Two-way sealing butterfly valve with hydraulic floating seat and anti-sediment function

A two-way sealing and floating technology, used in shaft sealing, engine lubrication, valve lift, etc., can solve the problems of difficult processing and assembly of butterfly valves, heavy metal retaining ring, etc., to overcome difficulties in processing and assembly, improve manufacturing and Assembly precision, light movement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

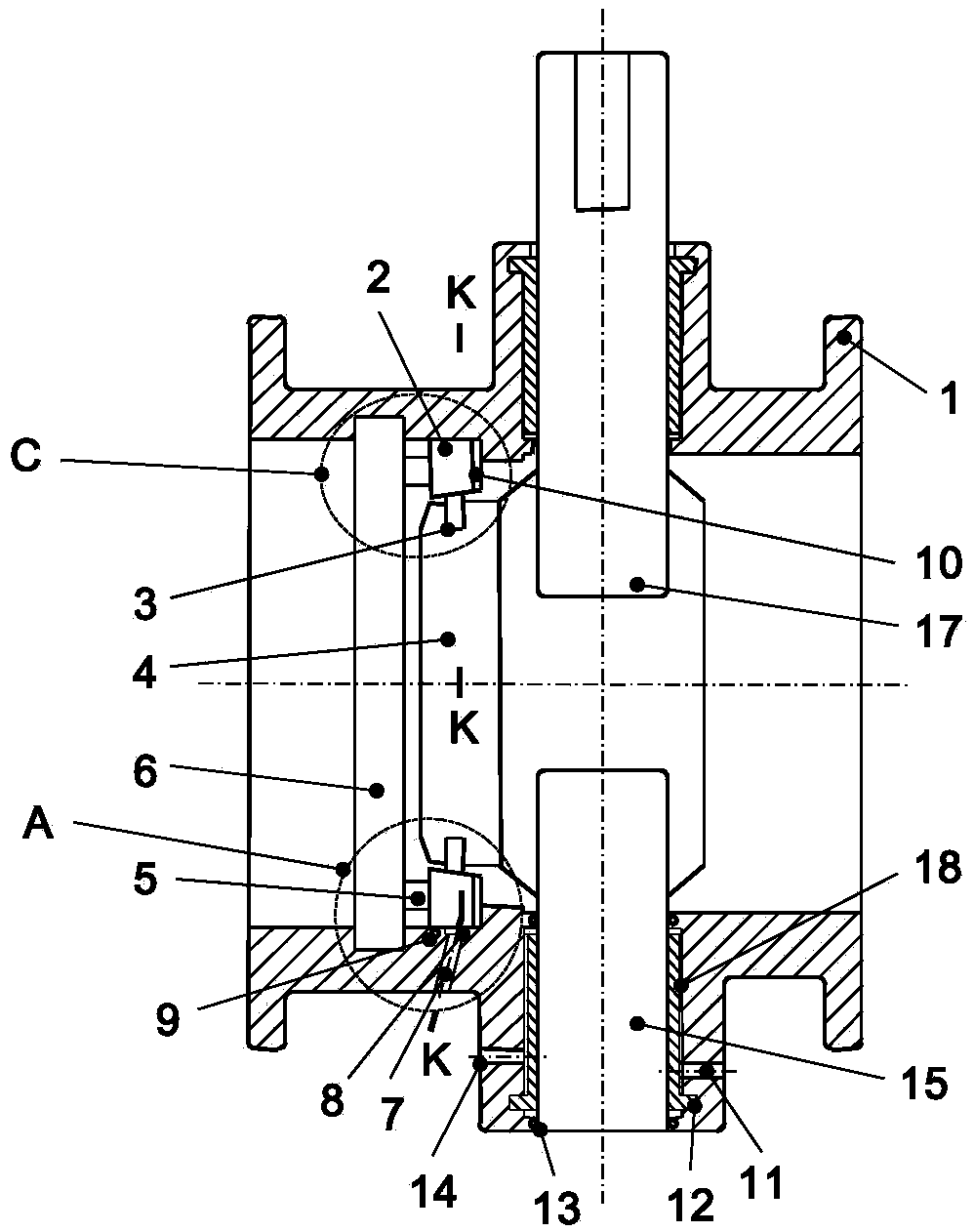

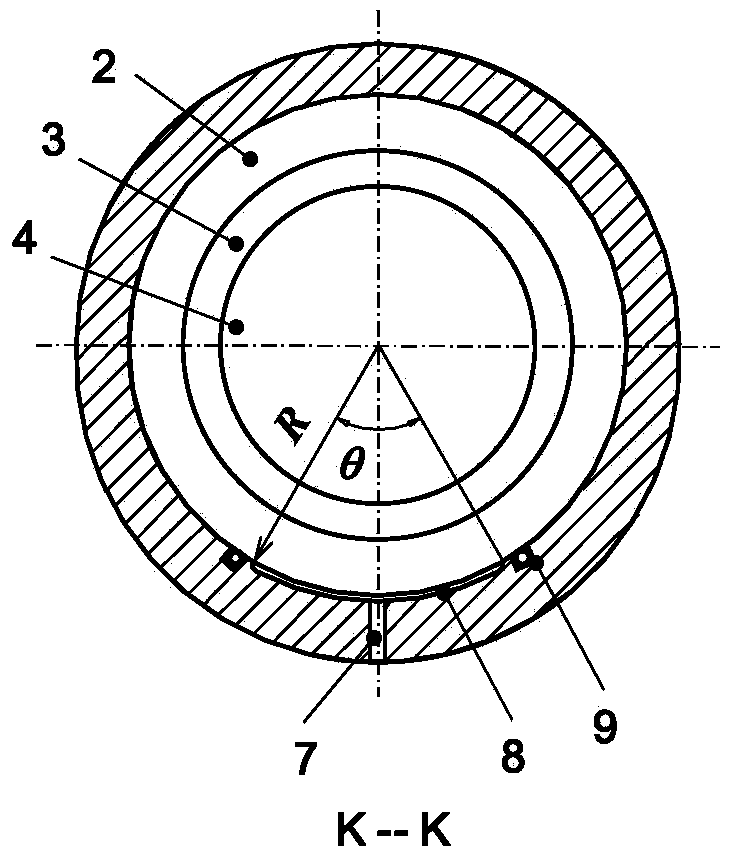

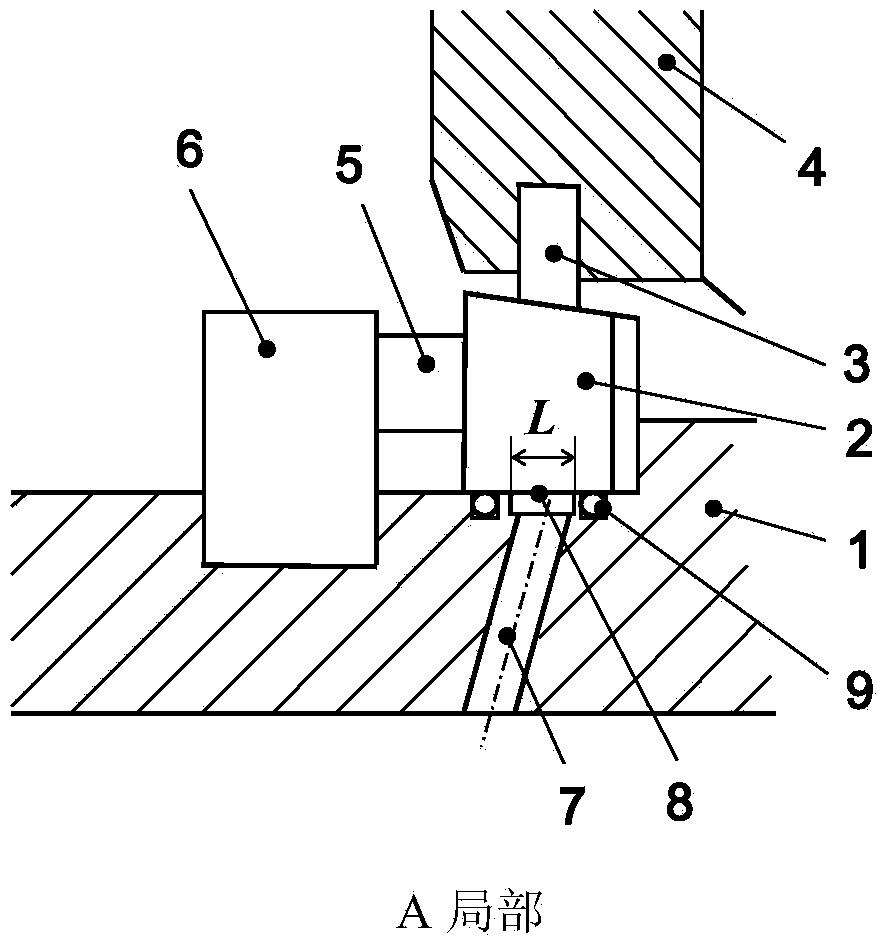

[0021] The principle and structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] figure 1 It is the main cross-sectional view of a two-way sealing butterfly valve with hydraulic floating seat and anti-sediment function. The two-way sealing butterfly valve includes a valve body 1, a valve seat 2, a sealing pressure plate 3, a valve plate 4, a pressure block 5, a retaining ring 6, a lower shaft sleeve 12, a lower shaft sleeve lubricating water tank 18, a lower valve shaft 15 and an upper valve shaft 17 . The sealing pressure plate 3 is fixed on the valve plate 4; the lower valve shaft 15 and the upper valve shaft 17 have the same center line, and both are installed on the valve body 1; the valve plate 4 is jointly supported by the lower valve shaft 15 and the upper valve shaft 17. When the upper valve shaft 17 rotates under the action of external force, it will drive the valve body to rotate around the center l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com