Pressure self-balancing bidirectional sealing valve seat structure

A two-way sealing and self-balancing technology, applied in the direction of valve devices, cocks including cut-off devices, mechanical equipment, etc., can solve the problems of unguaranteed sealing performance, damage to the sealing structure of the valve seat, and failure to restore to the ideal state, etc., to improve once Effective assembly qualification rate, reliable sealing, and elimination of internal leakage risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings.

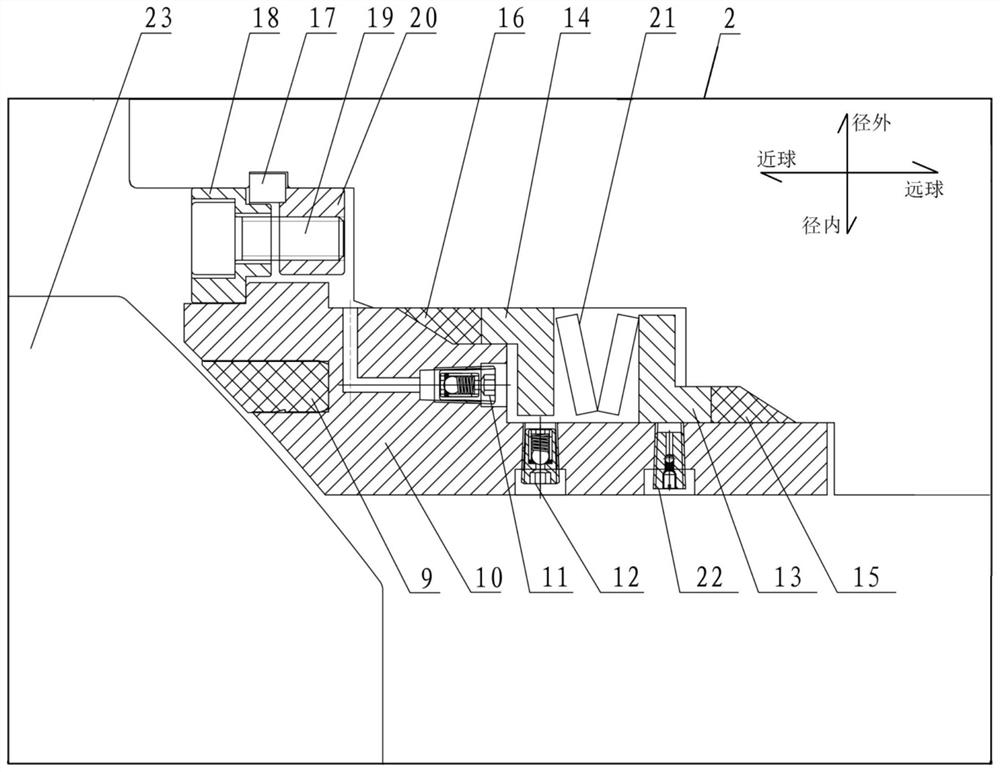

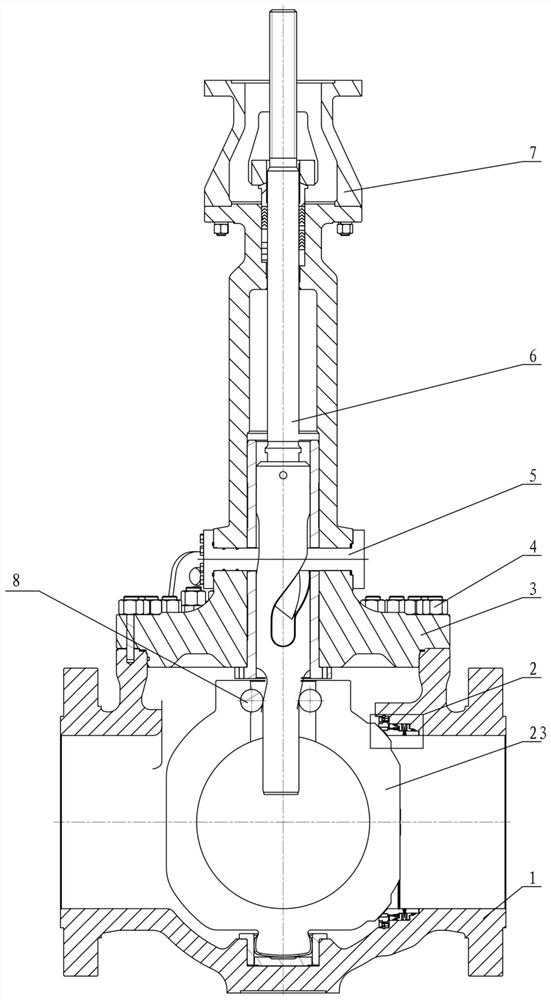

[0023] Such as figure 1 and figure 2 The illustrated embodiment of the present invention includes: a valve body 1, a valve seat assembly 2 and a ball 23, wherein the valve seat assembly 2 and the ball 23 are installed in the valve body 1, and the valve seat assembly 2 and the ball fixed to the valve body 1 23 sealing fit; valve seat assembly 2 includes: axial bolt connection assembly 30, valve seat support 10, pressure relief valve 22, insert 9, one-way valve and two-way sealing assembly; wherein the radial side of valve seat support 10 passes through the shaft The bolt connection assembly 30 is connected to the valve body 1, and the two-way sealing assembly is arranged in the inner cavity of the valve body connection part provided between the valve seat support 10 and the valve body 1; the pressure relief valve 22 is installed in the pressure relief hole i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com