Equal-thickness moulding surface splitting casting superplastic forming/diffusion connection forming mould and preparation method thereof

A technology of superplastic forming and diffusion joining, which is used in casting molding equipment, mold components, manufacturing tools, etc., to ensure quality and accuracy, reduce production costs, and be less prone to cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

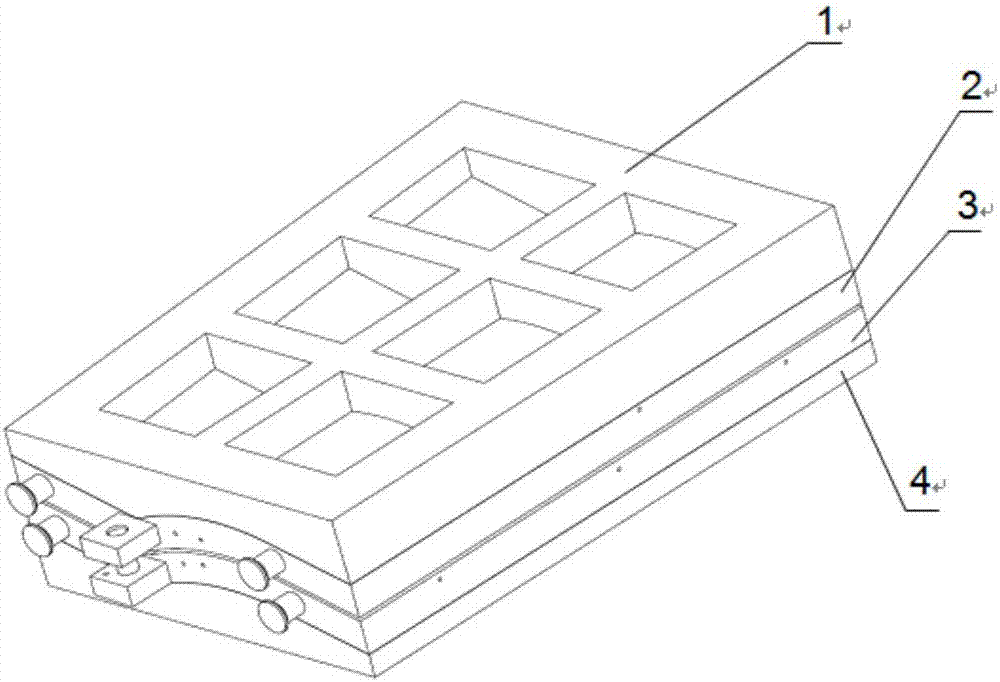

[0041] A method for preparing a superplastic forming / diffusion bonding forming mold for separate casting of equal-thickness profiles. The superplastic forming / diffusion bonding forming mold of equal-thickness separate casting includes two parts: an upper mold and a lower mold, the upper mold and the lower mold. The lower mold is composed of the surface part and the bracket part respectively, and the above four parts are processed separately, including the following steps:

[0042] The first step is to prepare the thick profile parts of the upper and lower molds

