Patents

Literature

65results about How to "Realize the blocking function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

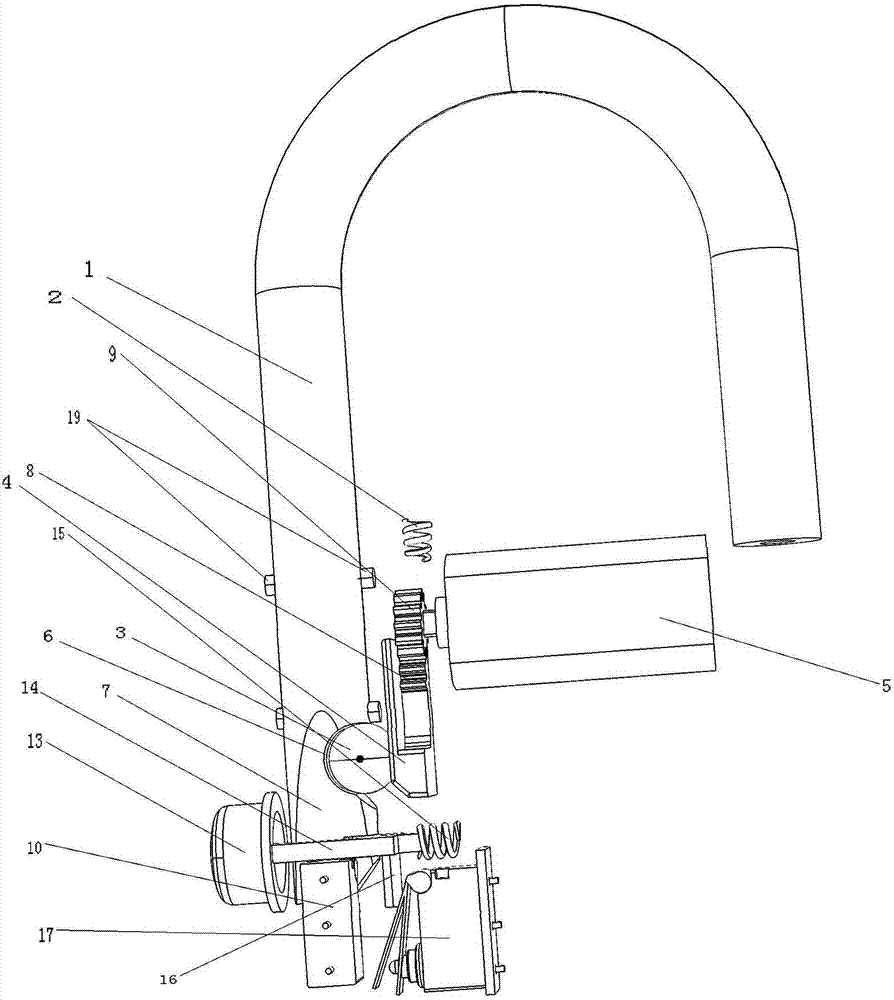

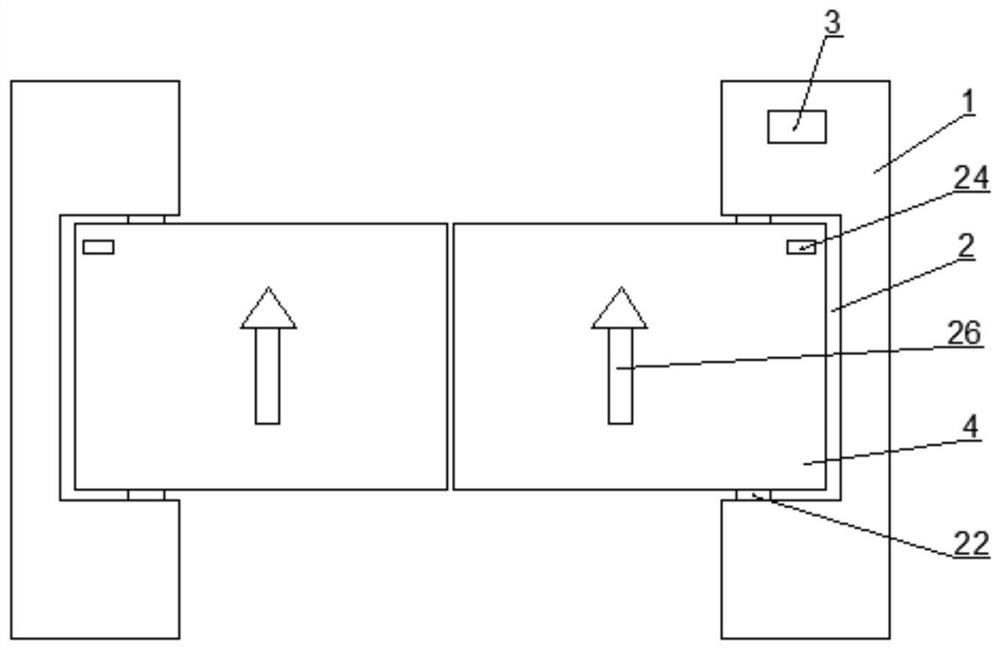

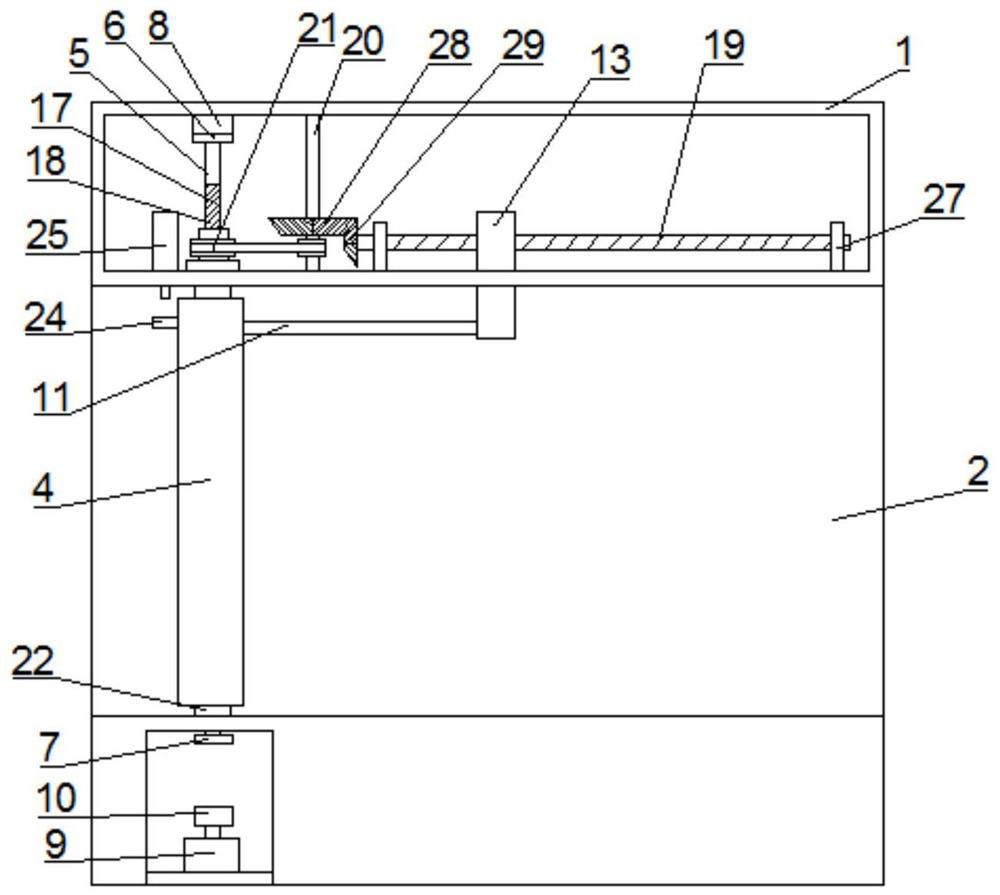

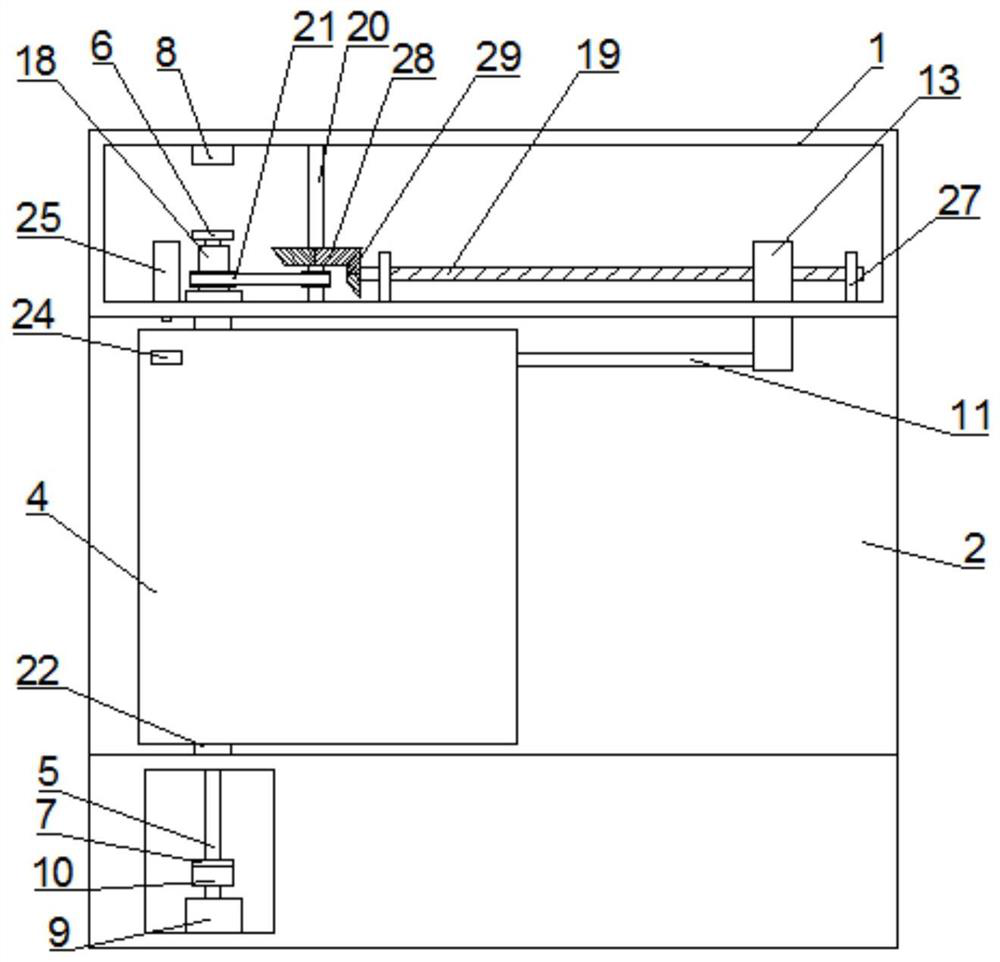

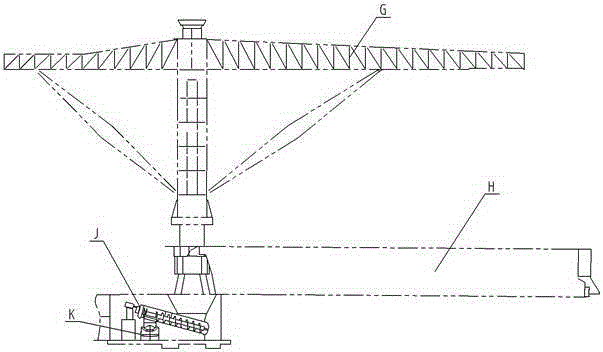

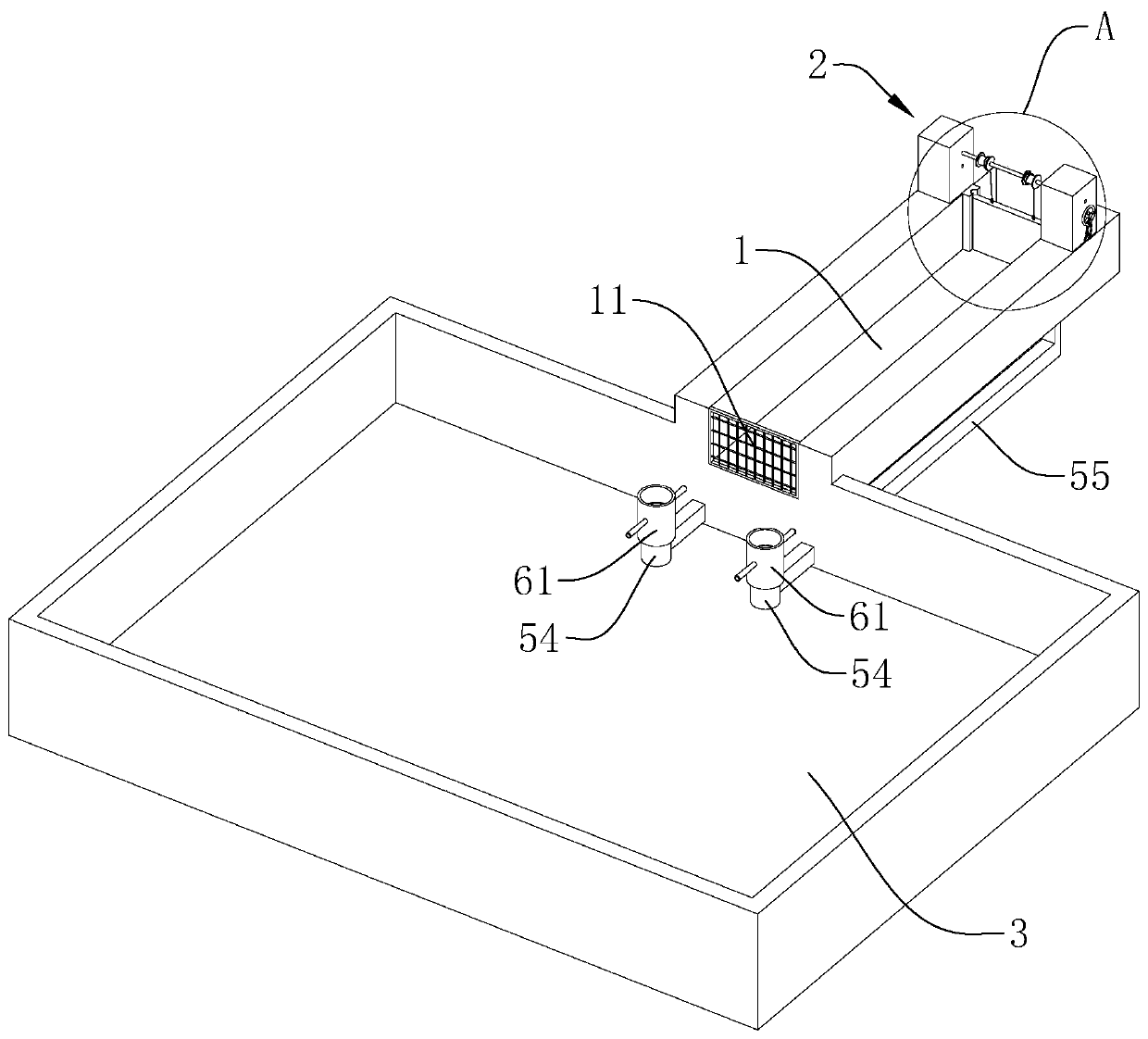

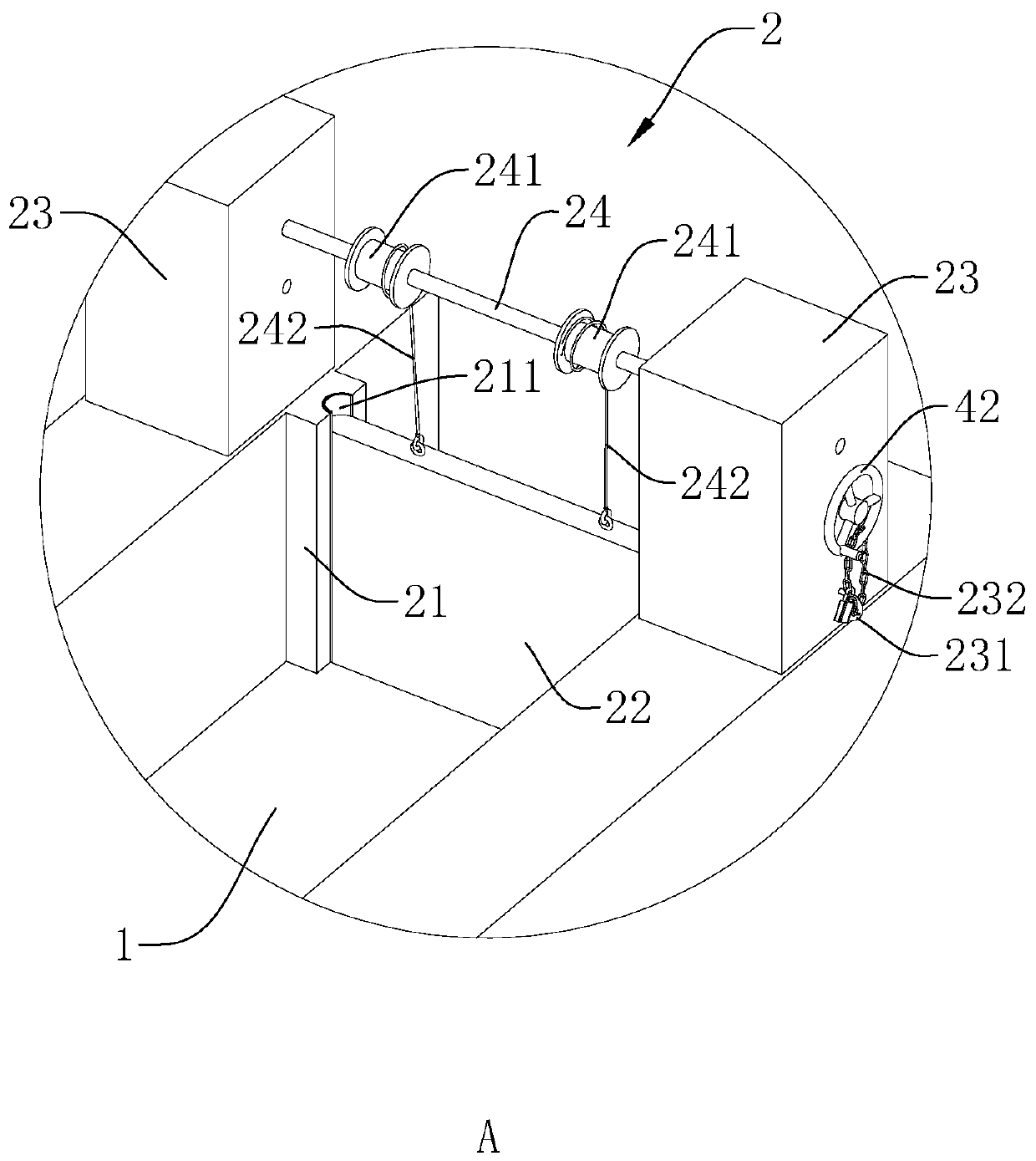

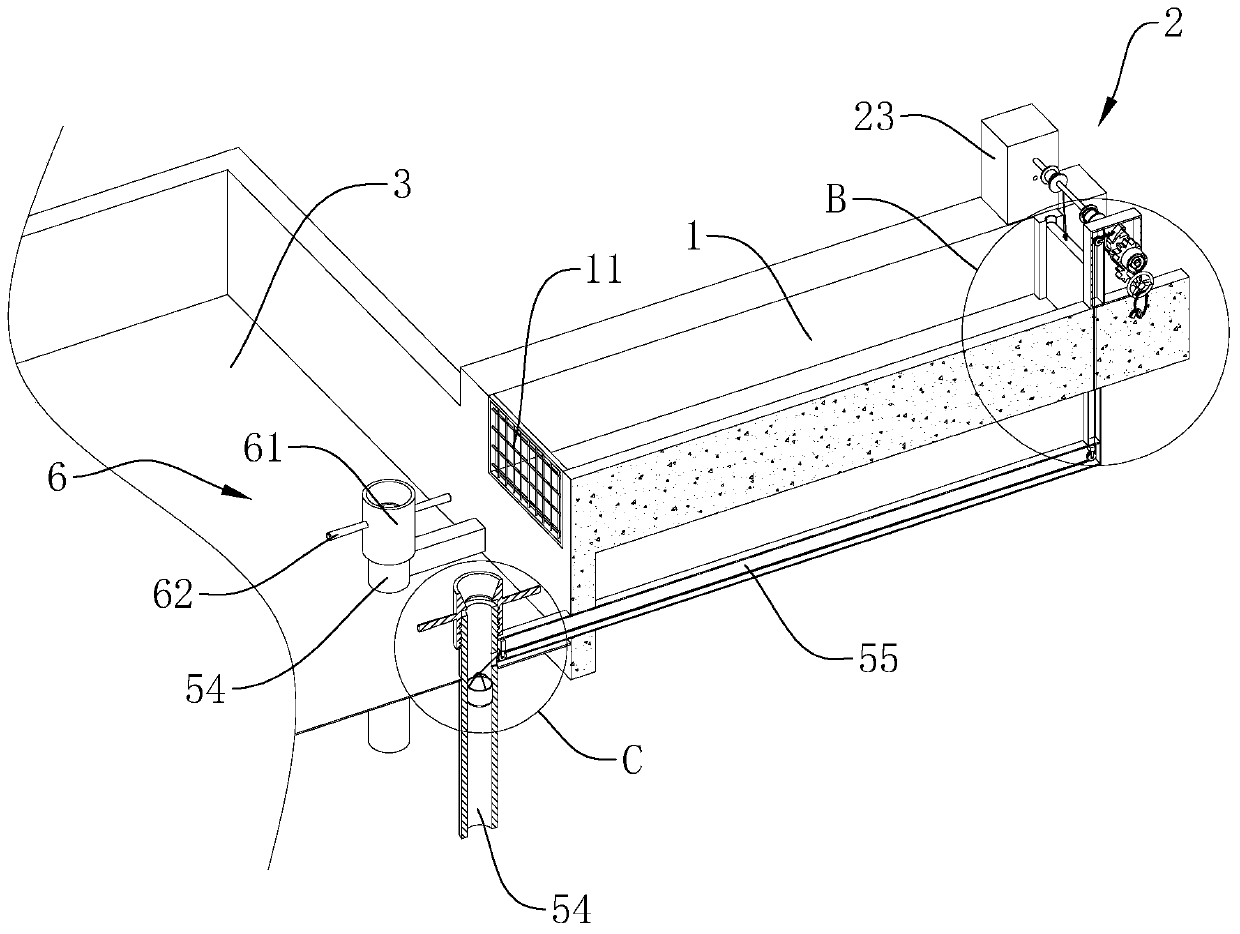

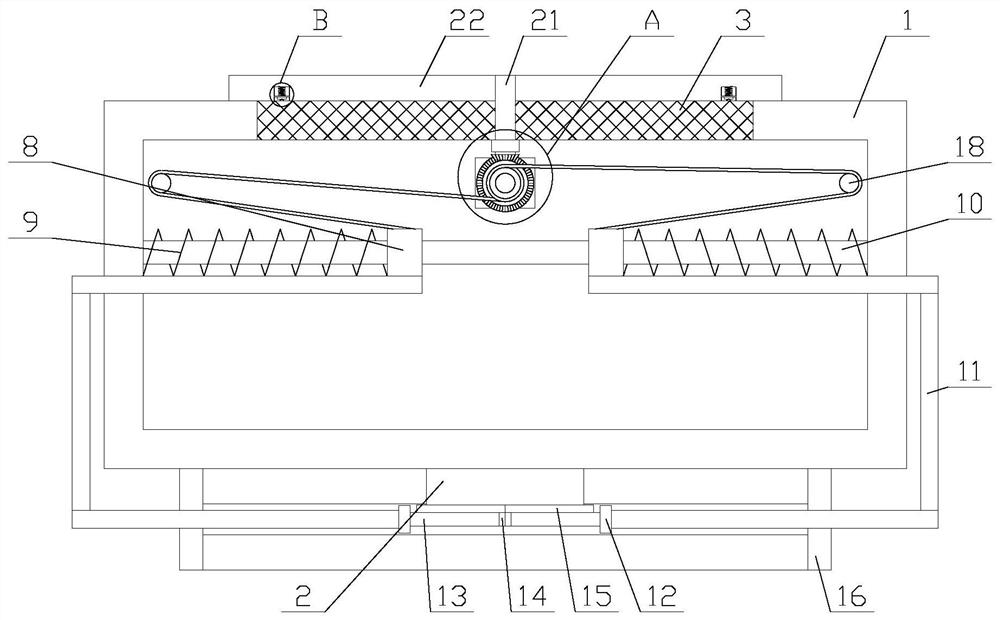

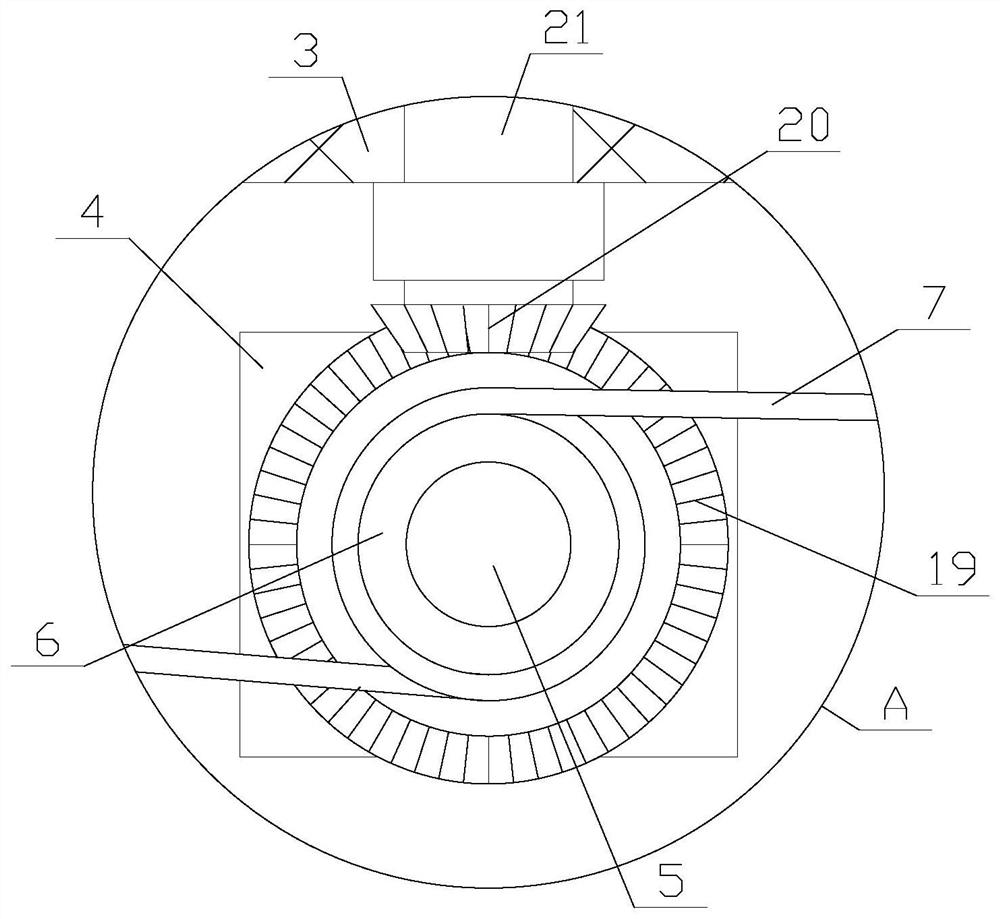

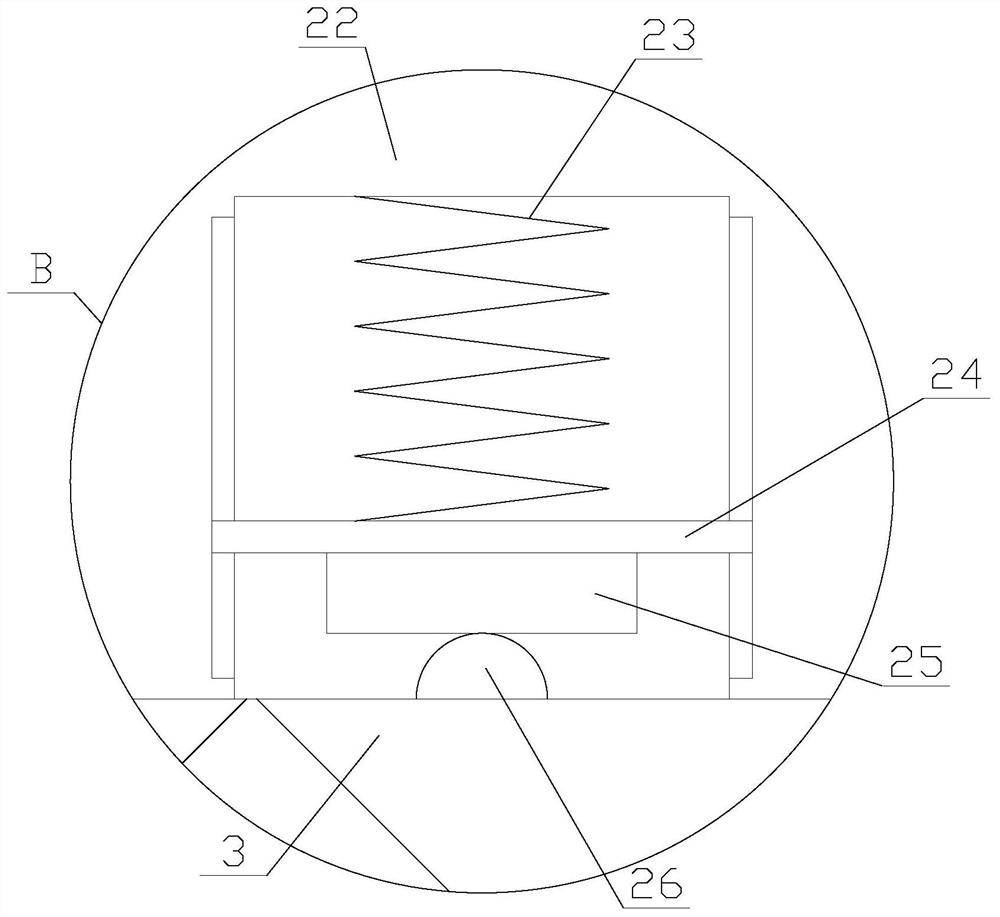

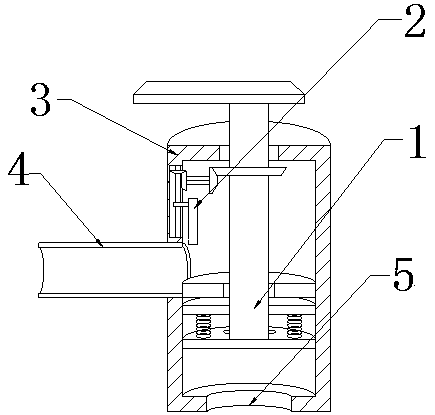

Maneuvering type unmanned aerial vehicle recovery device

ActiveCN107416224ARealize the blocking functionIncrease fuel capacityArresting gearVehicle carriersEngineeringKinetic energy

