An automatic sealing pipe arrangement

An automatic sealing and pipeline technology, applied in switchgear, switchgear settings, electrical components, etc., can solve the problems of easy misoperation, internal discharge, and inability to find, and achieve the effect of reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

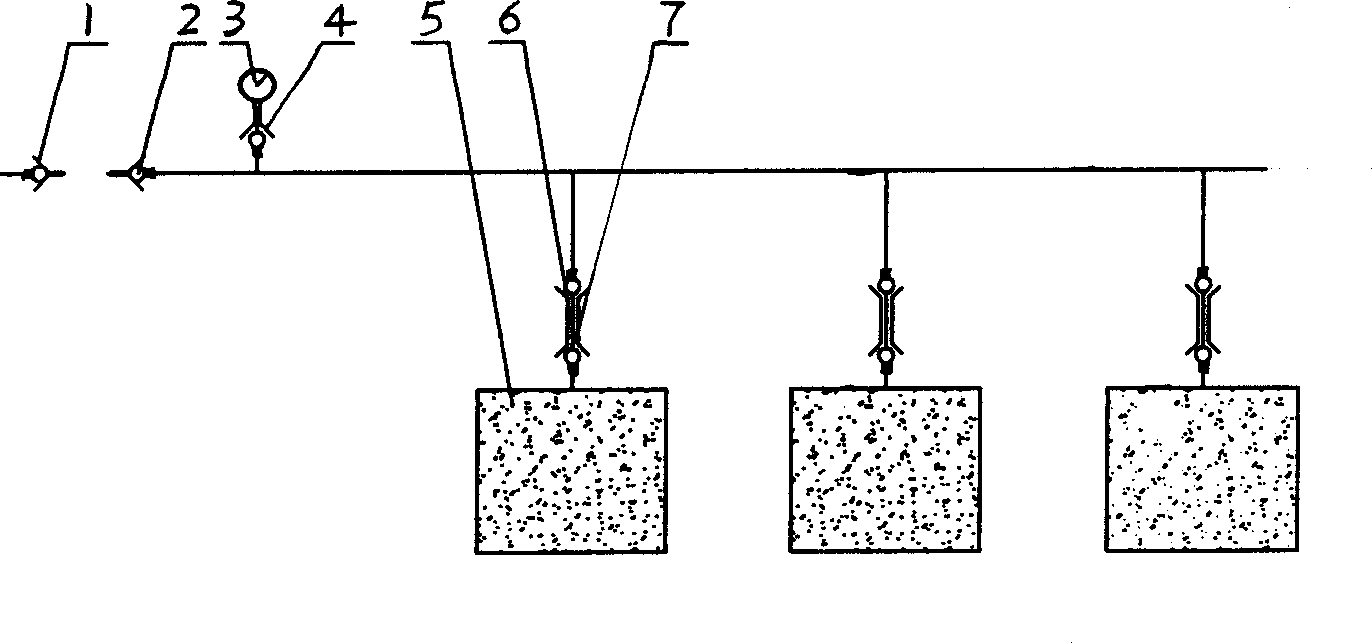

[0021] Figure 1 ~ Figure 4 Shown is an embodiment of the self-sealing pipeline device of the present invention, including three pressure chambers 5, a pressure (density) monitoring gauge 3, a self-sealing meter head 4 and a connecting valve. The connecting valves 1 and 2 are reversed and located at the inflation end of the device, and the connecting valves 6 and 7 are reversed and located at the pipeline connection of the pressure chamber. During normal commissioning or operation of gas-insulated power equipment, each pressure chamber is connected to form one or more large-pressure systems.

