Separated-type double-thread connected micro injection molding test mold

A test mold, double thread technology, applied in the field of micro-injection test molds, can solve the problems of reducing the manufacturing difficulty and cost of micro-injection molds, and the difficulty of installing and disassembling micro-cores, so as to facilitate disassembly and replacement of cores, and reduce manufacturing difficulty and cost. 、Reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

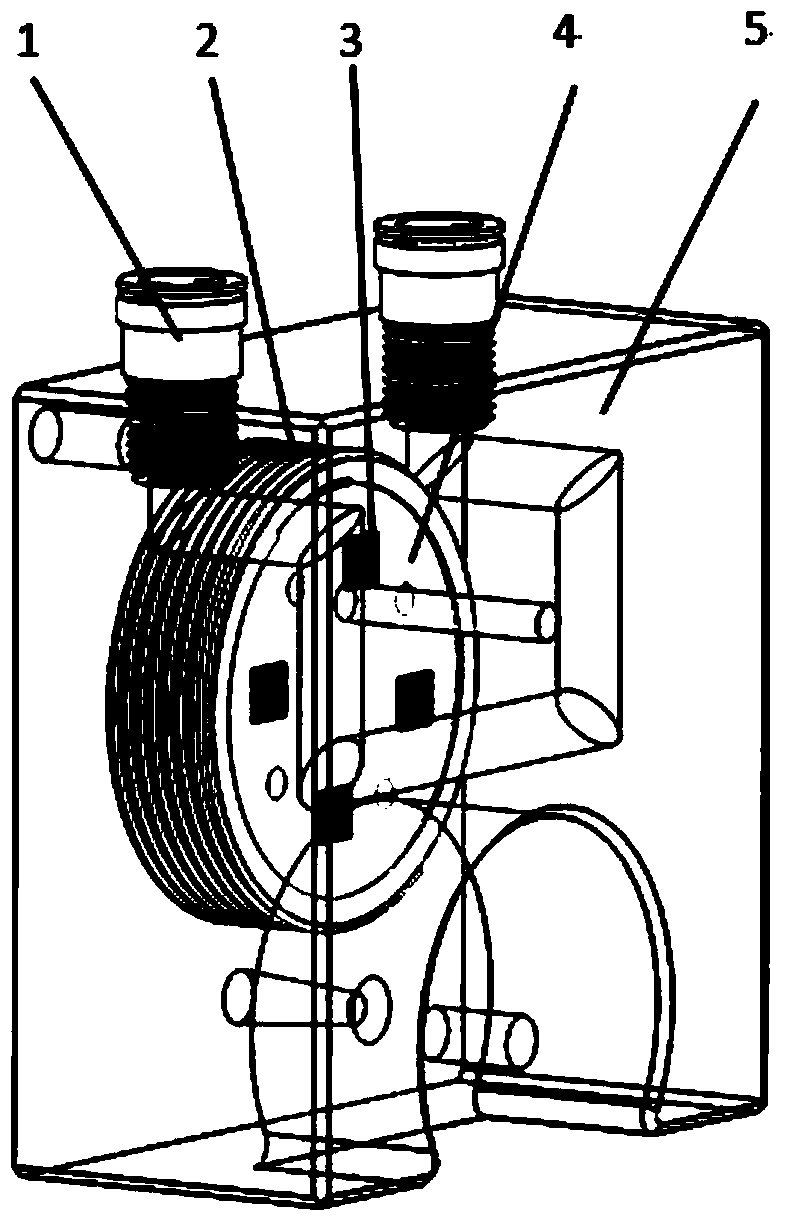

