AAccurate predictionImprove coaxialityGeometric CADDesign optimisation/simulationAviationPrediction algorithms

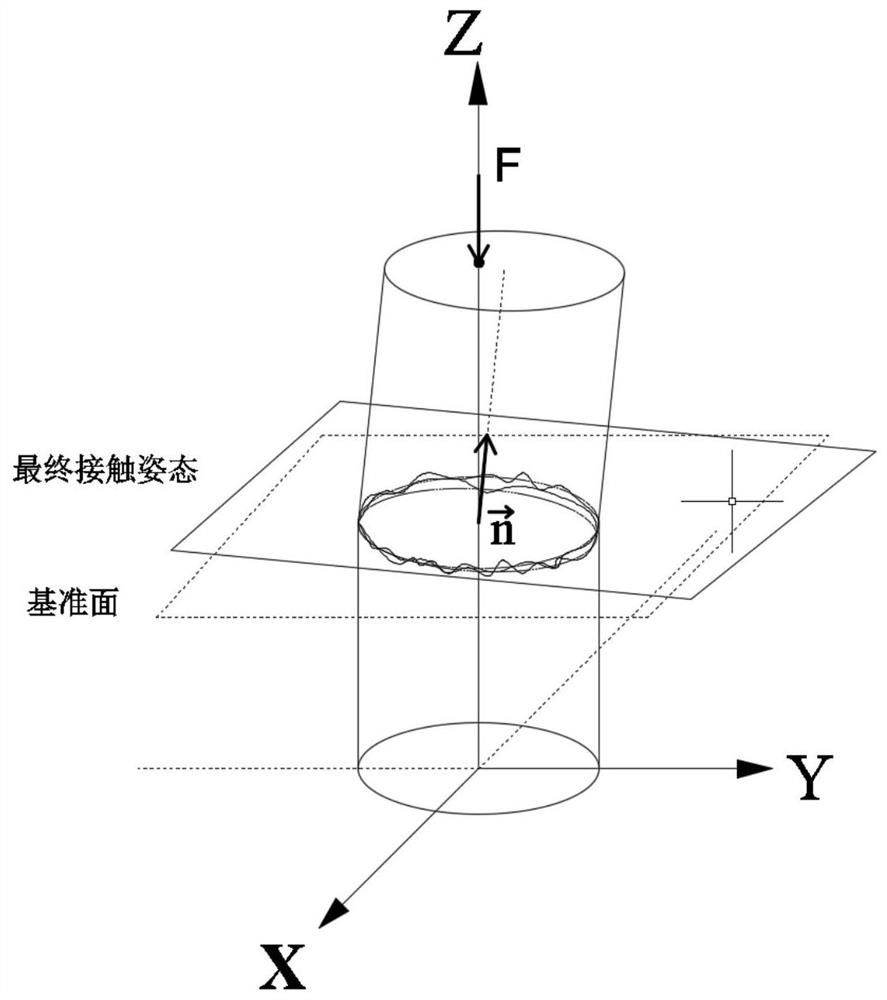

The invention discloses an elastic algorithm for calculating a rotor assembly pose based on end jump measurement. A rotor matching surface is equivalent to a plurality of micro-convex body contact pairs; the contact elastic deformation is calculated by using a Hertz contact rule, contact pairs which actually contact with each other are separated; the final contact state is judged through the energy and torque balance equation, the normal vector of the contact plane is finally solved to represent the contact pose, the rotor assembly pose prediction accuracy is improved, the assembly coaxialitycan be well reflected, and rotor assembly phase prediction and optimization are better achieved. The method is based on actually measured end hop data in actual production; elastic deformation generated in the assembly process is considered; the method has the advantages that the defects of a rigid prediction algorithm are overcome, the accurate prediction of the assembly pose before assembly is realized, the rotor coaxiality after assembly is improved, meanwhile, the one-time assembly qualification rate is greatly improved, and the method has important practical guiding significance for axisprediction and assembly phase adjustment and optimization in the assembly process of the aero-engine rotor piece.

Owner:DALIAN UNIV OF TECH

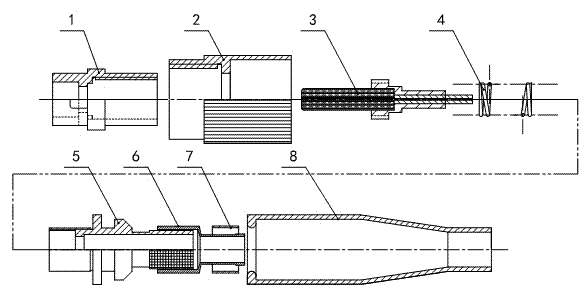

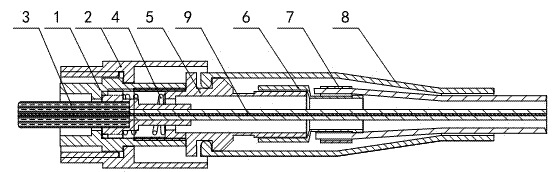

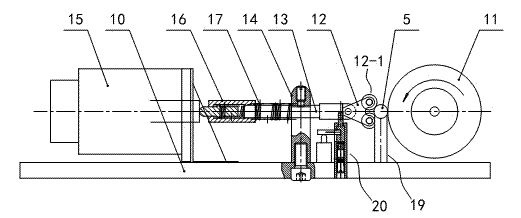

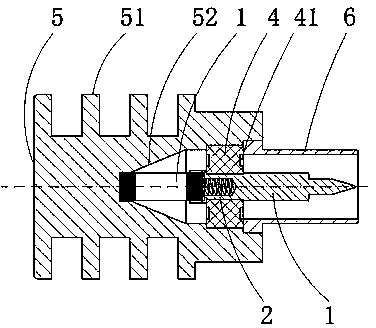

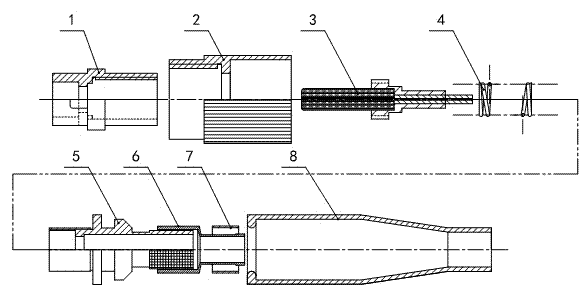

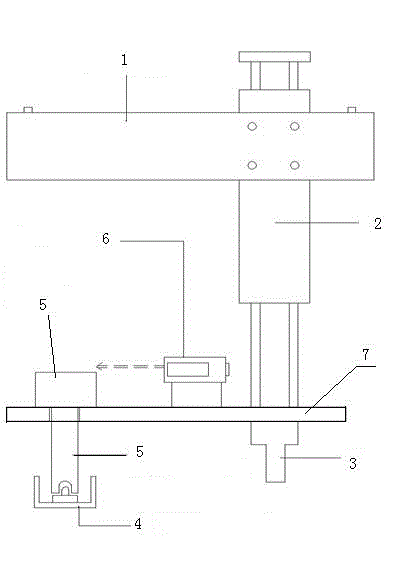

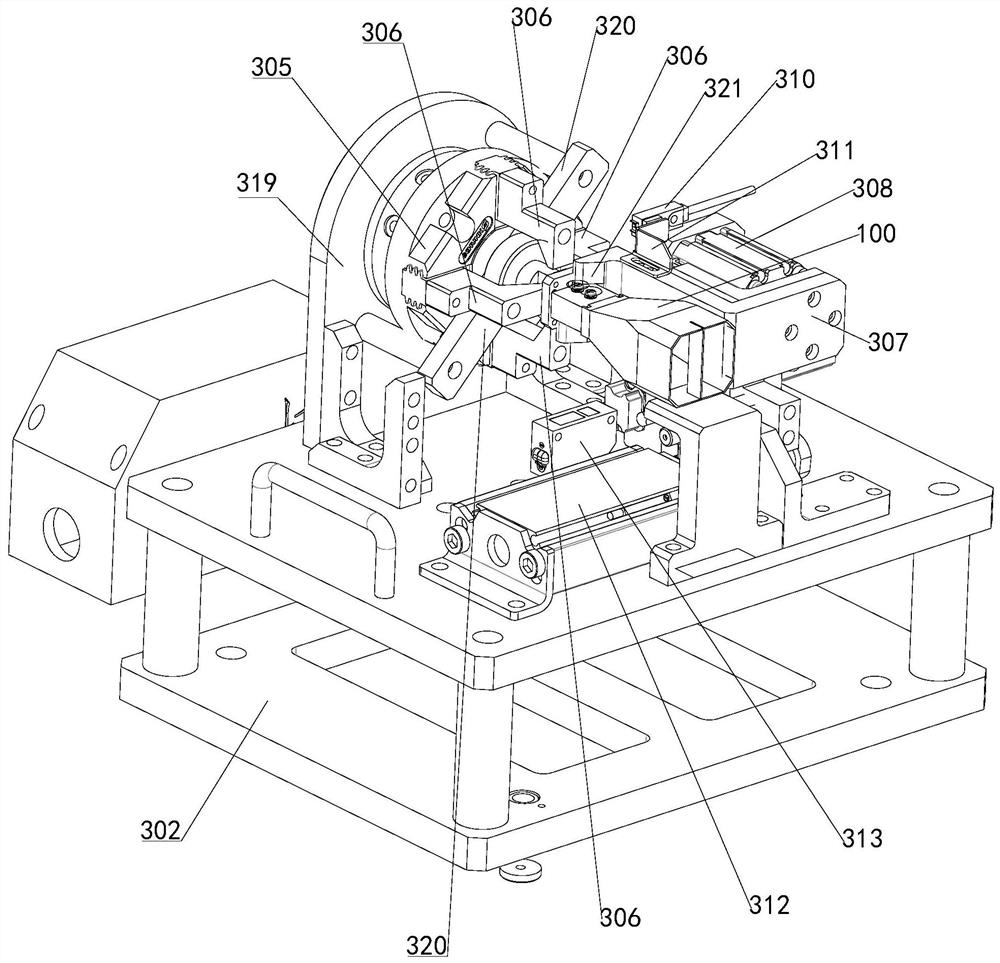

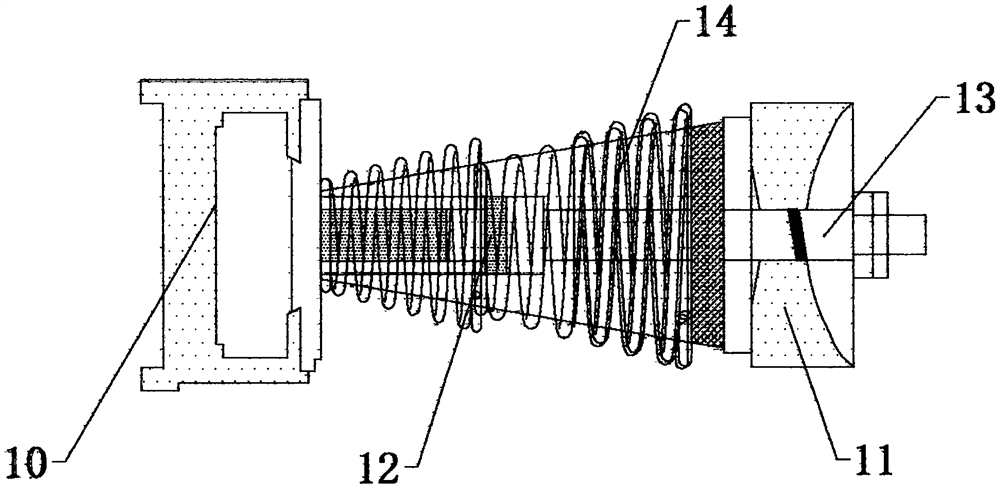

Rotary installation machine of movable optical-fiber connector

InactiveCN102335901AFast assemblyImprove one-time assembly pass rateMetal-working hand toolsDrive wheelEngineering

The invention discloses a rotary installation machine of a movable optical-fiber connector, which is characterized in that a base is provided with a friction-drive driving wheel in a rotating mode; a pressure head which forms a three-point positioning structure with the outer wheel edge of the driving wheel is installed near the outer wheel edge of the driving wheel; and the pressure head is in drive connection with a reciprocating drive mechanism. The rotary installation machine also comprises a fixture used for stopping a front positioning sleeve to rotate, wherein the fixture is connected with a torque control device for limiting a rotation degree between the front positioning sleeve and a connection sleeve. The phenomenon that the burrs of the workpiece hurt people in the manual assembling process can be avoided, and the assembling efficiency is greatly improved. Meanwhile, the defect that manual assembling and rotary installation can not achieve proper position, and screwing force is small can be overcome, the one-time assembling percent of pass of the movable optical-fiber connector is greatly improved, the phenomenon of pad control increase in the use process can be avoided, and the production and use cost of the movable optical-fiber connector can be lowered.