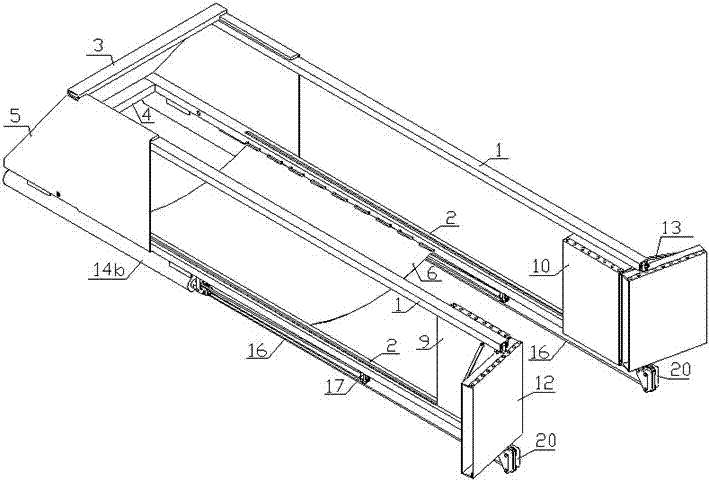

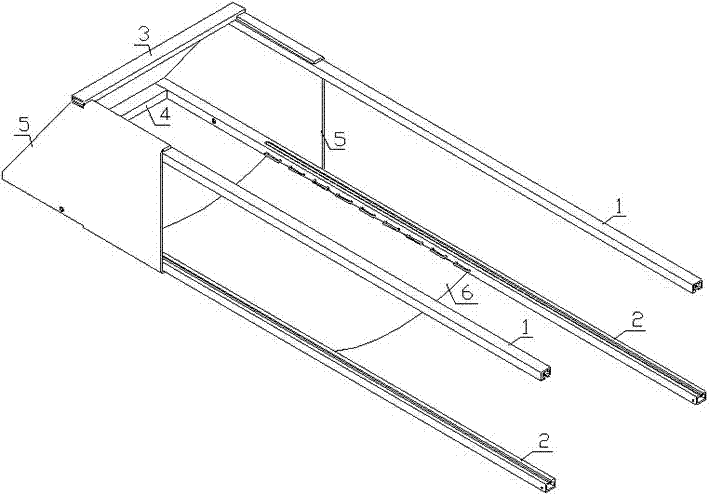

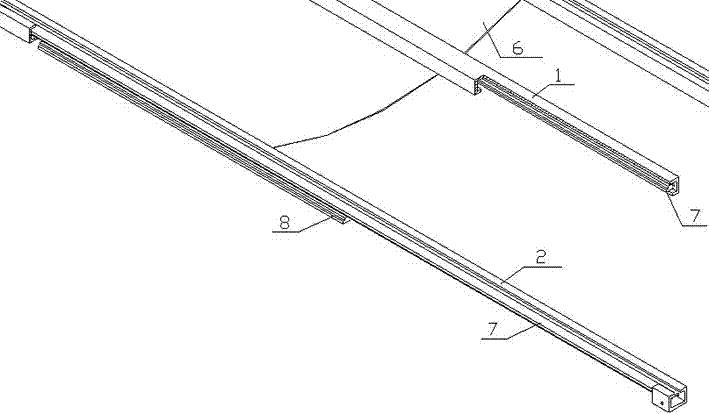

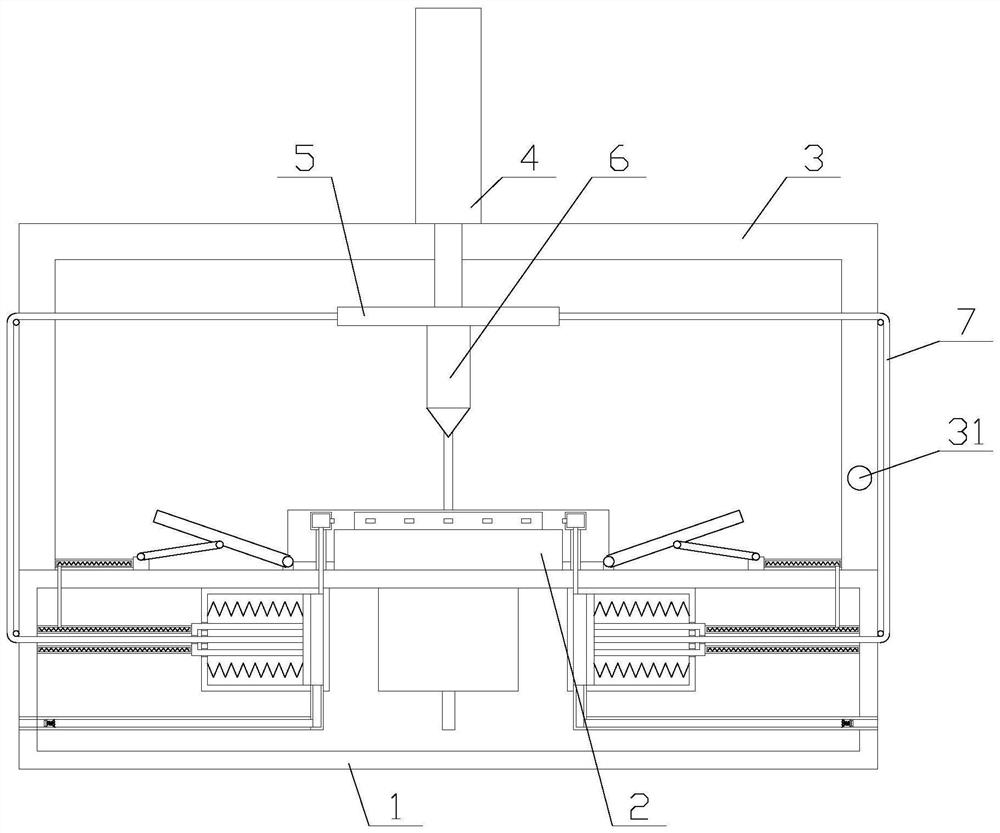

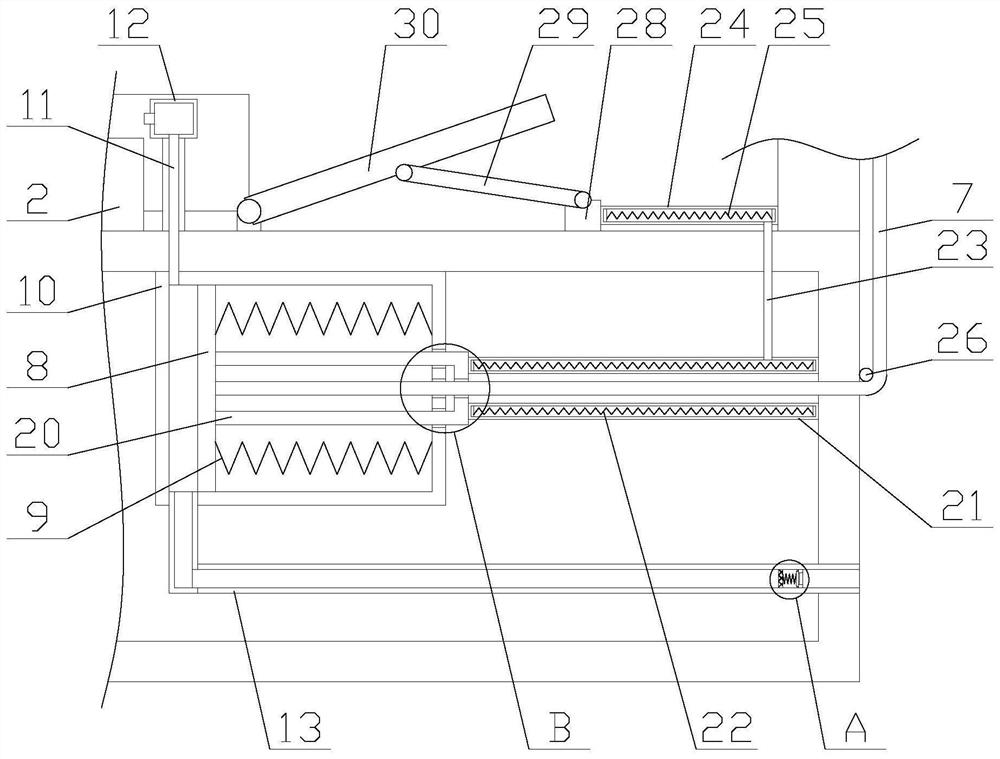

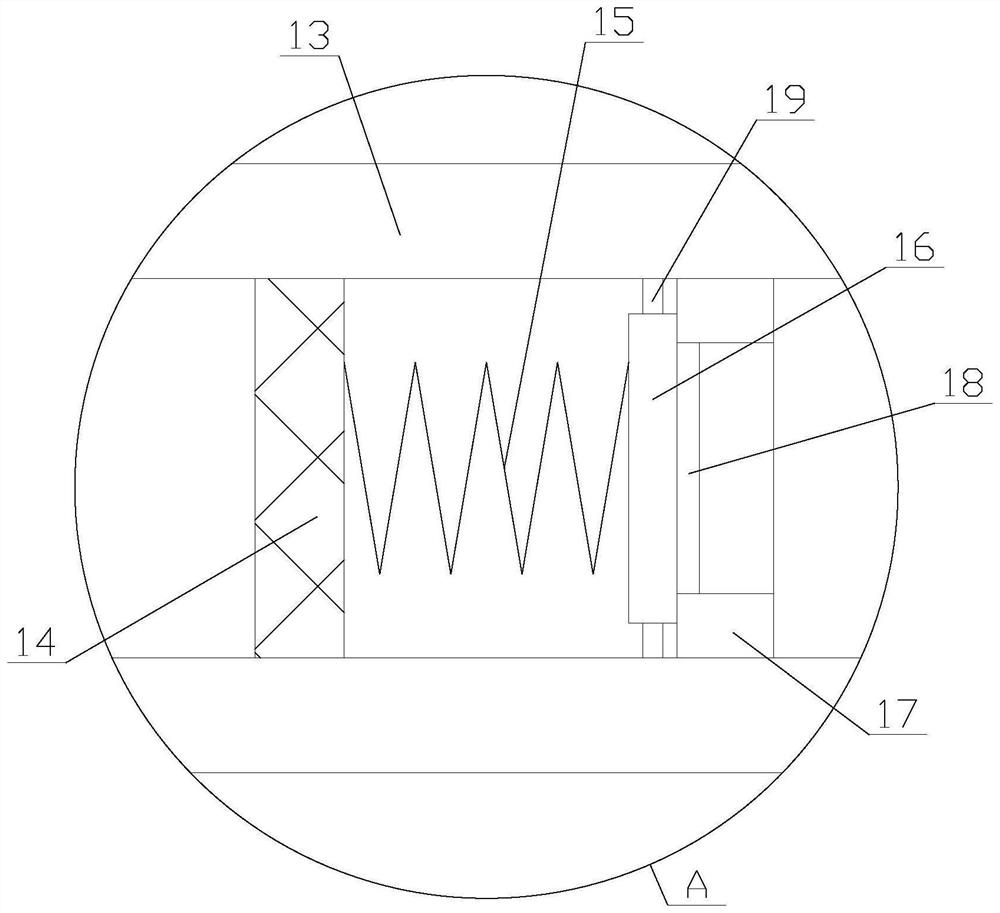

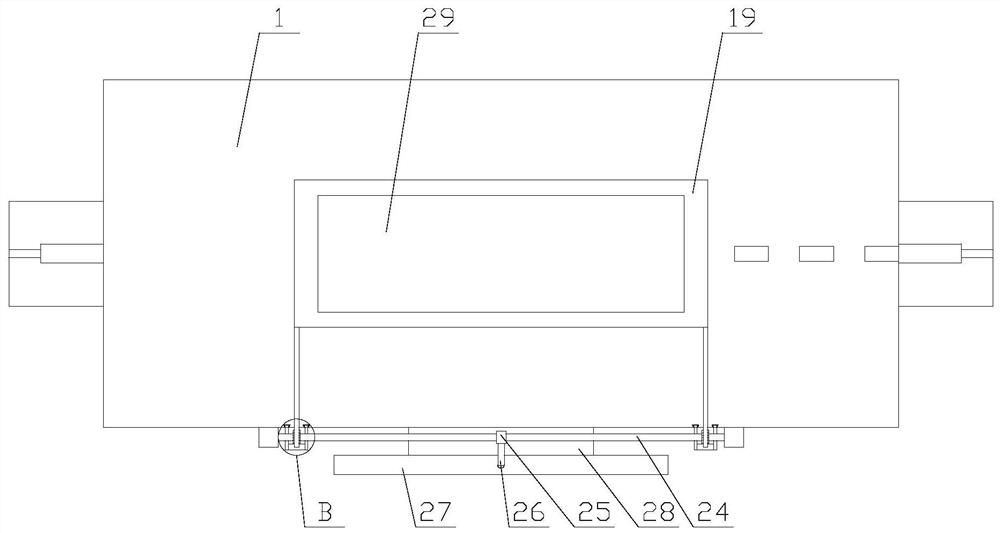

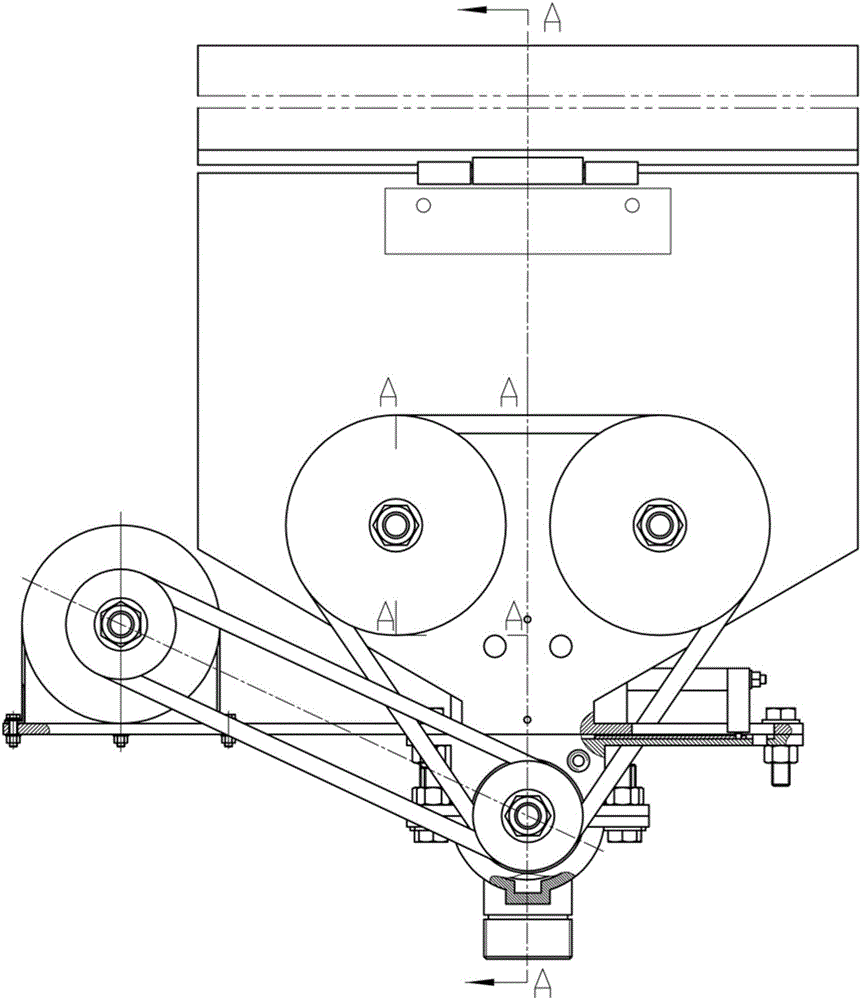

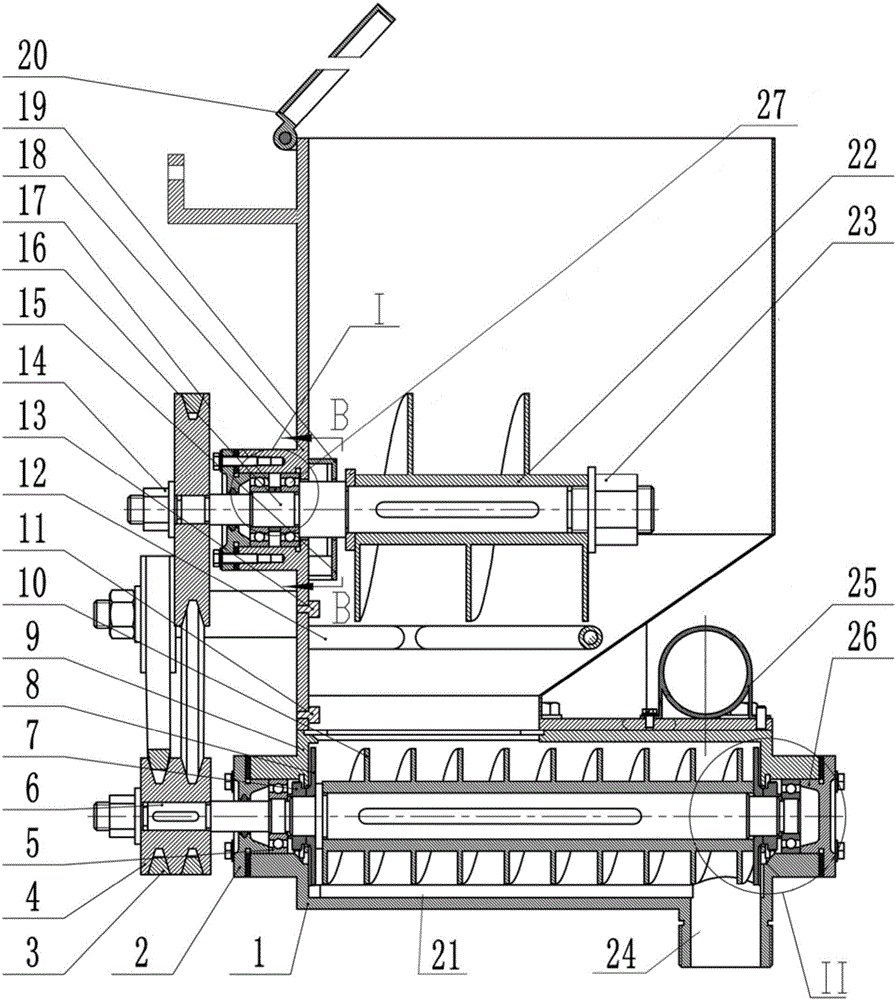

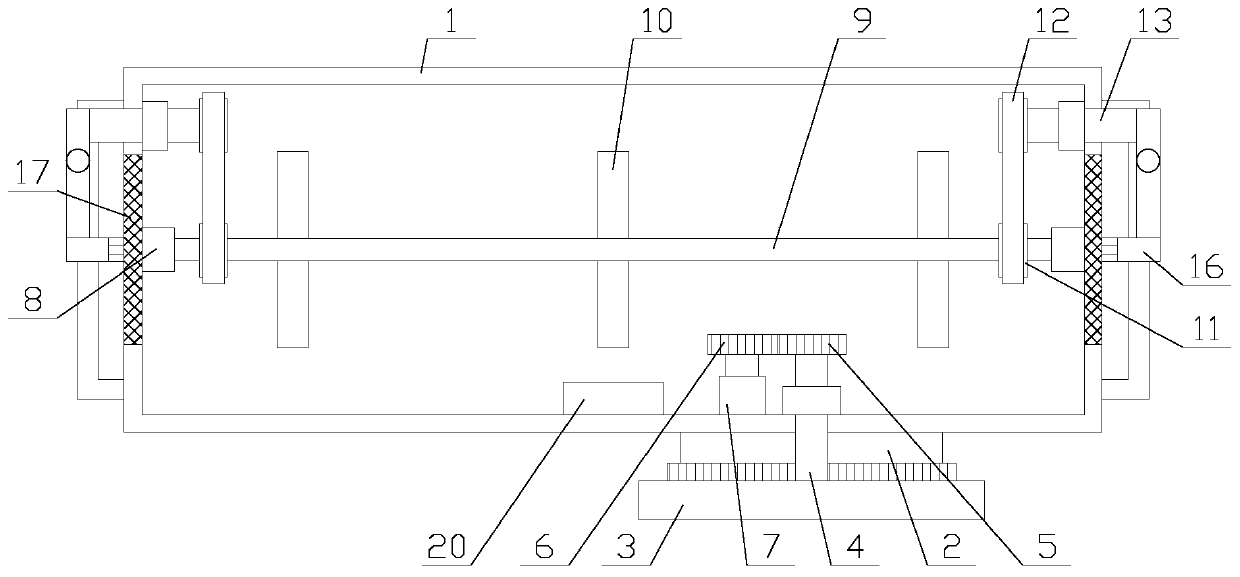

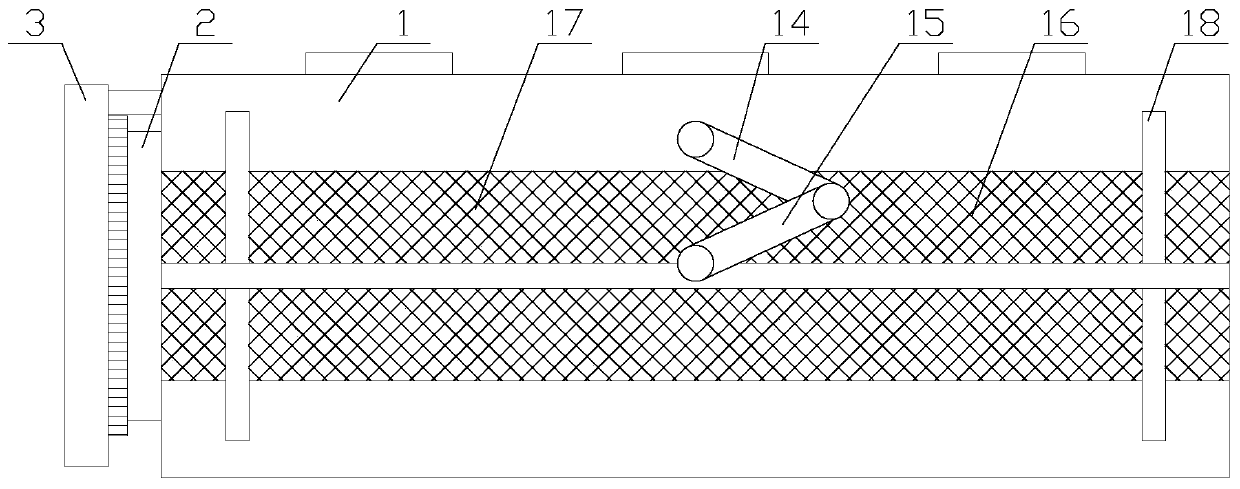

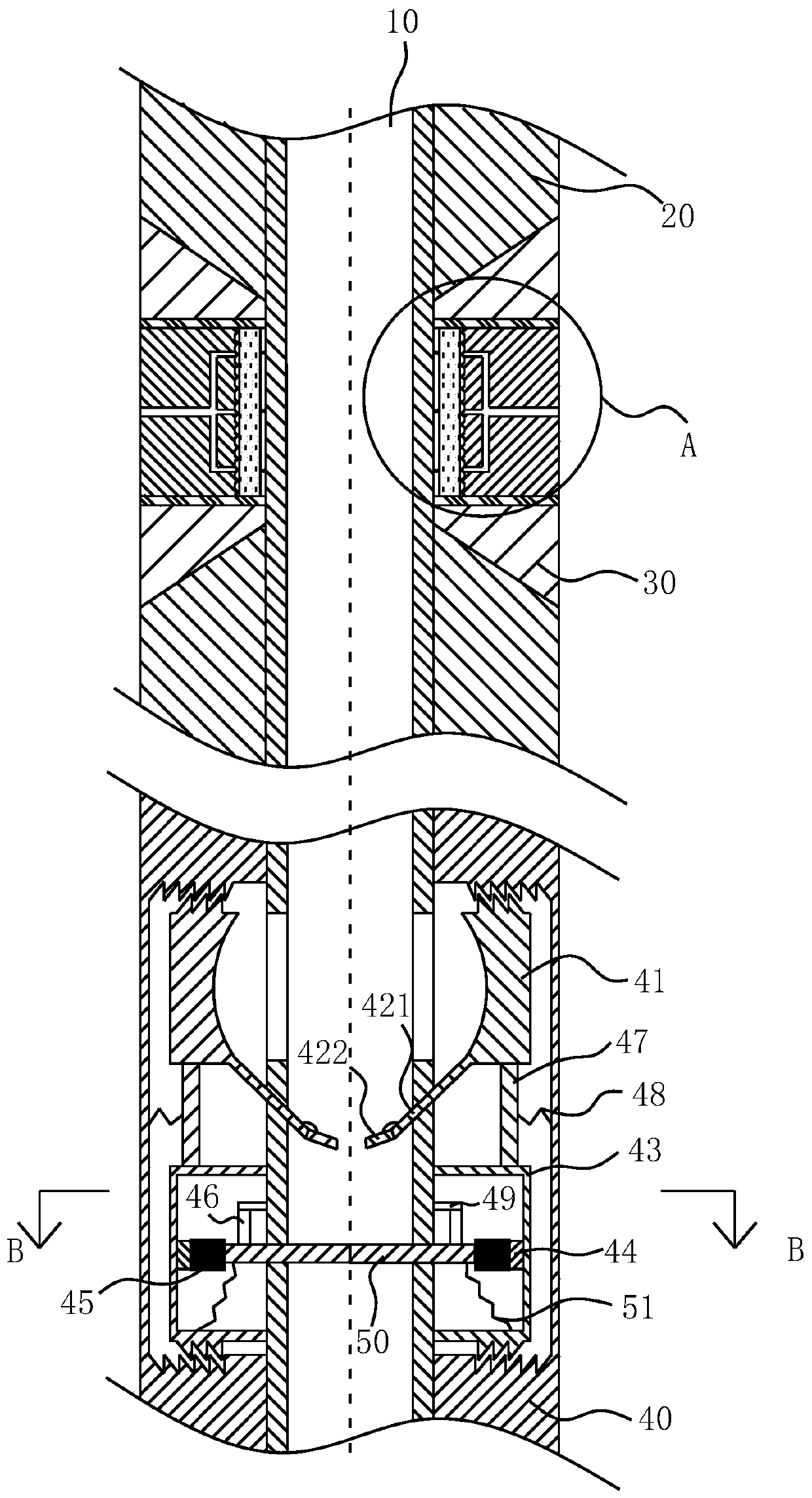

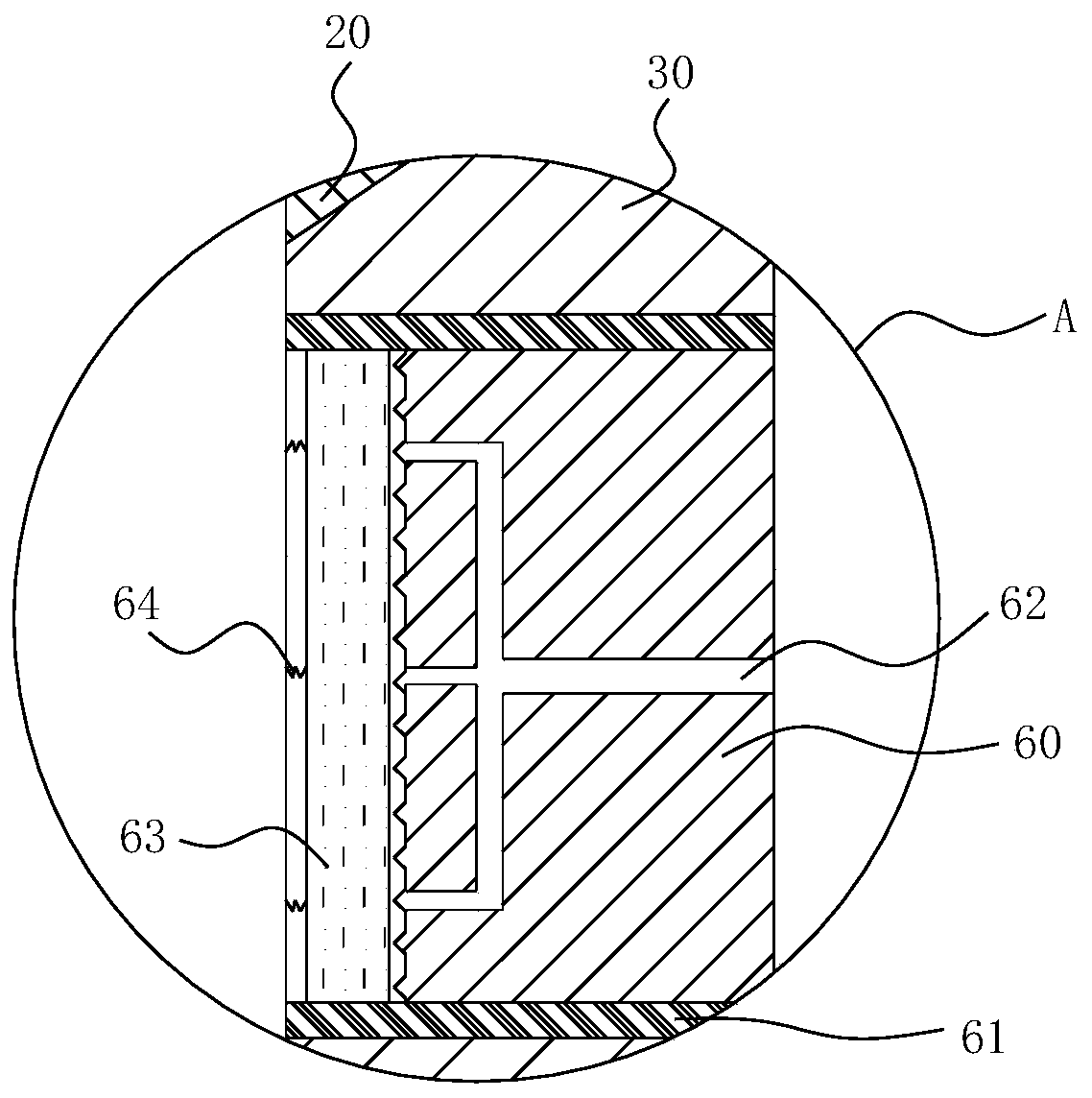

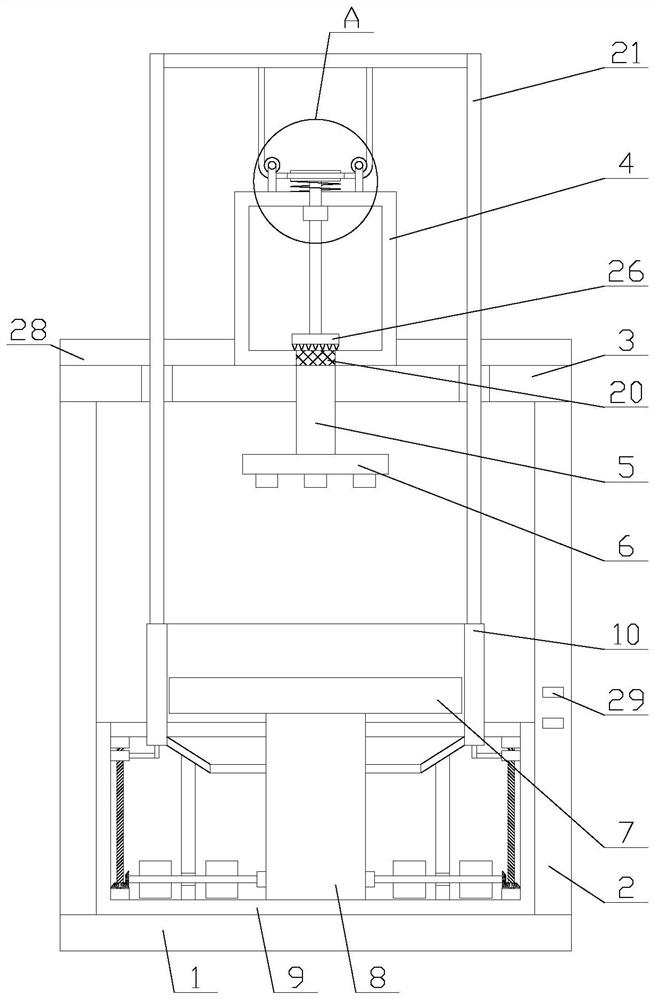

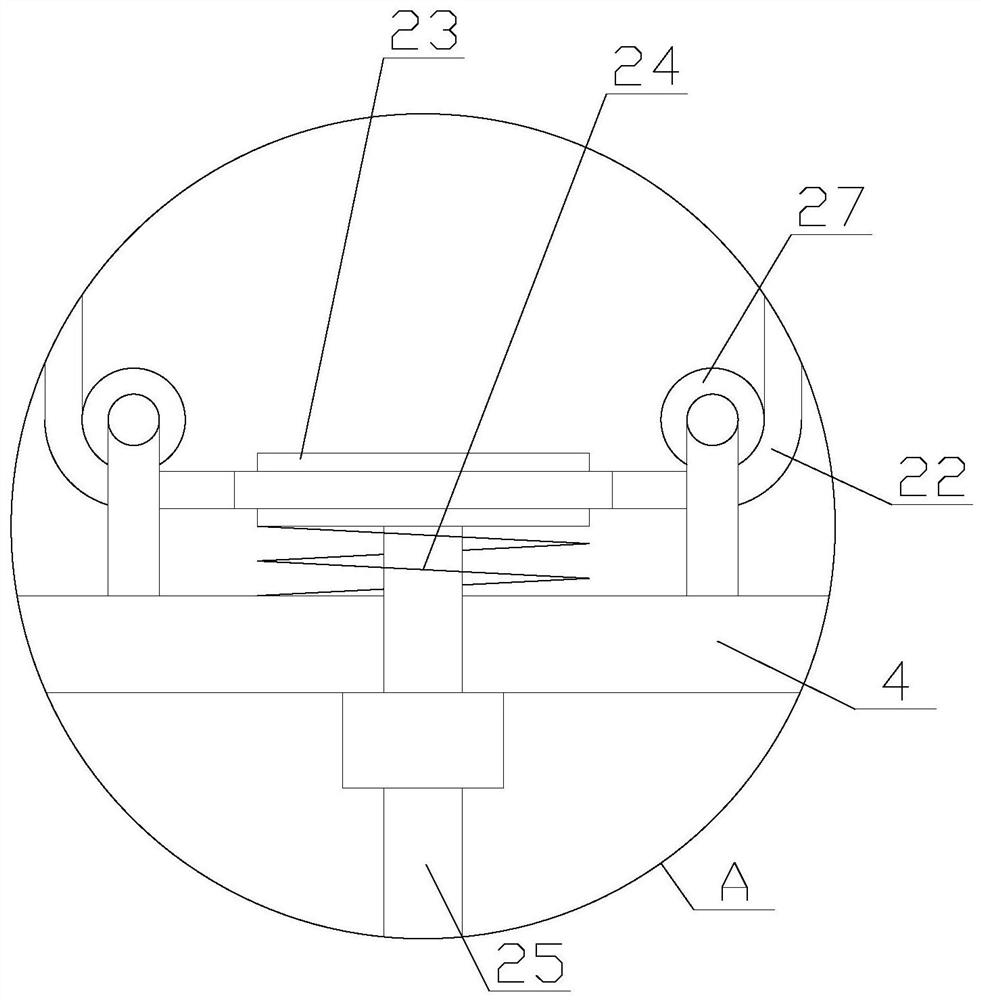

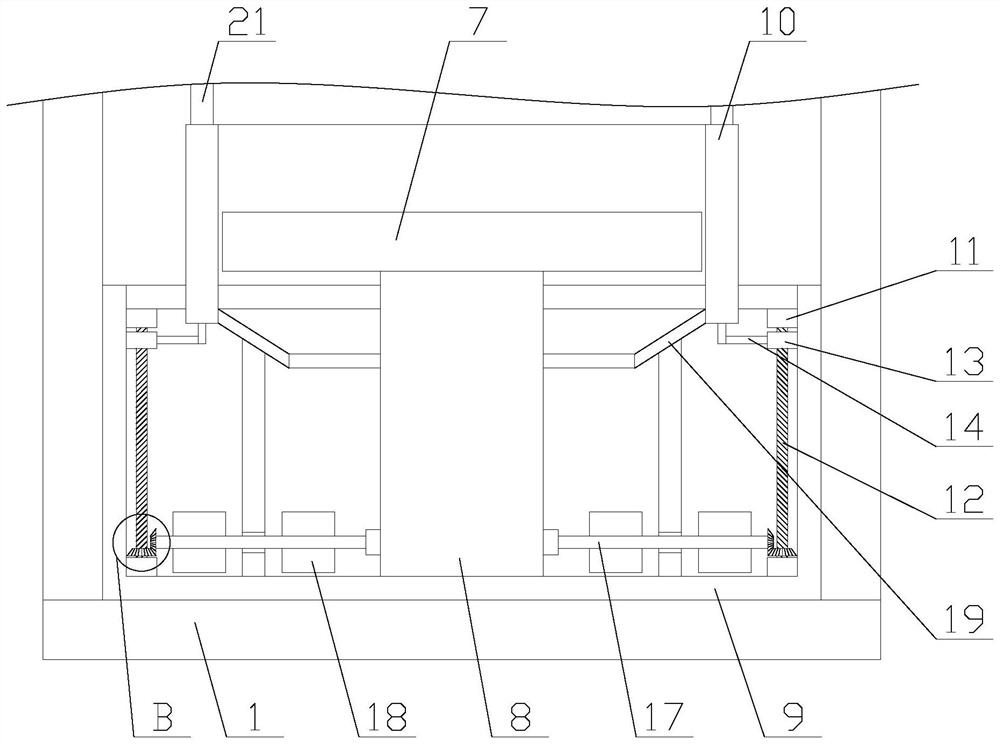

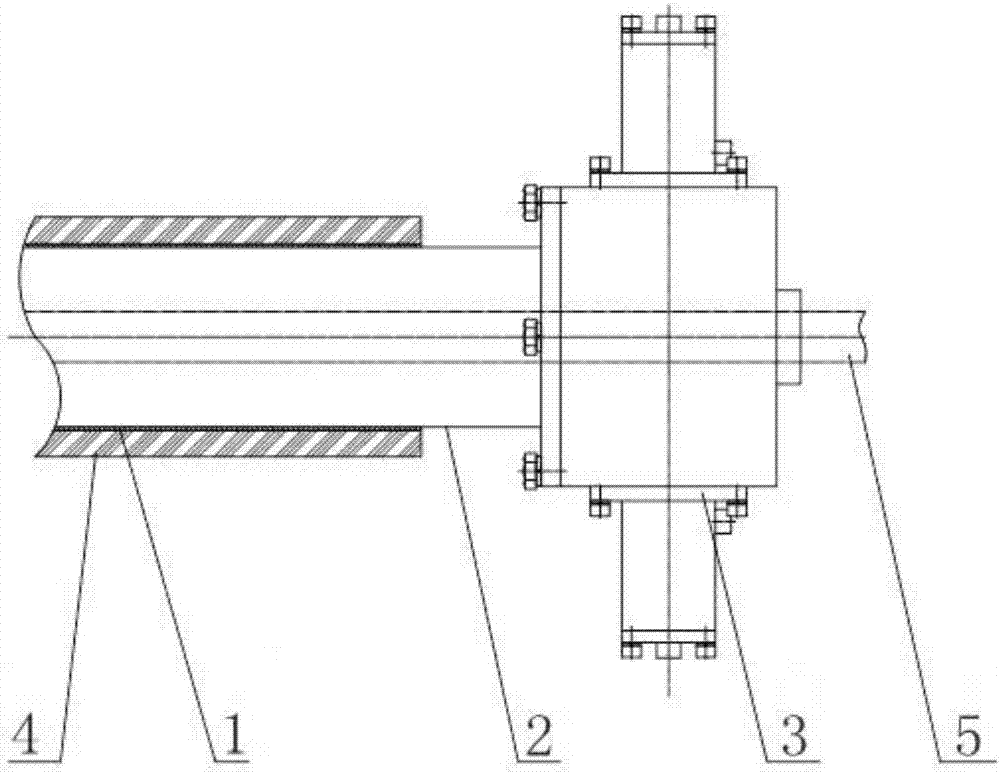

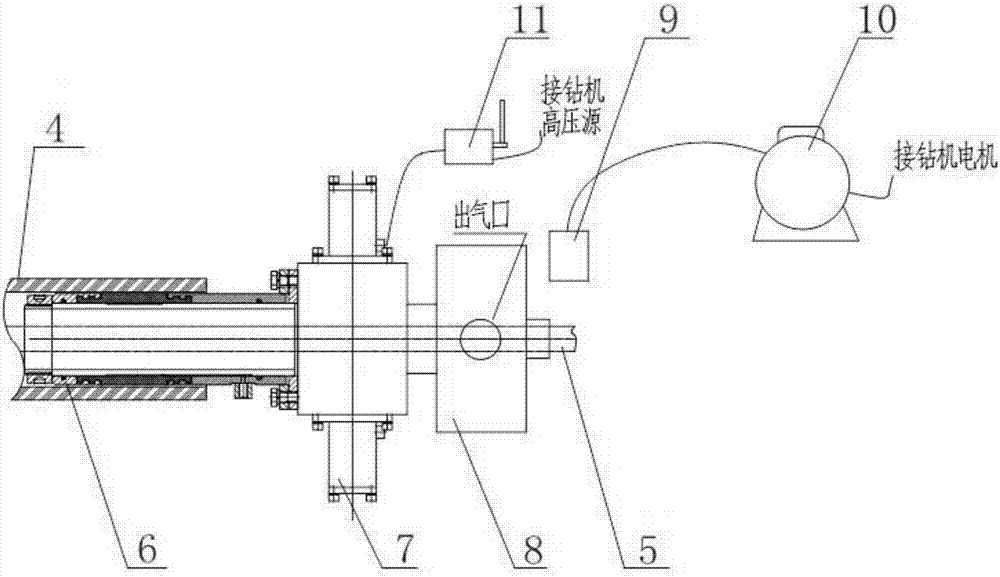

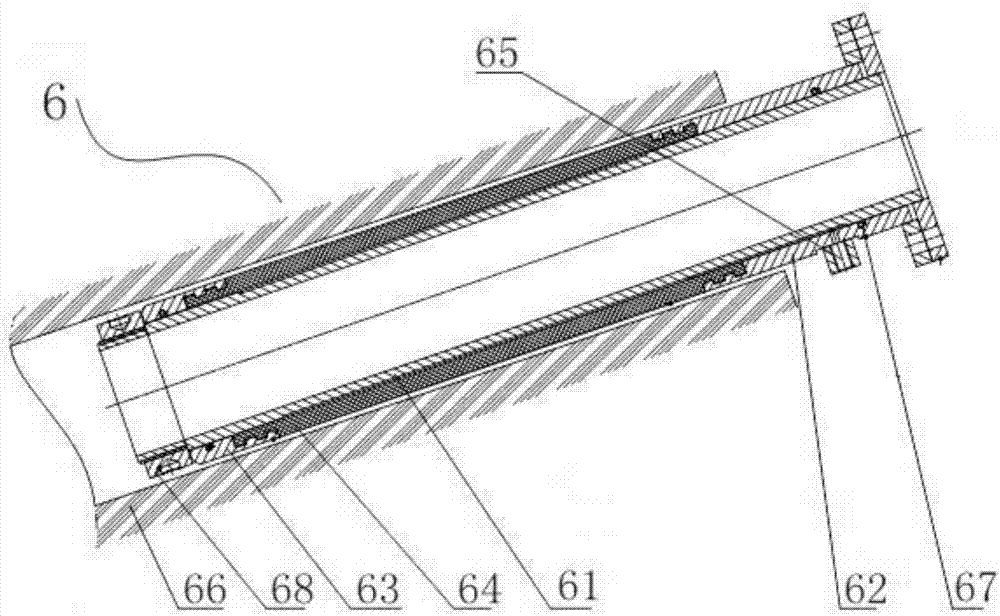

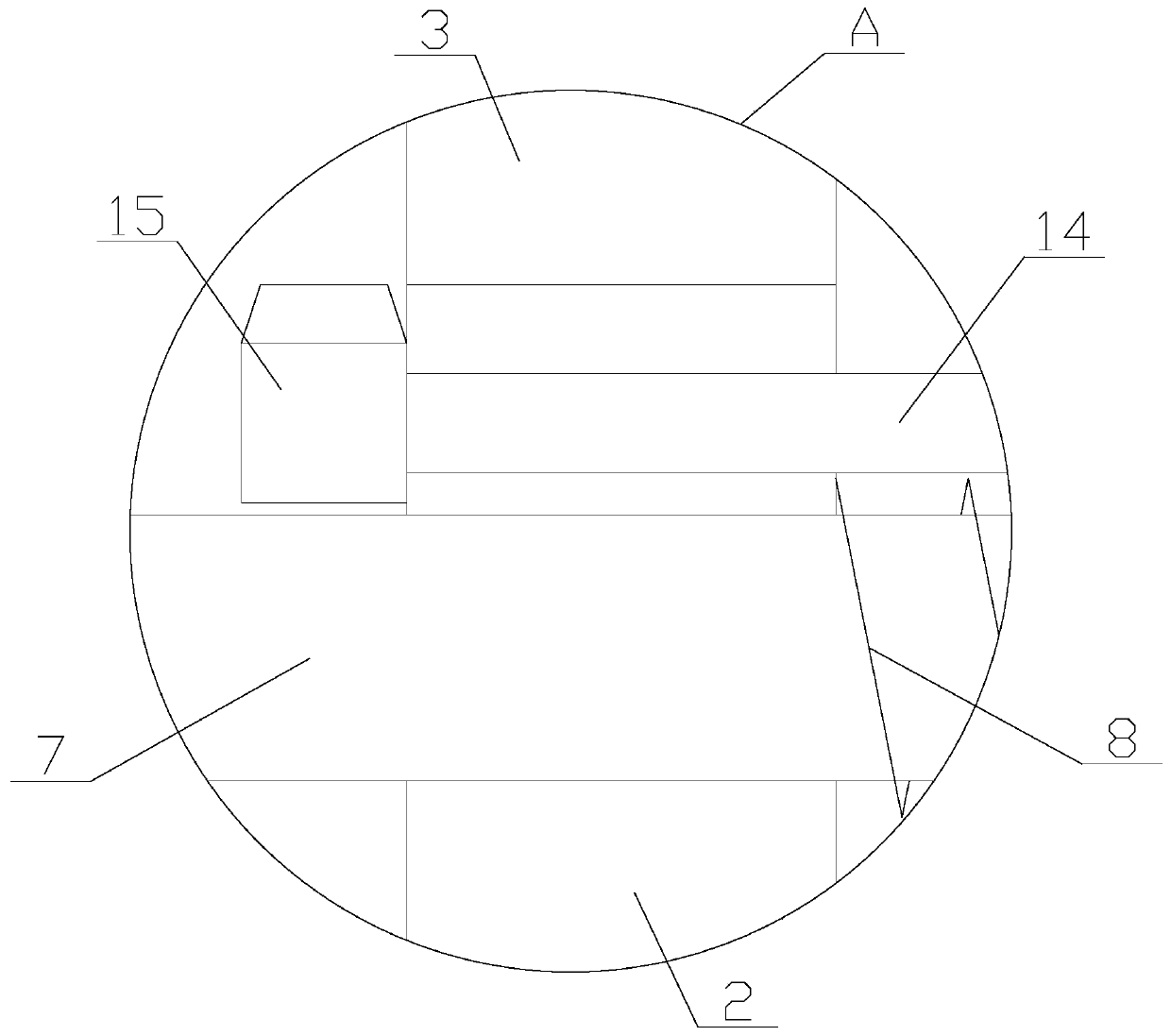

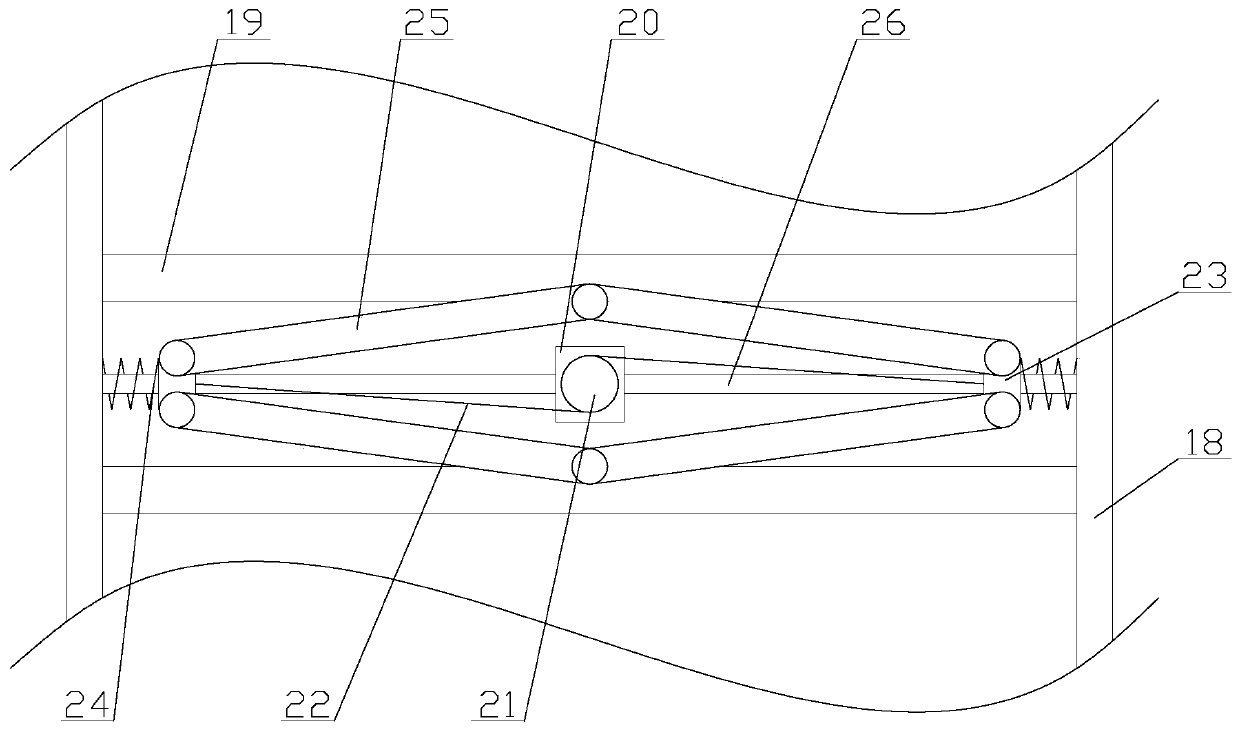

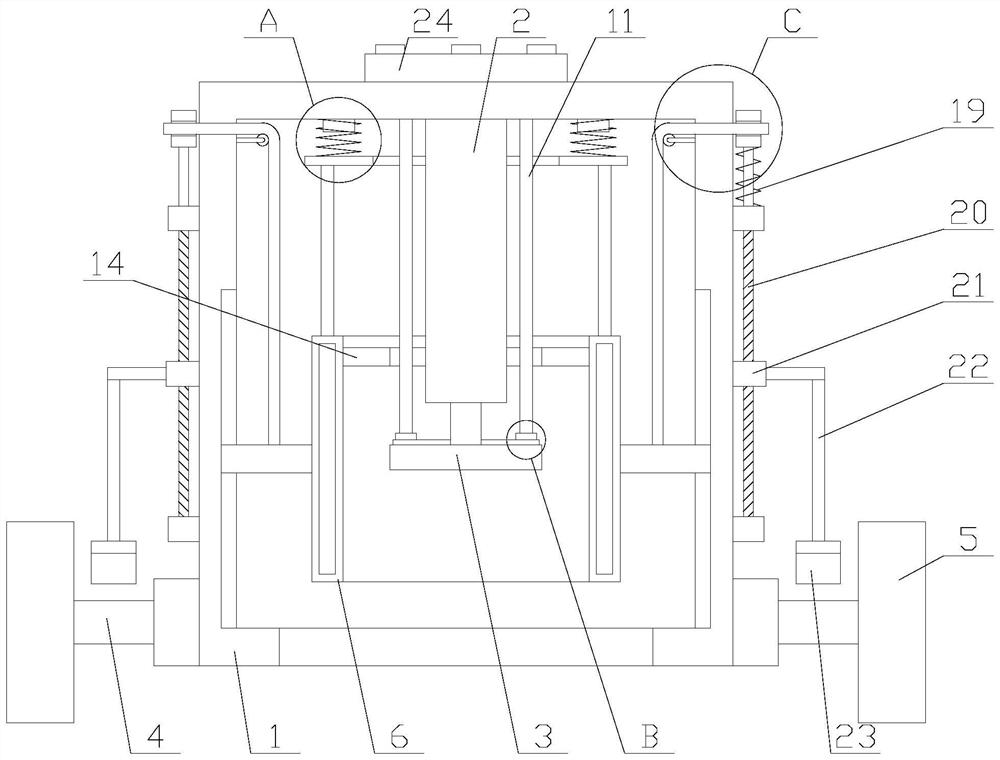

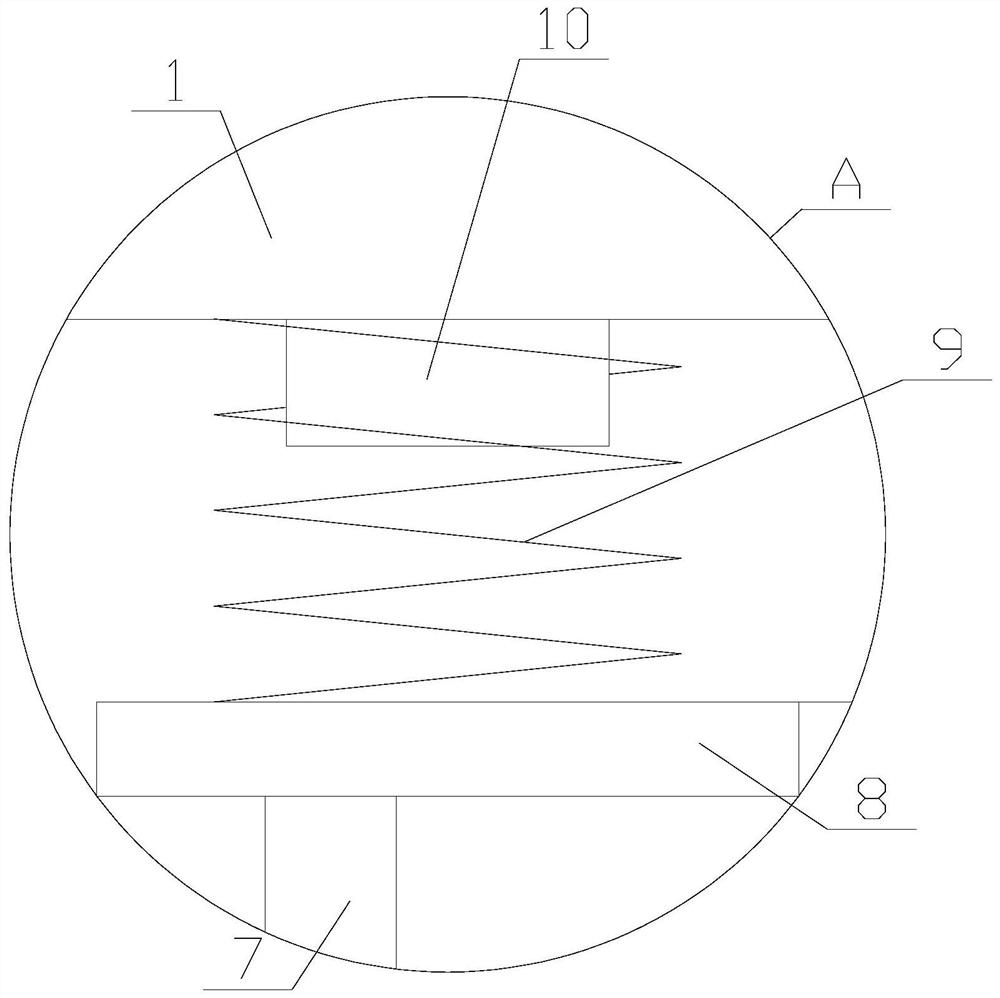

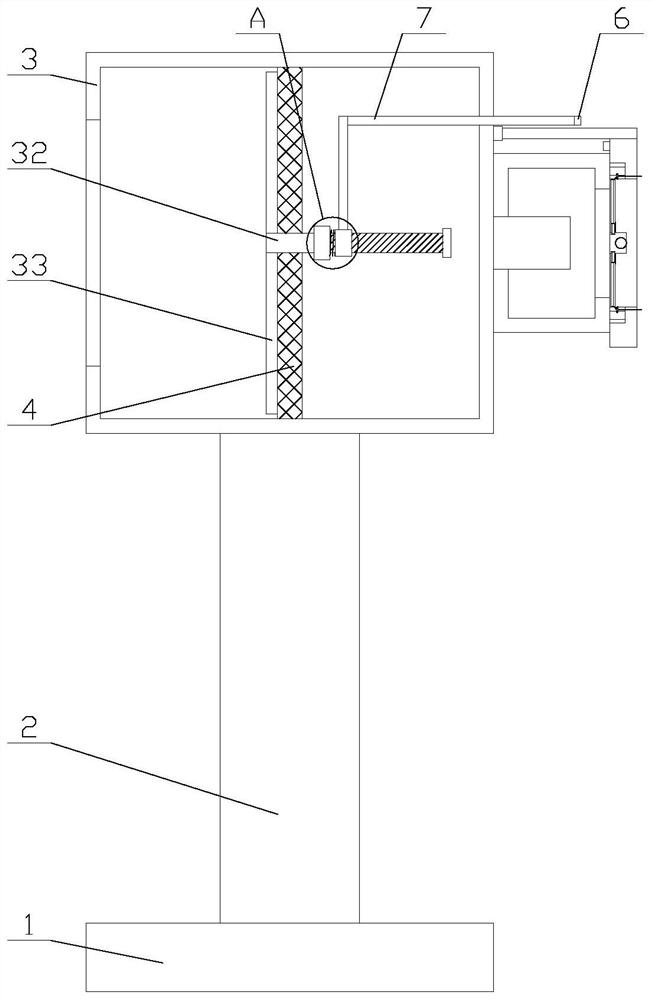

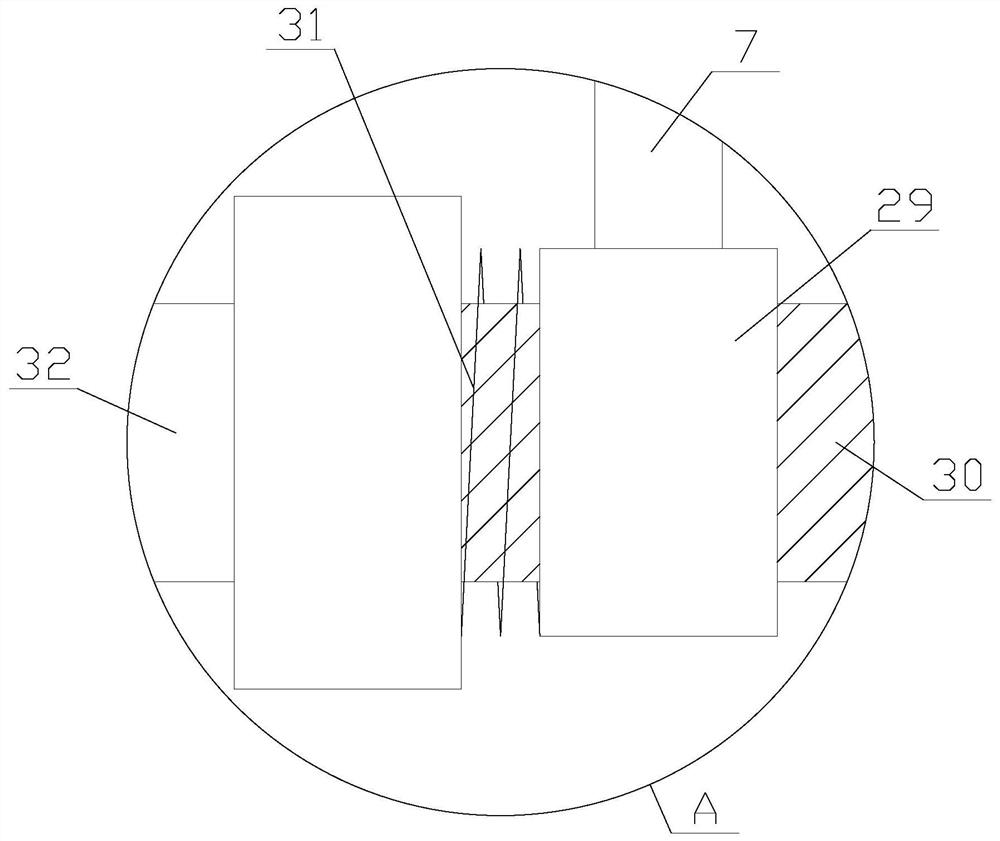

