Special corrugated pipe stop valve for chlorine gas

A bellows stop valve and bellows technology, applied in the direction of lift valves, valve details, valve devices, etc., can solve the problems of short service life, cumbersome installation, easy corrosion, etc., and achieve long service life, easy installation and connection, no external leaky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

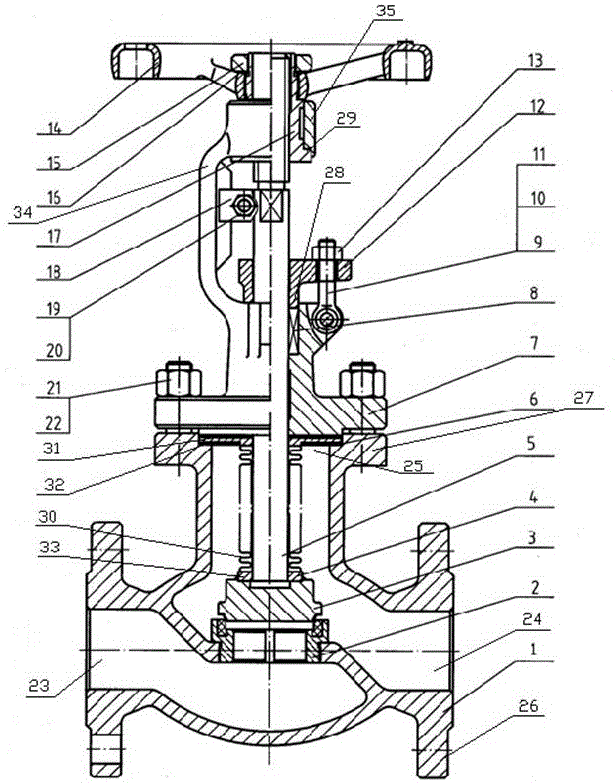

[0014] Such as figure 1 As shown, the bellows globe valve for chlorine gas includes valve body 1, valve stem 5, valve disc 3, valve seat 2, valve cover 7, valve body 1 is a symmetrical oval valve body, and valve body 1 includes , outlets 23, 24, middle installation port 25, inlet and outlet 23, 24 are respectively provided with interface flange 26, middle installation port 25 is provided with middle flange 27, valve cover 7 is connected with middle flange through flange, bolt 21, nut 22 27 is fixedly connected; the middle part of the valve body 1 is connected to the valve seat 2 through the channel partition, the valve stem 5 is installed through the valve cover 7, one end of the valve stem 5 is set inside the valve body 1, and the other end of the valve stem 5 is set outside the valve cover 7 , the valve disc 3 is fixedly connected to the inner end of the valve stem 5, the valve disc 3 is closely matched with the valve seat 2, a packing sealing mechanism 28 is set between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com