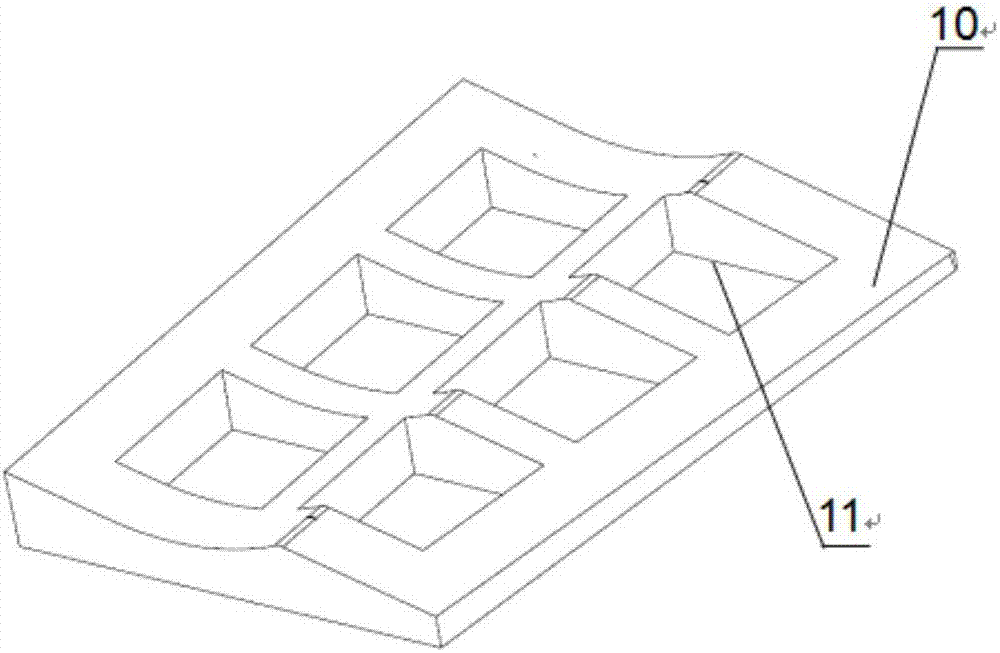

[0043] 1.1) First, extract the upper and lower surfaces of the parts in contact with the mold surface in the theoretical digital model of the CATIA part, and then stretch the contact surfaces along the normal direction to form a fractional mold of the mold surface with equal thickness. Parts are uniform in thickness.

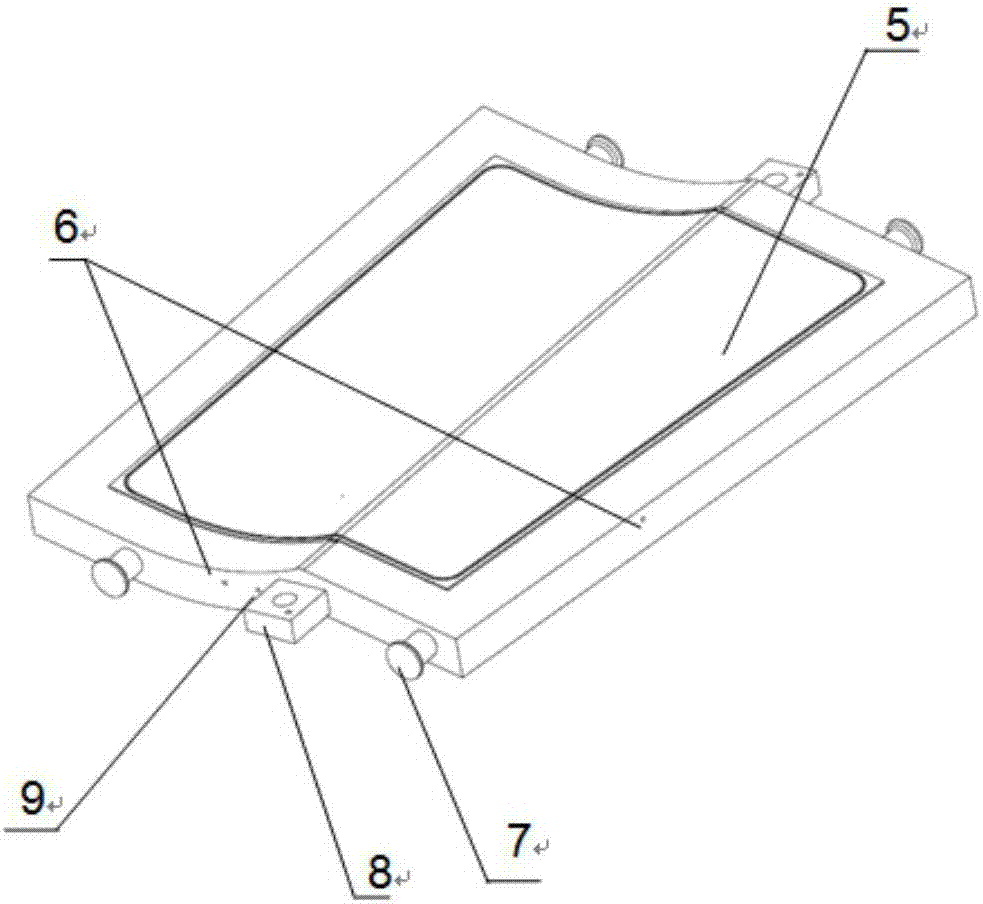

[0044] 1.2) According to the requirements on the digital model, design the blank holder, the inlet / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com