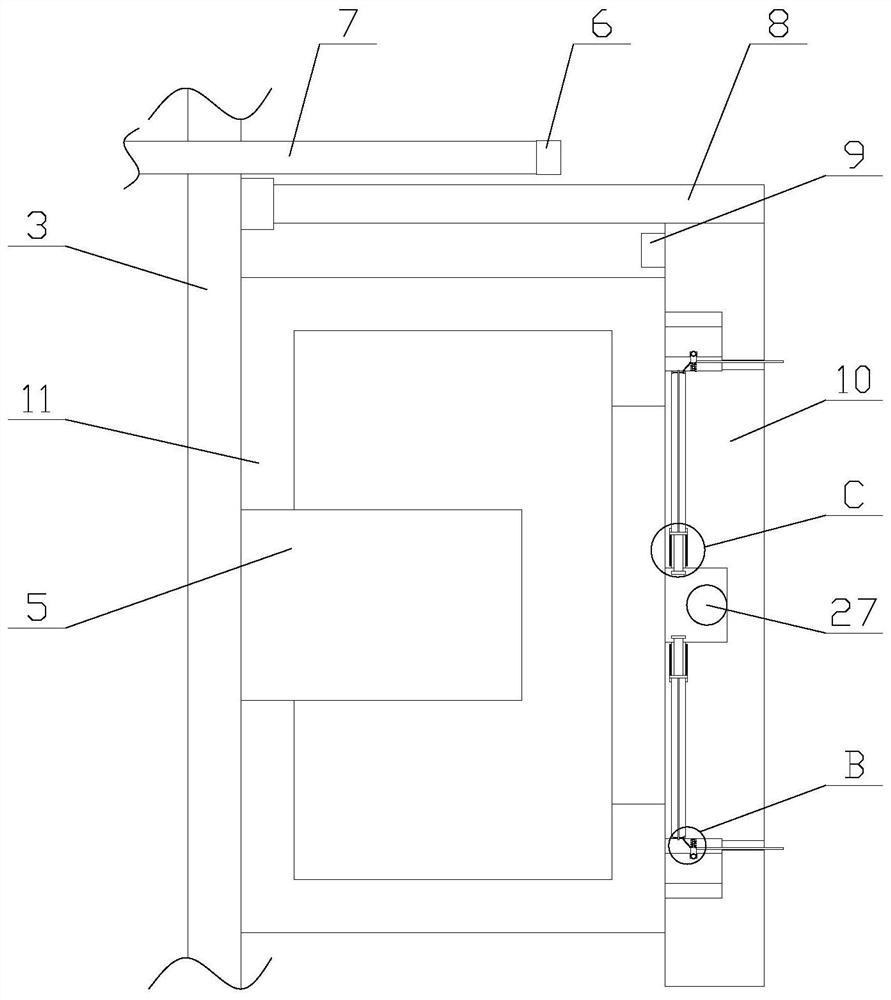

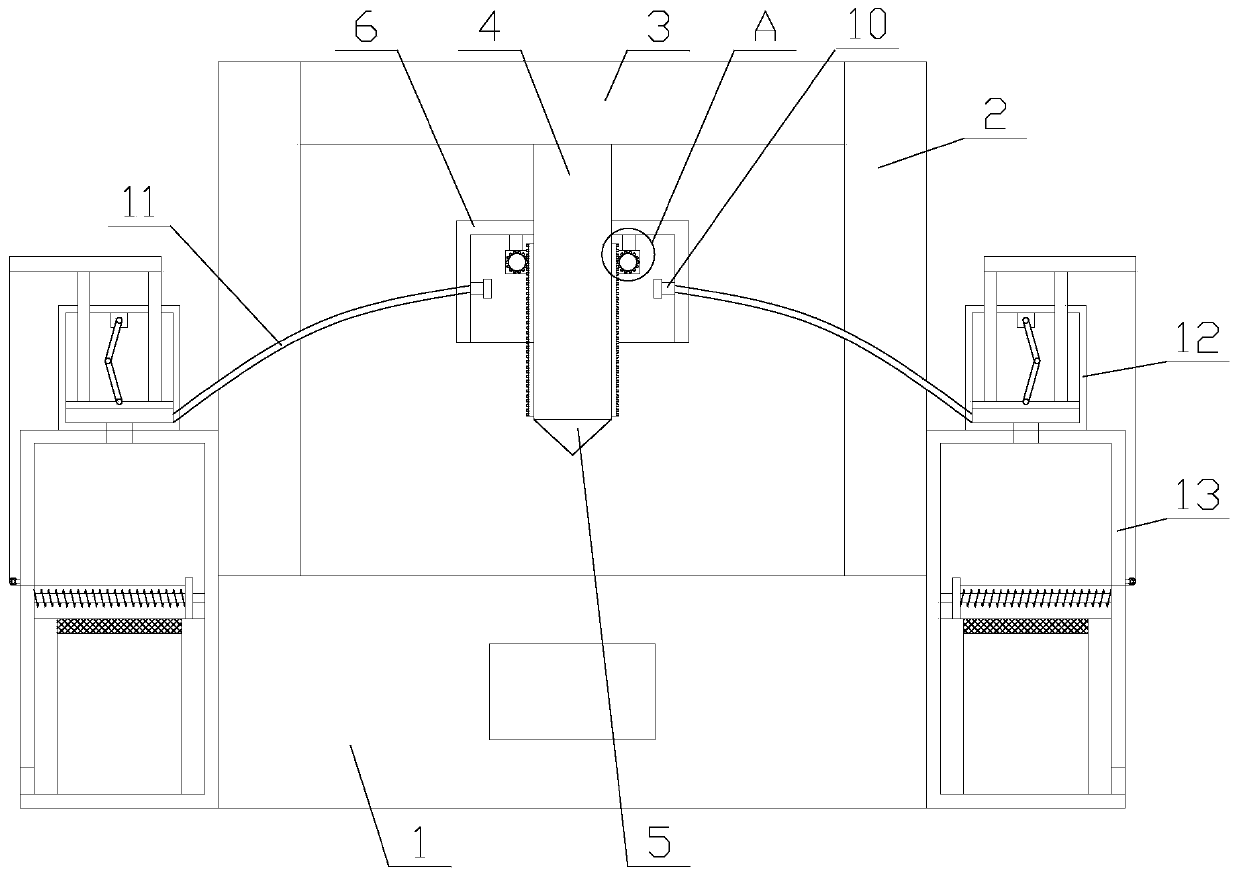

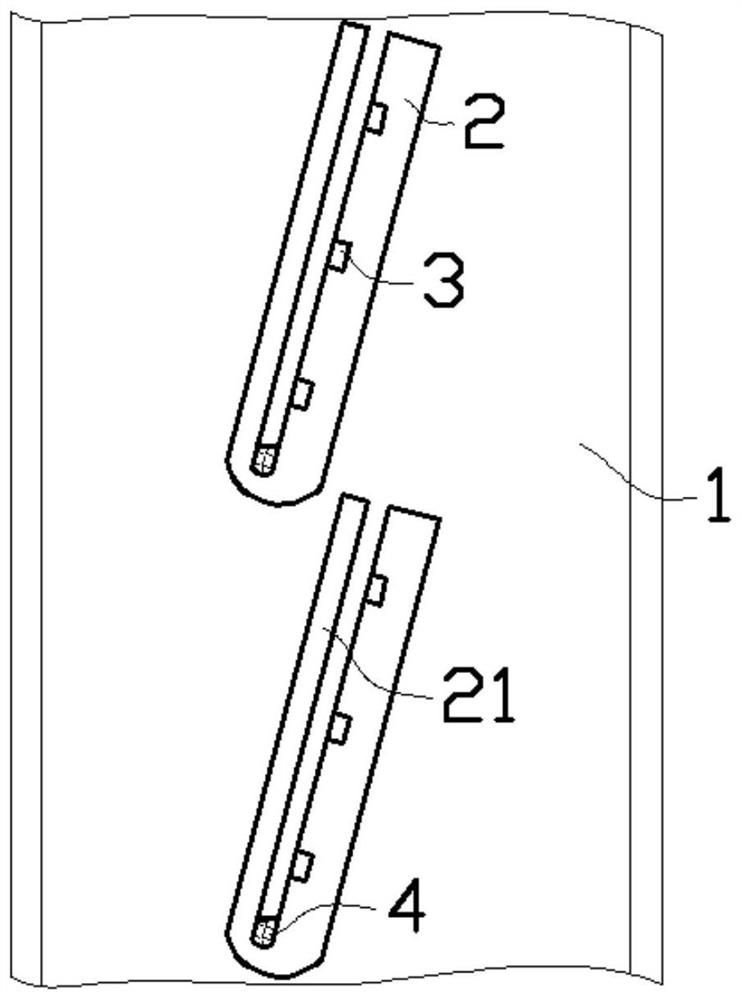

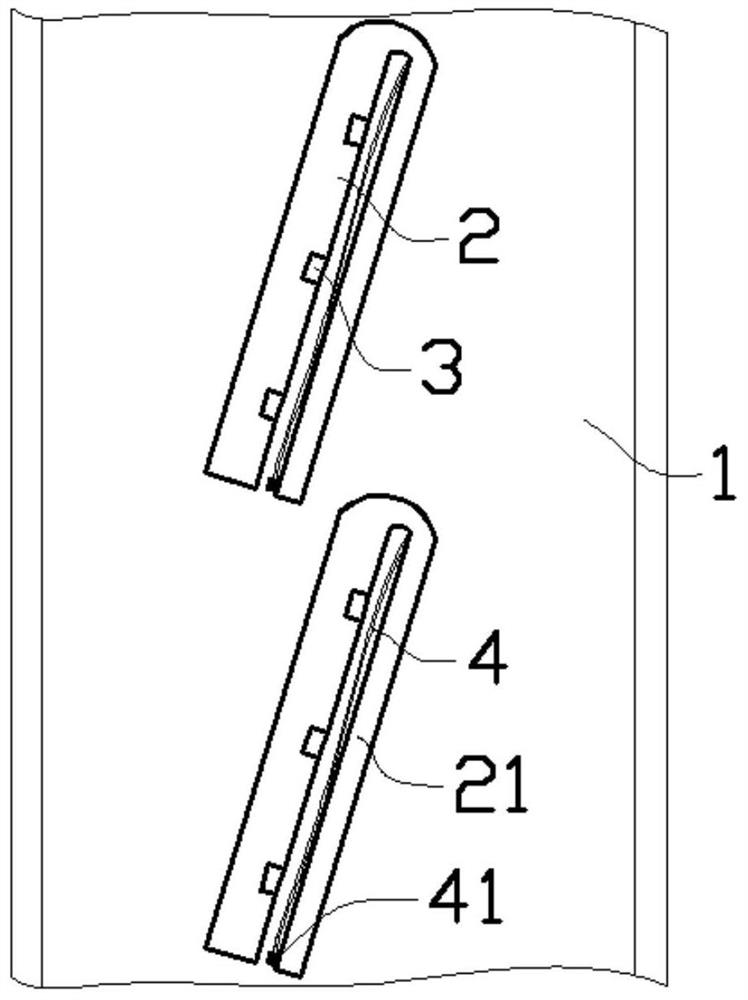

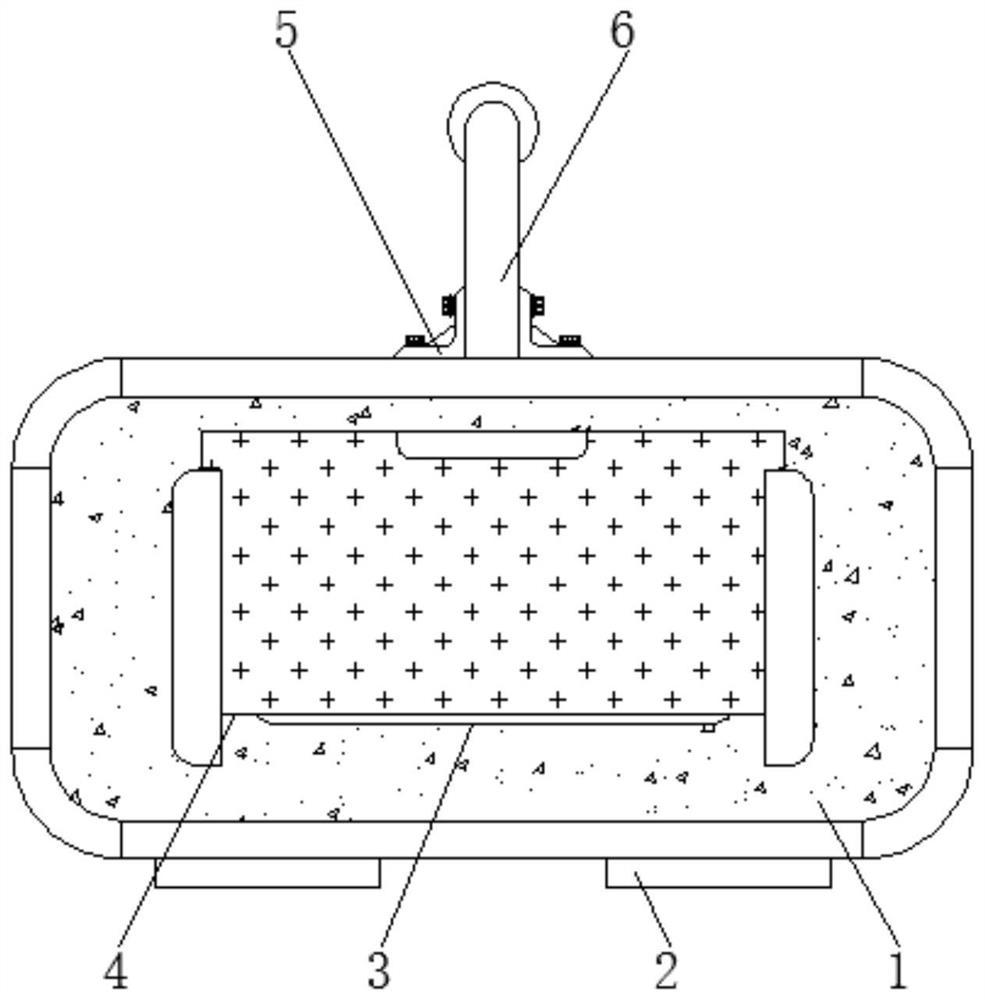

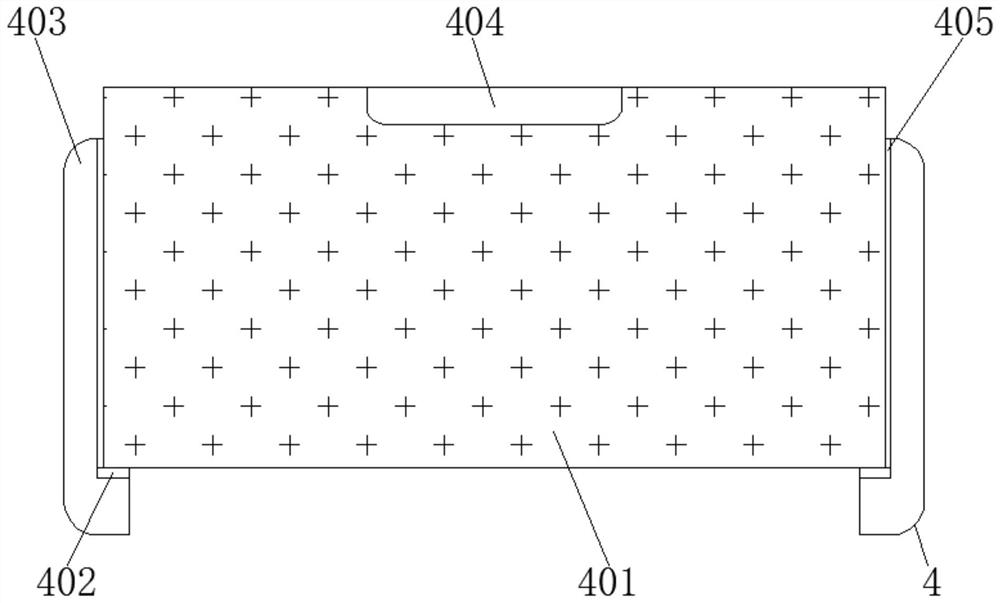

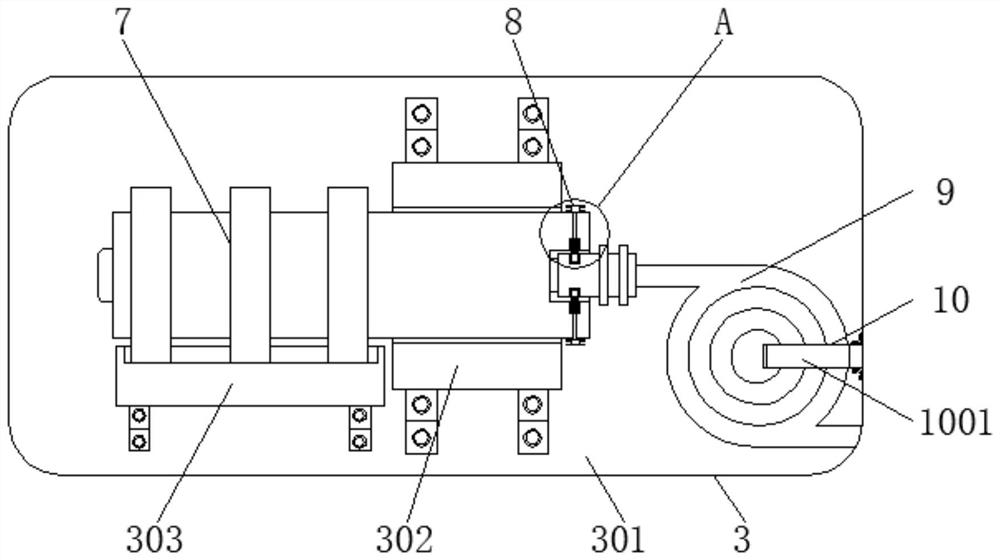

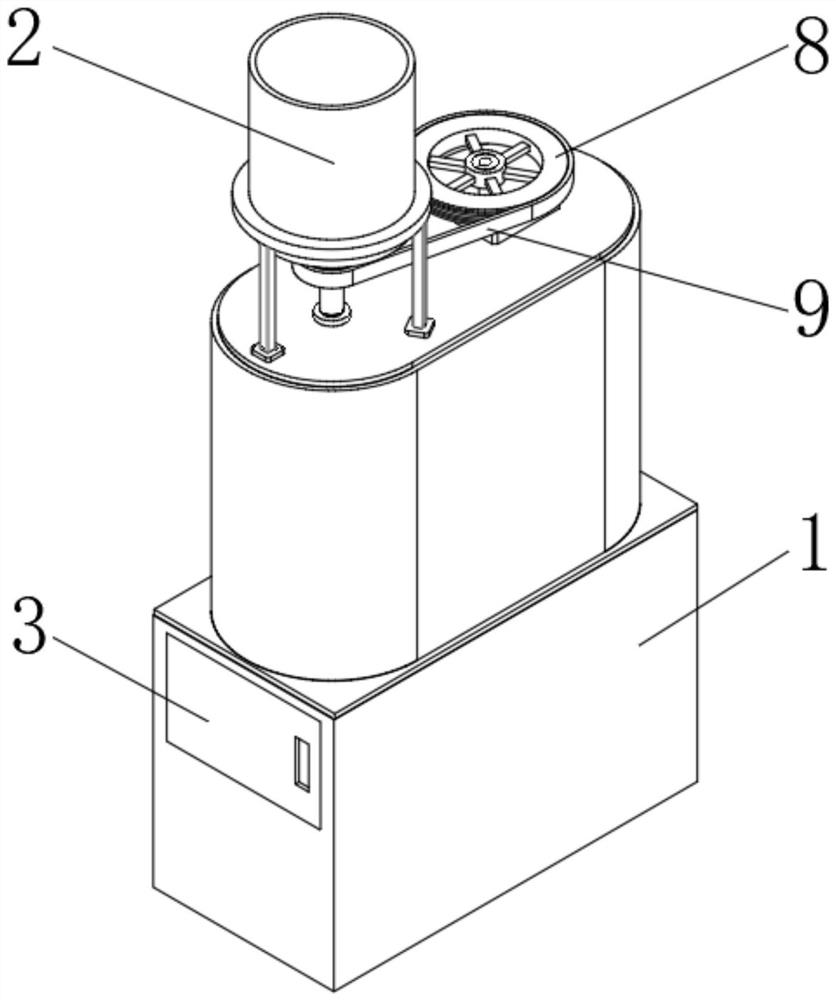

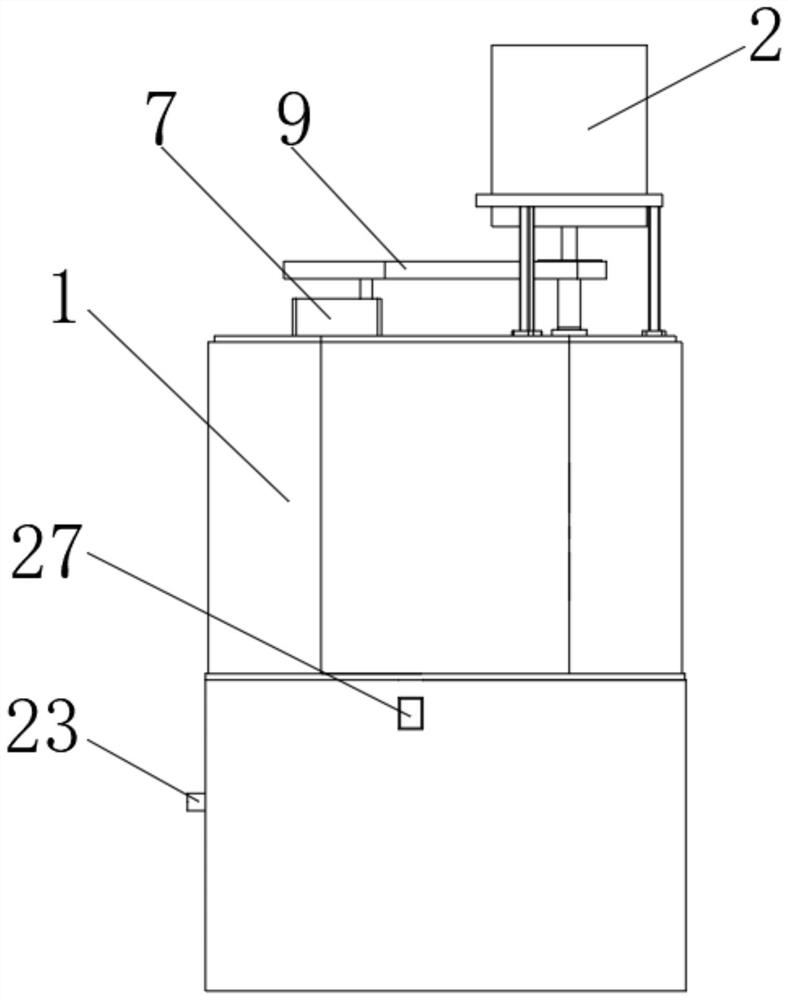

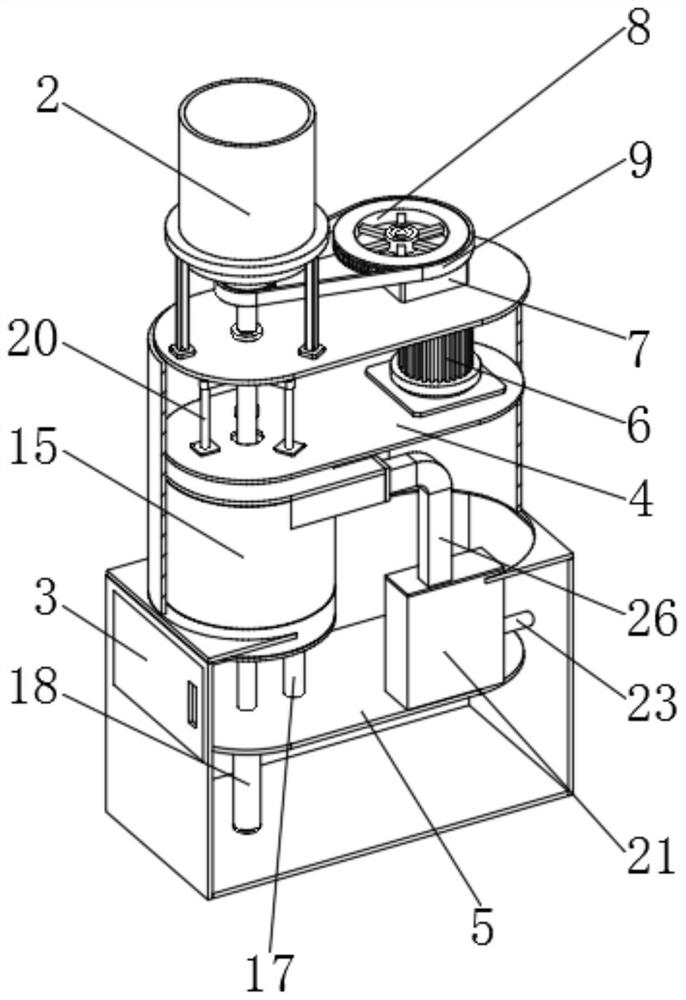

The invention provides a maneuvering type unmanned aerial vehicle recovery device, and belongs to the technical field of unmanned aerial vehicle recovery. The maneuvering type unmanned aerial vehicle recovery device comprises a blocking assembly, a U-shaped part, a lifting hydraulic cylinder, a support, a rotation base, an upper supporting hydraulic cylinder, a lower supporting hydraulic cylinder and a carrier. After an unmanned aerial vehicle rapidly rushes at the vertically unfolded blocking assembly at a certain recovery speed, the unmanned aerial vehicle pushes a blocking pulley to move forwards together, a pulling rope which is connected to the lower end of the blocking pulley surrounds a pulley block and pulls a damper piston rod in a damper cylinder body, the kinetic energy of the unmanned aerial vehicle and the blocking pulley is quickly absorbed, and therefore the purposes that the unmanned aerial vehicle and the blocking pulley are decelerated and stopped within a quite short period, and finally the unmanned aerial vehicle lands, is buffered by a belly buffering part, and is supported and recovered in a frame of the blocking assembly are achieved. By the adoption of the maneuvering type unmanned aerial vehicle recovery device, an undercarriage or a recovery parachute or a hooking rope device does not need to be additionally installed on the unmanned aerial vehicle, the quantity of loaded oil of the unmanned aerial vehicle can be increased, the flight resistance of the unmanned aerial vehicle can be reduced, and therefore the cruising time of the unmanned aerial vehicle is prolonged, and the flight speed of the unmanned aerial vehicle is increased.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