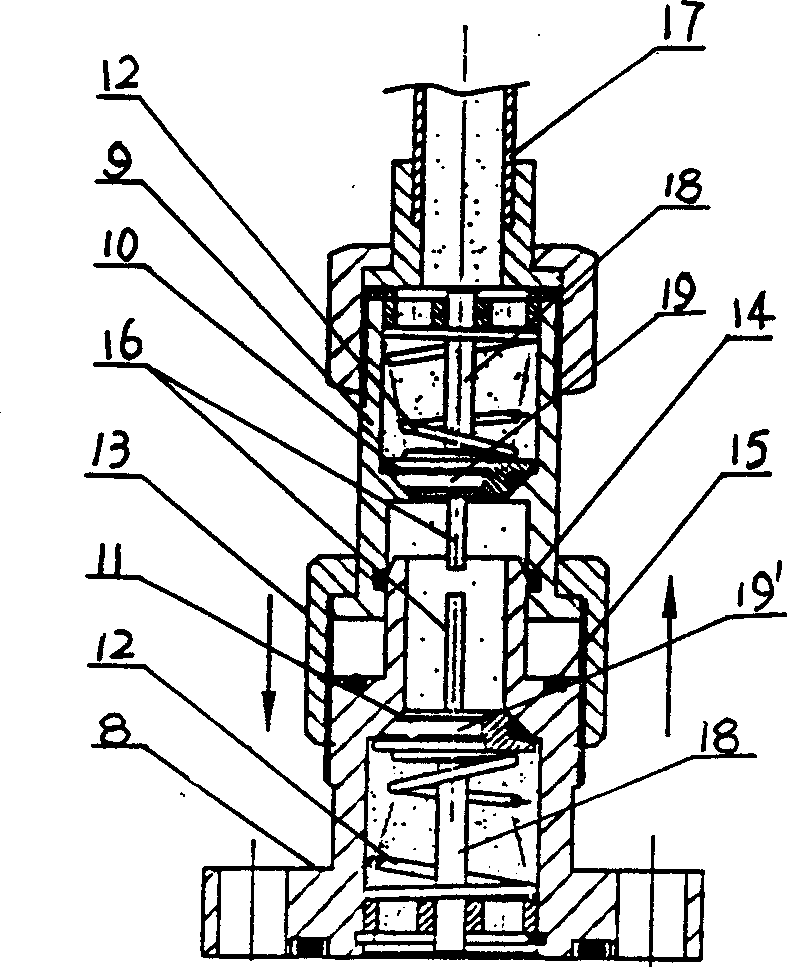

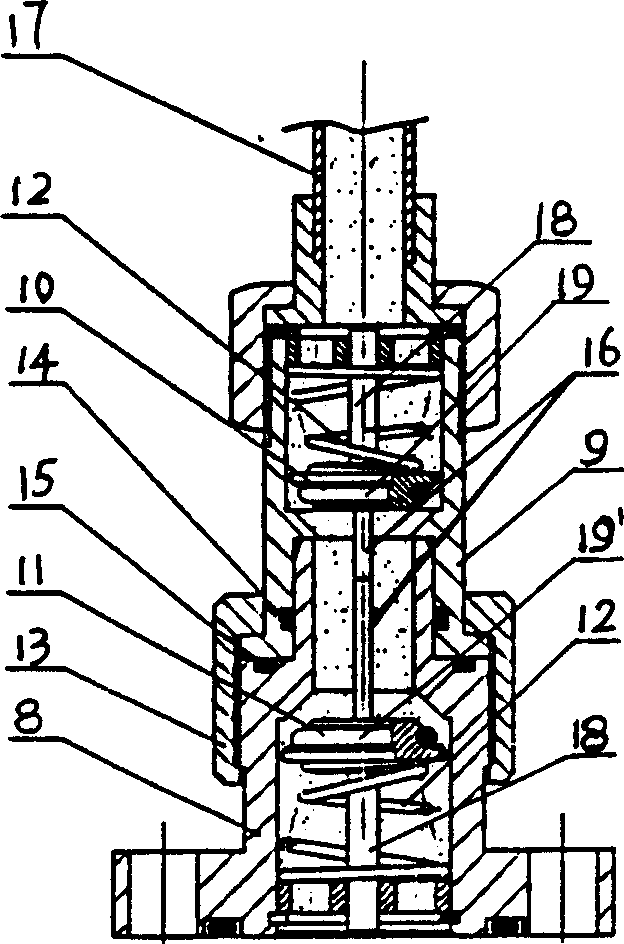

[0022] Such as figure 2 As shown, the connection valve includes a valve seat 8, a valve sleeve 9, an upper valve core 10, a lower valve core 11, a spring 12 and a nut 13. The valve seat 8 and the valve sleeve 9 both have channels, and the valve sleeve is engaged with the side of the valve seat. An axial sealing ring 14 is arranged at the place, an end face sealing ring 15 is arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com