Owner:HENAN COMM CABLE

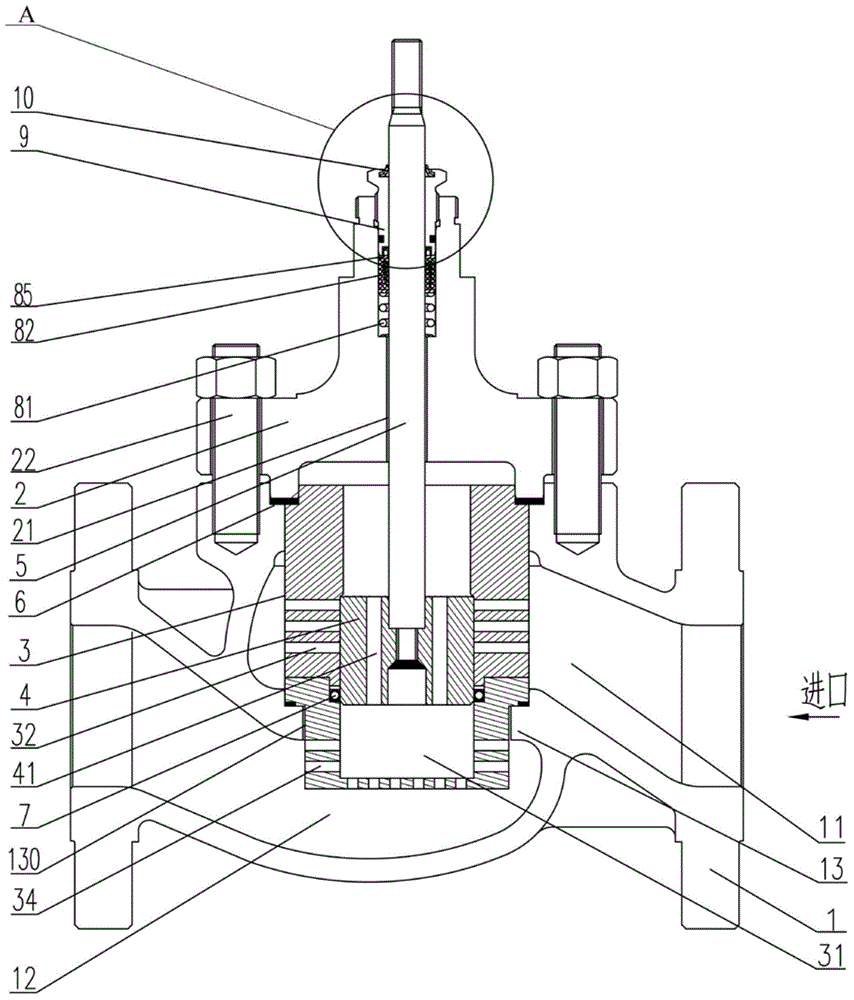

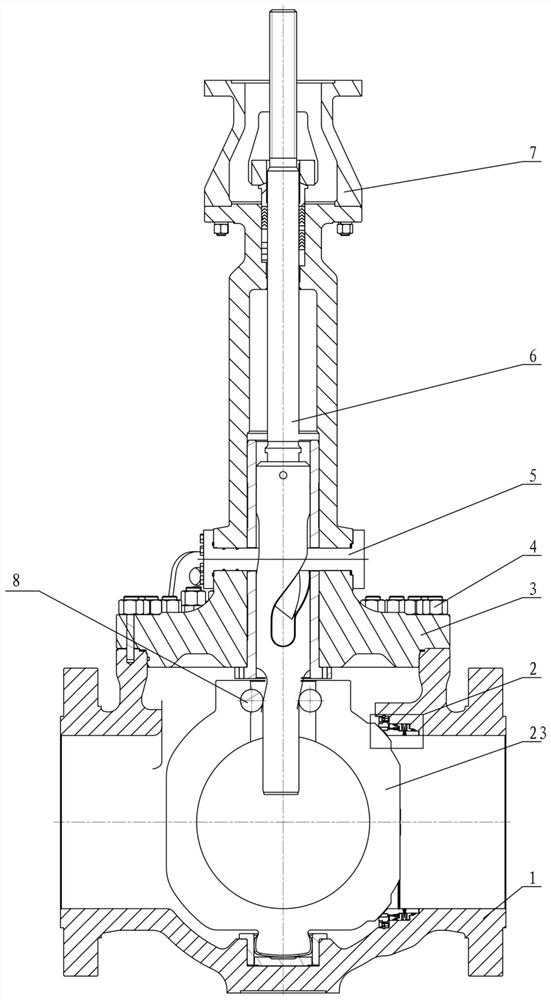

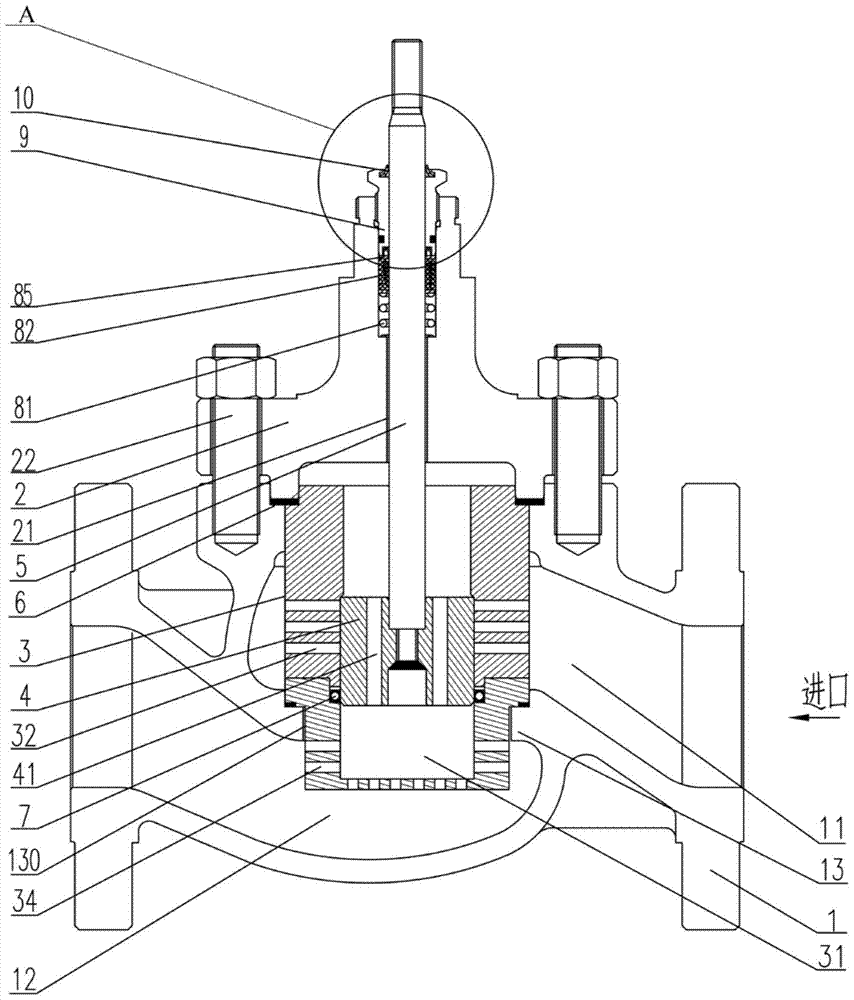

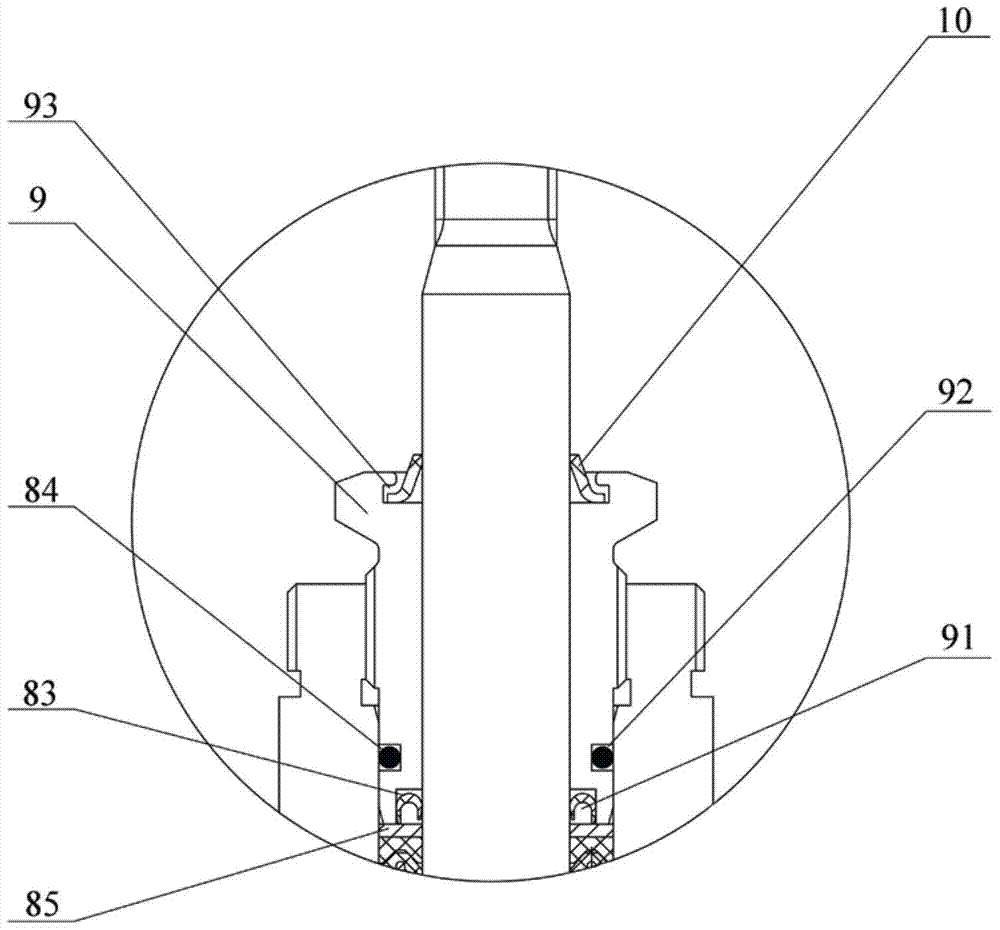

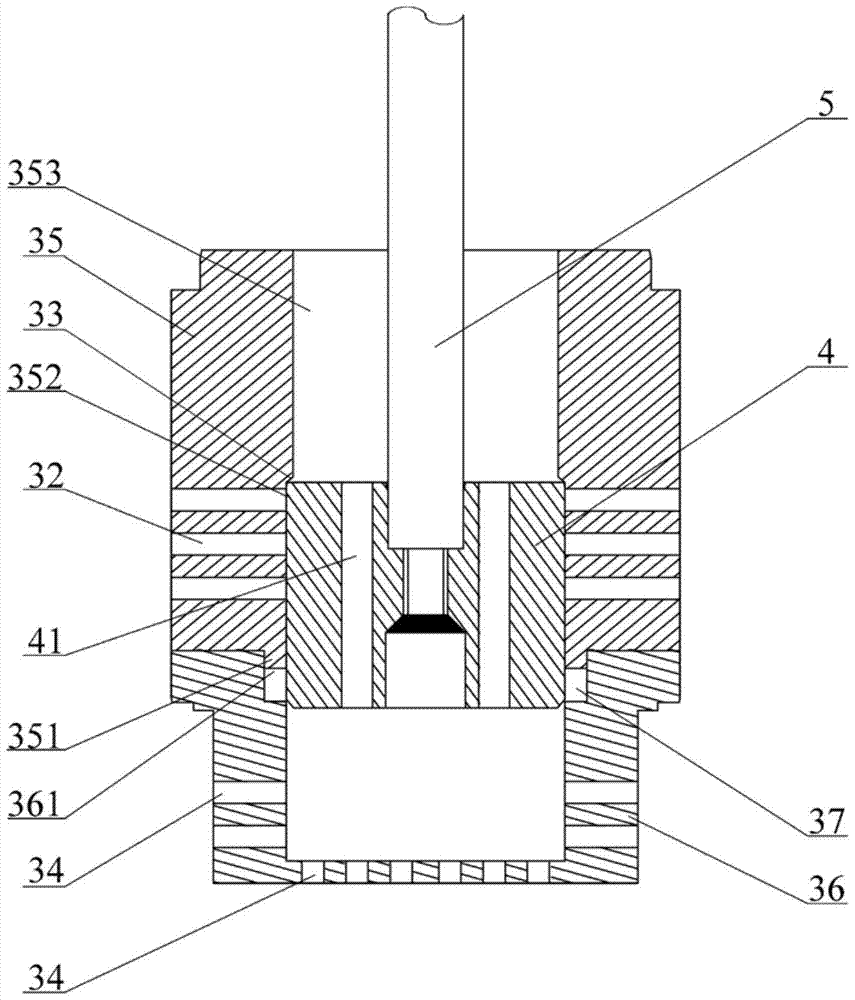

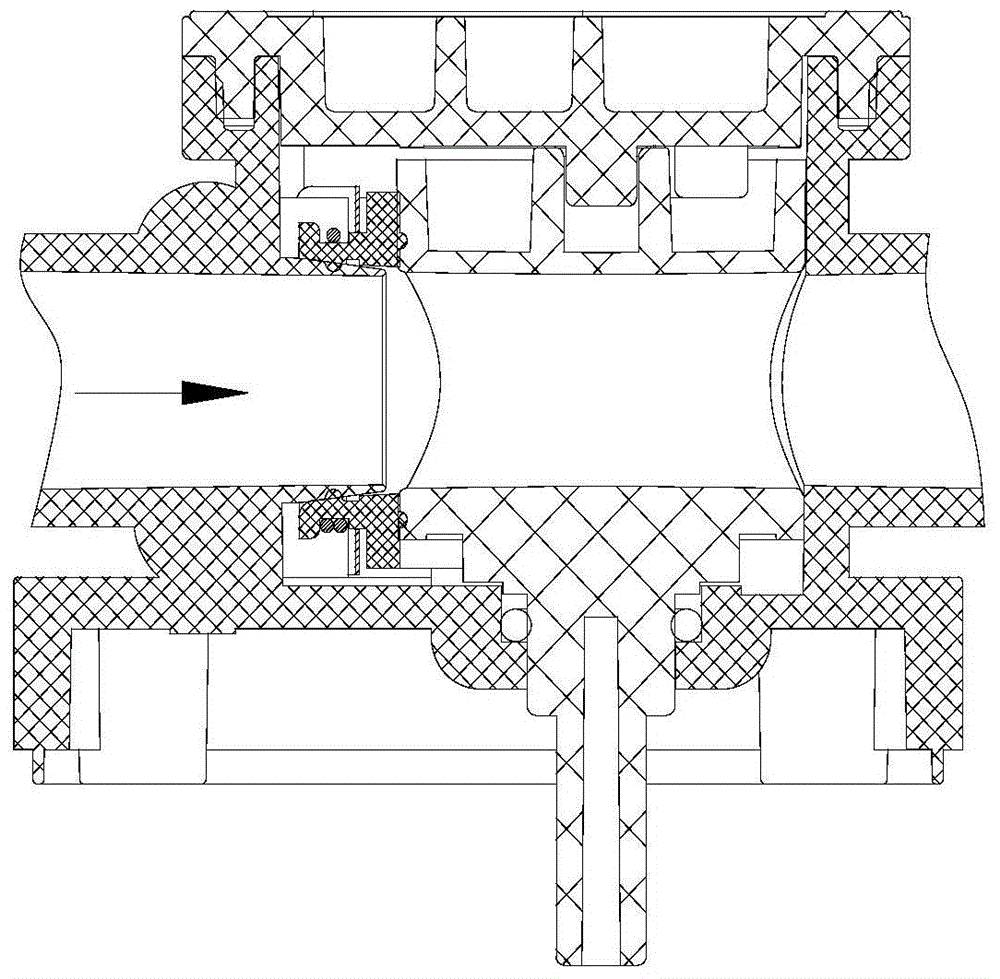

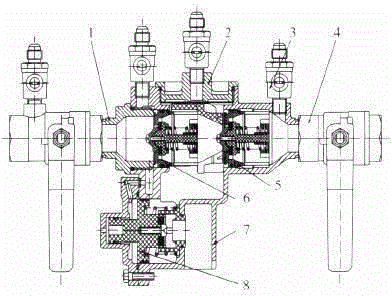

Low-noise high-pressure-difference adjusting valve

ActiveCN104633201AReduce output forceReduce leakageSpindle sealingsValve members for absorbing fluid energyLow noiseEngineering

The invention provides a low-noise high-pressure-difference adjusting valve which comprises a valve body, a valve cover, a sleeve, a valve element and a valve rod. The valve cover is connected to the top of the valve body through bolts, the sleeve is clamped between the valve cover and the valve body, a plurality of first-kind adjusting holes are formed in the upper portion of the side wall of the sleeve, a plurality of second-kind adjusting holes are formed in the lower portion of the side wall of the sleeve and the bottom face of the sleeve, the valve element is arranged in an inner cavity of the sleeve and can vertically move in the inner cavity of the sleeve, so that the low-noise high-pressure-difference adjusting valve is closed or opened, a plurality of pressure balance holes are formed in the valve element in the axial direction of the valve element, and the valve rod penetrates through a center through hole in the valve cover and is connected with the valve element. The low-noise high-pressure-difference adjusting valve is simple, compact and reasonable in structure, small in size and light, and has the advantage of being capable of bearing a high pressure difference and a high leakage level under the condition of the same drive source.