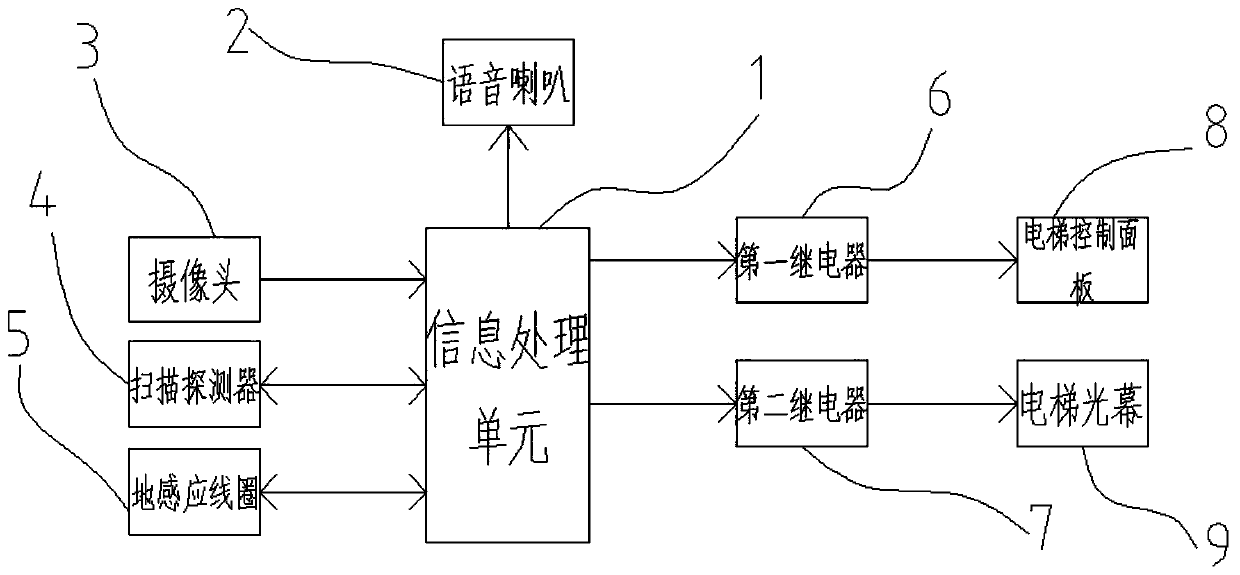

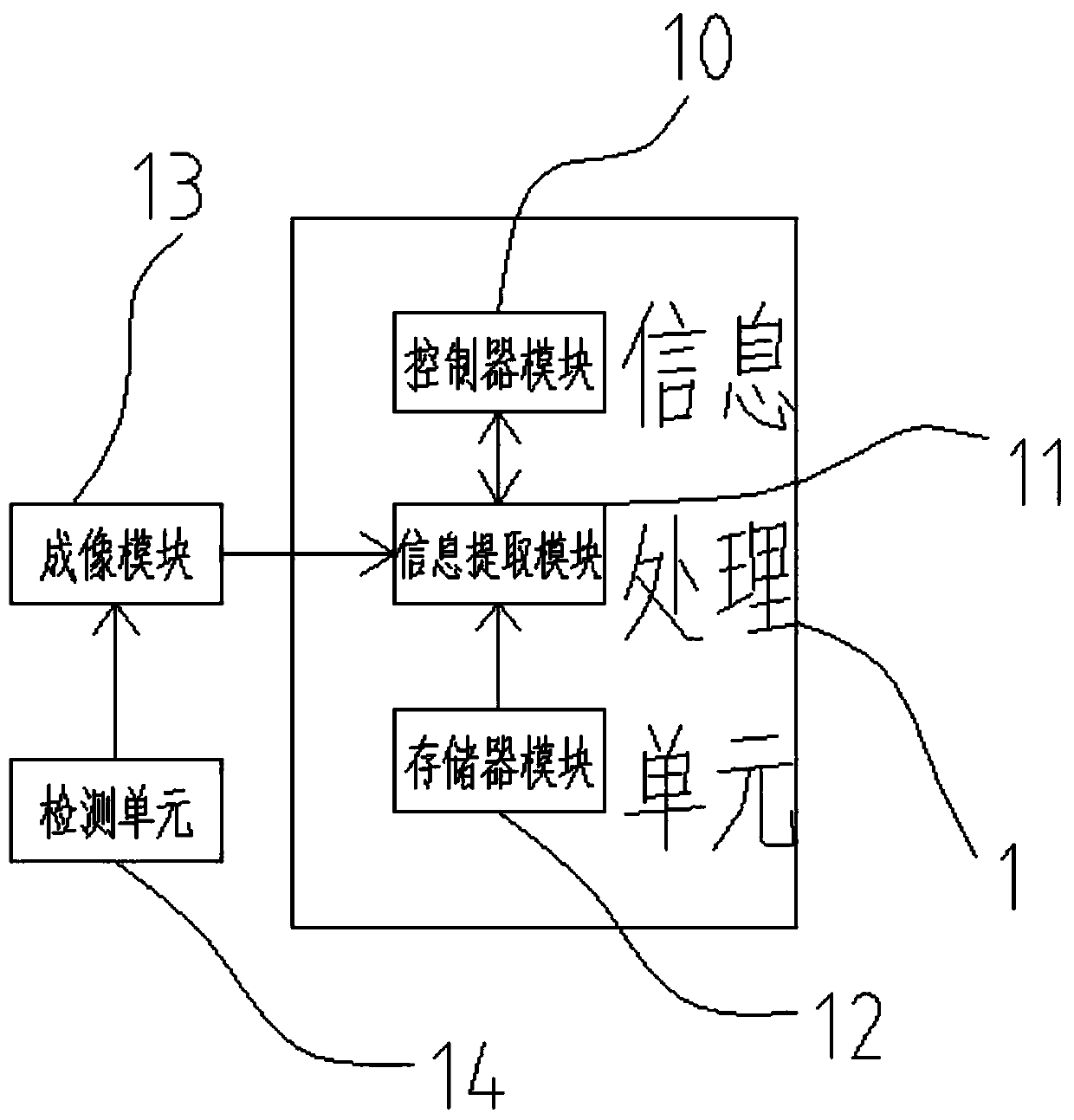

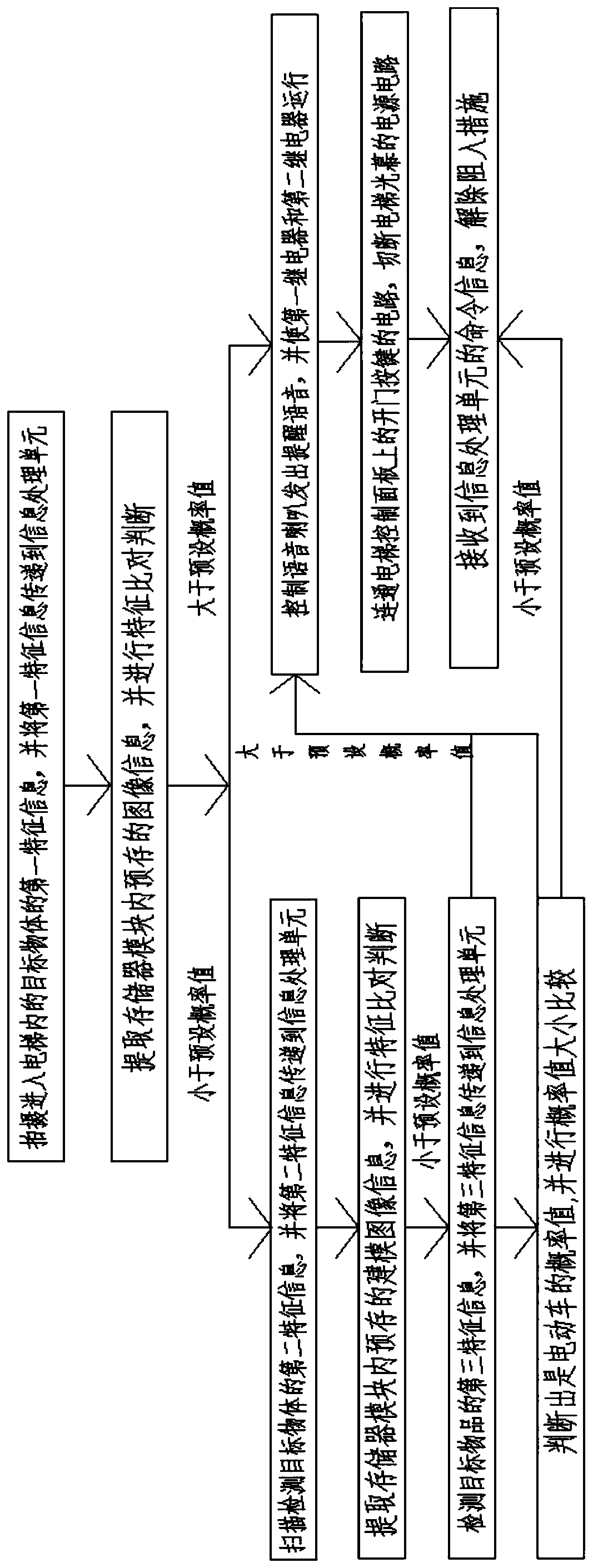

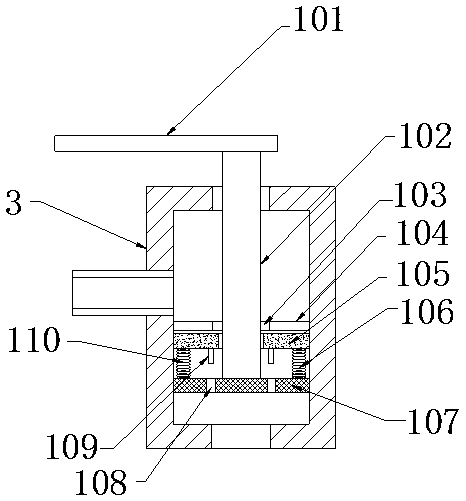

Electric bicycle blocking system and method for elevator

PendingCN110092257AImprove accuracyReduce power lossElevatorsSustainable buildingsLoudspeakerEngineering

Owner:唐政

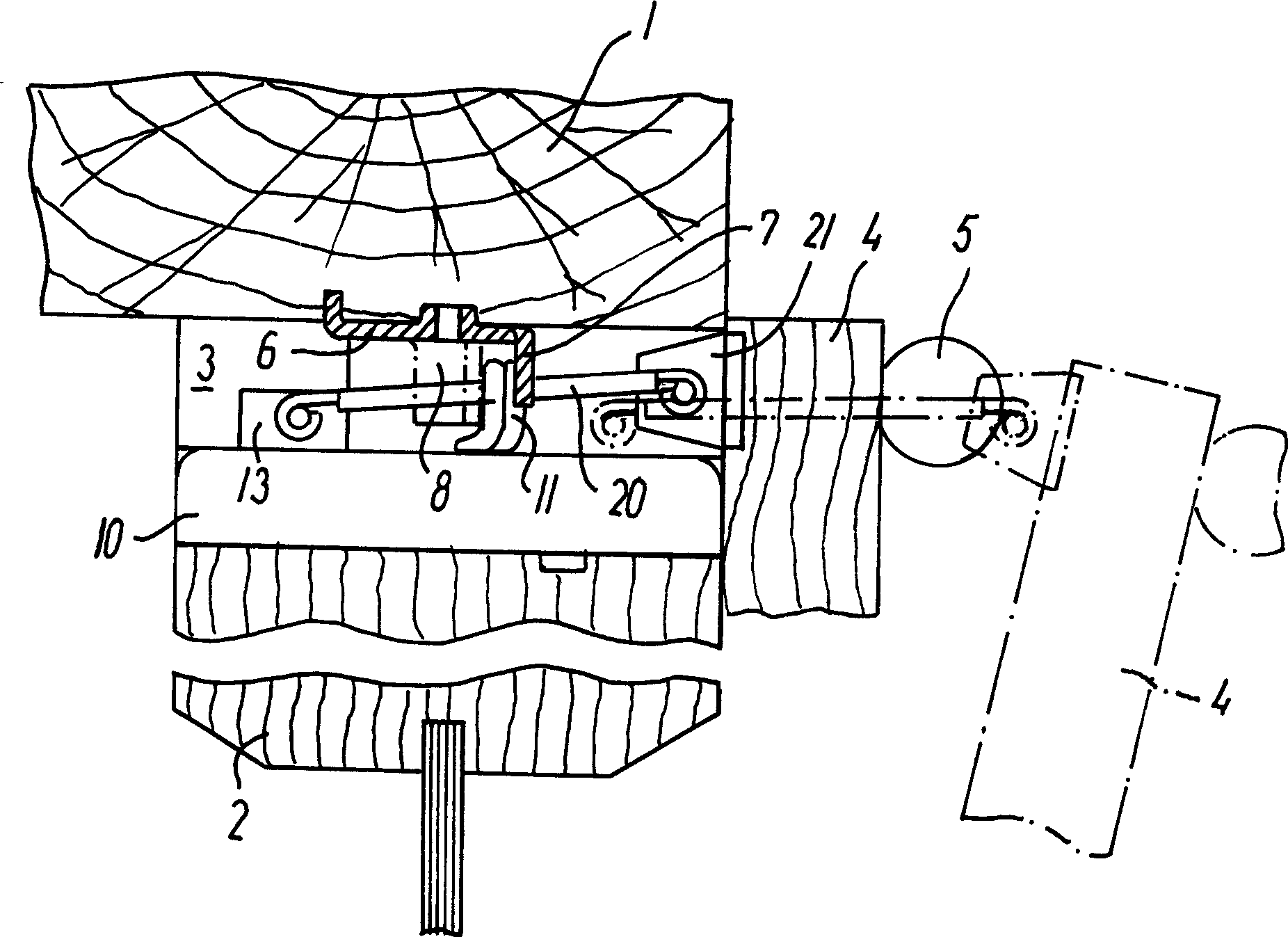

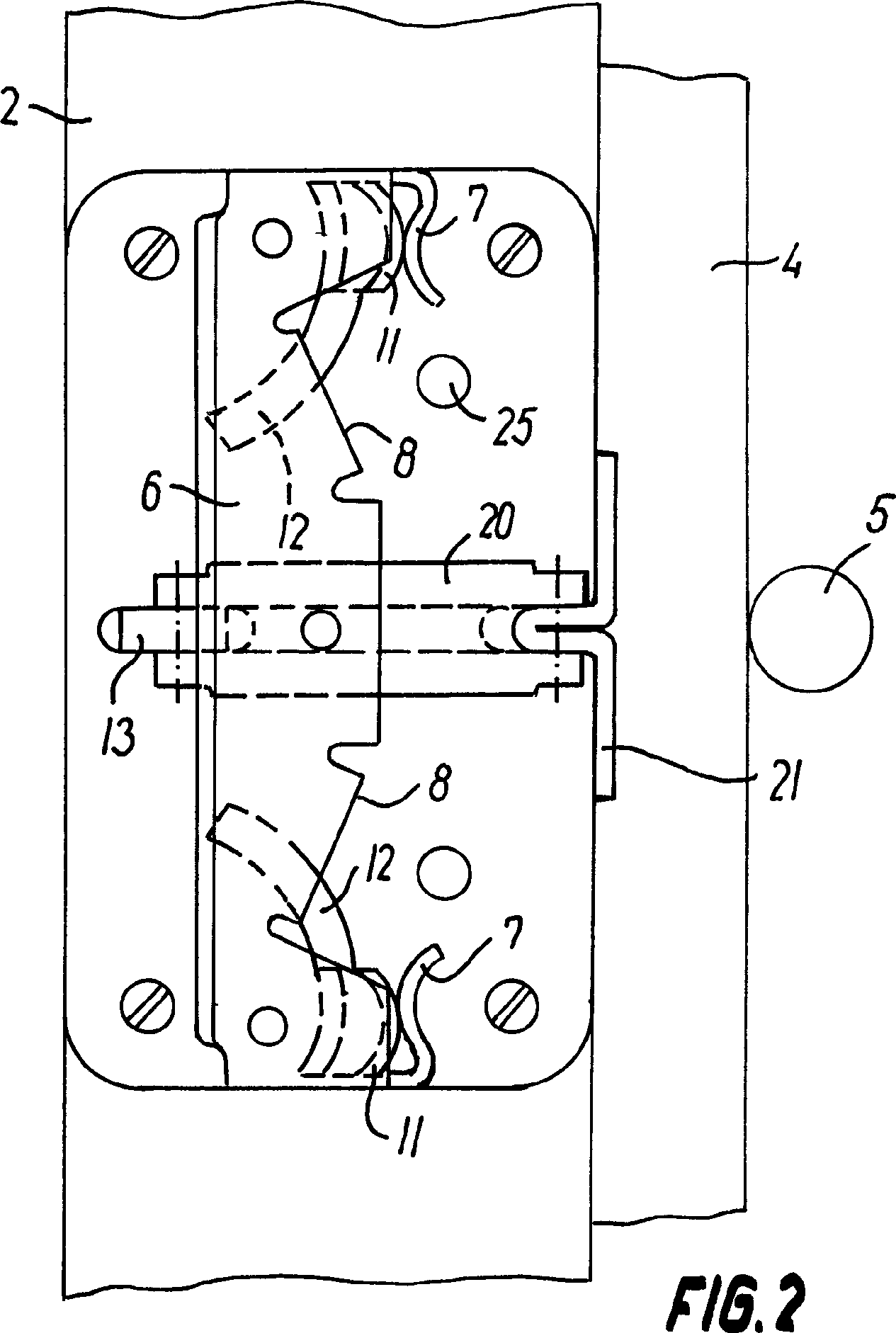

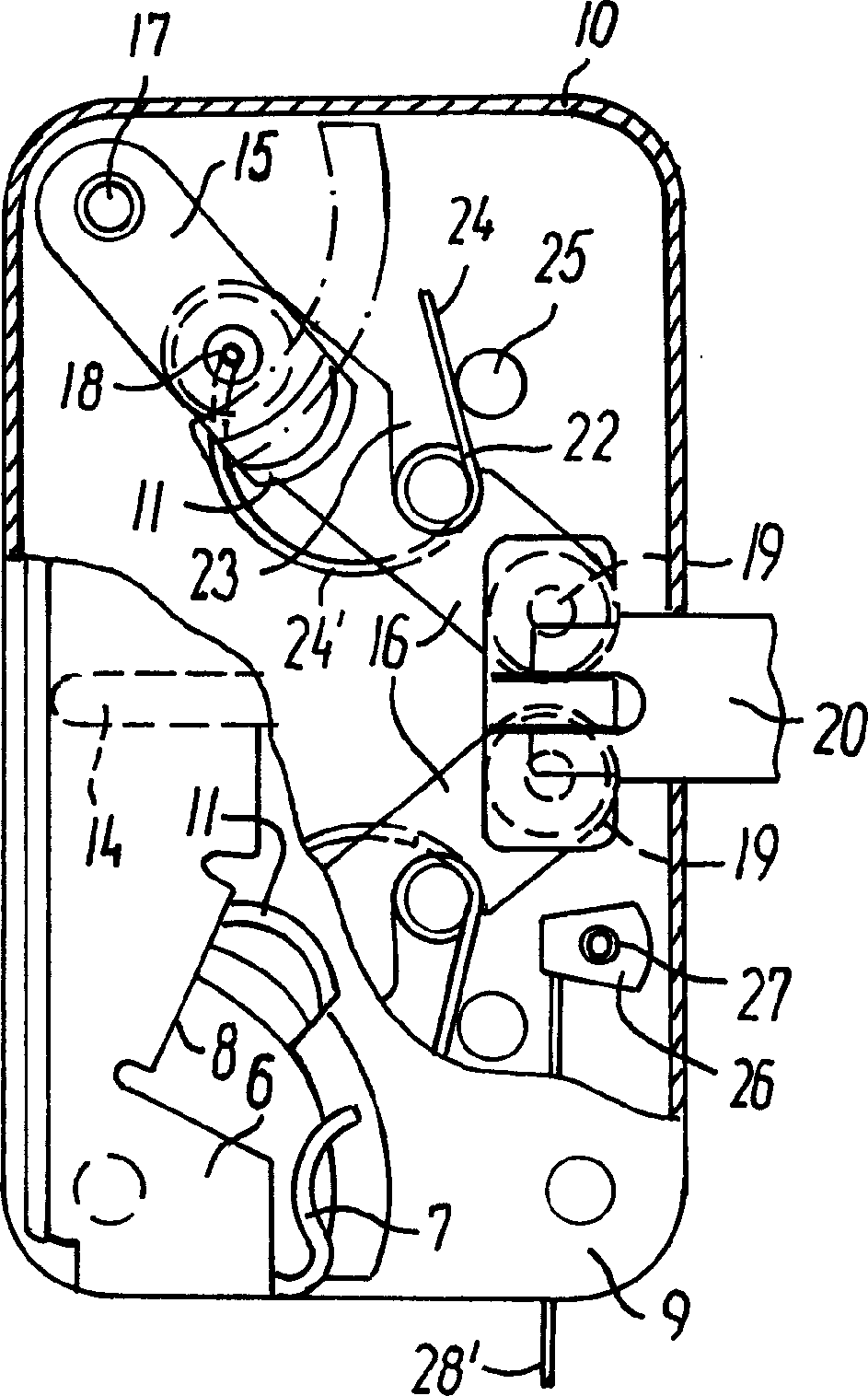

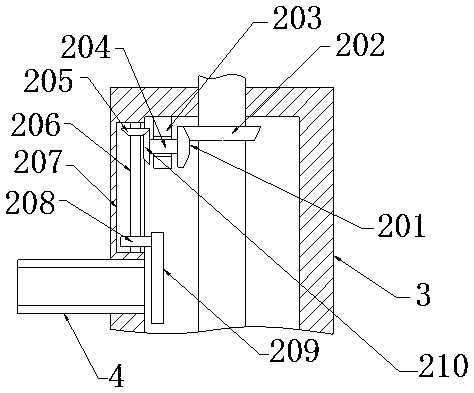

A locking device for a ventilating window

InactiveCN1502001AAvoid affecting airflowRealize the blocking functionNon-mechanical controlsWing fastenersEngineeringActuator

In a locking assembly for a ventilating window comprising a locking control mechanism connected with an operator member (4) via an actuator slide (13) release of locking engagement between movable and stationary locking members (11, 7) may be blocked by blocking means (26) acting on the locking control mechanism and / or the actuator slide (13). The blocking means (26) is selectively operable by user operated means functionally integrated with the operator member (4) for displacement between a blocking condition, in which the slide (13) is blocked against displacement from an intermediate locking position to a first end position, and a non-blocking condition, in which the slide (13) is freely displaceable by operation of the operator member (4).

Owner:VKR HLDG AS

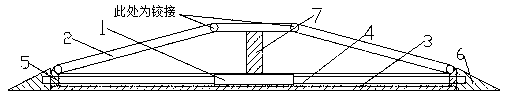

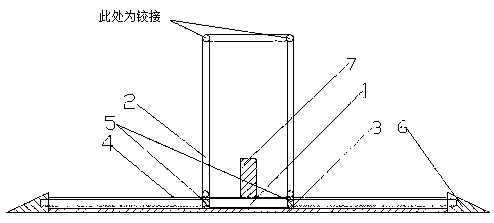

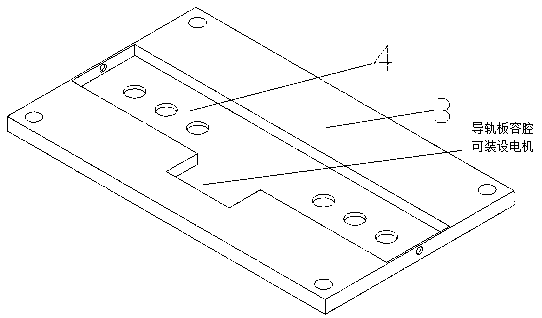

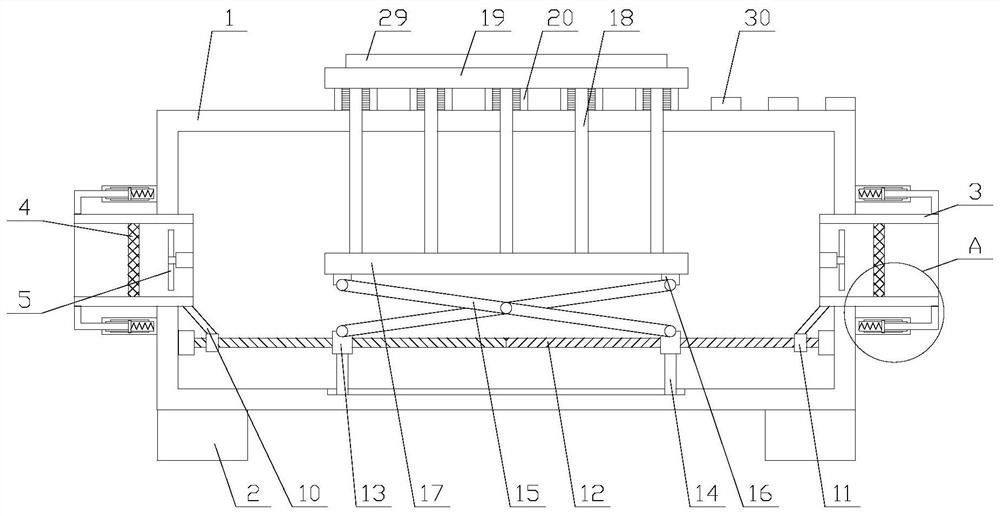

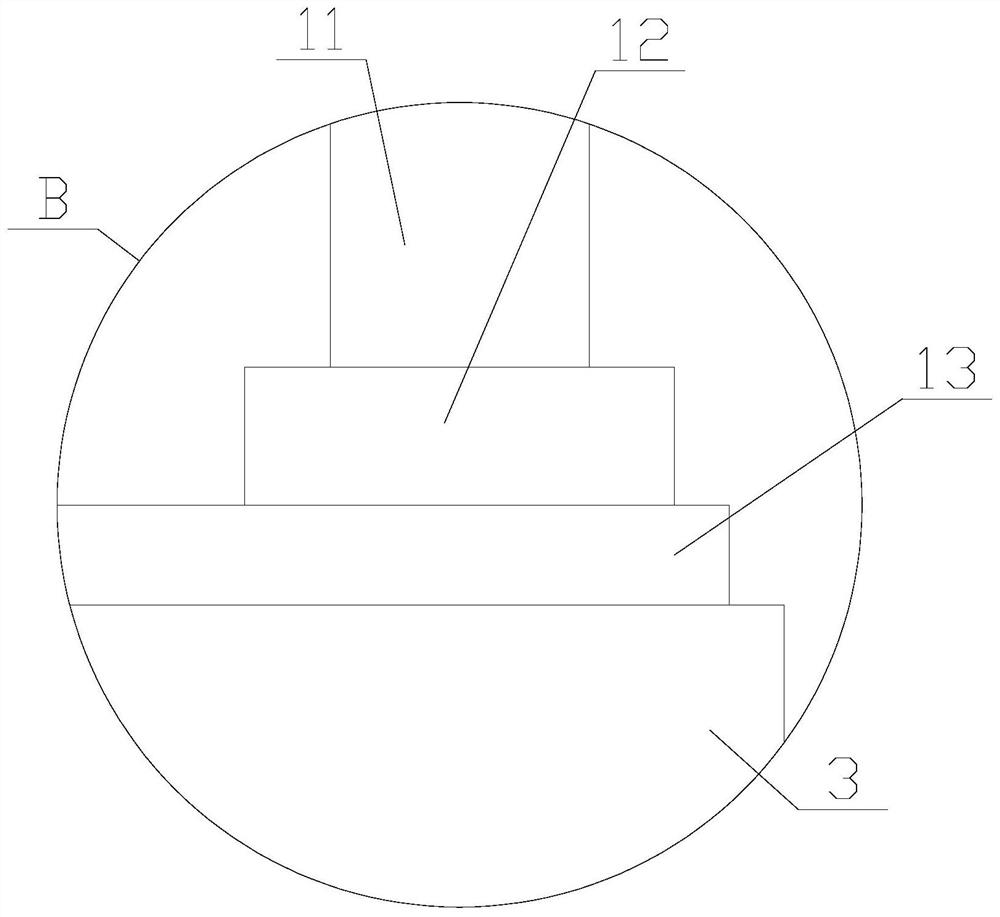

A speed bump that can be turned into an isolation pile

PendingCN109267507AAvoid damageRealize the deceleration functionTraffic signalsRoad signsSpeed bumpEngineering

The invention discloses a speed reduction belt which can be turned into an isolation pile, comprising a driving device, a trapezoidal foldable combined speed reduction belt, a guide rail plate, a guide groove, a slide block, a triangular baffle plate, a support block and the like; the speed reduction belt comprises a driving device and a trapezoidal foldable combined speed reduction belt. The bottom plate of the speed reduction belt is mainly composed of a guide rail plate, a guide groove and a triangular baffle plate, wherein the guide groove is arranged in the guide rail plate, and the triangular baffle plate is arranged at both ends of the guide rail plate. The two inclined surfaces of the speed reduction belt are articulated with the top surface, the inclined surface can rotate aroundthe top surface, the bottom end of the inclined surface is articulated with the slider, the slider is connected with the driving device, and the slider can slide in the guide groove. The device normally is a trapezoidal speed-down belt. If it is necessary to block the passage of a motor vehicle, the driving device controls the speed-down belt to slide in the middle of two oblique faces, and can beused as an isolation pile when the top plate is lifted and the side surface is vertical. The driving device controls the speed-down belt to slide on both oblique faces, and then the speed-down belt can be changed back. The device can be installed in the road section, in front of the unit door and other positions, and can play the function of decelerating and blocking the motor vehicle.

Owner:SHANDONG UNIV OF SCI & TECH

Welding equipment having high safety

InactiveCN112157347ARealize the cooling functionAvoid burnsLaser beam welding apparatusEngineeringWelding process

The invention relates to welding equipment having high safety. The welding equipment comprises a base, a supporting frame, an air cylinder, a workbench, a lifting plate and a welding device and further comprises four cooling mechanisms and four protection mechanisms; each cooling mechanism comprises a fixing box, a driving rope, a driving plate, an air inlet pipe, a filtering screen, a closing assembly, an air outlet pipe, a connecting box, a support, a transmission assembly, two fixing rods and a plurality of first springs; each transmission assembly comprises an annular air bag, a connectingpipe, a power air bag, a third spring, two power plates, two compression rings and a plurality of second springs; each sealing assembly comprises a fixing ring, a sealing plate and a fourth spring; and each protection mechanism comprises a supporting shaft, a protection plate, a hinge rod and a sliding block. According to the welding equipment having the high safety, the function of cooling a workpiece is achieved through the cooling mechanisms, the situations that the temperature of the welded workpiece is too high and a worker is scalded are avoided, the shielding function is achieved through the protection mechanisms, and high-temperature sparks generated in the welding process cannot be splashed to the body of the worker.

