Round air door

A damper and circular technology, which is applied in the field of round dampers, can solve the problems of affecting sealing performance, consuming a large amount of air source, not saving energy, etc., and achieve the effect of less air consumption, less air source and reliable sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

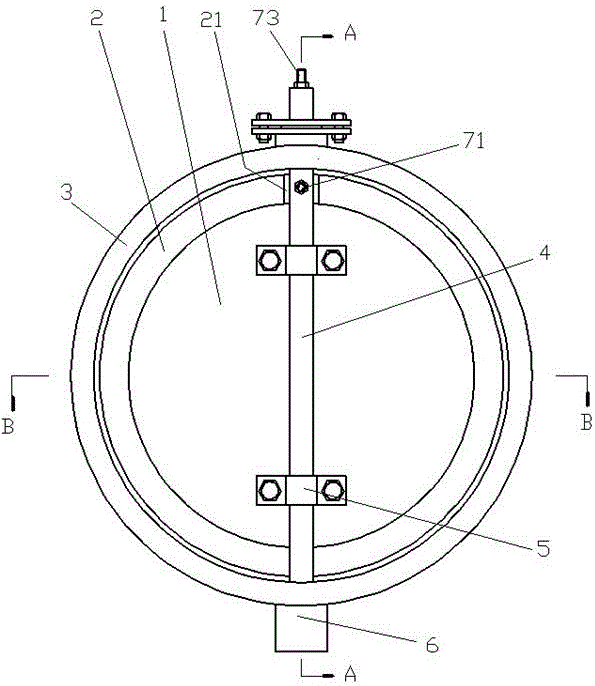

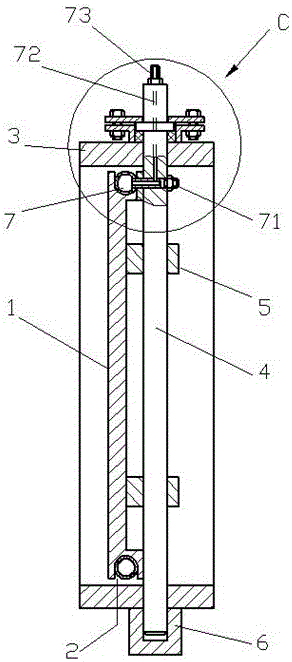

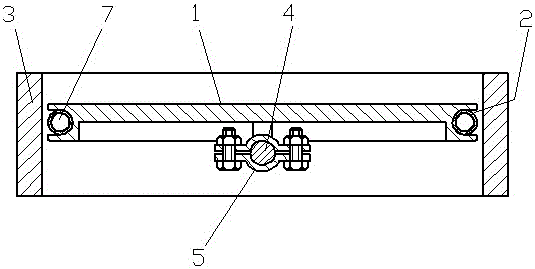

[0011] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

[0012] The round damper includes a circular housing 3, a circular baffle 1 is arranged in the housing, a hoop 5 is fixed on the baffle, a rotating shaft 4 is fixed on the baffle by the hoop, and the bottom of the rotating shaft The end is inserted into the support 6 arranged at the bottom of the housing, and the top end of the rotating shaft protrudes from the upper part of the housing.

[0013] A sealing device is provided on the periphery of the baffle, and the sealing device includes a rubber tube 7, the rubber tube surrounds the groove 2 on the periphery of the baffle, the head and tail of the rubber tube are sealed and connected, and the rubber tube is provided with an air nozzle 71, the gas The nozzle is sealed and connected with the rubber tube, one end of the gas nozzle protrudes from the groove wall and passes through the shaft along the radia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com