Solenoid valve and mass flow controller

A solenoid valve and electromagnetic technology, applied in the direction of flow control, flow control using electric devices, non-electric variable control, etc., can solve the problems of low production efficiency of electromagnetic regulating valves, failure of electromagnetic regulating valves, and inability to achieve sealing, etc., so as to improve once Assembly pass rate, reduce processing difficulty, and reduce processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

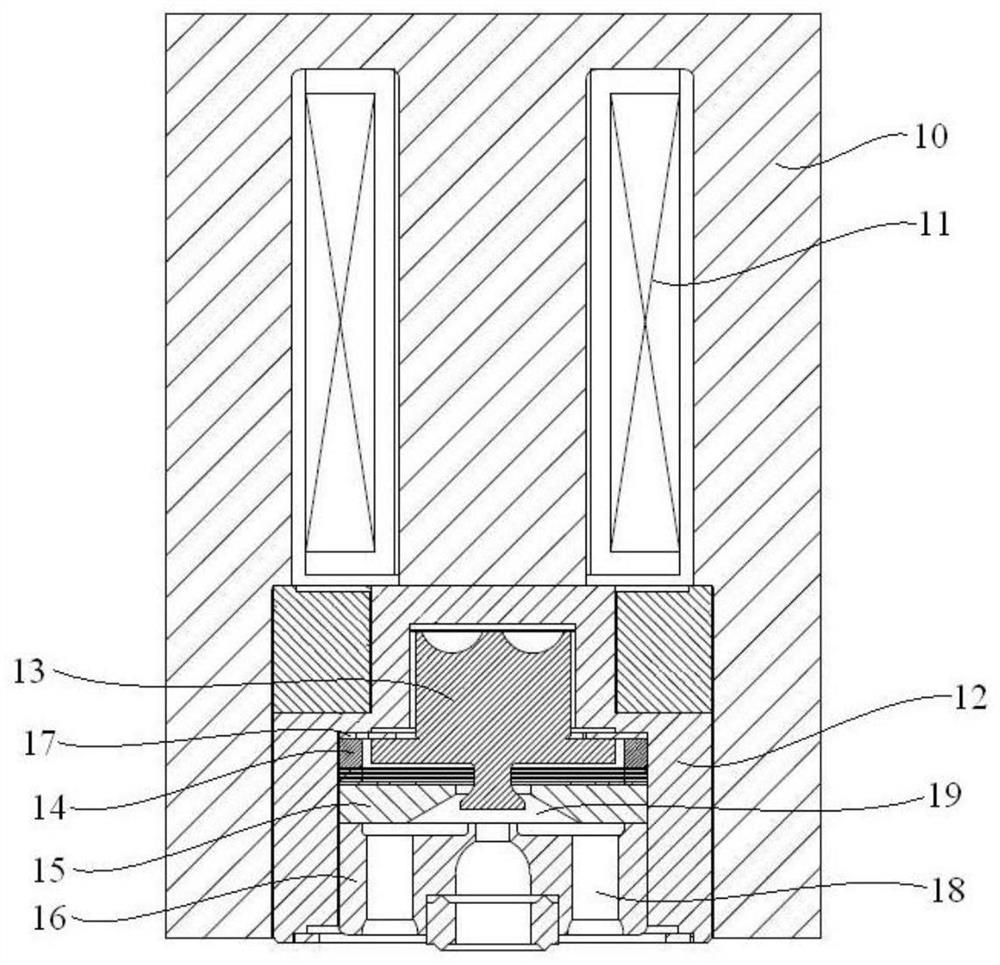

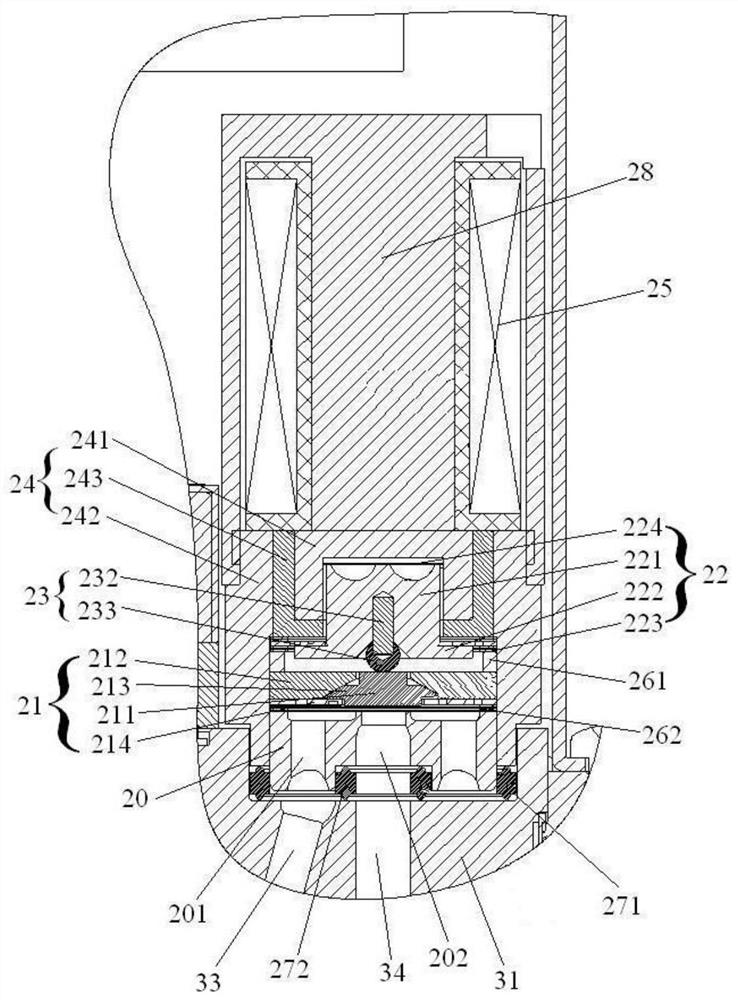

[0035] As shown in FIG. 2 and FIG. 10, the present embodiment provides a solenoid valve 2, including: a solenoid 25, a valve body assembly 24, a valve core