Owner:西安卧龙网络科技有限公司

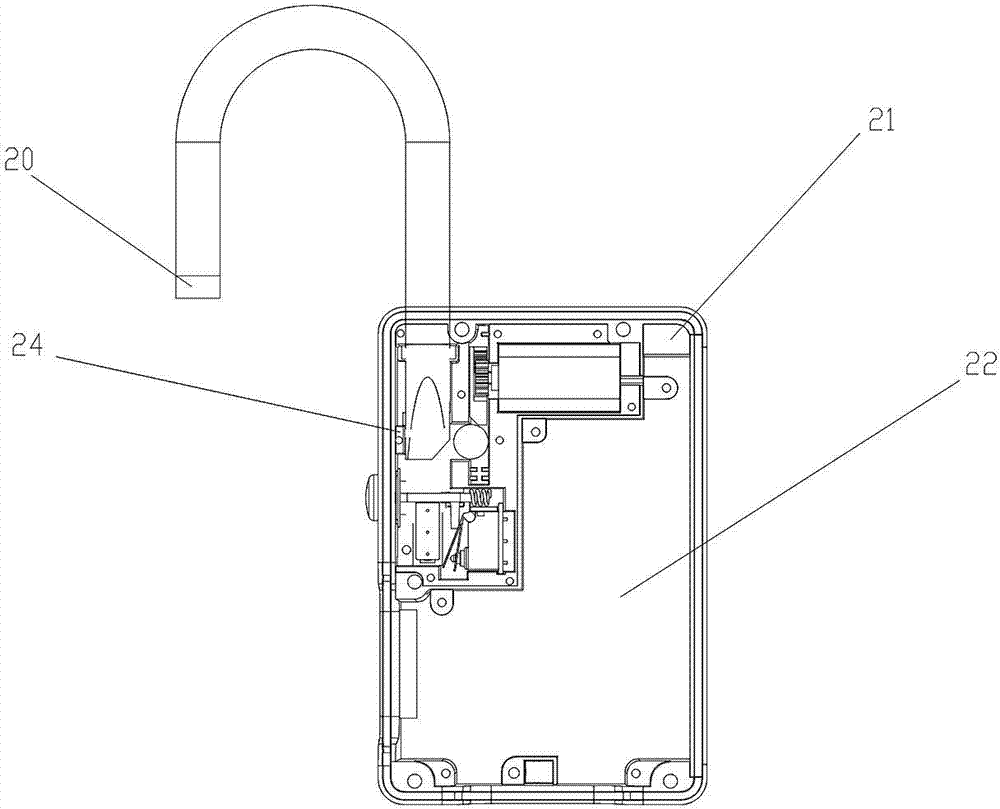

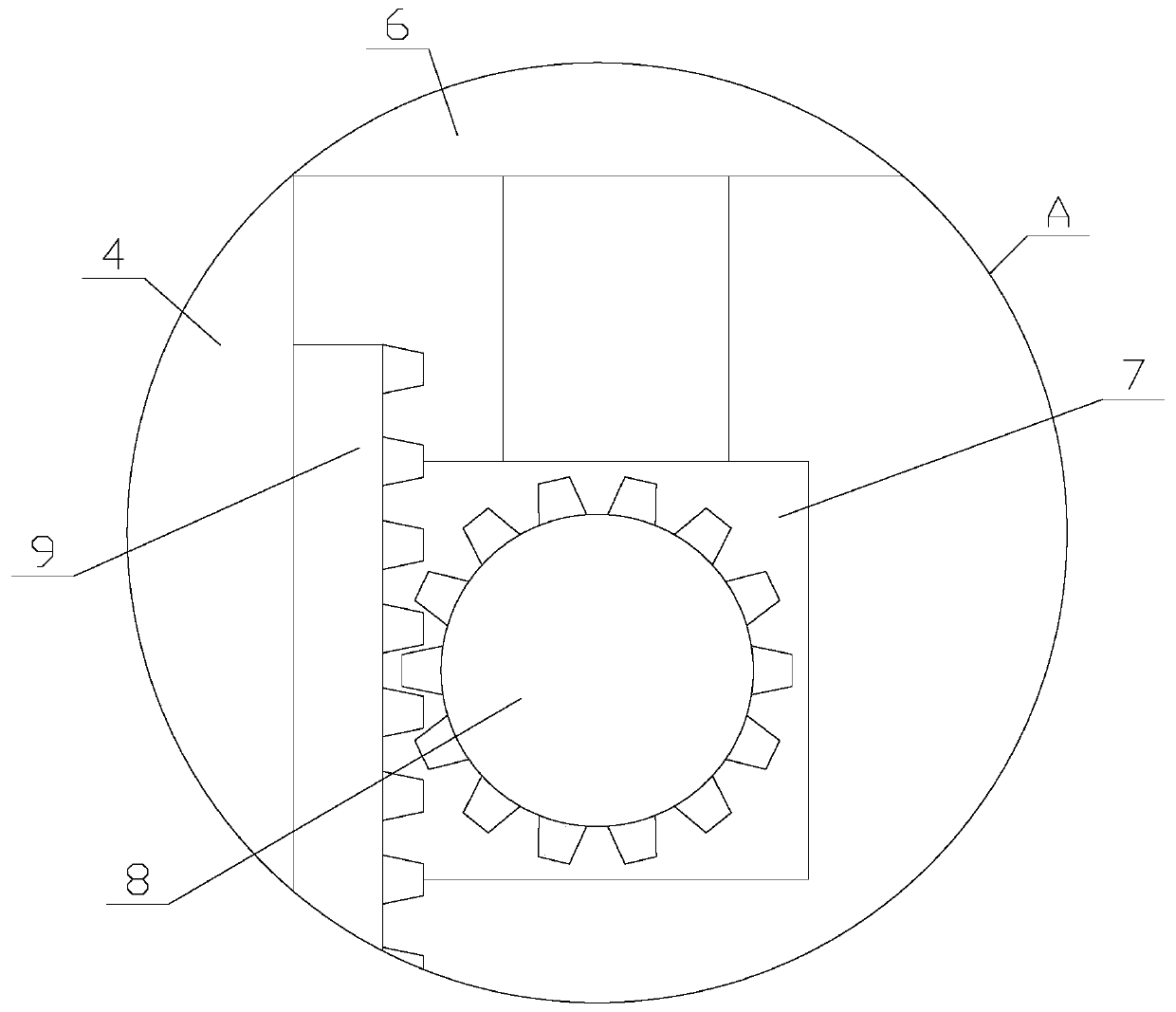

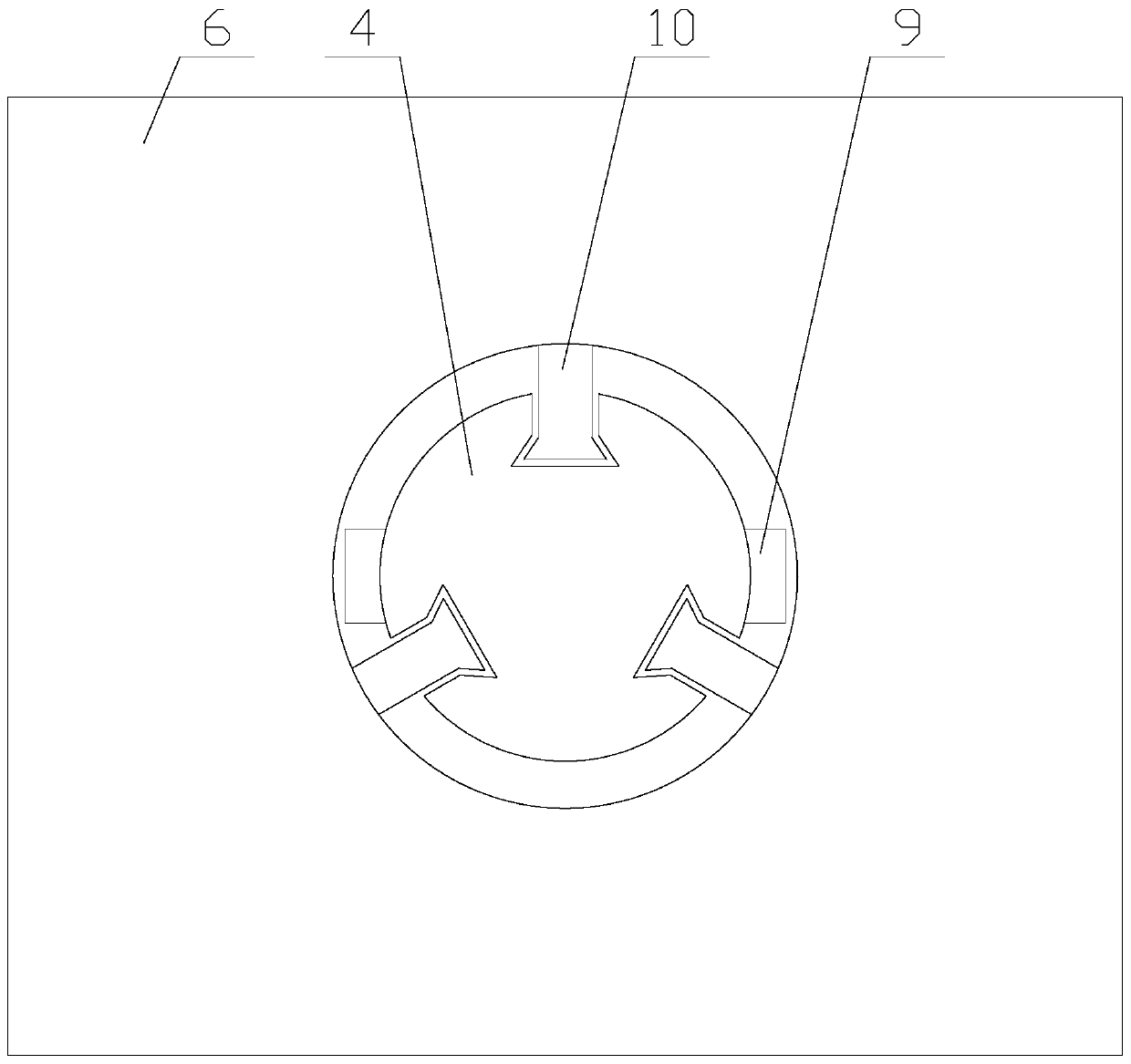

Remote communication control electronic lock

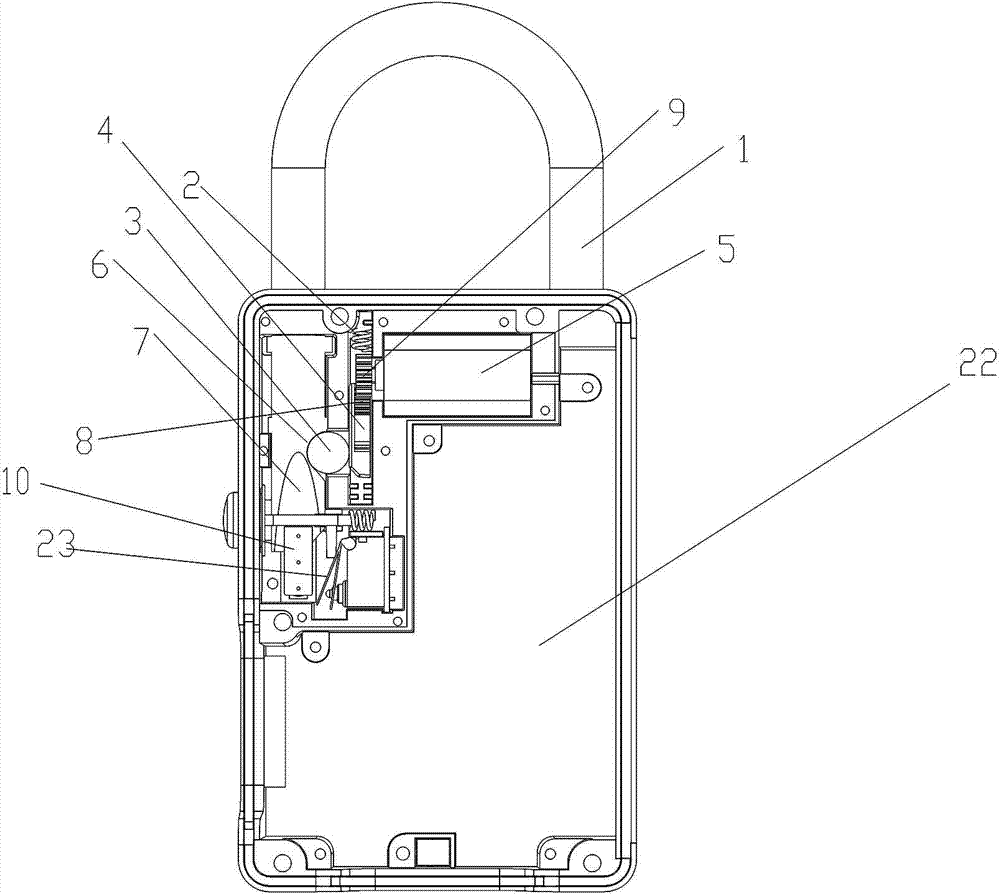

ActiveCN104775692AImprove locking effectAchieve connectionElectric permutation locksControl systemGear wheel

The invention discloses a remote communication control electronic lock which comprises a lock case, a locking mechanism and a remote communication control system. The remote communication control electronic lock is characterized in that the locking mechanism comprises a lock rod, a steel ball, a rack and a motor, wherein a sealing bayonet and a sealing detection inclined plane are arranged at the locking end of the lock rod; teeth are arranged on the rack; a gear is arranged at the output end of the motor and is occluded with the teeth of the rack; the steel ball is arranged at a position, close to the sealing bayonet, of the tail end of the rack and can freely move; the sealing detection inclined plane is close to a pressing sheet of a sealing detection switch; the sealing detection switch is electrically connected with the remote communication control system; the motor is electrically connected with the remote communication control system. The remote communication control electronic lock disclosed by the invention has the beneficial effects that the steel ball is clamped at the sealing bayonet and locks the lock rod, so that the locking performance of the lock rod is enhanced; the structure is very simple, and the reliability is improved.

Owner:深圳途泰科技有限公司

Projector with anti-blocking function

InactiveCN112631047AReduces the chance of filter cloggingPrevent impactProjectorsCleaning using toolsEngineeringMechanical engineering

The invention relates to a projector with an anti-blocking function. The projector comprises a main body, a lens and four supporting blocks, and further comprises an anti-blocking mechanism and a protection mechanism, the anti-blocking mechanism comprises a heat dissipation assembly and two auxiliary assemblies, and the protection mechanism comprises a protection plate, a rotating shaft, a connecting block, a supporting rod, two second bearings and two connecting assemblies. Each connecting assembly comprises a power rod, a gear, a rack and two movable rods. According to the projector with the anti-blocking function, through the anti-blocking mechanism, the function of cleaning a filter screen is achieved, the probability of blockage of the filter screen is reduced, the influence on heat dissipation work is prevented, and the reliability of equipment is improved; and through the protection mechanism, the function of shielding a lens is achieved, the probability that the lens is scratched is reduced, and the projection effect is prevented from being influenced, so that the reliability of equipment is improved.

Owner:南京思达捷信息科技有限公司

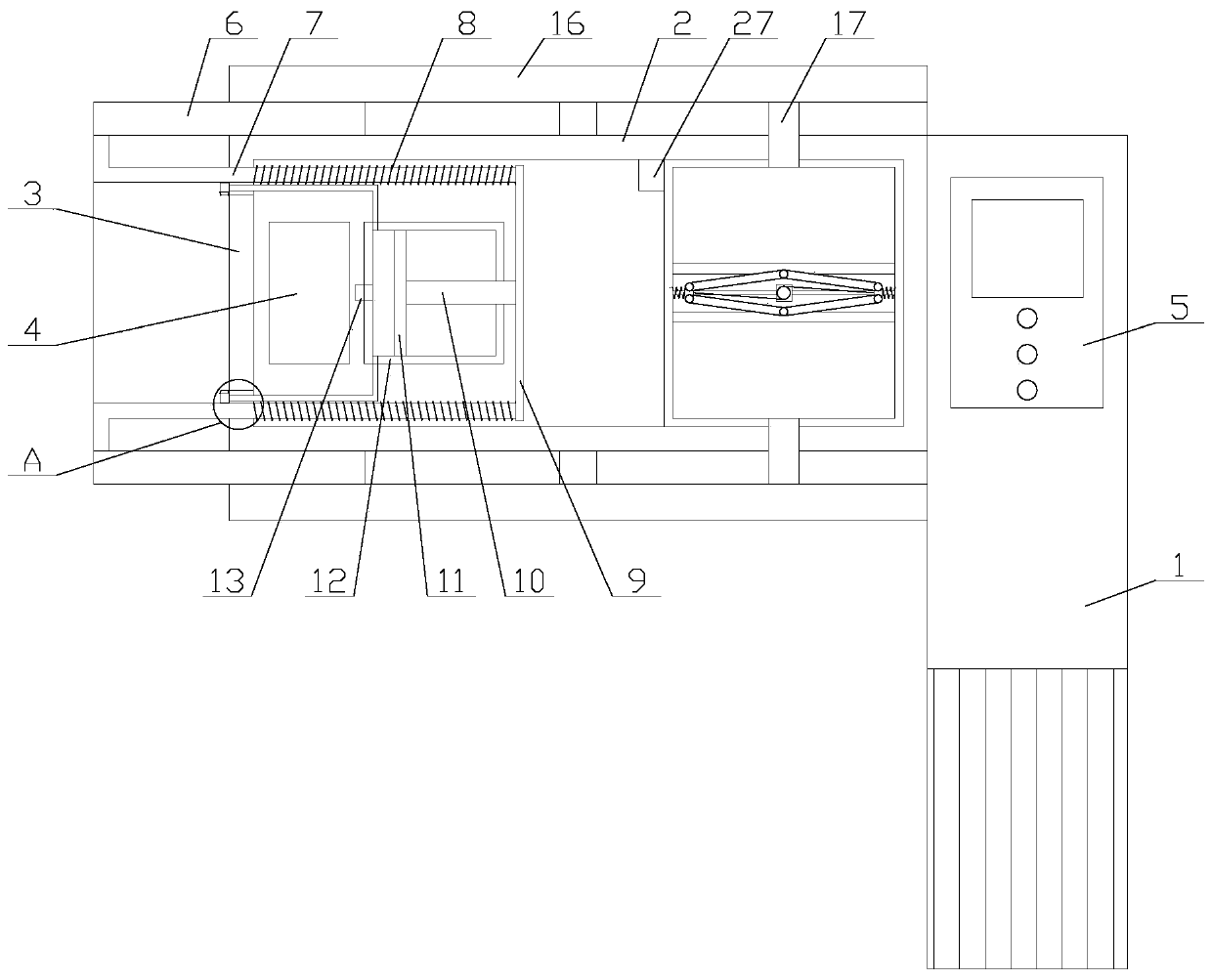

Sand spreading device of bullet train unit

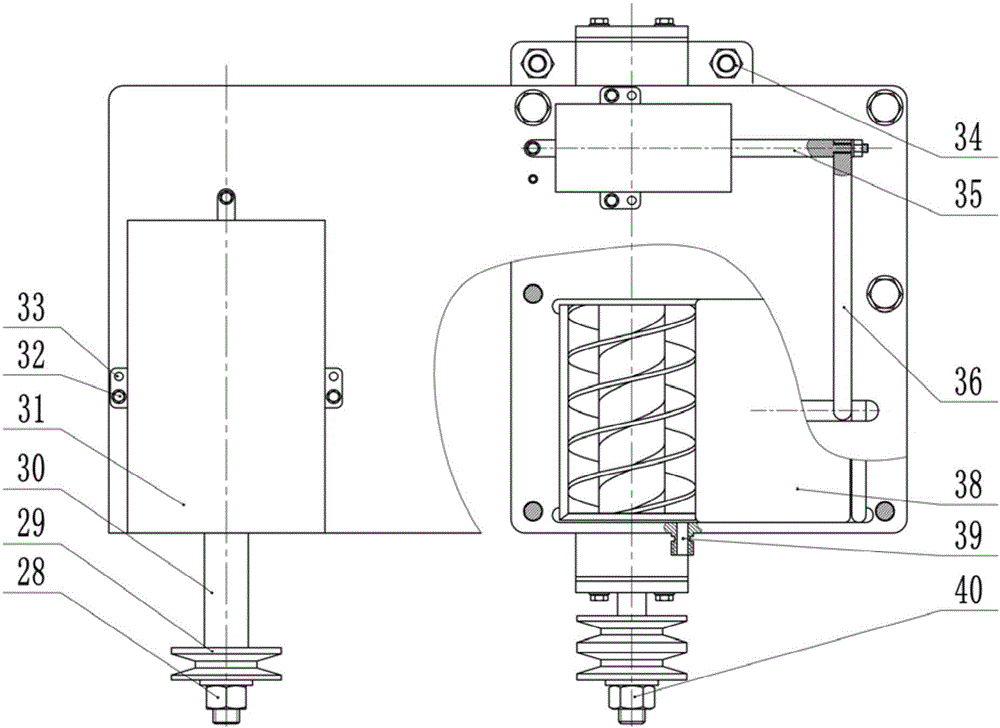

A sand spreading device of a bullet train unit is installed on a bogie frame of the bullet train unit, a speed governing motor drives belt pulleys to transmit power to a sand stirring mechanism and a sand conveying mechanism; a baffle driven by a pneumatic cylinder is installed between a sand box and the sand conveying mechanism, and the baffle and the sand box form a cabin door mechanism; when sand needs to be spread, the baffle can be slidingly opened in advance, so that the sand can enter the sand conveying mechanism; when sand spreading is completed, the baffle can be slidingly closed, the sand and the sand conveying mechanism are separated, and subsequent cleaning of the sand conveying mechanism is facilitated; the sand stirring mechanism is of a screw panel sleeve structure, sand stirring performance is good, and axial force is small; a heating device is installed between the sand stirring mechanism and a cabin door structure and used for heating the conveyed sand in time and sufficiently; a position sensor detects positions of the sand in the sand box and send control signals out; a temperature sensor monitors temperatures of the sand in the sand box; and the sand conveying device is of a double-screw-panel sleeve structure, and a sand stirring function is further achieved. The sand spreading device of the bullet train unit has the advantages that the volume is small, anti-block functions of the sand stirring mechanism and the sand conveying mechanism are achieved, and cleaning is easy.

Owner:DALIAN JIAOTONG UNIVERSITY

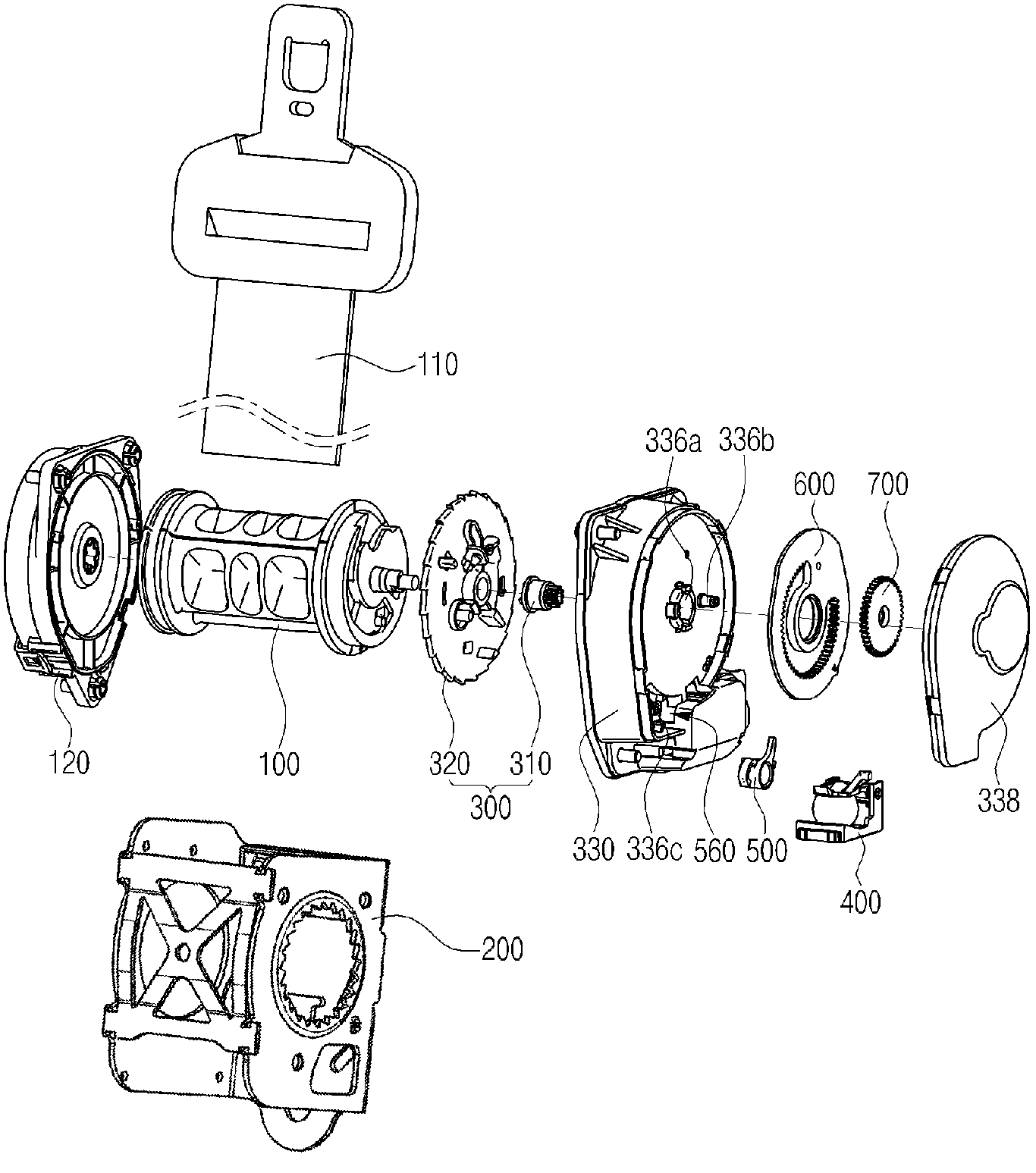

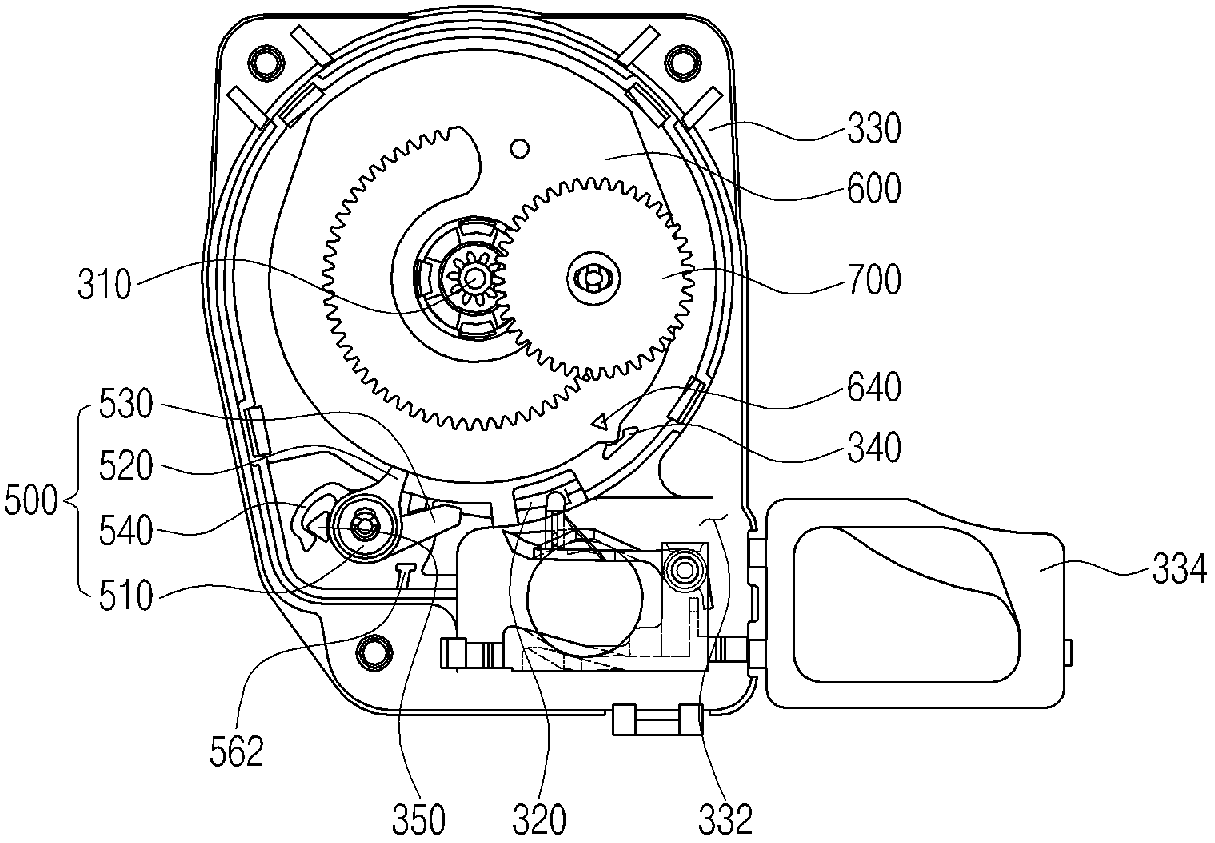

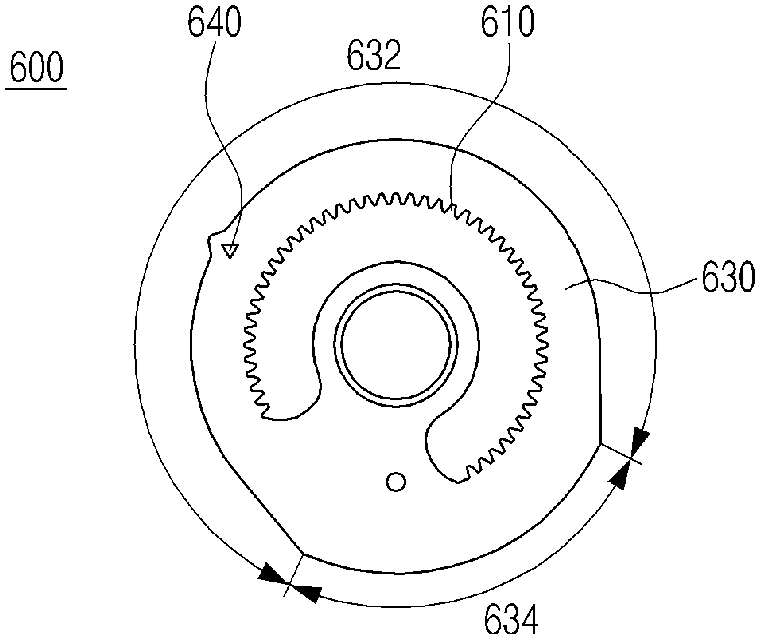

Retractor for seat belt

ActiveCN102933434ARealize the blocking functionReduce in quantityBelt retractorsBelt control systemsSeat beltEngineering

Disclosed is a retractor for a seat belt including a spool around which a webbing is wound, a frame rotatably coupled with the spool, a flywheel gear provided at a central portion thereof with a driving gear, having one-directional gear teeth formed along an outer circumferential surface thereof, and mounted on one end of the spool, a vehicle sensor locked with the one-directional gear teeth if the frame is inclined at a predetermined angle or more, a lever locked with the one-directional gear teeth if the webbing is withdrawn by a predetermined first length, and separated from the one-directional teeth if the webbing is introduced again so that the webbing is withdrawn by the second length, and an integrated plate including a driven gear, a first plate to adjust the lever according to a withdrawn length of the webbing, and a second plate integrated with the first plate.