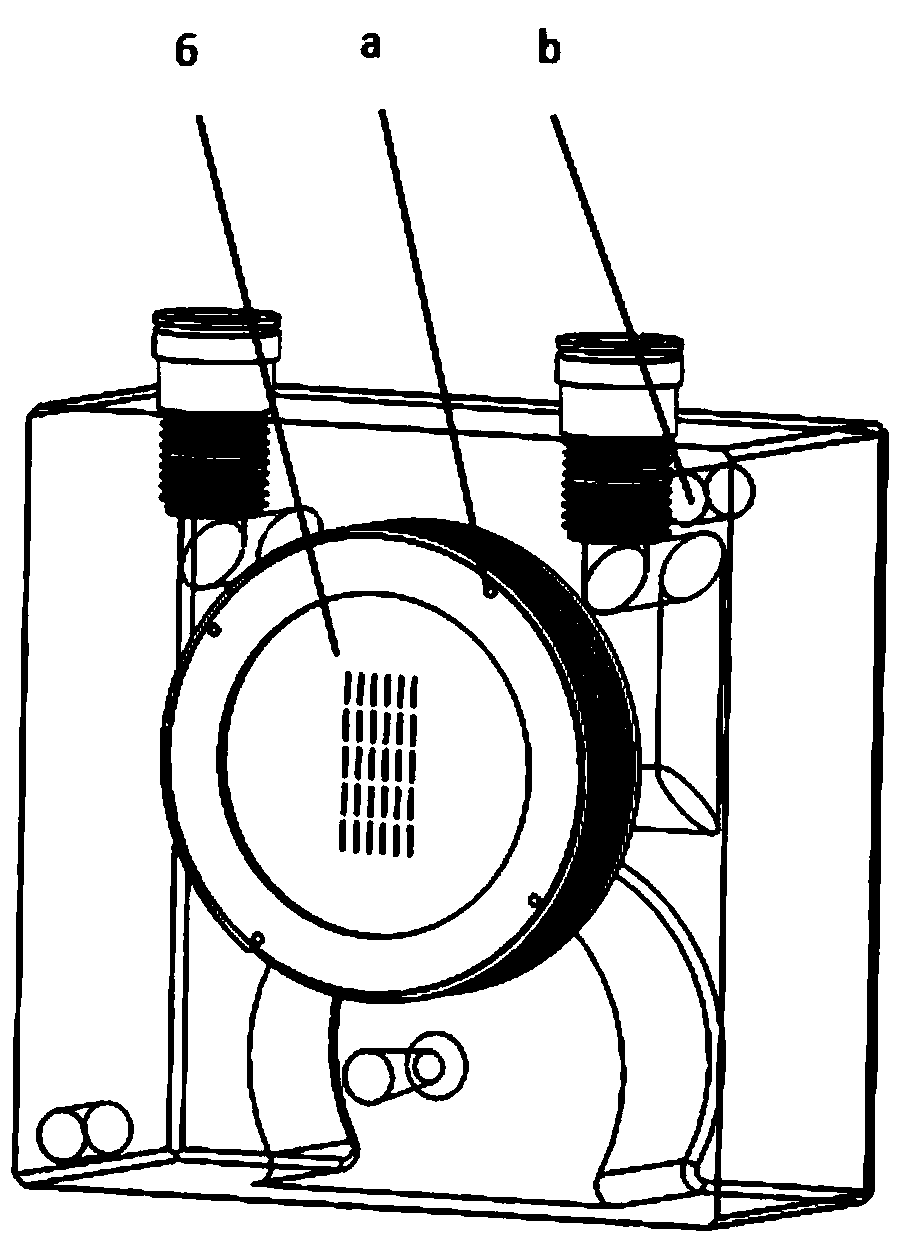

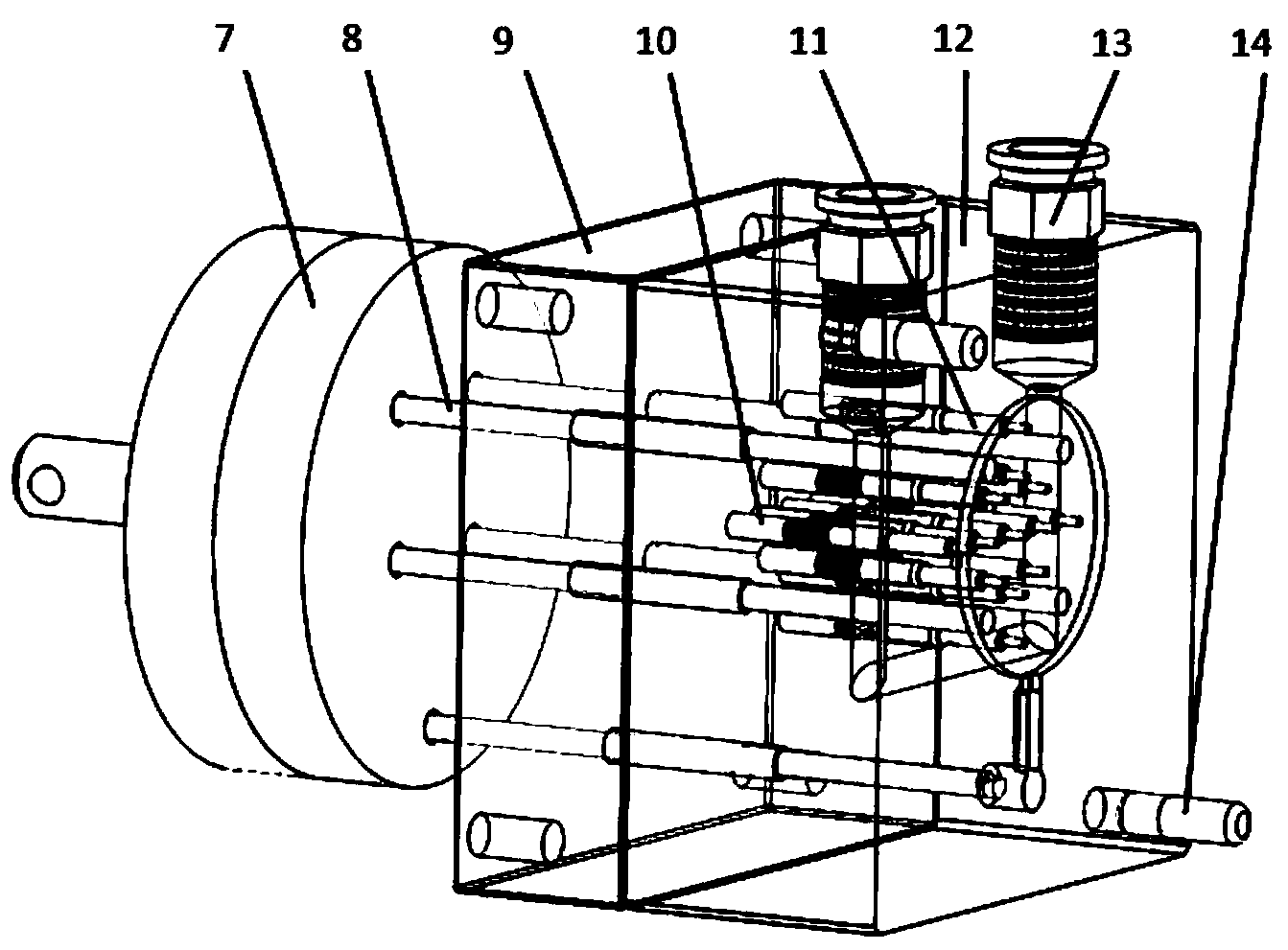

[0011] The specific implementation of the present invention will be described in detail below in combination with the technical scheme and accompanying drawings. The present invention solves the problem of difficult installation and disassembly of micro cores by using double thread connection technology, and combines the advantages of MEMS manufacturing and injection molding to form a micro core with a diameter of centimeters or more. Effective implementation of micro cores in injection molding. By integrating pressure and temperature sensors on the mold, the real-time monitoring of the dynamic changes and distribution of cavity pressure and temperature during the injection molding process is realized. Below in conjunction with accompanying drawing, take the PMMA micro-plate device with microstructure on the surface to utilize circular silicon micro-core to make the surface as an example, set forth the concrete implementation method of the present invention:

[0012] The fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com