Owner:上海铂嘉阀门有限公司

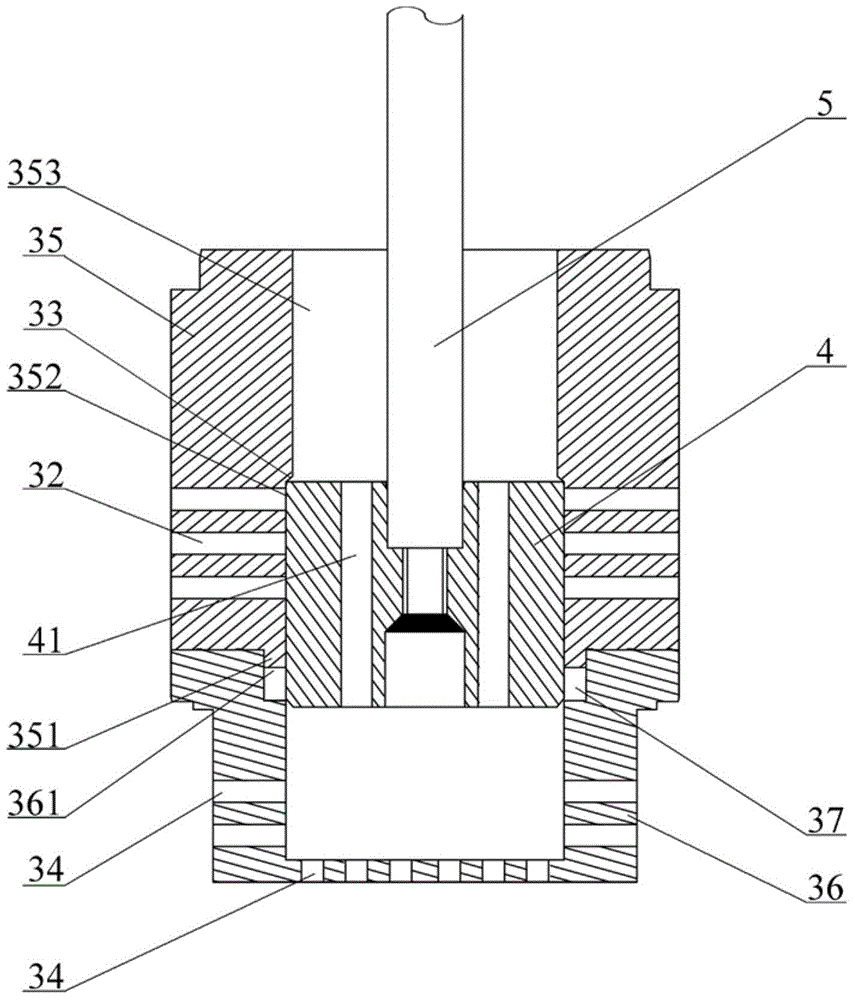

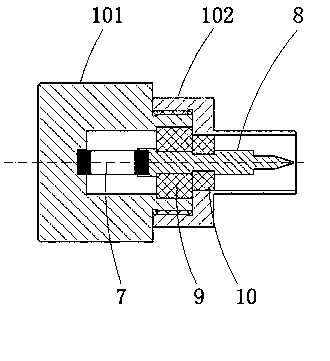

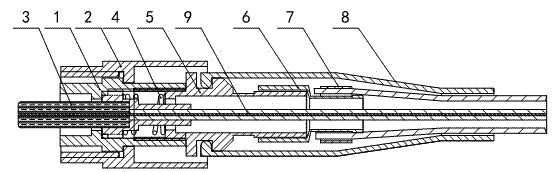

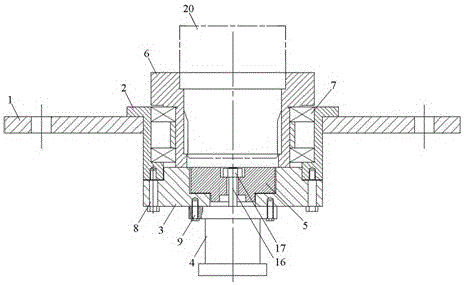

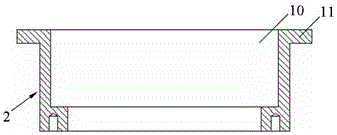

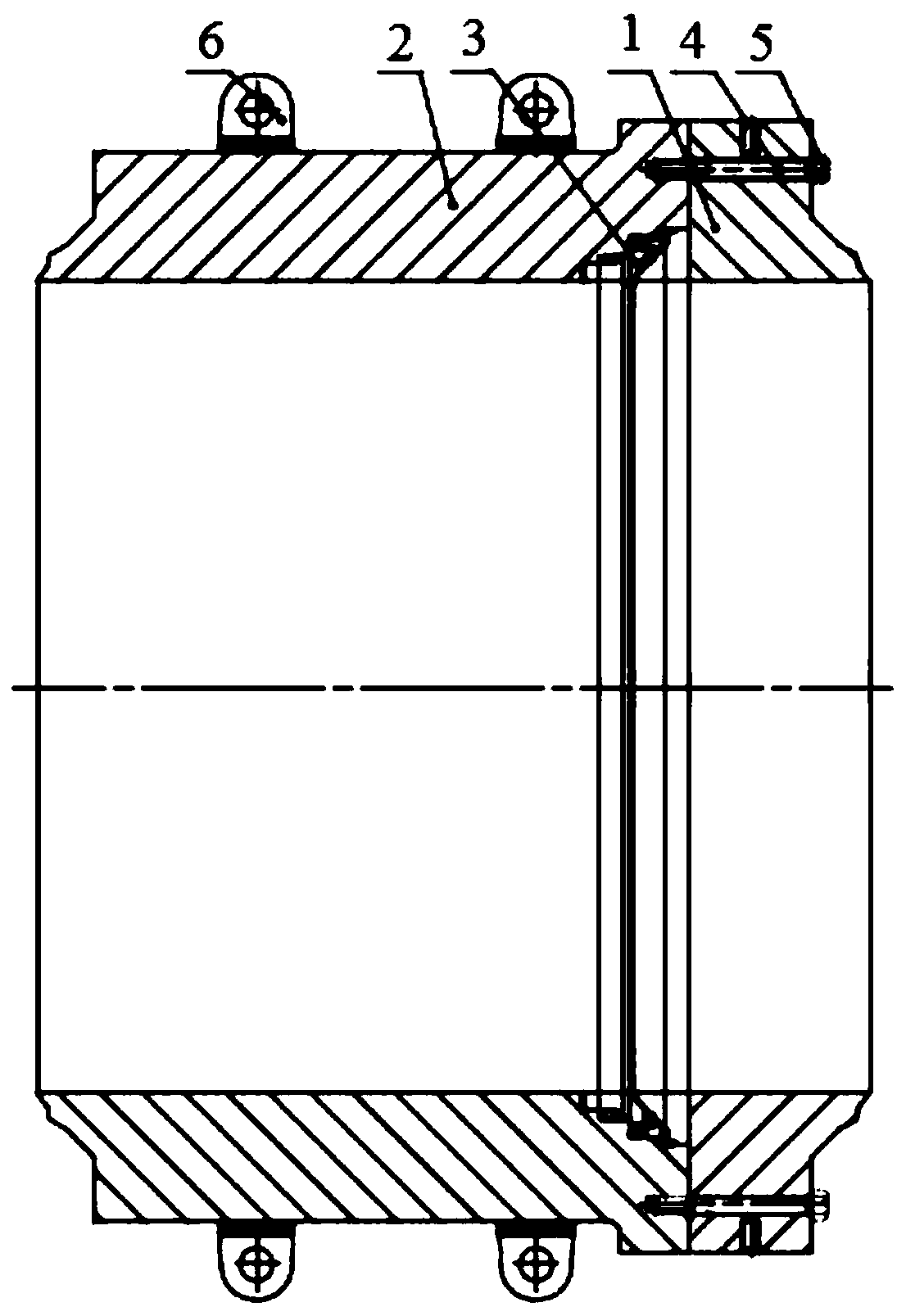

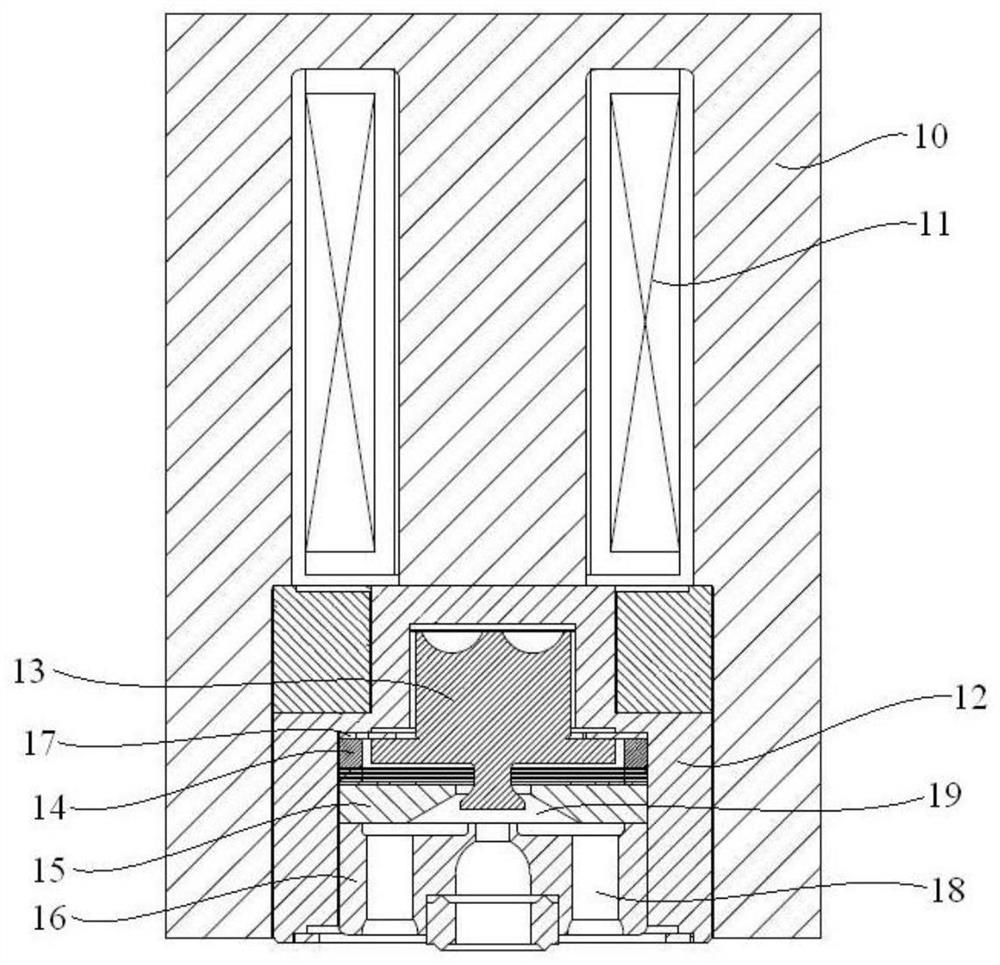

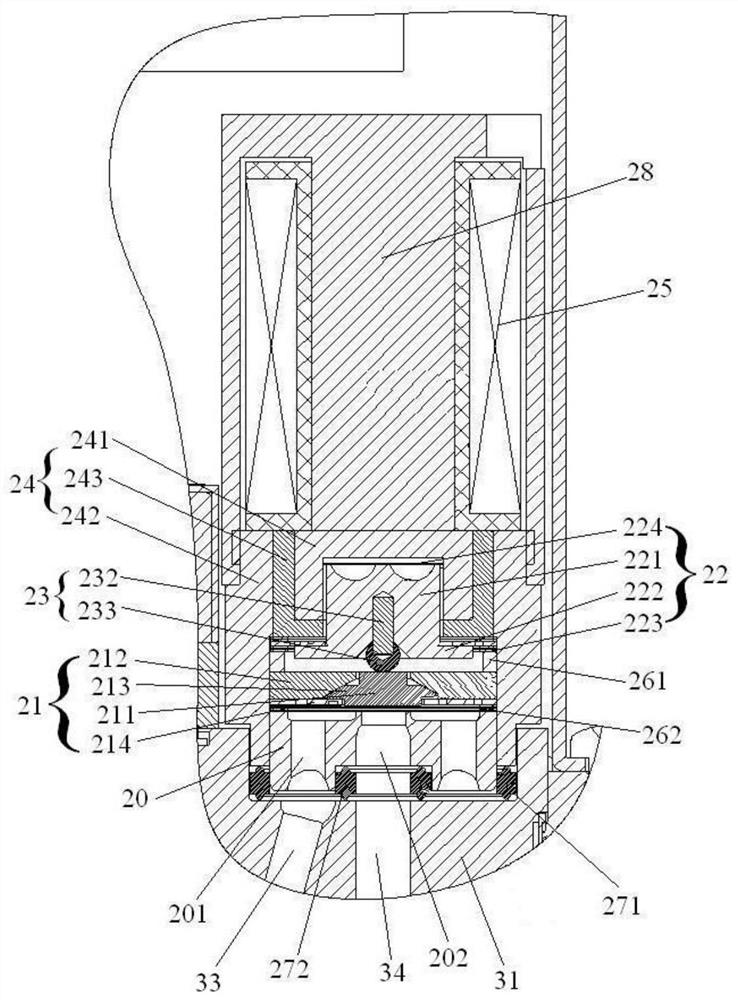

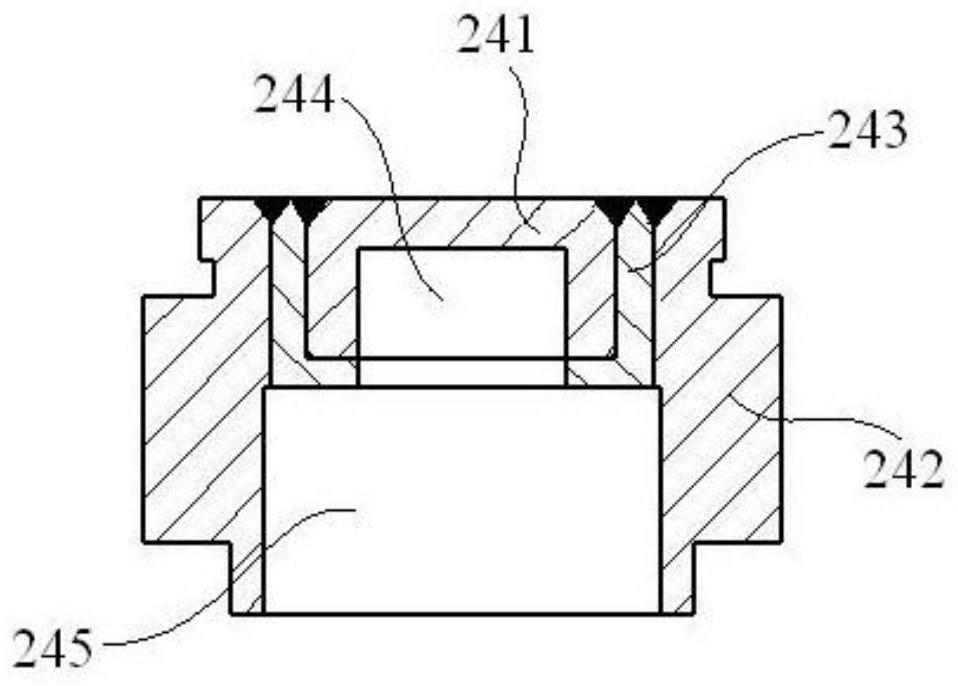

End pressure type coaxial load

InactiveCN104409819AImprove power carrying capacityReduce reflectance valueWaveguide type devicesFrequency bandHeat sink

The invention discloses an end pressure type coaxial load. The end pressure type coaxial load comprises a cylindrical resistor, a compressed spring, an inner conductor, an insulating medium and an outer conductor which are coaxially arranged, as well as an end face shaft sleeve, wherein a compressed spring and a resistor hole are formed in the tail of the inner conductor; the cylindrical resistor is cylindrical; the two ends of the cylindrical resistor are sintered with silver resistors, and the other part of the cylindrical resistor is sintered with a thick-film resistor; the insulating medium is of a circle structure; the single side of the insulating medium is cut off through a seamless cutting technology, and impedance compensation rings are arranged on the both sides; the end face shaft sleeve is positioned at the top part of the outer conductor, used for positioning the insulating medium, the inner conductor and the cylindrical resistor, and meanwhile participates in transmission of electrical performance; cooling fins are arranged on the outer periphery of the outer conductor; a coaxial step type conical transmission cavity is defined inside the outer conductor. The end pressure type coaxial load disclosed by the invention is simple in structure, stable and reliable in properties, high in signal transmission efficiency, high in working frequency band, simple to assemble, easy to operate, and suitable for large batch production.

Owner:安徽蓝麦通信股份有限公司

Automatic rotatable installing machine for movable optical fiber connector

InactiveCN102380847AFast assemblyImprove one-time assembly pass rateMetal-working hand toolsDrive wheelEngineering

The invention discloses an automatic rotatable installing machine for a movable optical fiber connector. In the rotatable installing machine, a driving wheel which is used for driving by a frictional force and is rotatablely assembled on a base, the vicinity of the outer wheel edge of the driving wheel is provided with a press head which forms a three-point positioning structure with the outer wheel edge of the driving wheel, and the press head is in drive connection with a reciprocating driving mechanism which is used for driving the press head to clamp a part of a connector on the driving wheel or to unclamp the part of the connector. The machine can prevent a user from being injured by a plurality of burrs when the machine is manually assembled, the assembly efficiency is greatly improved, the primary assembly yield of the movable optical fiber connector is greatly improved, the phenomenon that the increase of extinction can be avoided when the movable optical fiber connector is inuse, and the production and use cost of the movable optical fiber connector is reduced.