Owner:宇信 +1

Projection equipment with dustproof function and good heat dissipation effect

InactiveCN110764344ARealize the blocking functionAffect normal workProjectorsCleaning using toolsElectric machineryElectronic component

The invention relates to projection equipment with a dustproof function and a good heat dissipation effect. The projection equipment comprises a main body and a projection lamp, and further comprisesa heat dissipation mechanism and a dustproof mechanism. The dustproof mechanism comprises a cover plate, a first bearing, a connecting shaft, a first gear and a driving assembly. The heat dissipationmechanism comprises a heat dissipation assembly, two filter screens and two cleaning assemblies. The heat dissipation assembly comprises a first motor, a rotating shaft, a second bearing, two transmission units and a plurality of blades. According to the projection equipment with a dustproof function and a good heat dissipation effect, through the dustproof mechanism, the projection lamp can be shielded, and the problem that dust adheres to the projection lamp to influence the projection effect when the equipment is idle is avoided; and through the heat dissipation mechanism, air circulation inside and outside the main body is accelerated, the heat dissipation effect is improved, and the problem that normal work of electronic elements in the main body is affected due to too high temperature in the main body is avoided.

Owner:深圳市壹闻科技有限公司

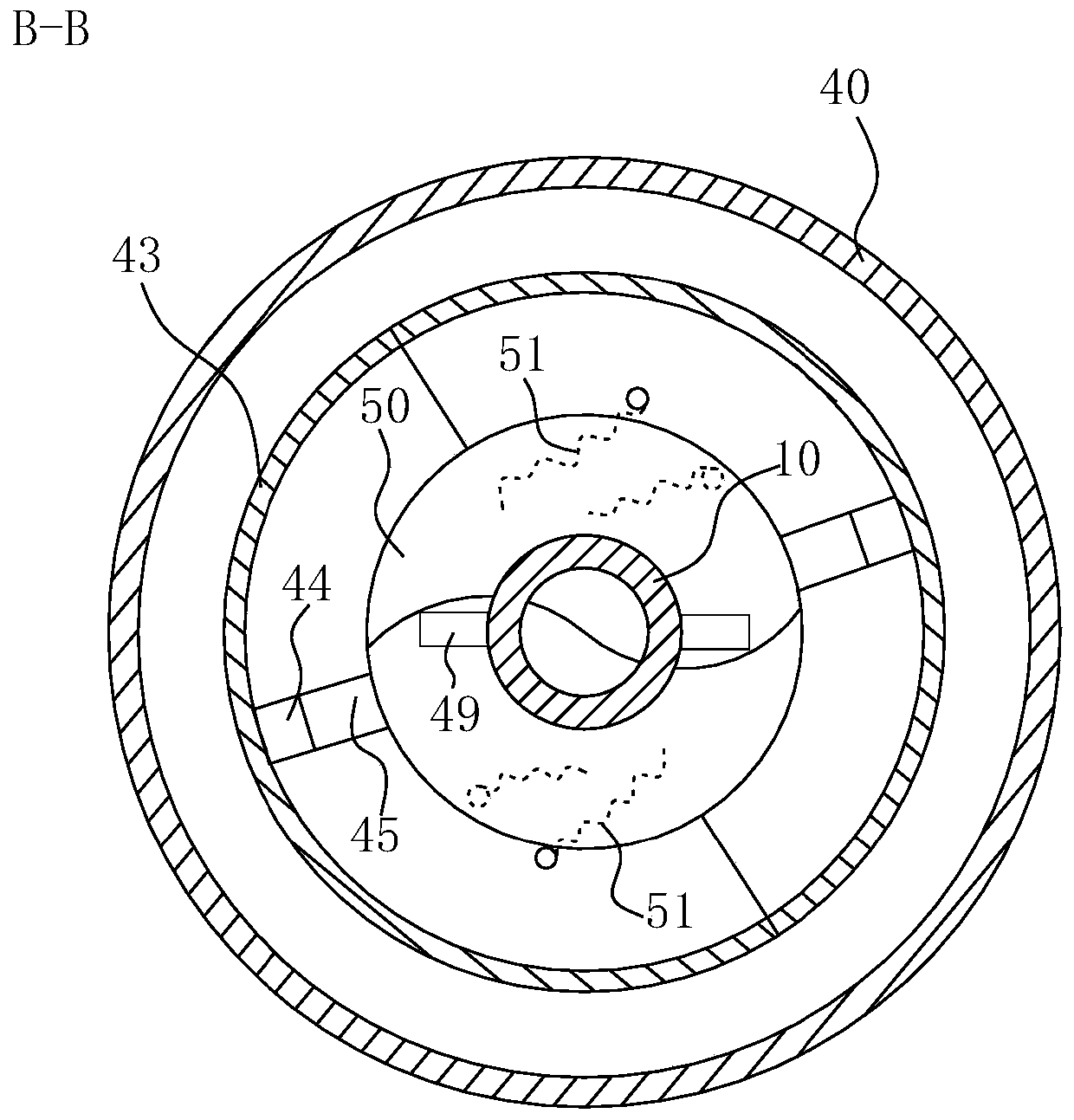

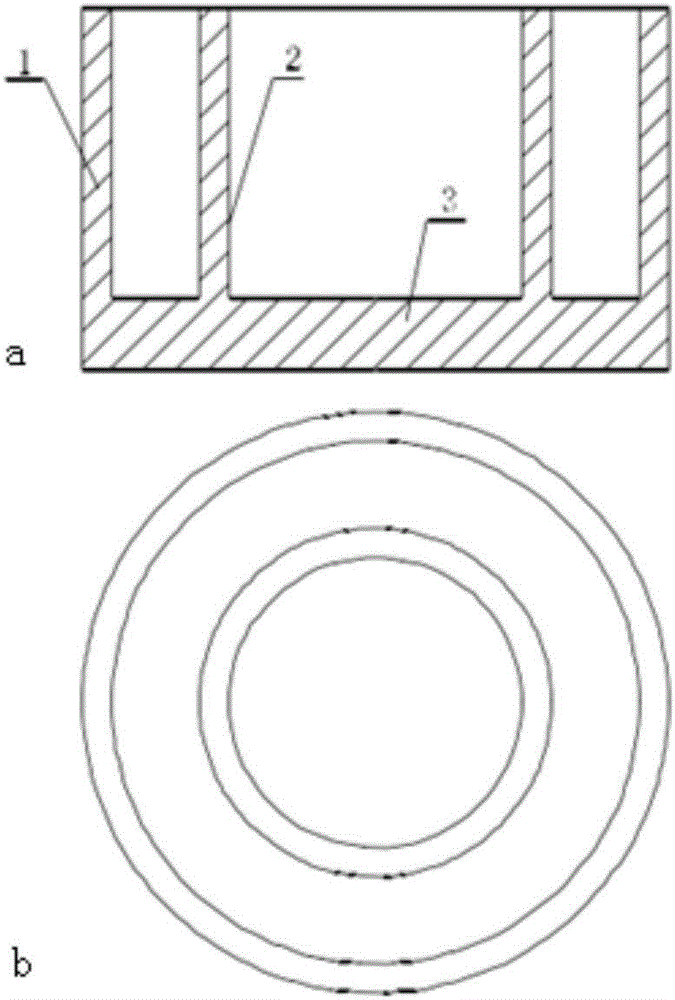

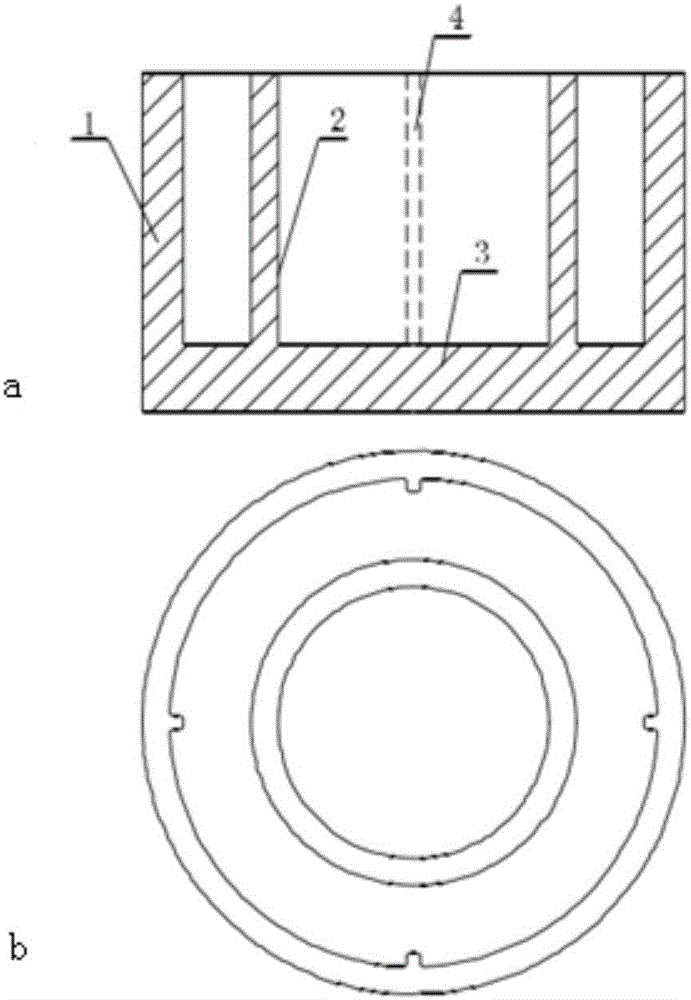

Self-adaptive high-performance bridge plug

ActiveCN110847853ARealize the blocking functionQuick self-remedialSealing/packingEngineeringStructural engineering

The invention belongs to the field of oil production tools, and particularly relates to a self-adaptive high-performance bridge plug. According to the specific technical scheme, the self-adaptive bridge plug includes central pipes, a rubber cylinder assembly sleeves the central pipes, the rubber cylinder assembly includes two compressed rubber cylinders arranged in surrounded modes, cross sectionsof the compressed rubber cylinders are inverted trapezoids with small inside and large outside, wedge-shaped extrusion parts with the shapes matched with those of the compressed rubber cylinders arearranged above and below the compressed rubber cylinders, self-expanding rubber cylinders are arranged in the middles of the compressed rubber cylinders around the central pipes, the outer surfaces ofthe compressed rubber cylinders are flush with the outer surfaces the first self-expanding rubber cylinders, the first self-expanding rubber cylinders are internally provided with first liquid storage boxes capable of being broken under the extrusion action of the first self-expanding rubber cylinders, and the first liquid storage boxes are filled with liquid capable of expanding the first self-expanding rubber cylinders. According to the self-adaptive high-performance bridge plug, the provided bridge plug has high adaptive capacity to a well wall, can be subjected to automatic remedy and secondary set in case of failure of set, can further unsealed easily in case of unsealing, and the bridge plug and a unsealing barrel can both be recycled and reused.

Owner:DAQING HAIXING GASOLINEEUM DEV OF SCI & TECH

Swing gate with anti-collision function

ActiveCN113756229ADoes not affect openingDoes not affect shutdownTraffic signalsRoad signsElectric machineClassical mechanics

The invention discloses a swing gate with an anti-collision function. The swing gate comprises a case which is provided with a groove on one side surface, a swing gate vertically and rotatably arranged in the groove, a vertical rod vertically arranged in the swing gate and slidably connected with the swing gate in the vertical direction, a first electromagnet, a servo motor, a supporting rod and a control unit, wherein the upper end and the lower end of the vertical rod are located in the case, and a first electromagnet attraction piece and a second electromagnet attraction piece are fixedly arranged at the upper end and the lower end of the vertical rod correspondingly; the first electromagnet is arranged right above the first electromagnet attraction piece; an output shaft of the servo motor is vertically arranged, and the servo motor is fixedly provided with a second electromagnet located under the second electromagnet attraction piece; the supporting rod is horizontally arranged on the back surface of the swing gate, one end of the supporting rod is slidably connected with the swing gate through a first sliding block, and the other end of the supporting rod is slidably connected with the case through a second sliding block; and the two ends of the supporting rod are hinged to the first sliding block and the second sliding block correspondingly. Damage to the motor can be effectively reduced, and the beneficial effects of prolonging the service life and reducing the operation cost are achieved.

Owner:北京中成科信科技发展有限公司

Paint spraying equipment with anti-splashing function

The invention relates to paint spraying equipment with an anti-splashing function. The paint spraying equipment comprises a bottom plate, a fixed box, a supporting column, a platform, a top plate, a material box, a connecting pipe, a paint spraying pipe and two supporting columns, and further comprises an anti-splashing mechanism and an impurity removing mechanism; and the anti-splashing mechanismcomprises a lifting plate, two moving assemblies, two stirring assemblies and four scraping assemblies, each moving assembly comprises a motor, a lead screw, a sliding block, a supporting rod and a first bearing, each stirring assembly comprises a second bearing, a rotating shaft, a transmission unit and two stirring units, and each scraping assembly comprises a scraping plate and a fixing rod; and the impurity removing mechanism comprises an impurity removing net, a smashing plate, a third bearing, a connecting shaft, a connecting disc, a torsion spring, a support and two connecting ropes. According to the paint spraying equipment with the anti-splashing function, the shielding function is achieved through the anti-splashing mechanism, it is avoided that paint splashes to the body of a worker to affect the cleanliness of the worker, the impurity removing function is achieved through the impurity removing mechanism, and it is avoided that the quality of a finished product is affecteddue to the fact that the paint contains too much impurities.

Owner:南京欧伊工程技术有限公司

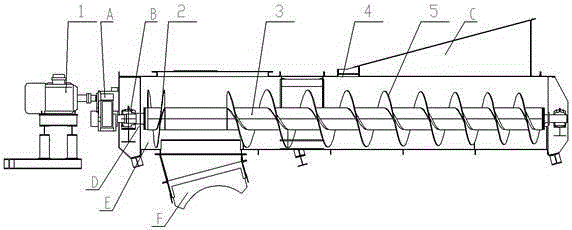

Screw conveyor provided with material blocking and cleaning device

InactiveCN105197516ARealize the blocking functionRealize the function of cleaning deposited materialsPackagingLoading/unloadingPapermakingEngineering

A screw conveyor provided with a material blocking and cleaning device comprises a main screw drive, a material blocking and cleaning reverse screw blade, a screw shaft, a material trough body and a screw blade, wherein the material blocking and cleaning reverse screw blade and the screw blade are welded on the screw shaft and mounted into the material trough body after welding, and the main screw drive and the screw shaft are connected through a speed reducer A and a bearing seat B and sealed through a seal ring D; the main screw drive is started, the screw shaft drives the screw blade to rotate, the material blocking and cleaning reverse screw blade rotates synchronously with the screw shaft, materials enter the material trough body from a material inlet C, and when the materials are accumulated in a material accumulation position E, the material blocking and cleaning reverse screw blade conveys the accumulated materials synchronously in an opposite direction into a material discharge opening F. The screw conveyor can realize both the material blocking function and the accumulated material cleaning function, is high in continuity and is applied to the technical fields of metallurgy, electric power, chemical engineering, coal, papermaking and building materials.

Owner:NORTHERN HEAVY IND GRP CO LTD

Water conservancy irrigation closed system

InactiveCN111264344ARealize the blocking functionFunction increaseBarrages/weirsWatering devicesAgricultural scienceAgricultural engineering

The invention relates to a water conservancy irrigation closed system which includes a water channel for water diversion and a water blocking mechanism installed on the water channel. The water channel communicates with a crop pond for planting crops; the water blocking mechanism includes a sliding chute fixedly arranged in the water channel, a flashboard slidably matched in the sliding chute, a control box arranged on the water channel, and a supporting shaft rotatably supported on the control box; an unwinding reel is coaxially fixed to the supporting shaft, a drawstring is wound on the unwinding reel, one end of the drawstring is fixed to the unwinding reel, the other end of the drawstring is fixed to the flashboard, and the supporting shaft is connected with a driving device; and a control device is arranged between the crop pond and the water blocking mechanism. By arranging the control device between the crop pond and the water blocking mechanism, when the water level in the croppond reaches a certain height, the control device can control the flashboard of the water blocking mechanism to automatically lower to block water, and convenience during use is improved.

Owner:郑州市水利工程监理中心

Full-automatic gas ultralimit preventing device

PendingCN106869855AHole fastEasy to fix holesDrilling rodsSealing/packingControl engineeringProcess engineering

The invention discloses a full-automatic gas ultralimit preventing device, which comprises a high-pressure capsule hole fixing apparatus, an automatic reset hole sealing apparatus and a buffer box which are sequentially connected. The high-pressure capsule hole fixing apparatus utilizes capsules to replace cement to serve as a hole fixing medium, so that hole fixing time is greatly reduced, and reuse is further achieved; the automatic reset hole sealing apparatus achieves a normally-closed function through force provided by a nitrogen spring, can clamp a drill rod under the situation without an external power source and achieves the purpose of plugging burst gas. In general, the gas ultralimit preventing device improves work efficiency, achieves an automatic plugging function in gas emission moment, also can achieve the plugging function when losing the power source and effectively ensures construction safety.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

High-reliability soil heavy metal detector with anti-falling function

InactiveCN110988001AAffect healthAvoid affecting the detection accuracyMaterial analysis using wave/particle radiationCleaning using gasesSoil heavy metalsDust control

The invention relates to a high-reliability soil heavy metal detector with an anti-falling function. The detector comprises a main body, a glass plate, a detection device, a handle, a protection mechanism and a shielding mechanism. The shielding mechanism comprises a shielding plate, a dust removal assembly, a connecting plate and a plurality of connecting assemblies; and each connecting assemblyincludes a connecting rod and a first spring. The protection mechanism comprises an annular air bag, an acceleration sensor, a connecting box, a driving assembly, two moving plates, two communicatingpipes and two fixing blocks. According to the high-reliability soil heavy metal detector with the anti-falling function, with the protection mechanism, a buffer force is provided for the main body byrapidly inflating the air bag to realize the anti-falling function; with the shielding mechanism, the shielding function can be realized, and a situation that X-rays emitted by the detector irradiatethe body of a user, and the health of the user is affected is avoided.

Owner:虞伟明

Anti-splashing rammer compactor

InactiveCN112342870AAvoid damageReduce the chance of transmissionDirt cleaningRoads maintainenceDrive shaftControl switch

The invention relates to an anti-splashing rammer compactor which comprises a main body, an air cylinder, a ramming compaction plate and two moving devices, and further comprises an anti-splashing mechanism and two stabilizing mechanisms, and the anti-splashing mechanism comprises a protection plate, a moving plate, two control assemblies, two electromagnets, two supporting rods, two limiting blocks and a plurality of first springs; each control assembly comprises a fixing rod and a control switch, the stabilizing mechanism comprises a lead screw, a sliding block, a supporting rod, a fixing plate, a transmission disc, a transmission shaft, a transmission rope, a torsion spring and two second bearings, and the anti-splashing rammer compactor achieves the shielding function through the anti-splashing mechanism. By the adoption of the structure, mud on the ground cannot be splashed to the body of a worker during tamping, so that the reliability of the equipment is improved, the function of fixing the position of the equipment is achieved through the stabilizing mechanism, the probability that tamping is affected by position deviation during tamping is reduced, and therefore the reliability of the equipment is improved.

Owner:深圳市琦美创科技有限公司

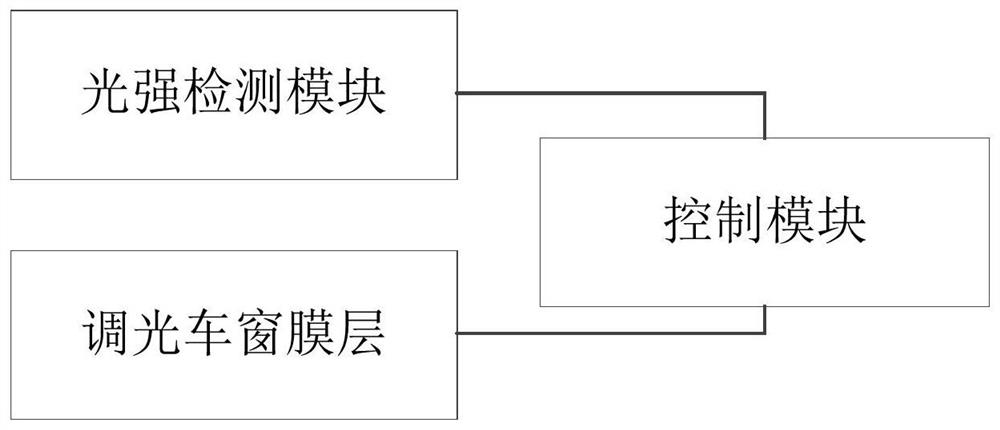

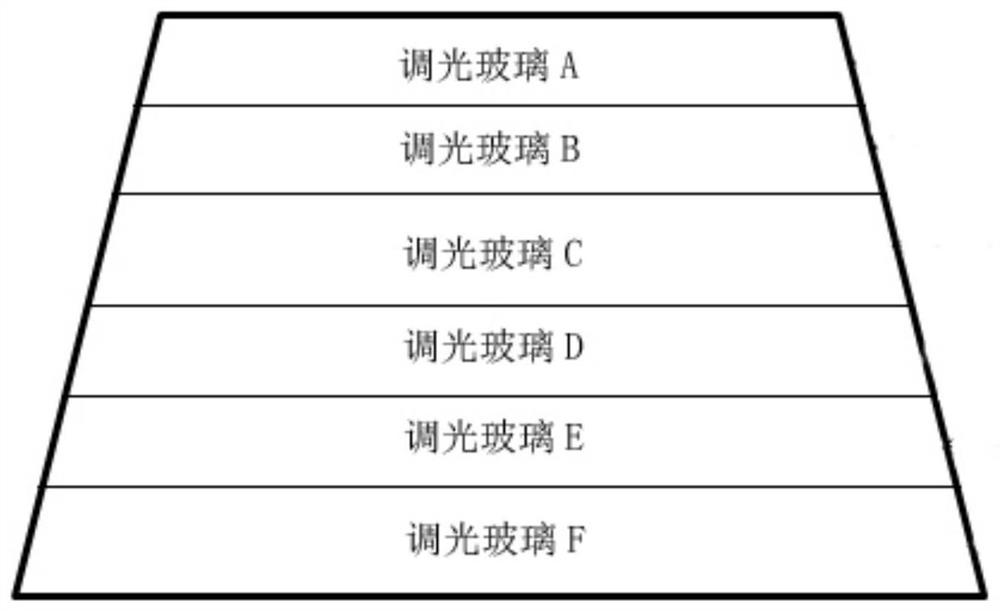

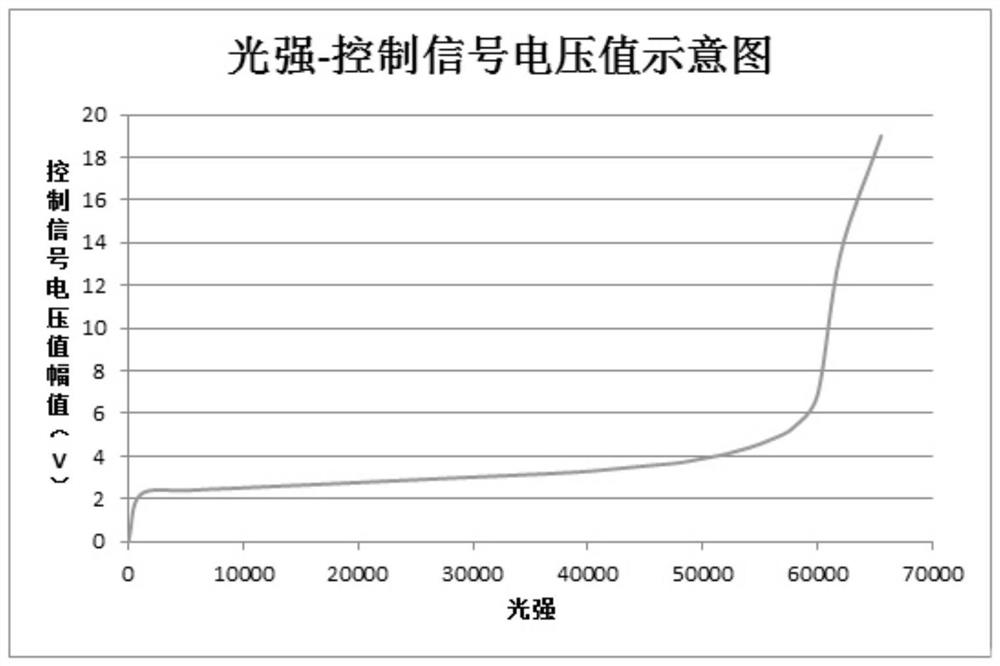

Motor vehicle auxiliary device, motor vehicle and using method of auxiliary device

ActiveCN111660774ARealize the blocking functionEliminate operationAntiglare equipmentDriver/operatorControl signal

The invention discloses a motor vehicle auxiliary device, a motor vehicle and a using method of the auxiliary device. The motor vehicle window auxiliary device comprises a dimming vehicle window filmlayer, a light intensity detection module and a control module; the dimming vehicle window film layer serves as a front windshield of the motor vehicle or is arranged on the inner surface or the outersurface of the front windshield of the motor vehicle and comprises a plurality of pieces of dimming glass which are arranged in the vertical direction of the front windshield and are electrically insulated from one another; the light intensity detection module is arranged on the dimming vehicle window film layer and used for detecting the light intensity of light; and the control module is used for calling a pre-stored dimming scheme matched with the light intensity in response to the detected light intensity, so that the control module inputs different control signals to at least part of thedimming glass based on the dimming scheme, and the transmittance of the at least part of the dimming glass is changed. Potential safety hazards of driving of a driver can be reduced.

Owner:BOE TECH GRP CO LTD +1

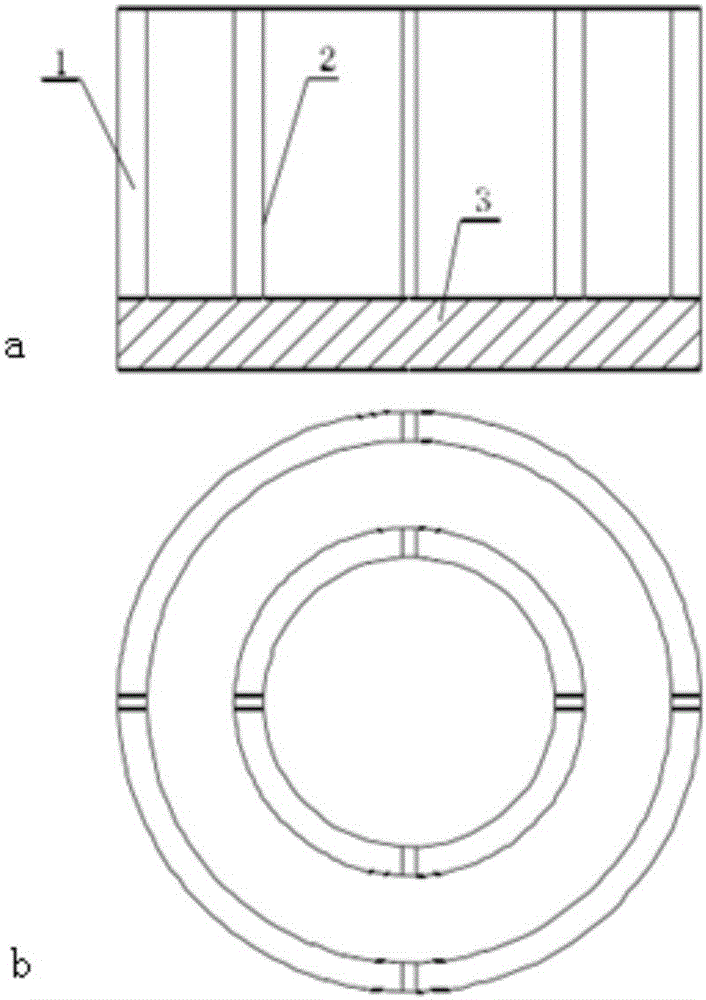

Double-lumen tube connector, preparation thereof and using method

The invention belongs to the technical field of connection and plugging of a memory alloy pipeline, and particularly relates to a double-lumen tube connector, a preparation thereof and a using method. The double-lumen tube connector comprises an outer ring, an inner ring, a middle connecting pillar body and a bottom circle; the middle connecting pillar body is connected with the outer ring and the inner ring at both ends; the outer ring and the inner ring are rib structure or rib-free structure. The double-lumen tube connector combines the advantages of the tube joint and the plugging device, and applies the heating fastening and contraction of the outer ring to generate sustainable fastening of the connected tube; the inner ring carries out the elastic support of the inside diameter of the connected tube, and memory recovery support, so as to realize the pipeline connection and blocking functions, and solve the problems that the existed plugging device is easy to leak after connecting. Meanwhile, the two-side double-lumen tube design is applied to the pipeline connection; the inside of the outer ring and the outside of the inner ring are provided with axial supporting ribs or the peripheral supporting ribs; through the design of the supporting rib, the twisting resistance, fastening connection, sealing and pugging performance can be effectively improved.

