Forming method of special-shaped optical clear resin

A technology of optical glue and molding method, which is applied to optical components, household appliances, other household appliances, etc., can solve the problems of time-consuming, laborious, and easy to overflow glue, so as to improve manufacturing accuracy, reduce manufacturing time, and reduce The effect of mold use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to achieve the above-mentioned objectives and effects, the technical means adopted by the present invention, its structure, and the method of implementation, etc., the preferred embodiments of the present invention will now be described in detail with reference to drawings to fully understand the present invention.

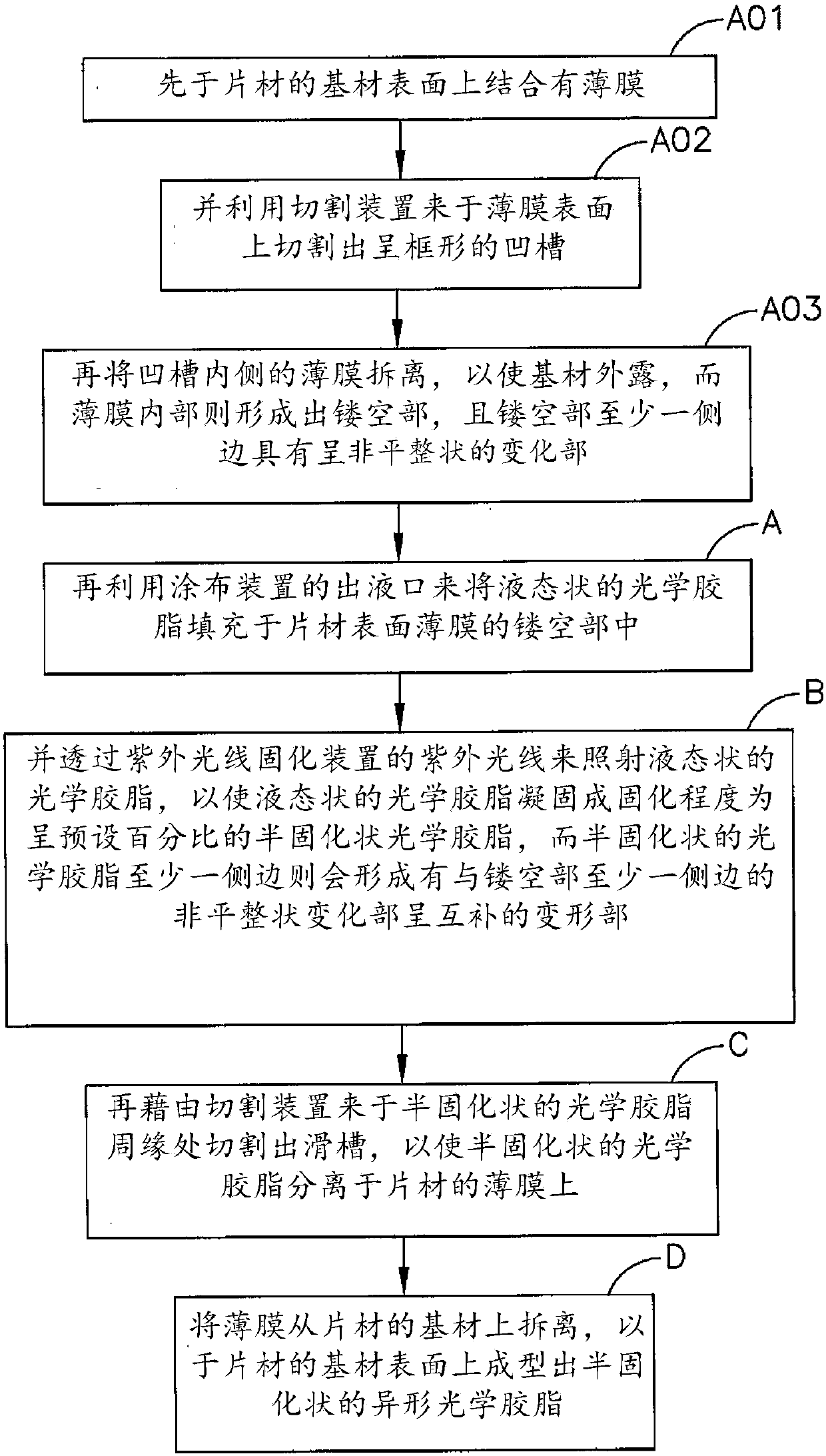

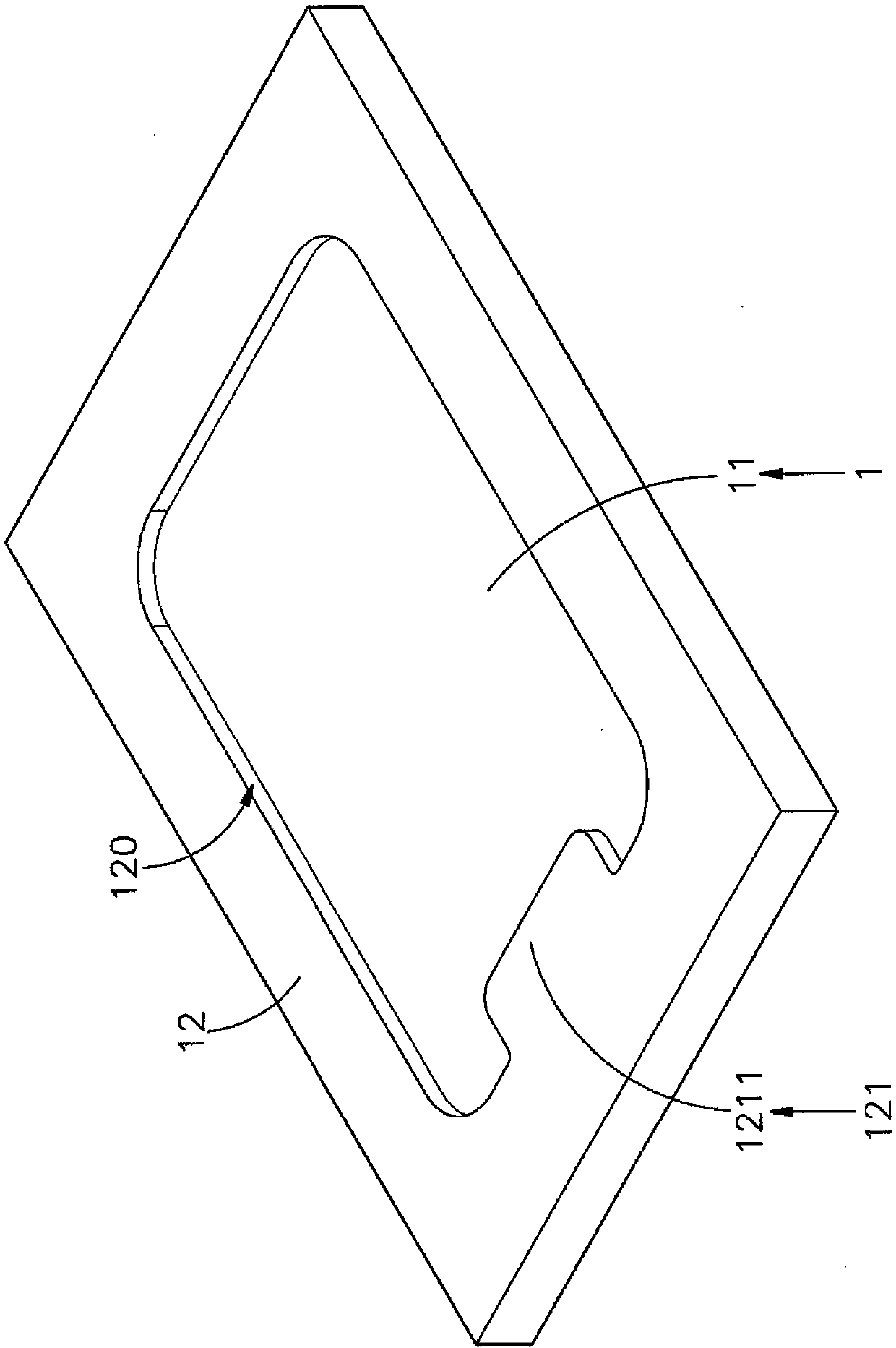

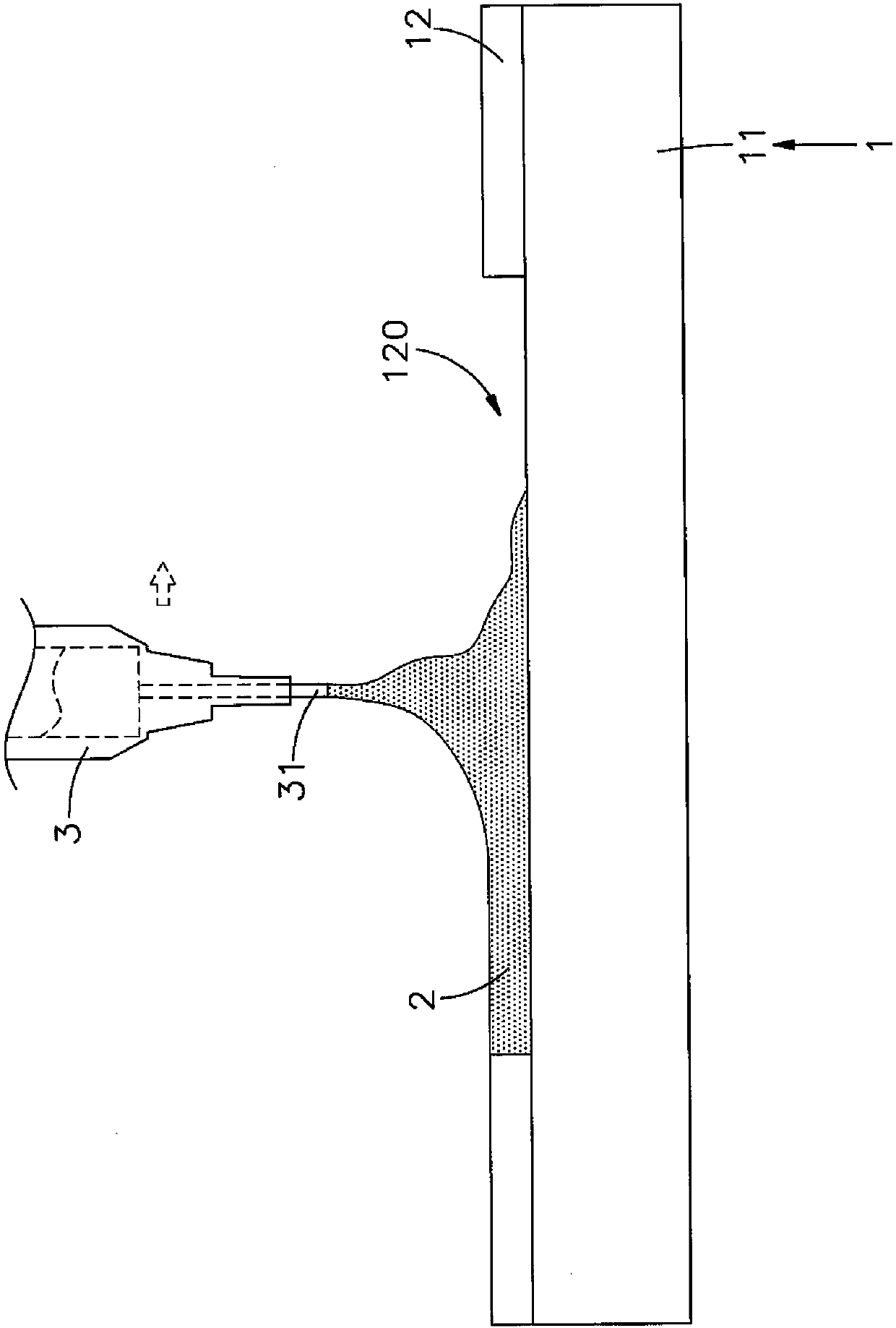

[0039] Such as Figure 1 to Figure 7 Shown are the flow chart of the present invention, the top view of the sheet, the schematic diagram of the operation when the coating device is used, the schematic diagram of the operation when the UV curing device is used, the top view of the semi-cured optical glue, and the schematic diagram of the cutting device when used. The schematic diagram of the action and the side view after the film of the sheet is torn off. It can be clearly seen from the figure that the molding method of the shaped optical adhesive of the present invention can form a semi-cured shaped optical adhesive 2 through the sheet 1, wherein The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com