Owner:HENAN COMM CABLE +2

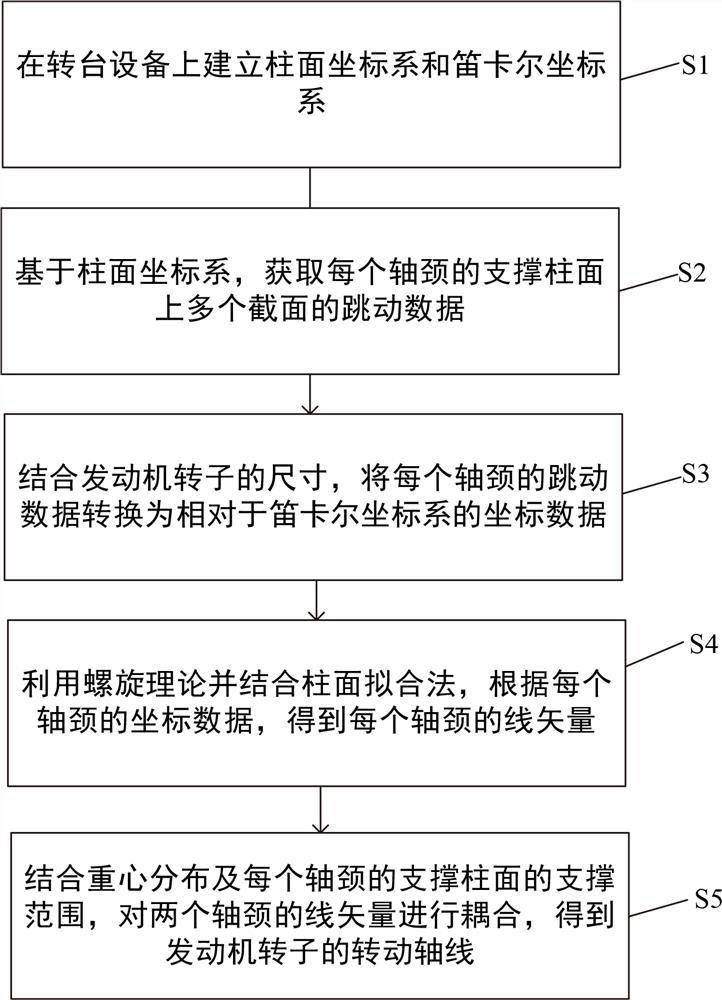

Rotation axis determination method and system

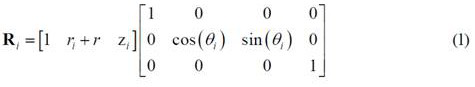

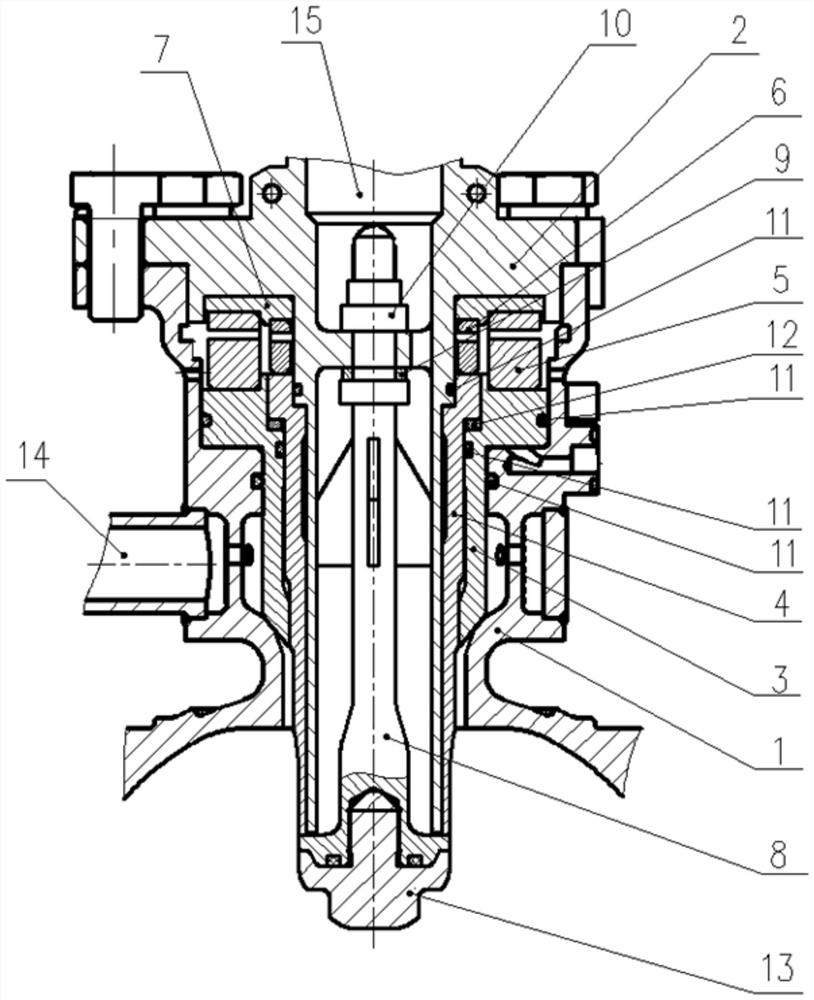

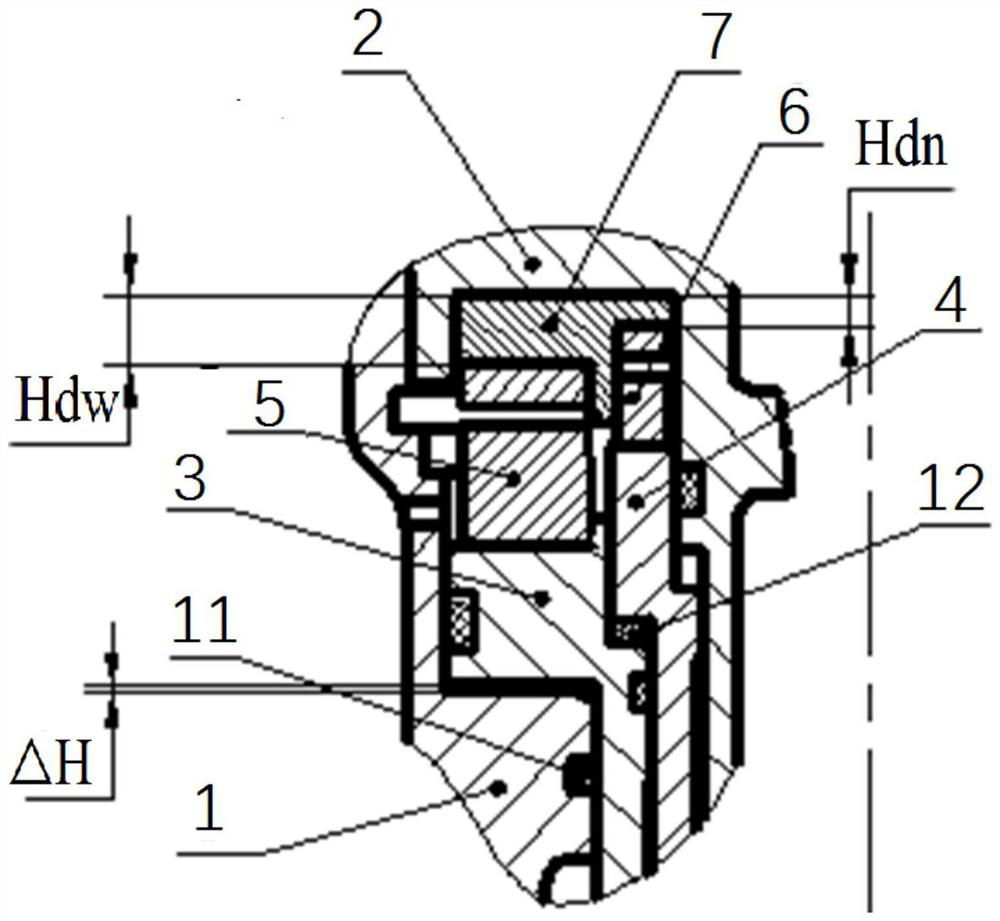

ActiveCN112307426AImprove the determination accuracyImprove assembly qualityMechanical measuring arrangementsComplex mathematical operationsData acquisitionEngineering

The invention provides a rotation axis determination method, which is used for determining the rotation axis of an engine rotor, the engine rotor comprises two journals which are aligned and assembledon turntable equipment, and the method comprises the following steps of: establishing a cylindrical coordinate system and a Cartesian coordinate system on the turntable equipment; based on the cylindrical coordinate system, acquiring bounce data of a plurality of sections on the supporting cylindrical surface of each journal, wherein the bounce data comprises bounce values, angular phases and z-direction index values of the data acquisition points; converting the runout data of each journal into coordinate data relative to a Cartesian coordinate system in combination with the size of the engine rotor; obtaining a linear vector of each journal according to the coordinate data of each journal by utilizing a spiral theory and combining a cylindrical surface fitting method; and in combinationwith the gravity center distribution and the supporting range of the supporting cylindrical surface of each journal, coupling the linear vectors of the two journals, and obtaining the rotating axis of the engine rotor. The determination method can improve the determination precision of the rotation axis of the engine rotor.

Owner:AECC SHANGHAI COMML AIRCRAFT ENGINE MFG CO LTD +1

Assembling and testing method for two-way sealing bolt type injector

ActiveCN114718767AAvoid the problem of function failure and reduced reliabilityGuaranteed movement characteristicsNuclear energy generationRocket engine plantsStructural engineeringReliability engineering

The invention provides an assembly test method for a two-way sealing bolt type injector, and mainly solves the problems that the assembly test process of an existing bolt type injector is not standard, so that the surface shutdown function fails, and the reliability is reduced. According to the two-way sealing bolt type injector assembling and testing method, assembling and testing of the face shutdown bolt type injector can be completed normatively and rapidly, it is guaranteed that the motion characteristic, the sealing characteristic and the injection characteristic of the face shutdown bolt type injector meet the design requirements, and assembling testing qualification and delivery use of the injector are rapidly achieved.

Owner:XIAN AEROSPACE PROPULSION INST

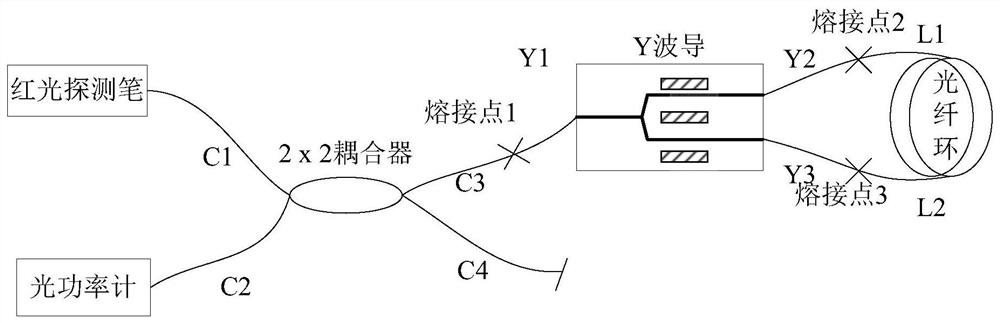

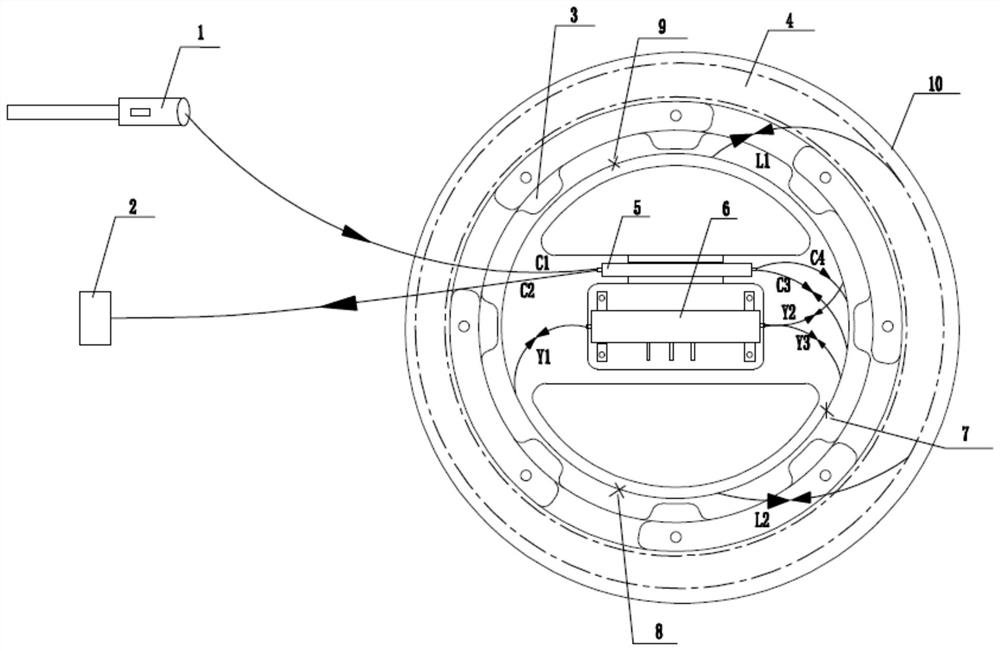

Fiber-optic gyroscope optical path assembly method based on tail fiber stress monitoring

PendingCN112161640AAvoid stabilityAvoid cycleForce measurement by measuring optical property variationSagnac effect gyrometersGyroscopeEngineering

The invention provides a fiber-optic gyroscope optical path assembly method based on tail fiber stress monitoring, which can effectively monitor the existence of tail fiber stress and effectively prevent the tail fiber stress during assembly. According to the invention, the tail fiber stress is monitored during gyroscope assembly, the position of a device and the coiling direction of a tail fiberare convenient to adjust in time, the problem of unstable gyroscope output signals or short working period caused by the existence of optical fiber stress after gyroscope assembly is avoided, and theone-time assembly qualification rate is improved. The method is simple and effective to operate, is also suitable for other types of fiber-optic gyroscopes, especially for small or ultra-small fiber-optic gyroscopes with more complex assembly processes, and solves the key technology in batch production of fiber-optic gyroscopes.

Owner:HEBEI HANGUANG HEAVY IND

Anti-fault detecting device used in automated assembly production devices

ActiveCN102941247AImprove one-time assembly pass rateSimple structureMetal working apparatusRhythmLaser

The invention discloses an anti-fault detecting device used in automated assembly production devices, comprising a set of vacuum adsorption molds which are connected through a mechanical arm and can complete absorb and release assembly parts, the vacuum adsorption molds and a set of detection units for sensing whether the assembly parts exist or not by laser are arranged on a same fixed plate in parallel to each other, the fixed plate is connected up to the mechanical arm, and the center distance between the detection unit and the vacuum adsorption mold is identical to the distance between adjacent two assembly parts in the automated assembly production device. According to the invention, the anti-fault detecting device disclosed herein can accurately sense whether there is a failure of assembling parts or not, thus the primary assembling qualification of the products is significantly raised; the structure is simple, the installation is convenient, and the flexibility and practicality are achieved; there is no influence on the production rhythm, and the primary assembling qualification is significantly raised.