[0036] The solenoid valve 2 provided in this embodiment, because the valve core assembly 22 is in point contact with the plug 211, therefore, in the magnetic seat

[0037] Specifically, as shown in FIG. 2 , the valve core assembly 22, the plug assembly 21, and the valve port component 20 are sequentially stacked on the valve body assembly 24.

[0038] However, in practical applications, the valve core assembly 22, the plug assembly 21, and the valve port component 20 are sequentially stacked on the valve body assembly.

[0041] Optionally, the electromagnetic member 25 can use an electromagnetic coil.

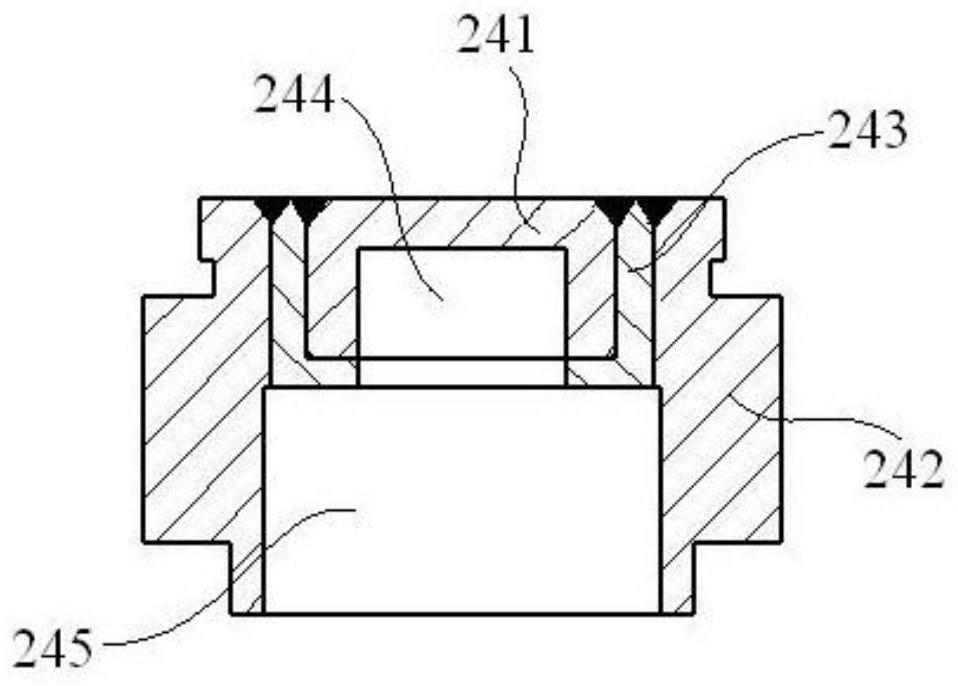

[0045] As shown in FIG. 2 and FIG. 3, in a preferred embodiment of the present invention, the valve body assembly 24 may include a valve body magnetic seat

[0047] Optionally, the valve body magnetic seat 241, the valve body 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com