Method for calculating rotor assembly axis eccentricity based on radial skip measurement

A rotor assembly and rotor technology, which is applied in the field of rotor assembly axis eccentricity calculation, can solve the problems of irregular error, difficult adaptation, and difficulty in ensuring the accuracy of axis eccentricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] A method for calculating the eccentricity of the rotor assembly axis based on radial runout measurement, the steps are as follows:

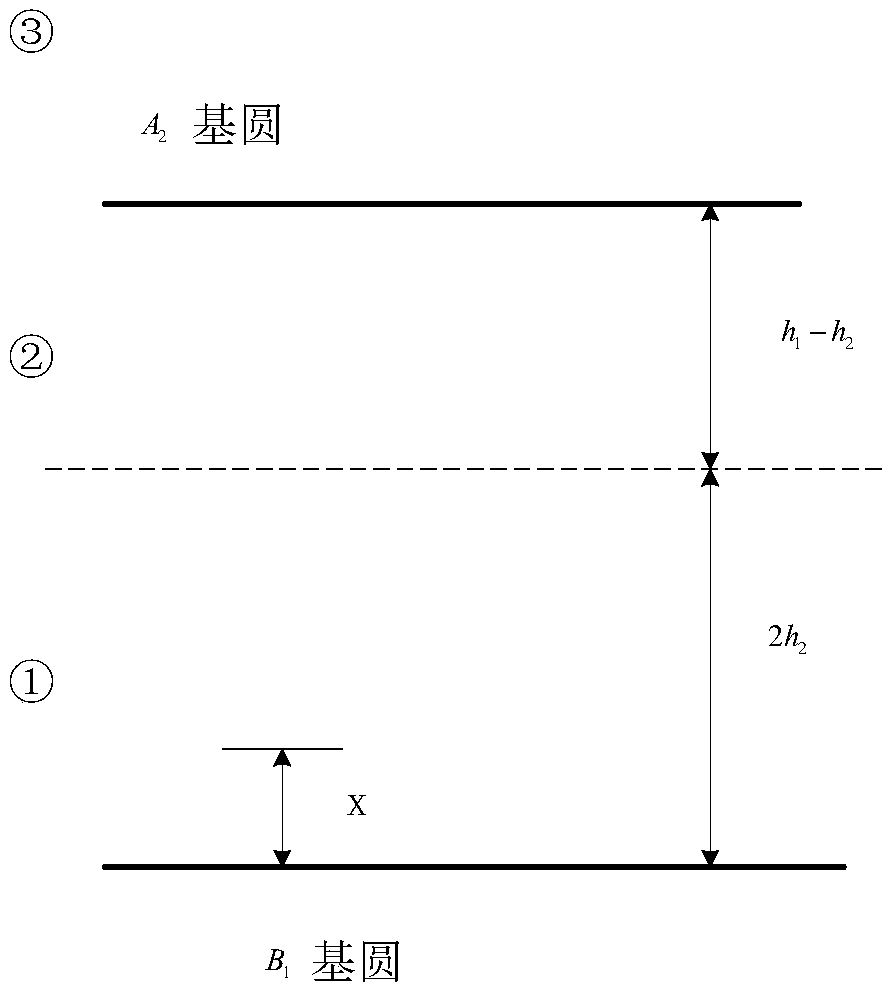

[0021] Step A: The adjacent two-stage disks, the connection between the lower-stage rotor A and the upper-stage rotor B are positioned by interference fit, and the centers of each surface from bottom to top are A O1 、A O2 , B O1 , B O2 , read the radial runout value of the measured two rotor seam mating surfaces and represent it in a matrix, the form of the data is a ring, then the radial runout data of the lower end surface of the upper end piece B is expressed as: B O1 (α,z b1 ), the radial runout data of the upper end surface of the lower end piece A is expressed as: A O2 (α,z a2 ); characterized by polar coordinate representation; the position of the center O in the global coordinate system is O(0,0), and the radius R of the matching seam is known;