Owner:曲阜天博汽车零部件制造有限公司

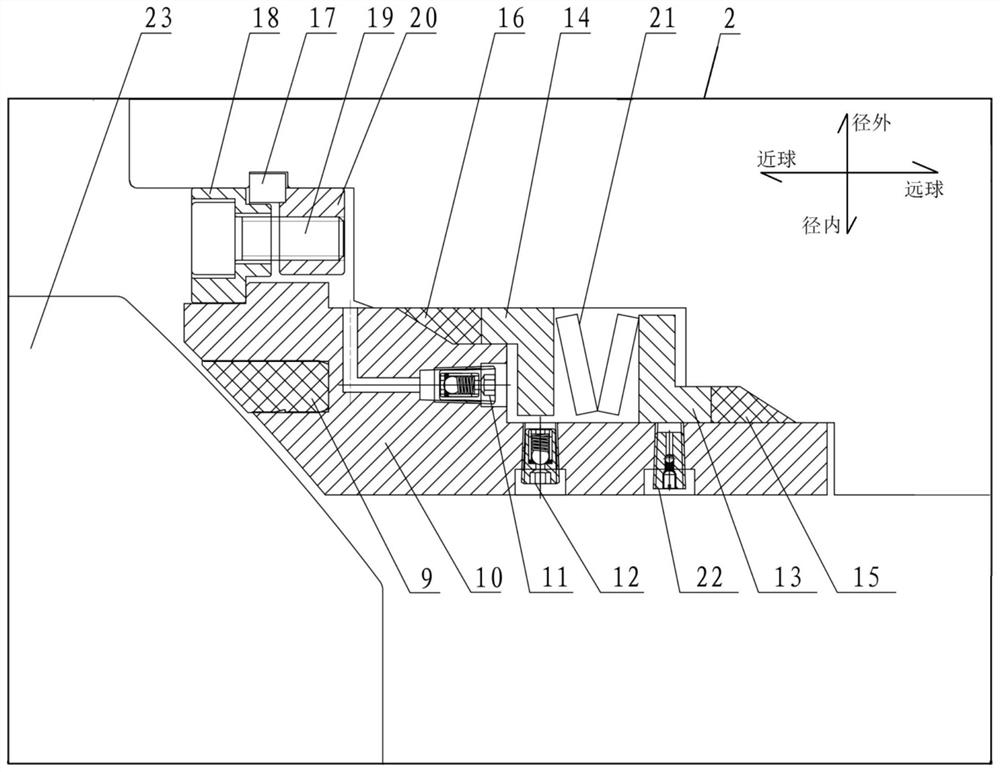

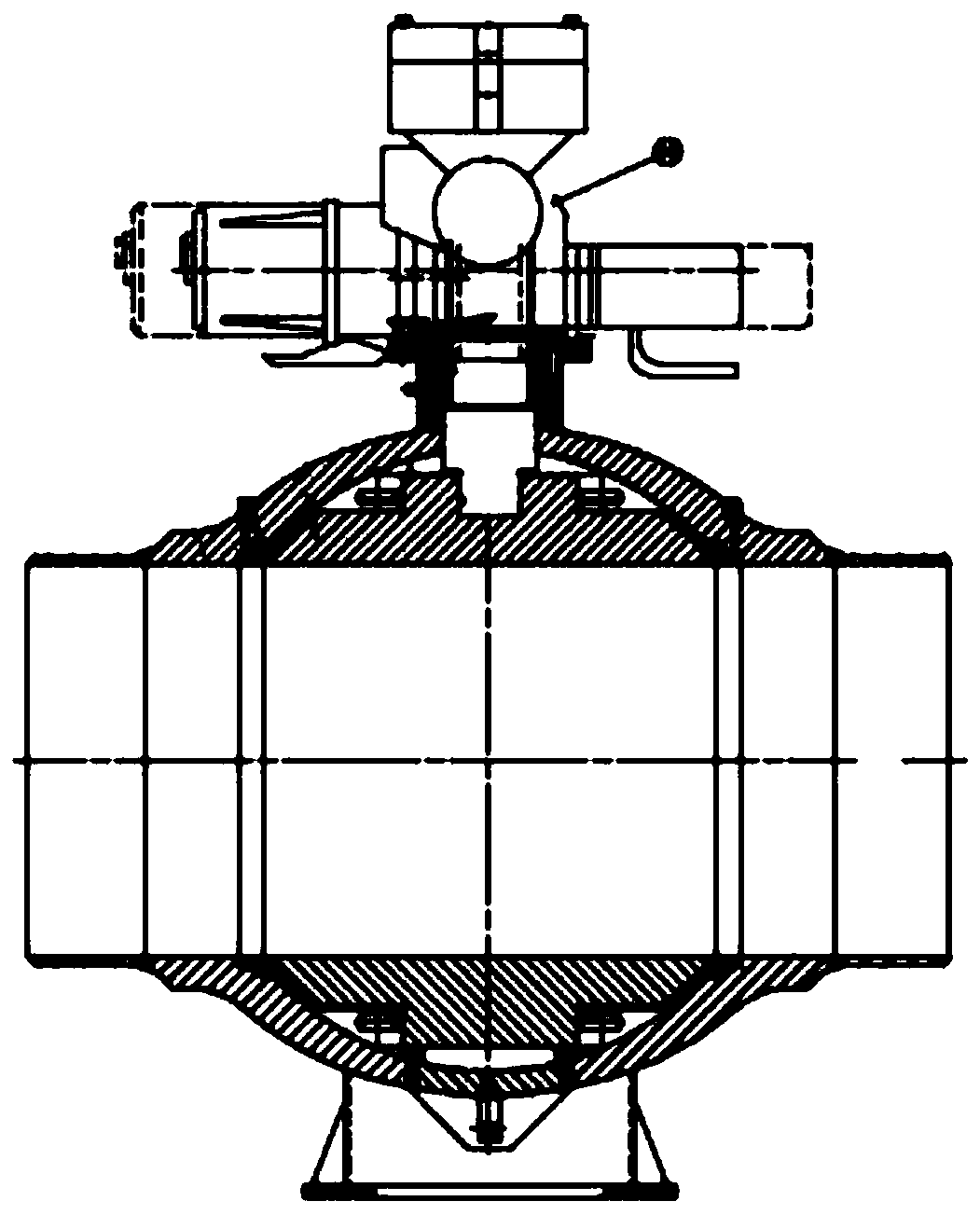

Pressure self-balancing bidirectional sealing valve seat structure

ActiveCN113503375AEliminates the risk of damage to the seat bi-directional seal assemblyRealize bi-directional sealing functionPlug valvesWorking pressureEngineering

The invention discloses a pressure self-balancing bidirectional sealing valve seat structure, and belongs to the technical field of cryogenic valves. A valve seat assembly and a ball body are installed in a valve body; the valve seat assembly comprises a valve seat support installed in the valve body, a bidirectional sealing assembly arranged in an inner cavity of a valve body connecting part between the valve seat support and the valve body and a pressure release valve arranged in the valve seat support, and the pressure release valve is communicated with the inner cavity of the valve body connecting part and a medium channel outside the valve seat support. By designing the pressure release valve, when the pressure in the cavity provided with the bidirectional sealing assembly abnormally rises and exceeds 1.33 times of the designed rated working pressure of the valve, excess pressure in the cavity is released into the channel through the pressure release valve, and the risk that the valve seat bidirectional sealing assembly is damaged under pressure accumulation can be eliminated.

Owner:TSINGHUA UNIV

A Method for Calculating Eccentricity of Rotor Assembly Axis Based on Radial Runout Measurement

ActiveCN109117461BReduce the number of repeated disassembly and assemblyImprove one-time assembly pass rateComplex mathematical operationsContact forceMechanics

A method for calculating the eccentricity of the rotor assembly axis based on radial runout measurement, including the matrix representation of each point data and the calculation of the relative runout value, the establishment of the spring equivalent model and the calculation of the contact force of each point under the ideal state, the direction and size of the eccentricity; The calculation of the relative runout value of each point, and the process of calculating the assembly interference of each point according to the radial runout data of the two seam mating surfaces; the establishment of the spring equivalent model is based on the assumption of elastic deformation, and analyzes the force and contact at each stage during the contact process. Displacement relationship, the non-uniform contact force of each point is obtained by the non-uniform interference; the determination of the eccentricity is based on the spring equivalent model, and the final determination of the eccentricity is calculated according to the equilibrium state equation. This method is based on the measured radial runout data in actual production, realizes the prediction of the axis eccentricity before assembly, improves the rotor coaxiality after assembly, and predicts the axis, adjusts and optimizes the assembly phase during the assembly process of the aeroengine rotor parts It has important practical guiding significance.

Owner:DALIAN UNIV OF TECH

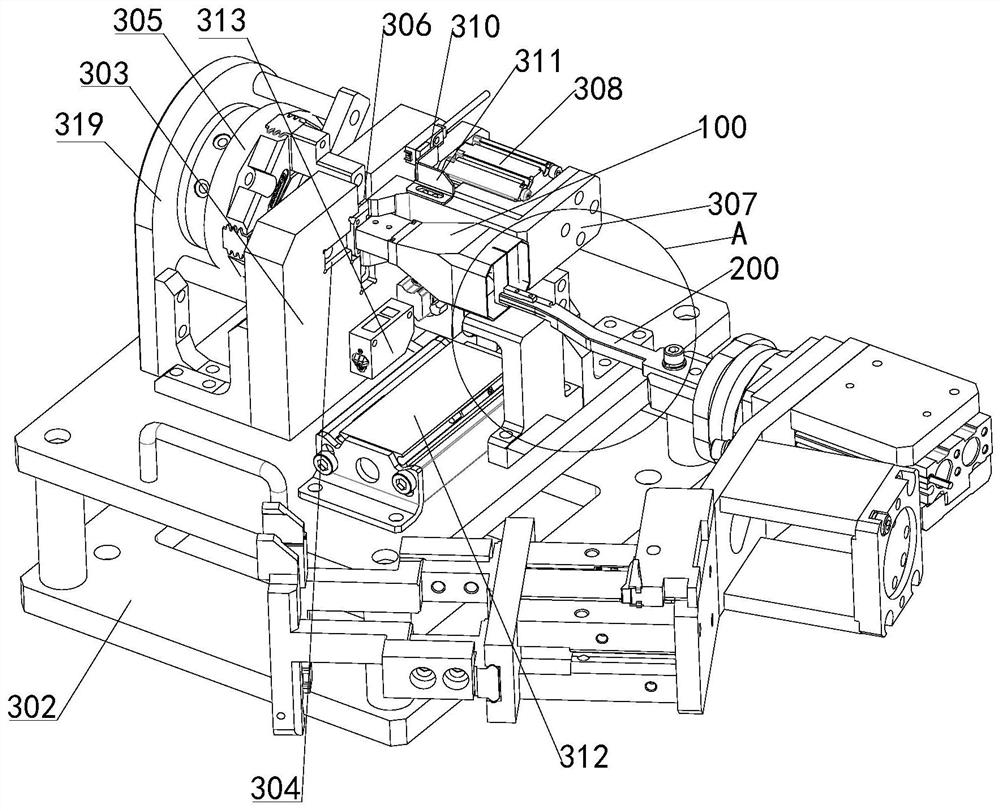

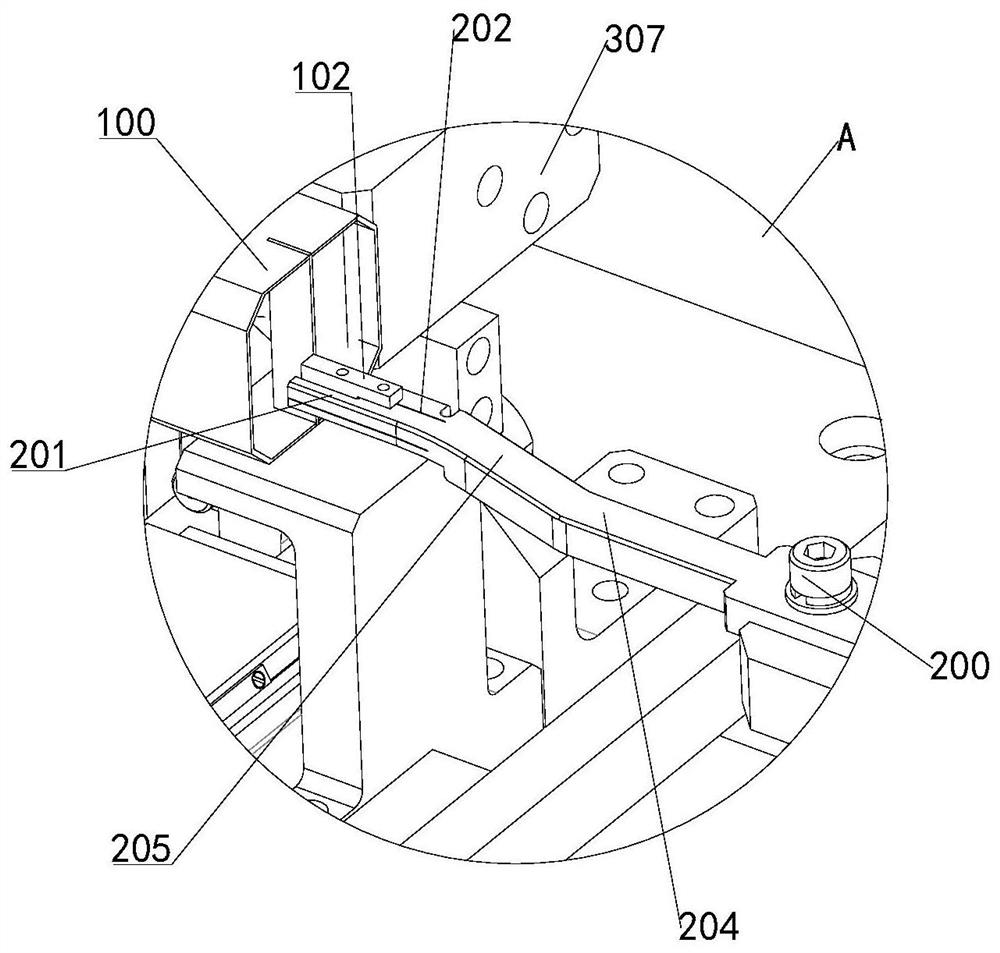

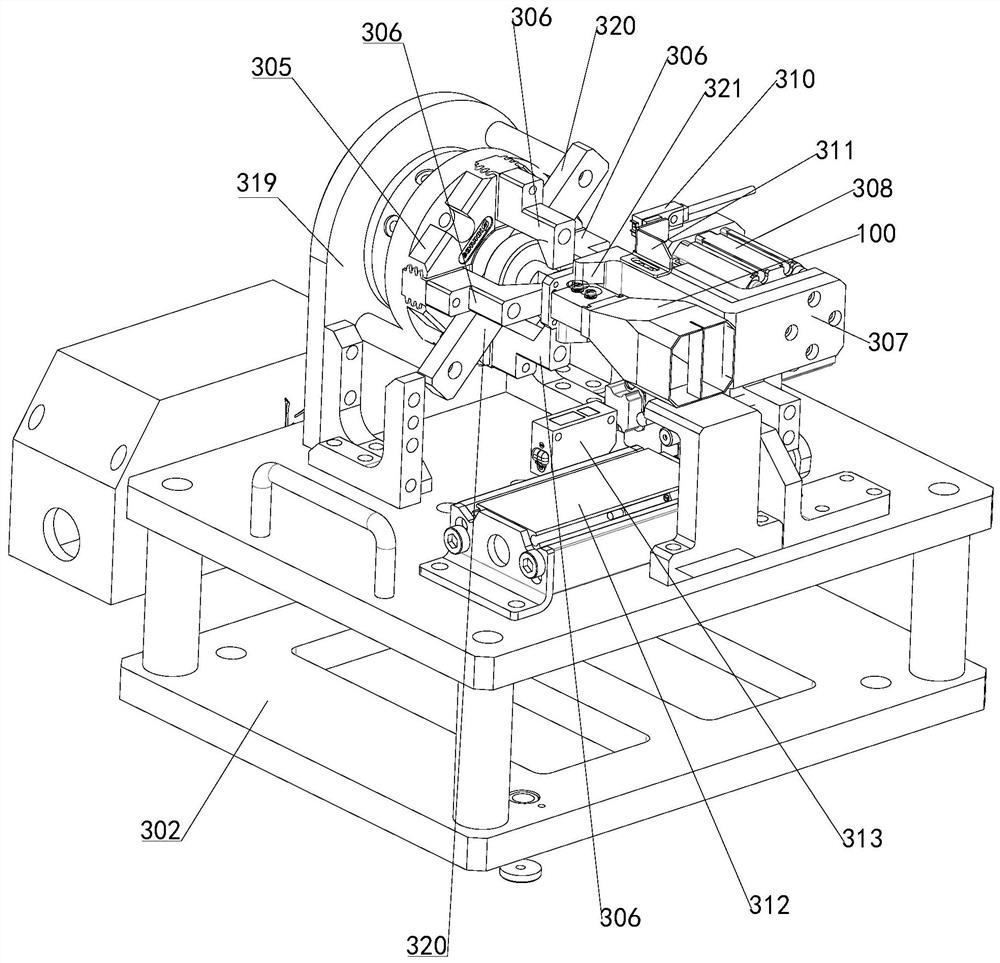

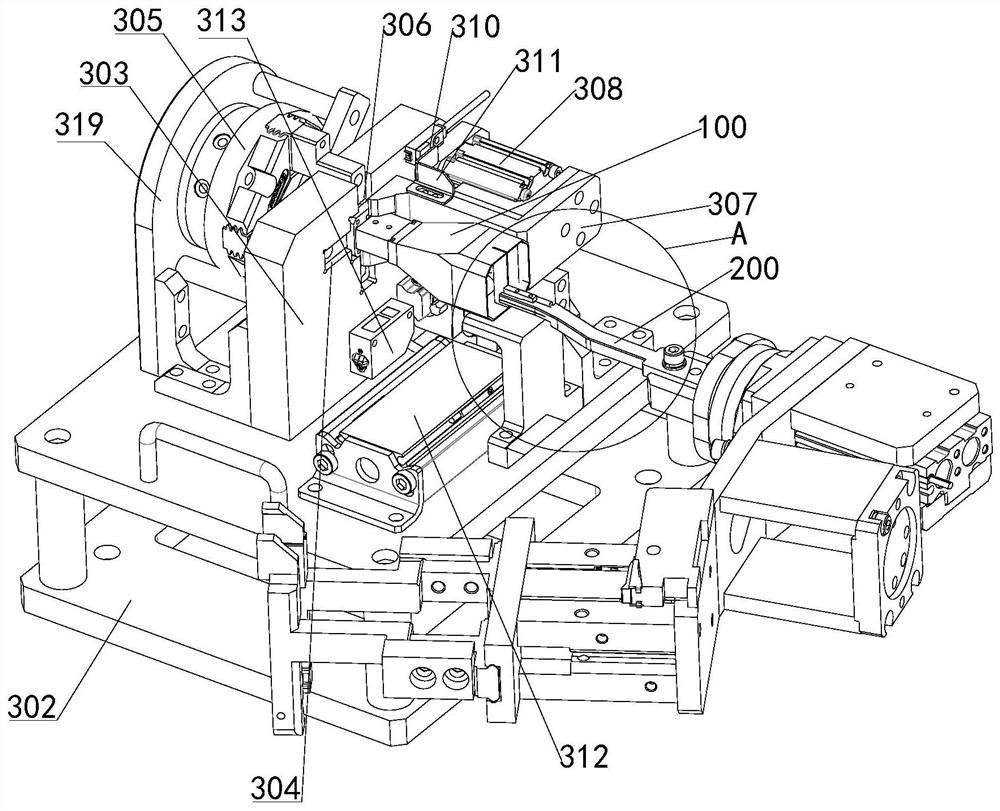

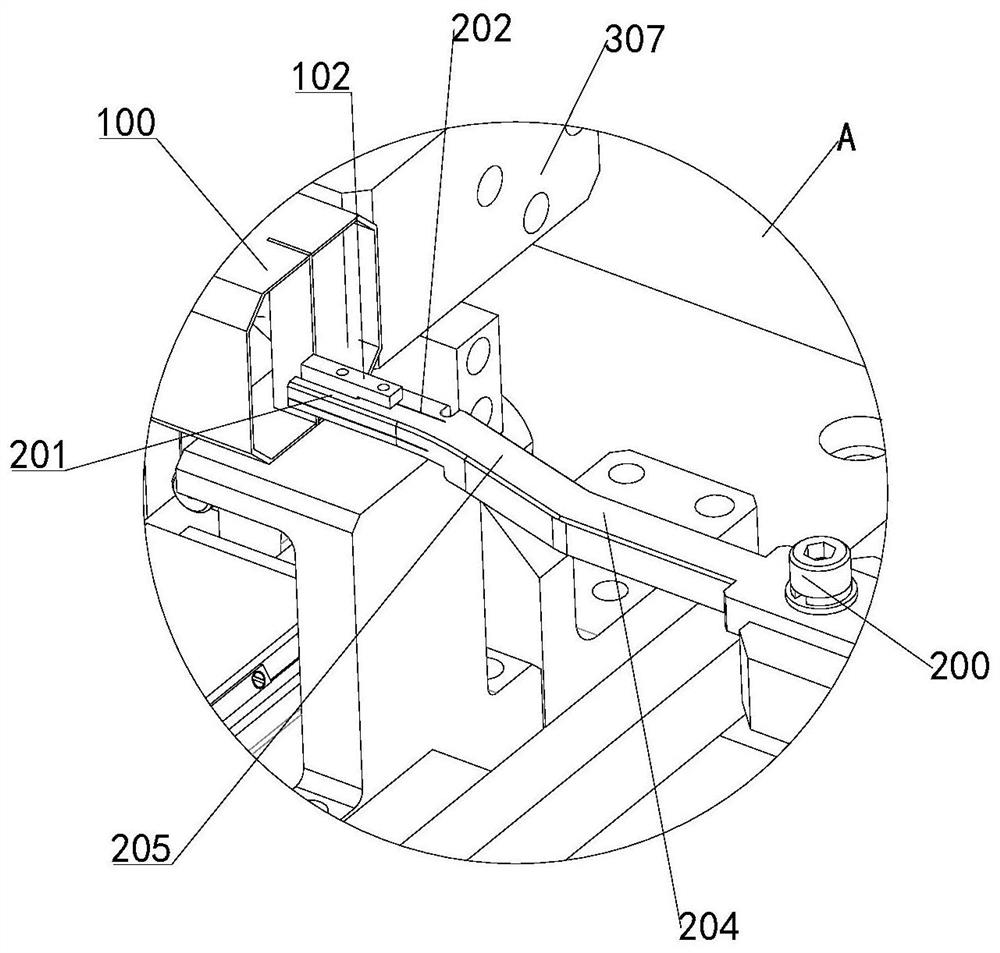

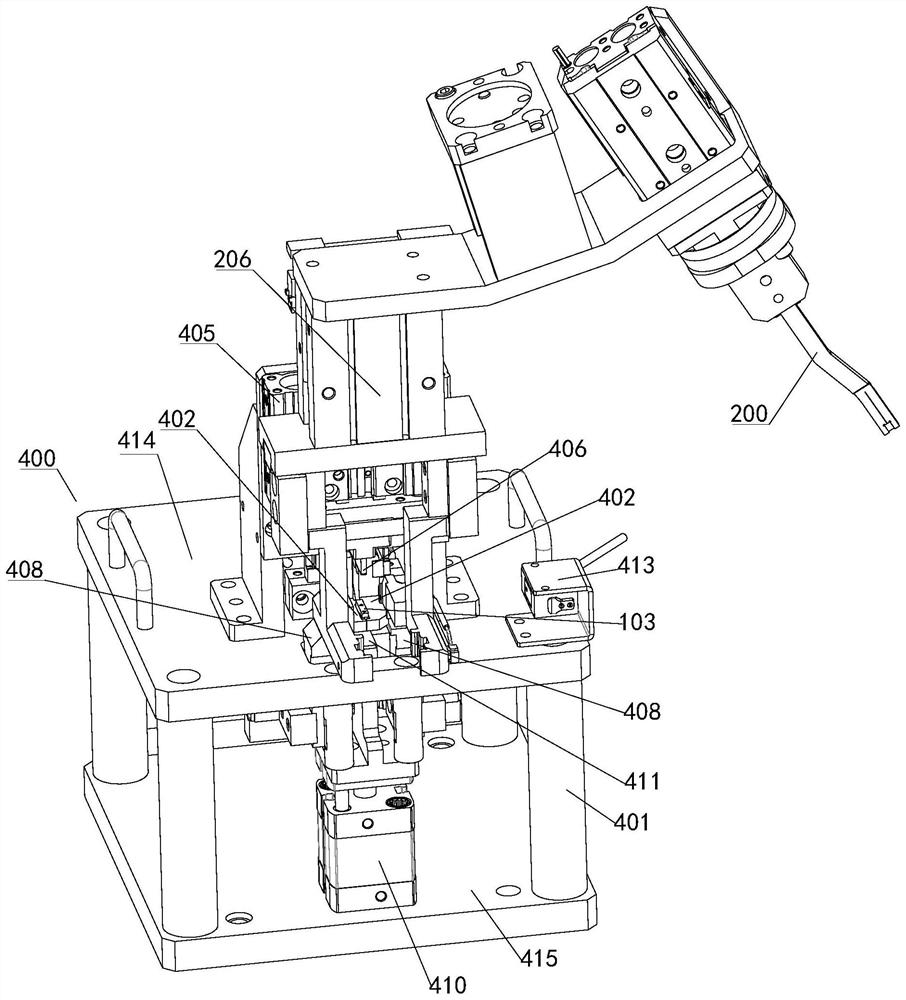

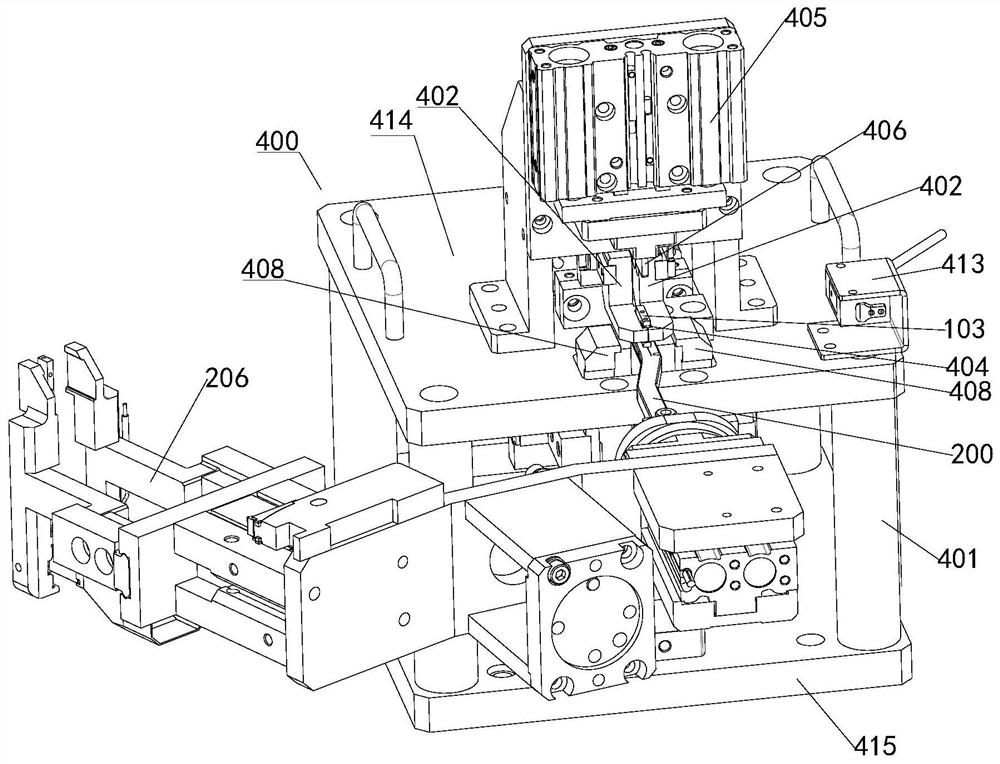

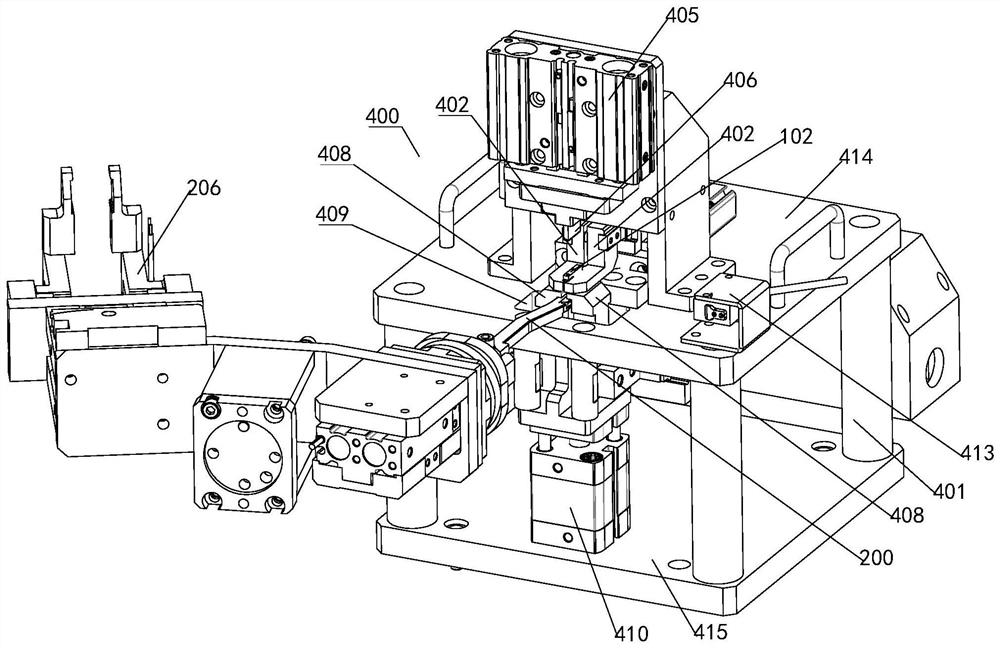

A radiation unit matching block assembly device and method

ActiveCN112676807BQuick installationSolve the problem of precise installation and positioningRadiating elements structural formsMetal working apparatusStructural engineeringMechanical engineering

The invention relates to a radiation unit matching block assembly device and method. The assembly device includes a matching block clamp and a radiation unit clamp. An elastic pin is arranged in the radiation unit clamp, and a matching block limiter is provided on one side of the matching block clamp close to the end. slot, one end of the matching block fixture is provided with a limit opening connected with the limit groove of the matching block; wherein, when the matching block fixture drives the matching block to extend into the radiation unit, the elastic pin in the radiation unit fixture extends from the limit opening Matching block stop slot and abut one end of mating block. The invention sends the matching block into the radiation unit fixture through the matching block fixture, and uses the elastic pin to limit the matching block in the matching block limit groove, so that the fast installation of the matching block in the narrow space of the speaker cavity can be realized, and the traditional The problem of precise installation and positioning of the matching block improves the stability and consistency of assembly accuracy, ensures the distance dimension accuracy between the matching block inside the cavity of the antenna radiation unit and the positioning reference plane of the flange, and improves the first-time assembly qualification rate.

Owner:BEIJING INST OF RADIO MEASUREMENT

Low noise and high pressure differential regulating valve

ActiveCN104633201BReduce output forceReduce leakageSpindle sealingsValve members for absorbing fluid energyLow noiseDifferential pressure

The invention provides a low-noise high-pressure-difference adjusting valve which comprises a valve body, a valve cover, a sleeve, a valve element and a valve rod. The valve cover is connected to the top of the valve body through bolts, the sleeve is clamped between the valve cover and the valve body, a plurality of first-kind adjusting holes are formed in the upper portion of the side wall of the sleeve, a plurality of second-kind adjusting holes are formed in the lower portion of the side wall of the sleeve and the bottom face of the sleeve, the valve element is arranged in an inner cavity of the sleeve and can vertically move in the inner cavity of the sleeve, so that the low-noise high-pressure-difference adjusting valve is closed or opened, a plurality of pressure balance holes are formed in the valve element in the axial direction of the valve element, and the valve rod penetrates through a center through hole in the valve cover and is connected with the valve element. The low-noise high-pressure-difference adjusting valve is simple, compact and reasonable in structure, small in size and light, and has the advantage of being capable of bearing a high pressure difference and a high leakage level under the condition of the same drive source.

Owner:上海铂嘉阀门有限公司

Radiation unit matching block assembling device and method

ActiveCN112676807AQuick installationSolve the problem of precise installation and positioningRadiating elements structural formsMetal working apparatusControl theoryMechanical engineering

The invention relates to a radiation unit matching block assembling device and method. The assembling device comprises a matching block clamp and a radiation unit clamp, an elastic pin is disposed in the radiation unit clamp, a matching block limiting groove is disposed at the position, close to the end part, of one side of the matching block clamp, and a limiting port communicated with the matching block limiting groove is disposed on the end surface of one end of the matching block clamp; and when the matching block clamp drives a matching block to extend into a radiation unit, the elastic pin in the radiation unit clamp extends into the matching block limiting groove from the limiting port and abuts against one end of the matching block. The matching block is sent into the radiation unit clamp through the matching block clamp, the matching block in the matching block limiting groove is limited through the elastic pin, rapid installation of the matching block in a narrow space of a horn cavity can be achieved, the problem of accurate installation and positioning of a traditional matching block is solved, the stability and consistency of the assembly precision are improved, distance dimension precision between the matching block in an antenna radiation unit cavity and a flange plate positioning reference surface is guaranteed, and one-time assembling qualified rate is improved.

Owner:BEIJING INST OF RADIO MEASUREMENT

Process for assembling front lower swing arm of automobile through robot

InactiveCN111069893AHigh precisionHigh precision and high production efficiencyAssembly machinesWorking environmentIndustrial engineering

Disclosed is a process for assembling a front lower swing arm of an automobile through a robot. The process is characterized by comprising the steps of press fitting of a ball pin shell, spin rivetingof the edge of the ball pin shell, coating of lubricating grease, installation of a protecting sleeve, installation of a lower clamping ring of the protecting sleeve, checking, oiling and dischargingfrom a line. The product quality is stable and reliable, the one-time assembly qualification rate is high, the operation is simple, convenient and safe, the working environment is good, the filling amount of the lubricating grease is accurately controlled, coating of the lubricating grease is uniform, the precision of the mounting position of the clamping ring is high, the production efficiency is high, the cost is low, and popularization and application values are achieved.

Owner:HENGYANG FENGSHUN AXLE CO LTD

Pressure-bearing and sealing structure of water valve

The invention relates to a pressure-bearing and sealing structure of a water valve. The structure comprises an upper cover and a lower cover which are vertically connected, wherein a water channel is formed between the upper cover and the lower cover, the lower cover is communicated with a water inlet, a plate valve structure for controlling passing of a water flow is arranged between the upper and lower covers and comprises a valve plate, a rotating shaft and a combined sealing ring, the valve plate is mounted in a position where the upper and lower covers are connected, the rotating shaft drives the valve plate to rotate, the combined sealing ring is attached to the valve plate to form a sealing surface, opening and closing of the water channel are controlled through rotation of the valve plate, and water holes for facilitating passing of the water flow are formed in the valve plate. The structure has the benefits as follows: sealing system parts are few, the structure is simple, assembly is convenient, the reliability is high, the operating torque is small, the internal leakage amount is small, and the one-time assembly percent of pass of the product is high.