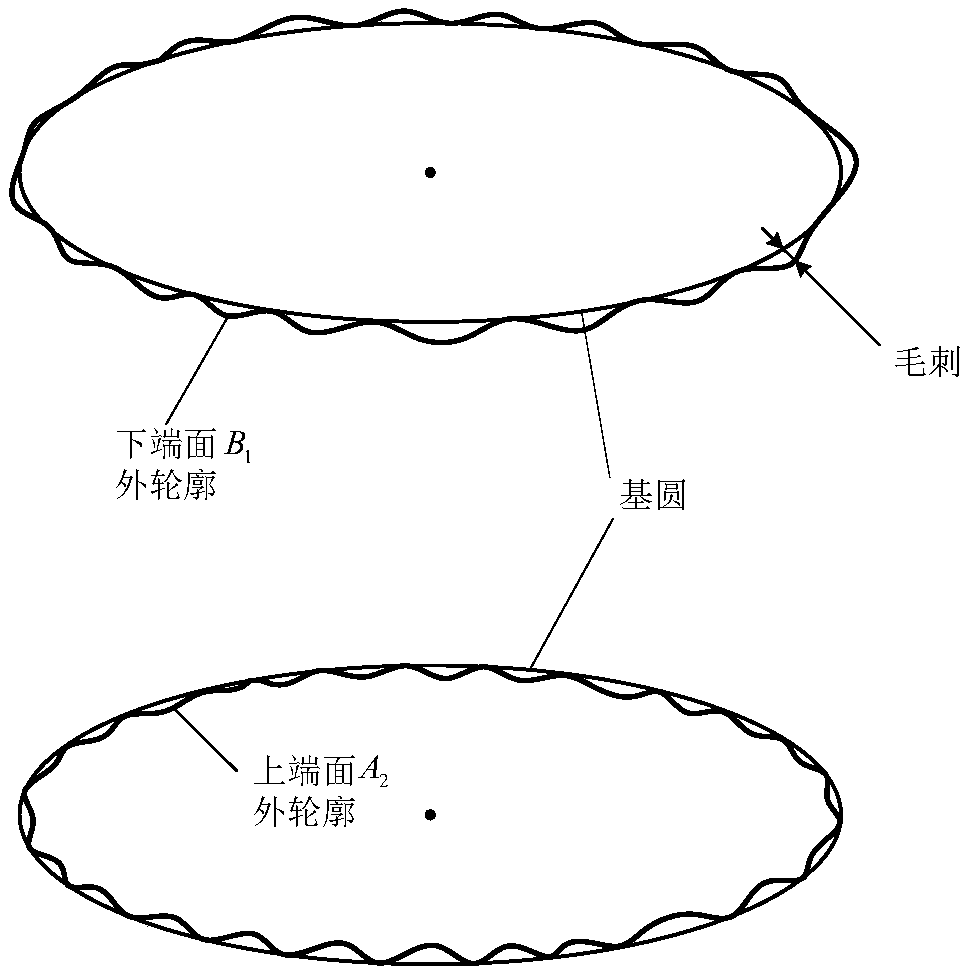

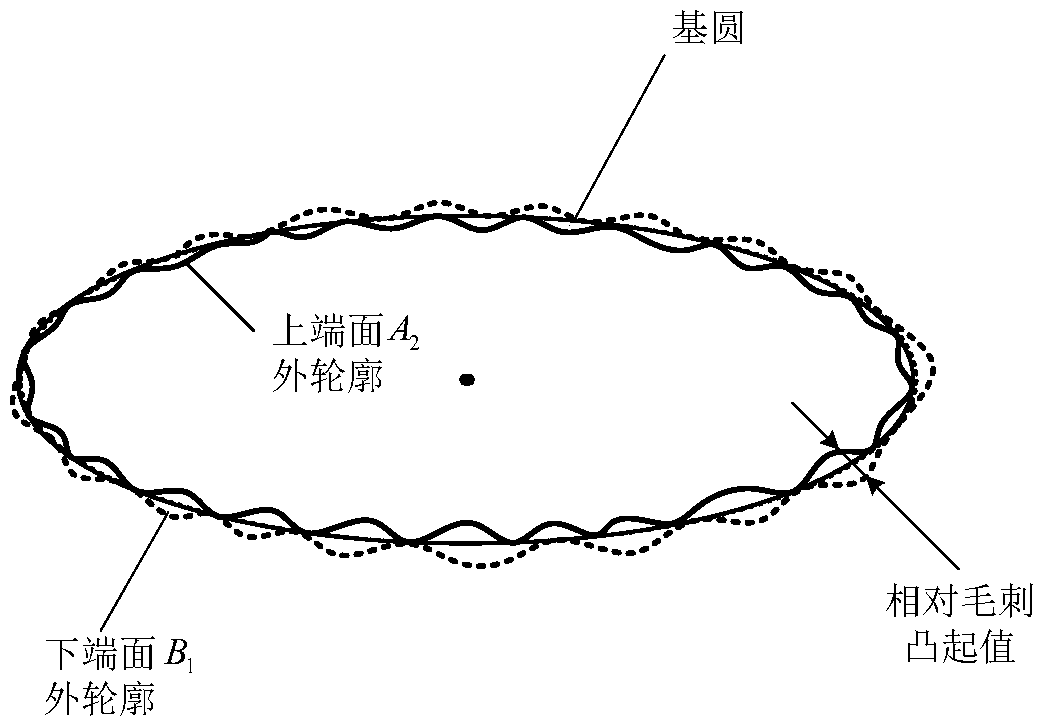

[0022] Step B: Calculate the relative runout value of each point. Such as figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com