Owner:赛兹(常州)塑料传动器件有限公司

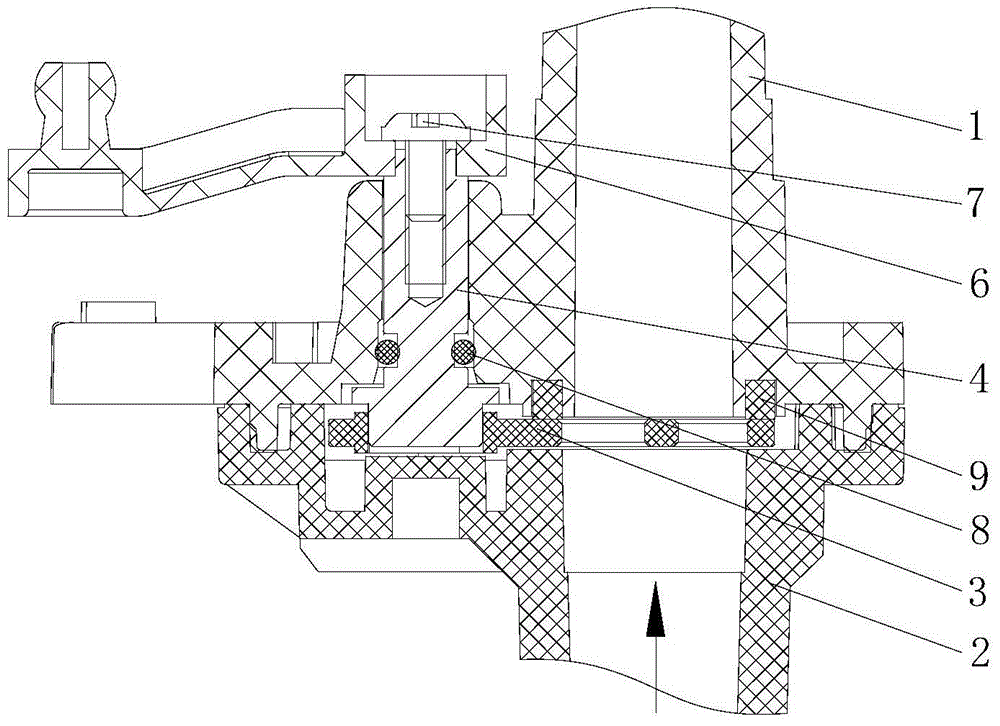

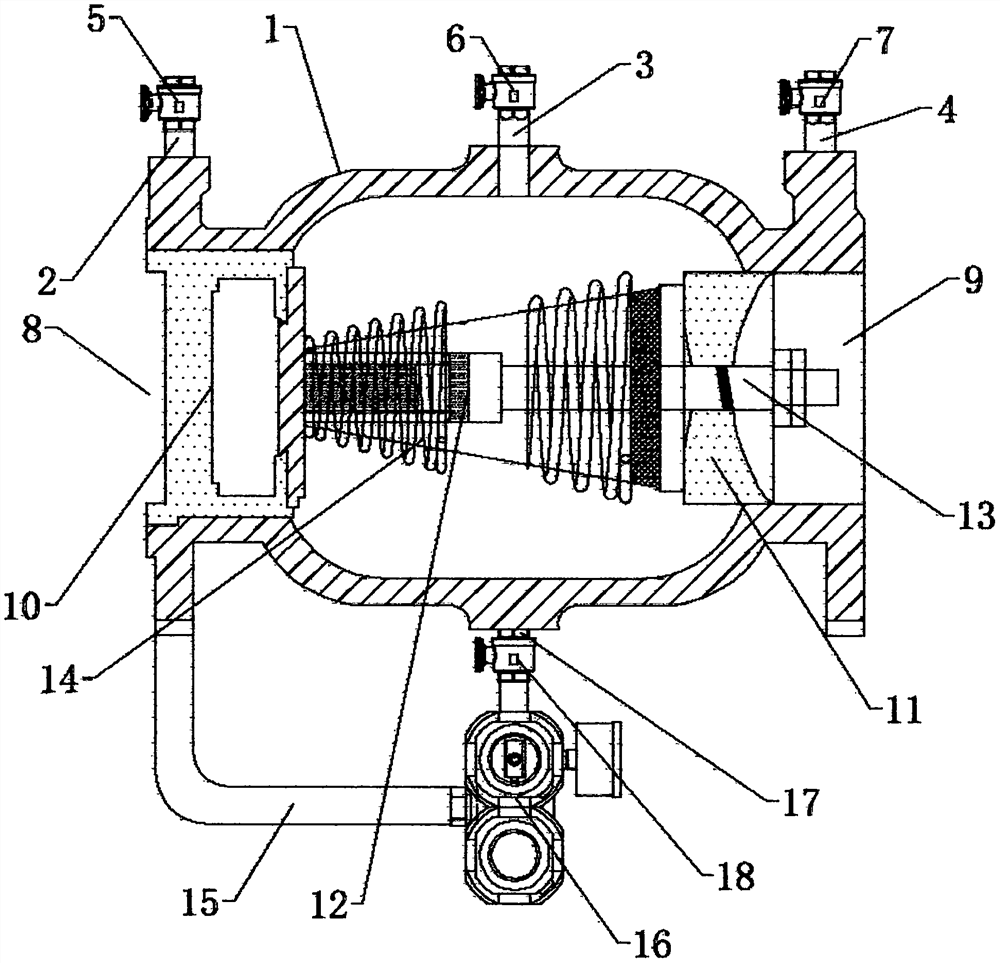

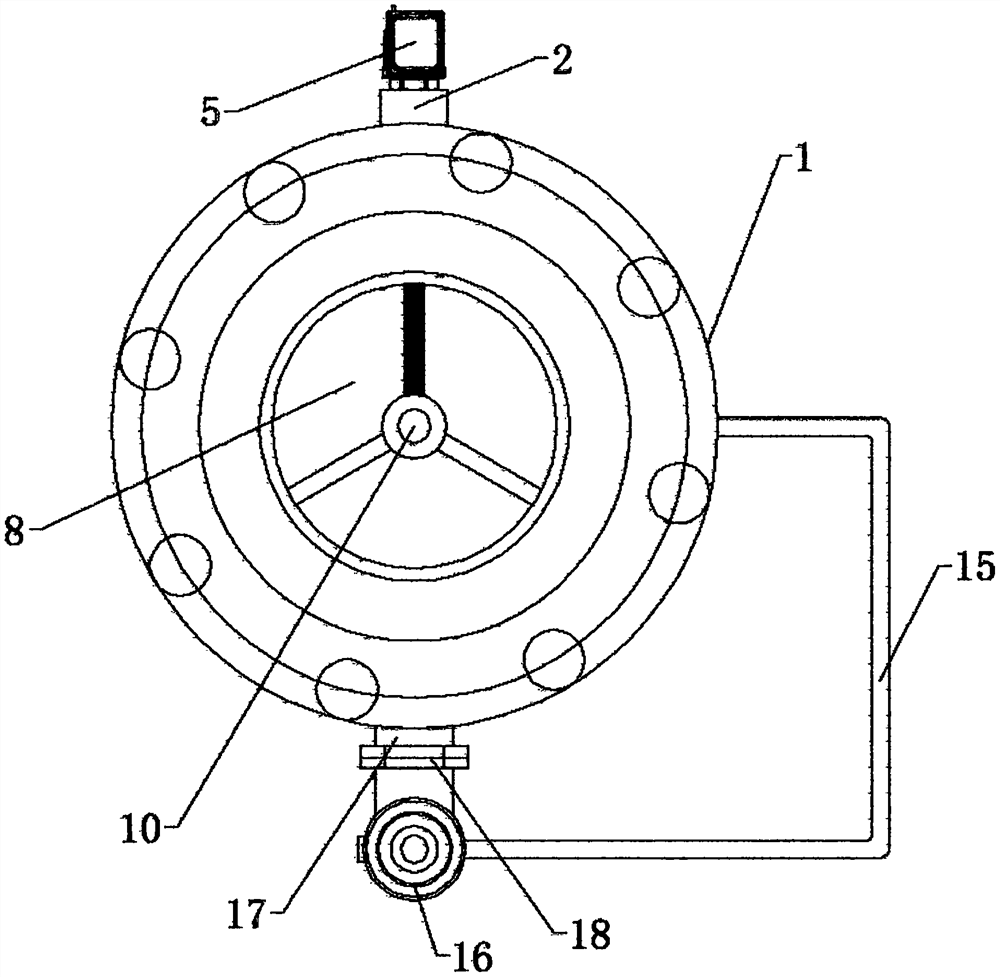

Pressure reduction type backflow preventing device

InactiveCN105805365ASimple structureSimple processing technologyCheck valvesEngineeringHigh pressure water

Owner:HARBIN REYAX TECH CO LTD

Coaxiality adjustment positioning device

ActiveCN104384917BEasy to liftSolve the problem of being stuck in the positioning toolMetal working apparatusEngineeringRelative motion

The invention discloses a coaxiality regulating and locating device. The coaxiality regulating and locating device comprises a bottom plate and a bearing seat, wherein the bearing seat is clamped in a through hole of the bottom plate through an upper flange, and the base is fixedly connected with the bearing seat through a screw; an air cylinder is fixedly connected with the base through a stud; an ejecting block in which an I-shaped hole is formed in the middle part is in clearance fit with a differential diameter hole, a piston rod of the air cylinder stretches into the I-shaped hole and is fixed with the I-shaped hole through a nut, a locating seat is arranged in a stepped hole of the bearing seat, and two bearings are arranged in a left gap and a right gap between the locating seat and the bearing seat. According to the coaxiality regulating and locating device disclosed by the invention, a workpiece and a locating tool can be rotated together by rotating the bearings, no relative motion is generated between the workpiece and the locating tool, friction is avoided, and thus the abrasion of a locating clamp is avoided; gaps between the locating tool and the workpiece are reduced, the regulating accuracy is increased, and the one-step assembling qualified rate is improved; a pneumatic lifting device is adopted, the problem that the workpiece is clamped in the locating tool due to high accuracy of the locating tool and small matching gaps between the locating tool and the workpiece is solved, and the workpiece can be conveniently lifted.

Owner:CHINA NTAIONAL NUCLEAR TIANJIN MACHINERY

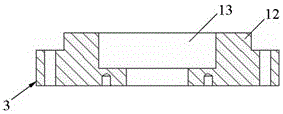

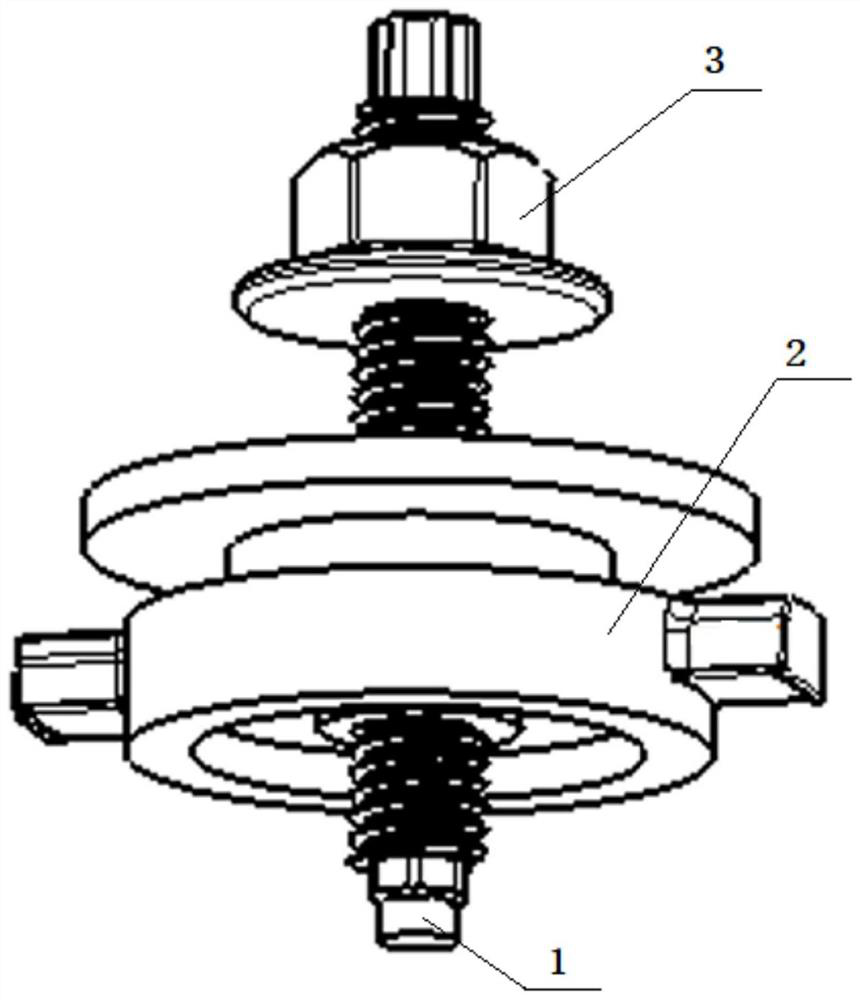

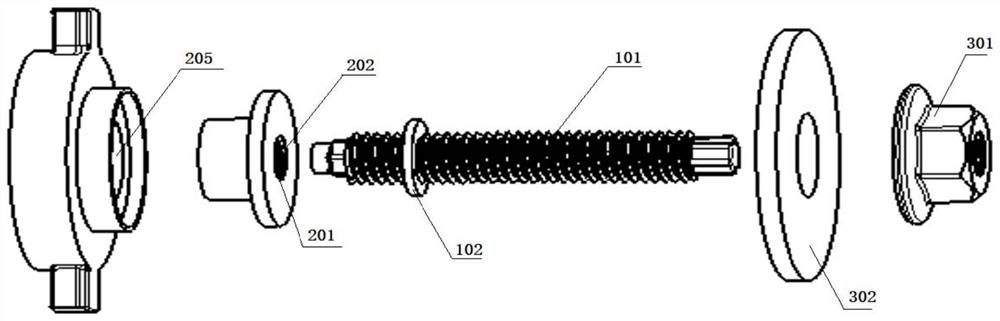

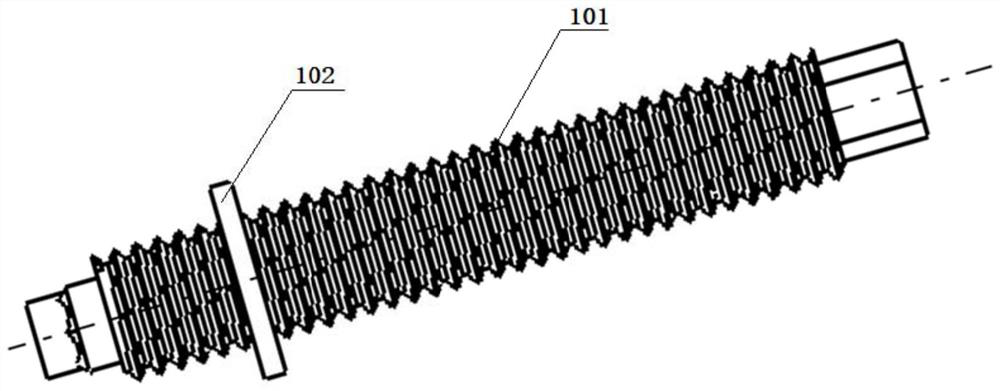

A tolerance adjusting device and an installation structure for concealing a door handle

ActiveCN112922468BImprove one-time assembly pass rateHigh positioning accuracyVehicle locksScrew threadFlange

The invention discloses a tolerance adjustment device and an installation structure for concealing a door handle. The tolerance adjustment device comprises a stud, a fixing bracket and a locking assembly; the outer wall of the stud is provided with a first thread and a flange surface; The flange surface is an annular structure surrounding the stud, and there is a preset distance between the flange surface and the end surface of the stud, and the flange surface is used to abut the stud for positioning The fixing bracket is provided with a first through hole, and the inner wall of the first through hole is provided with a second thread; the stud and the fixing bracket pass through the first thread and the second thread. Two threaded connections; the locking assembly is used for fixing the stud and the fixing bracket to the mounting surface. The tolerance adjustment device and the installation structure of the hidden door handle of the present invention can effectively solve the problem of preventing the tolerance adjuster from rotating in the prior art, improve the positioning accuracy, and effectively improve the qualified rate of one-time assembly of the hidden door handle.

Owner:杭州吉利汽车有限公司 +2

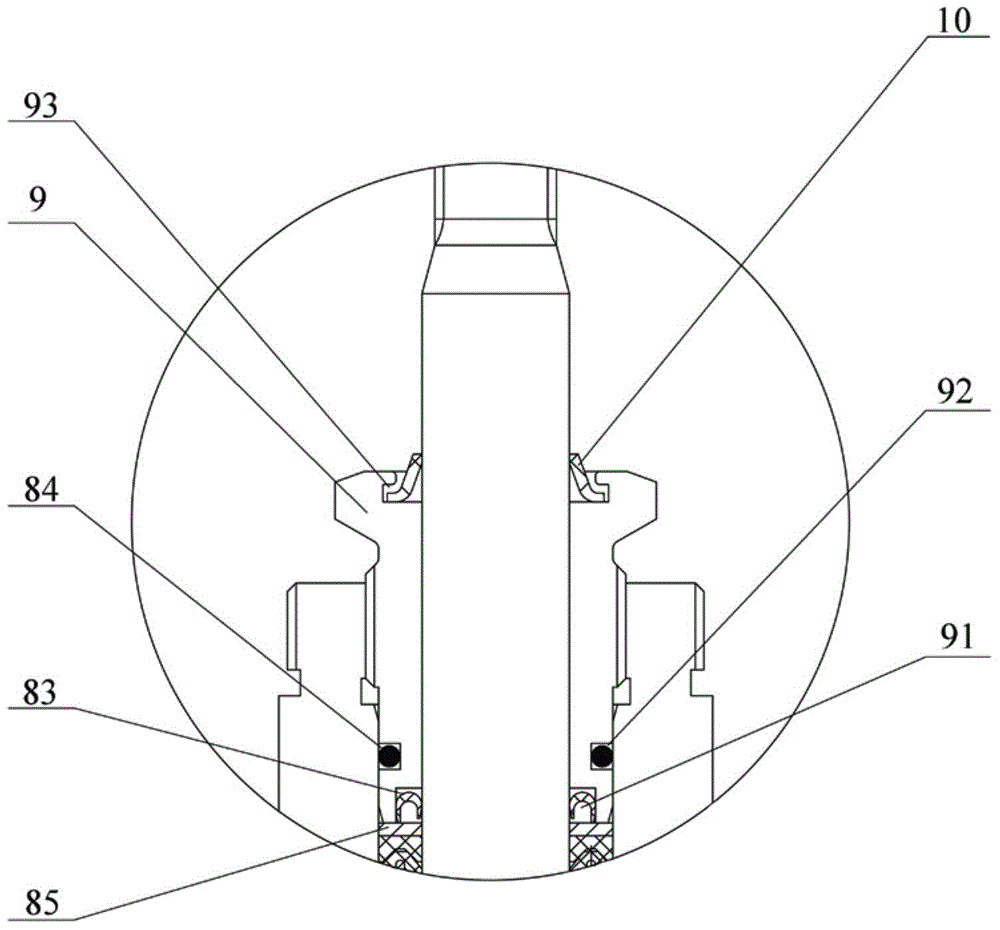

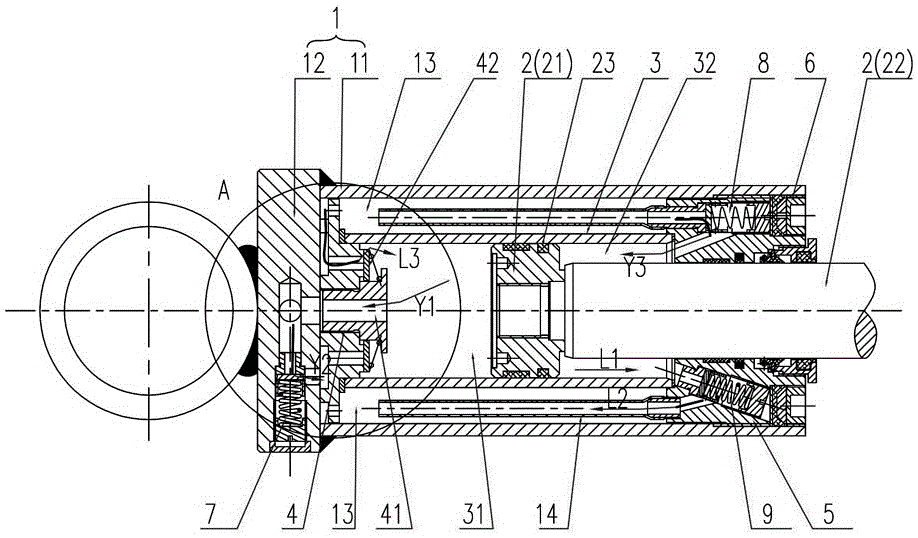

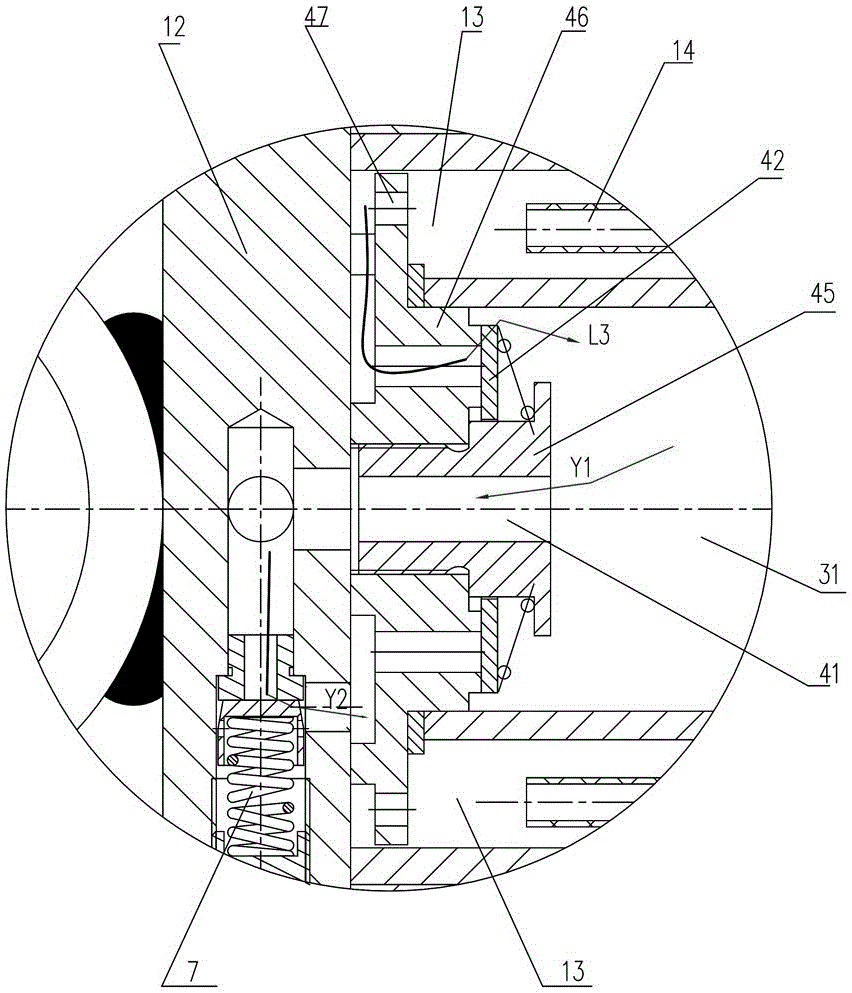

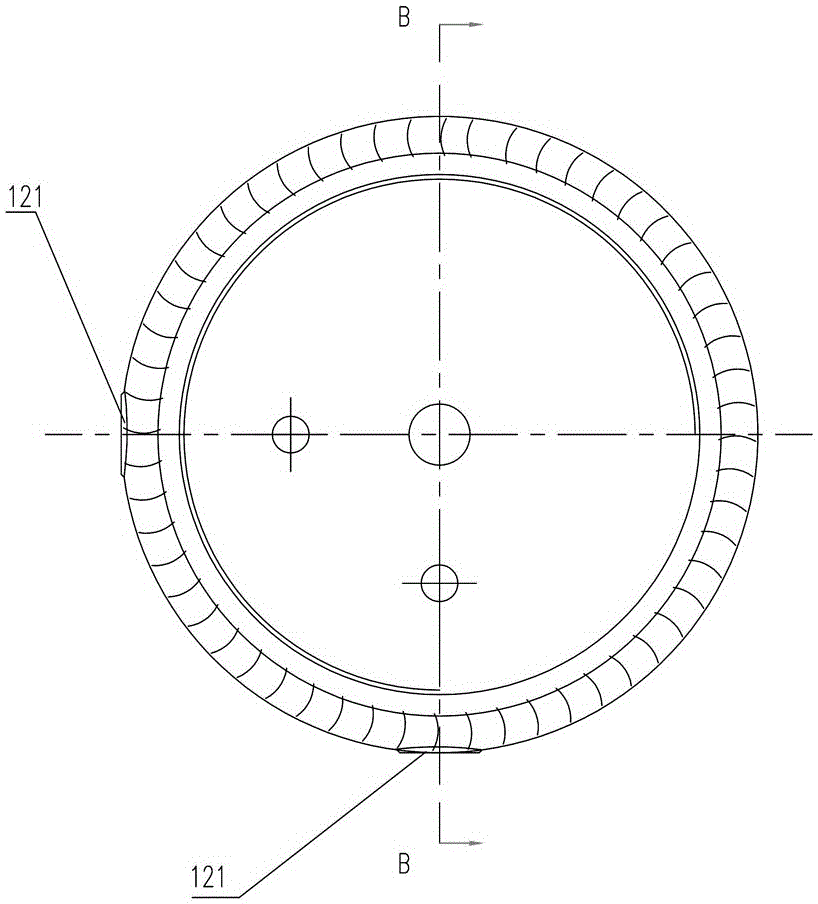

A hydraulic shock absorber

ActiveCN105240442BReduce manufacturing costFulfil requirementsSpringsLiquid based dampersEngineeringCylinder block

The invention discloses an oil damper. The oil damper comprises an oil storage cylinder, a piston assembly, a work oil cylinder, a bottom valve assembly, a guide assembly and a gland. The oil storage cylinder comprises an outer cylinder body barrel and a base. An oil storage cavity is formed between the work oil cylinder and the outer cylinder body barrel. The guide assembly is arranged at the rear end of the work oil cylinder. The end, away from a piston, of a piston rod of the piston assembly penetrates out of the guide assembly and the gland outwards, and the piston divides the work oil cylinder into a first cavity and a second cavity. The base is provided with a compressing damping regulation valve, the inlet of the compressing damping regulation valve is communicated with the first cavity, and the outlet of the compressing damping regulation valve is communicated with the oil storage cavity. The guide assembly is provided with a stretching check valve and a stretching damping regulation valve, the inlet of the stretching check valve is communicated with the oil storage cavity, the outlet of the stretching check valve is communicated with the second cavity, the inlet of the stretching damping regulation valve is communicated with the second cavity, and the outlet of the stretching damping regulation valve is communicated with the oil storage cavity. The bottom valve assembly is provided with a one-way check valve. The oil damper has the advantages that the stretching and compressing damping force can be symmetric or asymmetric, can be independently adjusted and can be externally adjusted.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

An Elastic Algorithm for Computing Rotor Assembly Pose Based on End Jump Measurement

ActiveCN110083906BAccurate predictionImprove coaxialityGeometric CADDesign optimisation/simulationPrediction algorithmsStructural engineering

An elastic algorithm for calculating the rotor assembly pose based on end-jump measurement. By equating the rotor mating surface into a plurality of asperity contact pairs, the Hertzian contact law is used to calculate the contact elastic deformation, and the actual contact contact pairs are separated. , use the energy and moment balance equation to judge the final contact state, and finally solve the normal vector of the contact plane to represent the contact pose, which improves the accuracy of the rotor assembly pose prediction, which can well reflect the assembly coaxiality, and better Realize the prediction and optimization of rotor assembly phase. This method is based on the measured end-jump data in actual production, and considers the elastic deformation generated during the assembly process, which makes up for the deficiency of the rigidity prediction algorithm, realizes the accurate prediction of the assembly pose before assembly, and improves the rotor synchronization after assembly. At the same time, the first-time assembly qualification rate is greatly improved, which has important practical guiding significance for axis prediction, assembly phase adjustment and optimization in the assembly process of aero-engine rotor parts.

Owner:DALIAN UNIV OF TECH

A filter assembly air tightness automatic detecting device

PendingCN108956034AReduce frequent operationsLabor savingDetection of fluid at leakage pointEngineeringAir tightness

The invention brings forward a filter assembly airtight automatic detecting device comprising a frame and a filter assembly, wherein one end of the frame is fixed with a bottom plate through bolts, and one side of the bottom plate is welded and fixed with a plurality of supporting blocks. A large water tank is placed on the corresponding ends of the supporting blocks. One side of the bottom plateis welded and fixed with a first bracket, and one side of the first bracket is fixed with a fixing plate through bolts. One side of the fixing plate is fixed with a reinforcing plate through bolts. One end of the reinforcing plate is fixed with a first air cylinder fixing plate, and the other end of the reinforcing plate is fixed with a supporting plate. One side of the supporting plate is fixed with a plurality of mounting jigs and a plurality of pressing members through bolts. Air tightness testing of four filters can be completed in a batch in twenty-five seconds, which greatly reduces theworkload and labor intensity of the employees. Furthermore, the use of automatic equipment for inspection can also avoid missed detection. The assembly qualification rate of products is further improved.

Owner:无锡铭方科技有限公司

A radiation unit matching block positioning mechanism, assembling device and method

ActiveCN112658661BPress tightlyEasy to press downMetal working apparatusClassical mechanicsControl theory

The invention relates to a radiating unit matching block positioning mechanism, an assembling device and a method. The positioning mechanism comprises a tooling frame, a first clamping cylinder and a first pneumatic clamping jaw, wherein the first clamping cylinder is installed on the tooling frame and Its driving end is connected to and drives the opening and closing of two first pneumatic clamping jaws. The first pneumatic clamping jaws are located above the tooling frame and are spaced apart from the tooling frame. After the two first pneumatic clamping jaws are closed, a Matching block holding hole for holding matching block. The invention adopts the first clamping cylinder to drive the first pneumatic clamping claw to clamp the matching block, and when the matching block clamp extends into the interval between the upper part of the tooling frame and the first pneumatic clamping claw, the first clamping cylinder drives the first pneumatic clamping claw. A pneumatic gripper releases the matching block so that the matching block falls into the matching block limiting groove of the matching block fixture.

Owner:BEIJING INST OF RADIO MEASUREMENT

Ball valve sealing seat test mould and use method

PendingCN109883614AImprove one-time assembly pass rateAvoid adverse effects caused by repeated weldingFluid-tightness measurementEngineeringValve seat

The invention relates to a ball valve sealing seat test mould and a use method. The ball valve sealing seat test mould comprises an upper mould and a lower mould, wherein the upper mould is used for simulating the ball body of an all-welded valve and is connected to the ball body installation end of a valve seat component to be tested; the lower mould is used for simulating the valve body of the all-welded valve and is connected to the valve body installation end of the valve seat component to be tested; and the upper mould and the lower mould are connected in a detachable connection way to fix the valve seat component to be tested. By use of the test mould, the valve seat component can be tested before the valve is assembled, and bad influences caused by repeated welding are avoided.

Owner:SHANGHAI INST OF SPECIAL EQUIP INSPECTION & TECHN RES +1

Pressure reduction piston type backflow preventer

PendingCN113933045AImprove accuracyImprove one-time assembly pass rateMeasurement of fluid loss/gain rateMachine valve testingSleeve valveCheck valve

The invention relates to the technical field of pressure reduction backflow preventers, in particular to a pressure reduction piston type backflow preventer which comprises a pressure reduction piston type backflow preventer body which is provided with a first test ball valve through a first test water nozzle. A first-stage check valve is arranged on the left side of the interior of the pressure reduction piston type backflow preventer body and corresponds to the water inlet, and a second-stage check valve is arranged on the right side of the interior of the pressure reduction piston type backflow preventer body and corresponds to the water outlet. A spring is arranged between the first-stage check valve and the second-stage check valve and located on the outer wall of the valve rod sleeve and the outer wall of the valve rod, a pressure reducing valve is installed at the end, away from the pressure reducing piston type backflow preventer body, of the pressure reducing pipe, and the valve rod sleeve and the valve rod are adopted between the first-stage check valve and the second-stage check valve to be used in cooperation with the spring through a piston connecting structure. The accuracy of spring force design of the pressure reduction part can be improved, and the one-time assembly yield of products is improved.

Owner:缪明镜

Solenoid valve and mass flow controller

ActiveCN111853329BHigh working reliabilityReduce the difficulty of assemblyOperating means/releasing devices for valvesFlow control using electric meansSolenoid valveEngineering

The invention provides a solenoid valve and a mass flow controller. The solenoid valve includes a solenoid, a valve body assembly, a valve core assembly, a plug assembly, and a valve port component, wherein the valve core assembly, the plug assembly, and the valve port component are stacked in sequence. Placed in the accommodation chamber of the valve body assembly, the valve core assembly is movably arranged in the accommodation chamber, the plug assembly includes a magnetic seat and a plug, the magnetic seat is fixedly arranged in the accommodation chamber, and the plug is movably arranged In the mounting hole of the magnetic seat, the valve core assembly is in point contact with the plug, and the end face of the valve port part facing the plug assembly is provided with a valve port, and the plug is set opposite to the valve port; the electromagnetic part is used to magnetize the valve core assembly and the magnet. seat, so that the magnetic seat attracts the valve core assembly to move, and then drives the plug to move, and adjusts the distance between the plug and the valve port. The electromagnetic valve and the mass flow controller provided by the present invention can improve the working reliability and reduce the difficulty of assembly, so as to improve the first-time assembly pass rate, reduce the processing difficulty of parts and components, reduce the processing cost, and reduce their own volume.

Owner:BEIJING SEVENSTAR FLOW CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com