Owner:GRIKIN ADVANCED MATERIALS +1

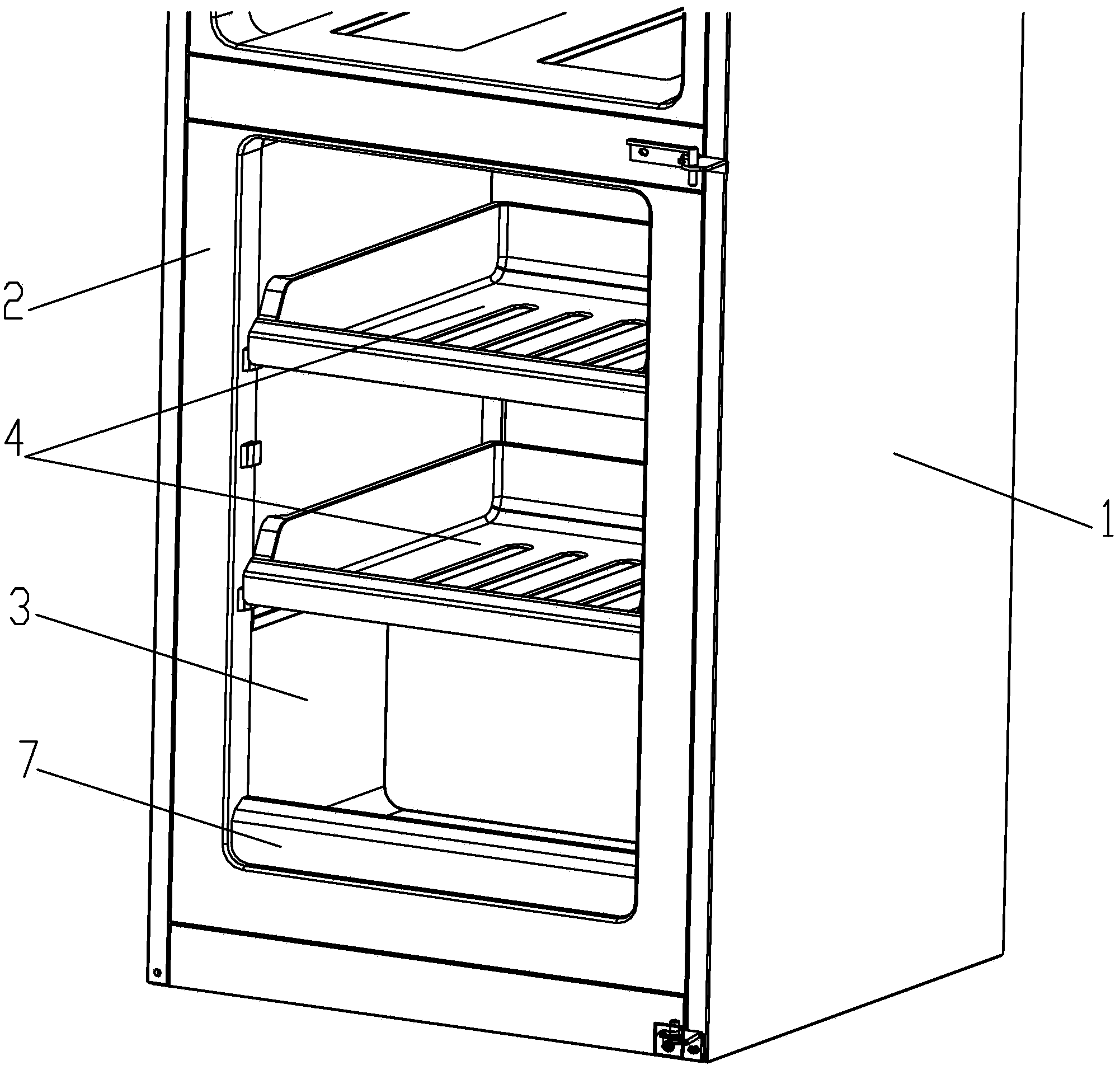

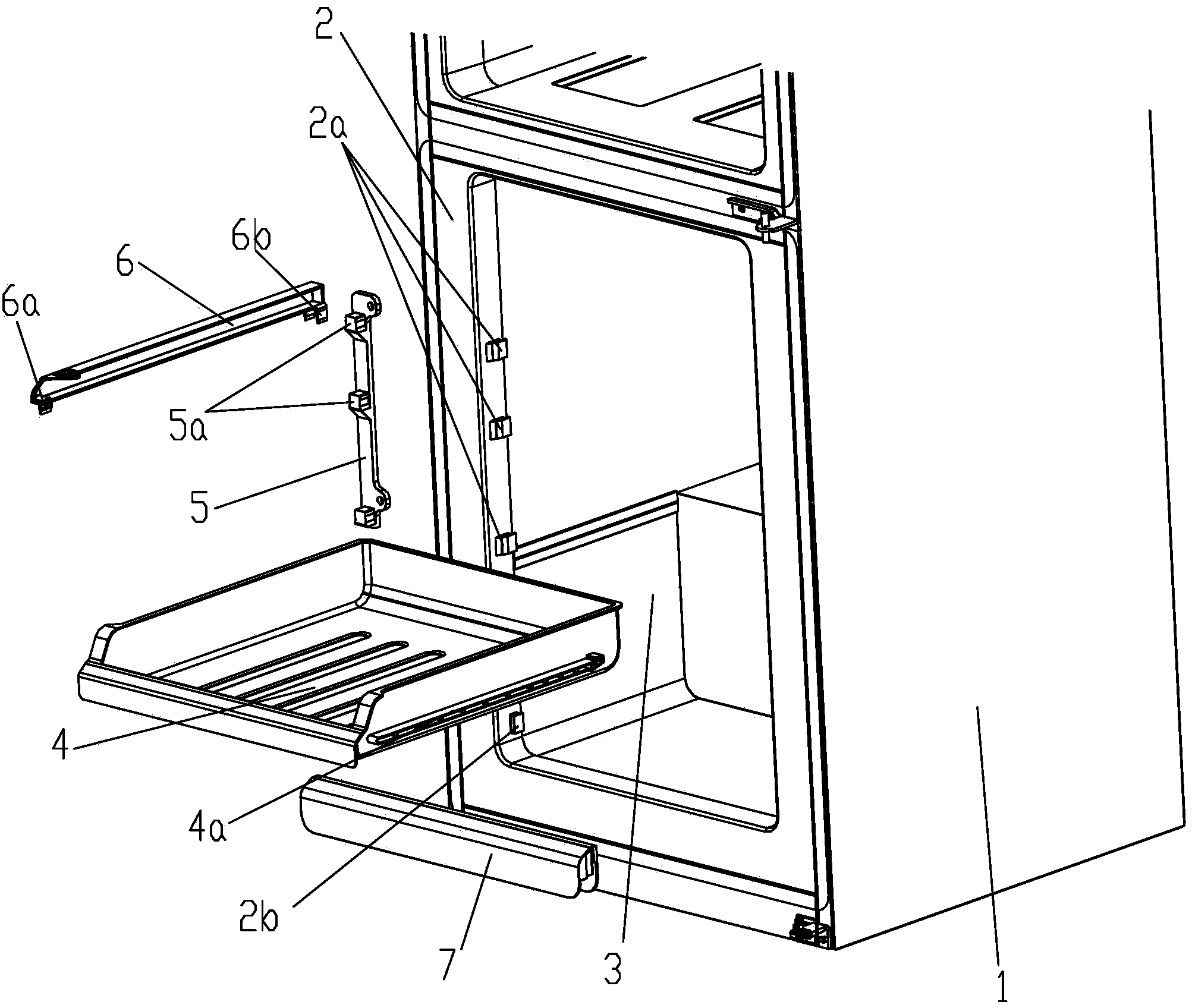

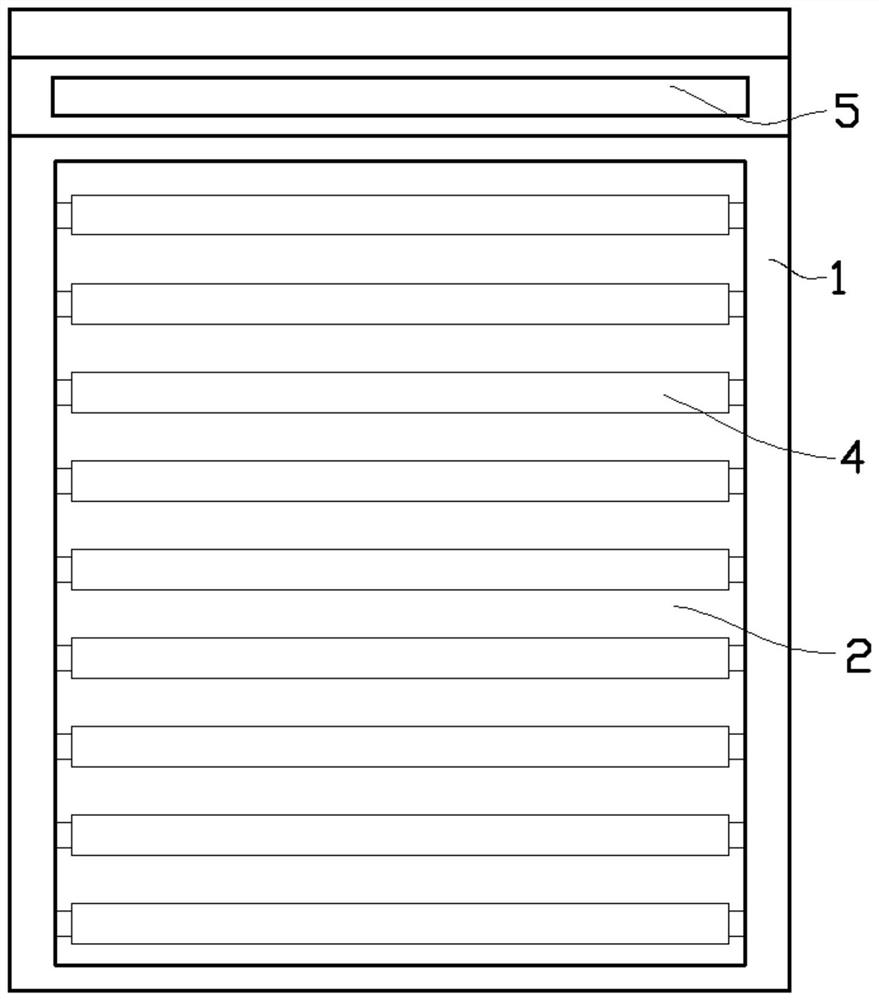

Freezing chamber structure of refrigerator

ActiveCN103868312AIncrease storage spaceSmall footprintLighting and heating apparatusSupportHeat conductingEngineering

The invention provides a freezing chamber structure of a refrigerator. The freezing chamber structure of the refrigerator solves the problems that the storage space of the existing freezing chamber is small, the utilization ratio is low, the drawer structure is heavy and is inconvenient to pick and place, frosting is apt to cause due to non-uniform refrigeration in the chamber, the refrigeration energy consumption is increased, and the like. The freezing chamber structure of the refrigerator comprises a refrigerator body with an inner chamber, wherein a refrigerator door is arranged at the opening in the side part of the refrigerator body, a liner with heat conducting performance is installed in the inner chamber of the refrigerator body, an enclosure frame is arranged at the opening of the refrigerator body, the liner is clamped with the enclosure frame, a freezing evaporator is arranged on the peripheral wall of the liner in a coiling way, a plurality of trays are erected in the liner, supporting and sliding mechanisms are arranged between the trays and the liner, a baffle is clamped at the bottom of the enclosure frame, and a detachable clamping structure is arranged between the baffle and the enclosure frame. The freezing chamber structure of the refrigerator has the advantages that the storage space is expanded and the uniform refrigeration effect is optimized; portable and comfortable picking and placing operation can be realized; the goal of firm positioning and supporting by using fewer and simple parts is realized and the flexible adjustment of the layout division of the internal part of the inner chamber is facilitated.

Owner:河南澳柯玛电器有限公司

Projection equipment with dustproof function

InactiveCN112748629AWith dustproof functionRealize dustproof functionFouling preventionProjectorsDust controlEngineering

The invention relates to projection equipment with a dustproof function. The projection equipment comprises a main body, a filter screen, a lens, a dustproof mechanism and a dust removal mechanism, wherein the dustproof mechanism comprises a driving assembly, a fixing frame and two dustproof assemblies; and the dust removal mechanism comprises a first bearing, a transmission shaft, a first bevel gear, a second bevel gear, two scraping plates, two knocking assemblies and a plurality of convex blocks. The projection equipment with the dustproof function realizes a function of shielding a lens through the dustproof mechanism, so that the lens cannot be exposed in the air, dust cannot cover the lens, therefore, the dustproof function is achieved, the projection effect is prevented from being affected by dust coverage, the reliability of the equipment is improved, the dust removal function of the filter screen is achieved through the dust removal mechanism, and the phenomenon that air circulation of the equipment is affected due to filter screen blockage is avoided.

Owner:曹燕红

Dustproof breathing machine

The invention relates to a dustproof breathing machine. The dustproof breathing machine comprises a bottom plate, a supporting column, a main body, a filter screen and an air outlet pipe and further comprises a dustproof mechanism and a cleaning mechanism, wherein the dustproof mechanism comprises a dustproof box, a first bearing, a rotating shaft, a cover plate, a first magnet block, a second magnet block, a power rod, a disinfection assembly and two limiting assemblies; and the cleaning mechanism comprises a lead screw, a third bearing, a ball screw bearing, a second spring, a connecting shaft and two scraping rods. According to the dustproof breathing machine, the function of shielding the air outlet pipe is achieved through the dustproof mechanism, when the breathing machine is idle, external dust cannot fall on the air outlet pipe, and therefore the air outlet pipe cannot be polluted and cannot be blocked, the influence on oxygen supply work is prevented, the function of cleaning the filter screen is achieved through the cleaning mechanism, and dust is separated from the filter screen through rotation of the scraping rods, so that filter holes in the filter screen cannot be blocked by the dust, the influence on air circulation is avoided, and the practicability of the device is improved.

Owner:陈科

Safety laser welding device with smoke treatment function

InactiveCN111195771AImprove the protective effectRealize the blocking functionLaser beam welding apparatusGear wheelElectric machinery

The invention relates to a safety laser welding device with a smoke treatment function. The device comprises a worktable, a top plate, a connecting column, a welding head and two supporting columns, and further comprises a protection mechanism and two purifying mechanisms, the protection mechanism comprises a protection cover, a limiting assembly and two lifting assemblies, each lifting assembly comprises a first motor, a fixed block, a gear and a rack, and each purifying mechanism comprises a connecting box, a purifying box, a filter net, a suction nozzle, a hose, a connecting pipe, a piston,a driving assembly, a connecting assembly, a cleaning assembly and two waste boxes. According to the safety laser welding device with the smoke treatment function, through the protection mechanism, the sheltering function of the welding head is achieved, sparks generated during welding can be prevented from being splashed to a body of a user, device safety is improved, through the purifying mechanisms, the smoke purifying function is achieved, the smoke is prevented from being directly released into atmosphere, the surrounding air environment is not affected, and the device environment friendliness is improved.

Owner:深圳市琦美创科技有限公司

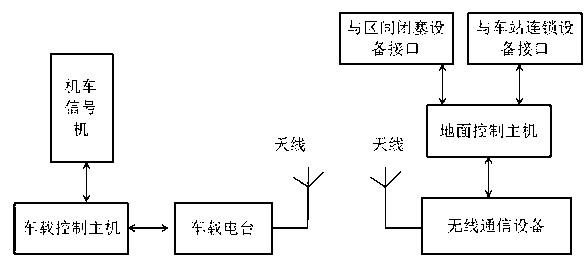

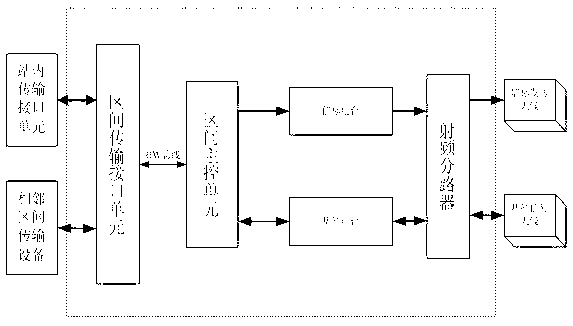

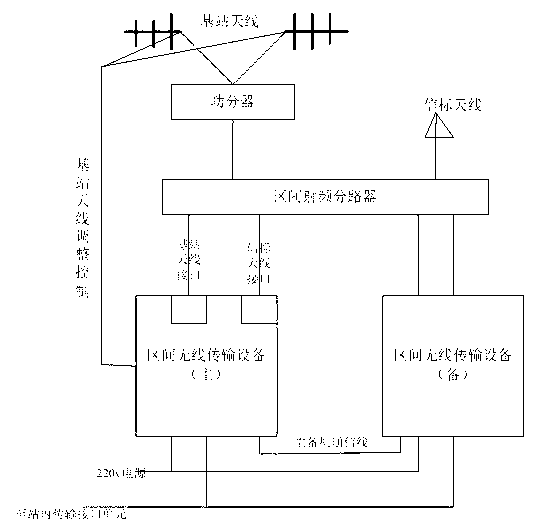

Information transmission system for railway section

InactiveCN102932381AImprove securityIncrease channel capacityTransmissionLoop controlInformation transmission

The invention discloses an information transmission system for a railway section. The system comprises section equipment, onboard equipment and in-station equipment, wherein the section equipment contacts with the onboard equipment in a wireless way, and contacts with the in-station equipment in a wired or wireless way; the section equipment, the onboard equipment and the in-station equipment form closed loop control over a locomotive signal; the section equipment comprises a master control unit, a master control unit backup, a section radio frequency splitter, a power divider, a plurality of base station antennae and beacon antennae; the section radio frequency splitter is connected with the master control unit, the master control unit backup, the power divider and the beacon antennae respectively; the power divider is connected with the base station antennae; and the master control unit is also connected with the master control unit backup and a plurality of antennae. The information transmission system for the railway section has the characteristics of high information transmission capacity, high anti-interference capability and high adaptability.

Owner:广东标顶技术股份有限公司 +1

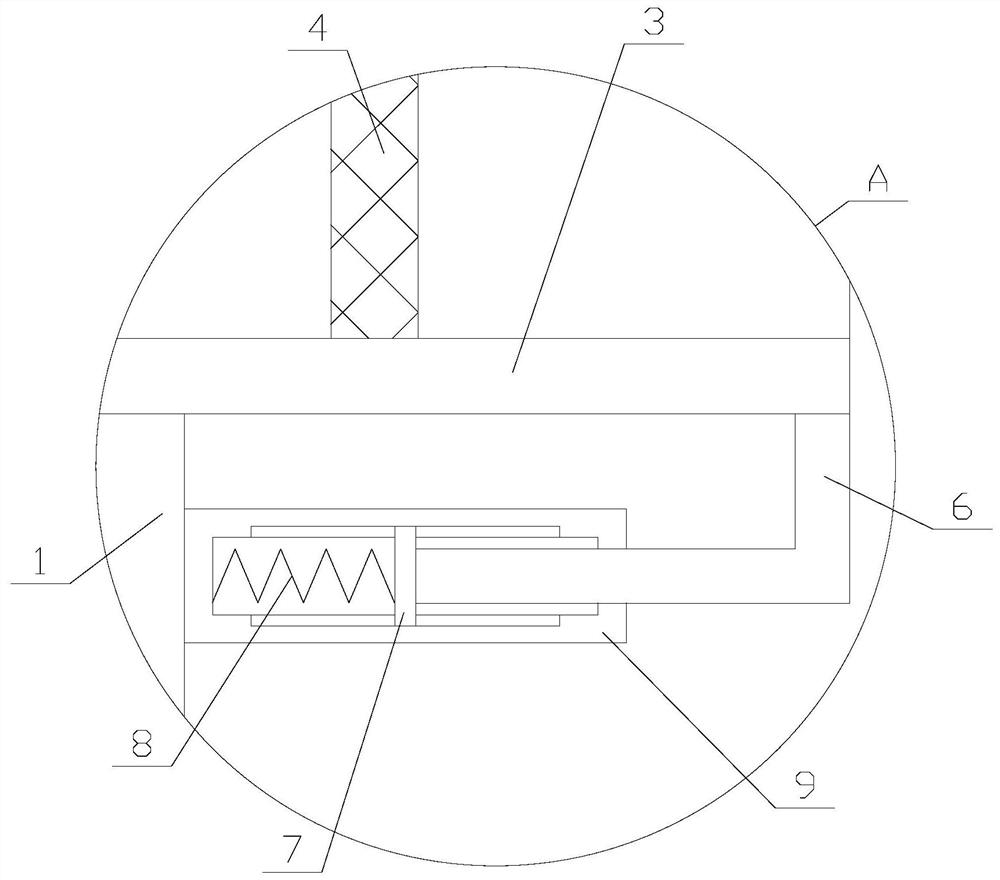

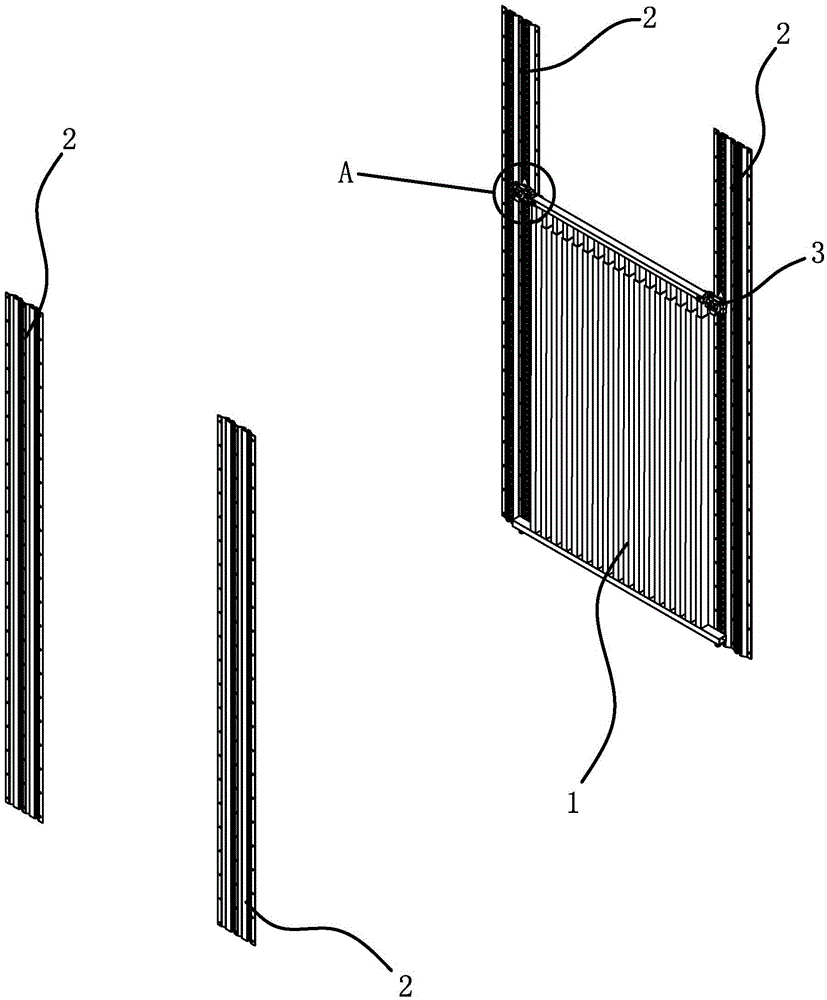

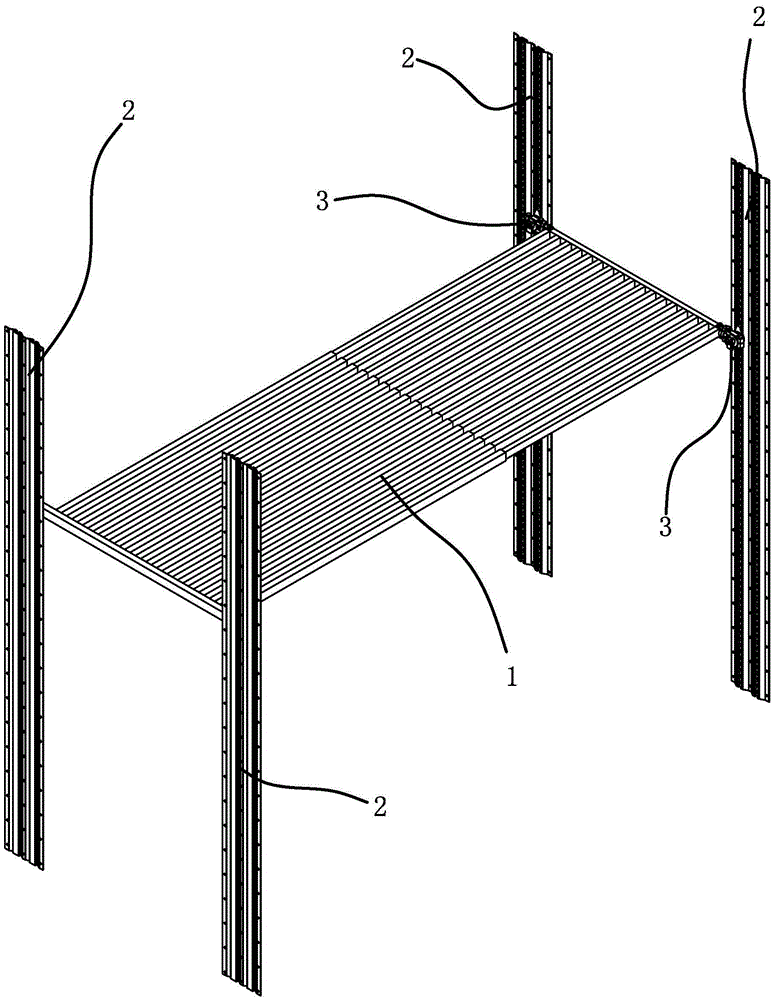

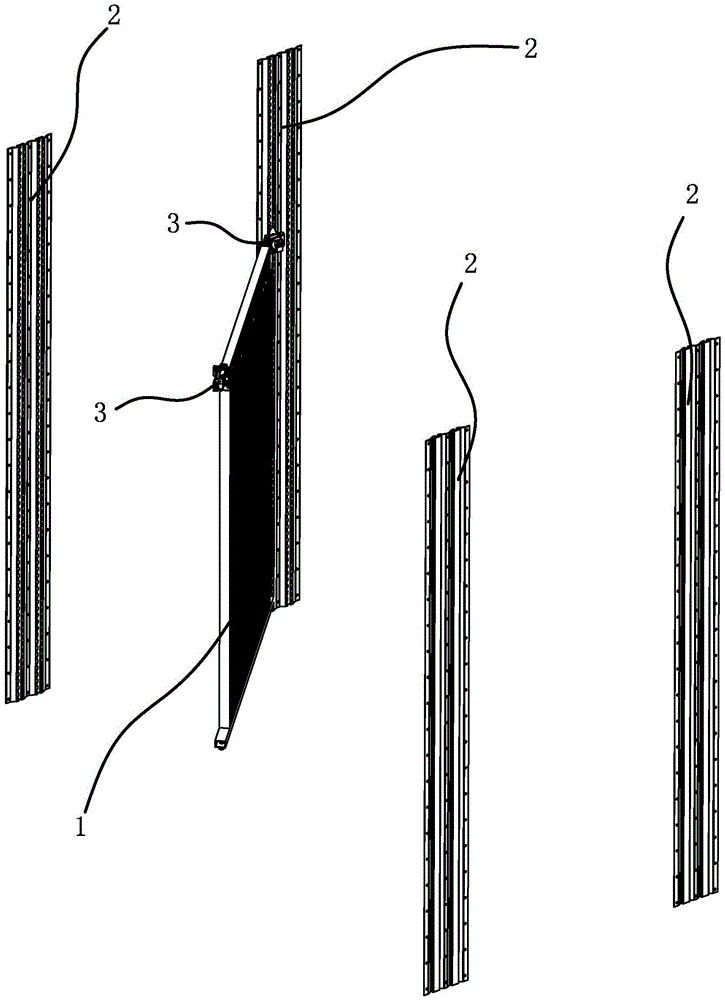

Layering device of container

ActiveCN105460443AImplement layeringRealize the blocking functionLarge containersEngineeringMechanical engineering

The invention provides a layering device of a container and belongs to the field of transportation. The layering device of the container solves the technical problems that an existing layering device of a container lacks of a structure capable of realizing both functions of up-and-down layering and goods blocking, and the like. The layering device of the container comprises a supporting plate and two locks arranged on a side edge of the supporting plate; each lock comprises a lock body, a first support and a second support, wherein the first support is connected to the lock body and capable of rotating relative to the lock body; the first support and the second support are connected through a rotating shaft; a connecting shaft is arranged on the second support, and connected with the supporting plate, such that the supporting plate is capable of rotating relative to the second support along a shaft axis of the connecting shaft; a rotating shaft axis of the first support, the shaft axis of the connecting shaft and a shaft axis of the rotating shaft are perpendicular to each other; and a positioning piece is arranged on the other side edge of the supporting plate. The layering device of the container has the advantage of realizing both the functions of layering the container by using the supporting plate and blocking goods.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Safety valve plate buffer mechanism

InactiveCN108591501ARealize the buffer functionRealize the blocking functionOperating means/releasing devices for valvesNon-rotating vibration suppressionPipingEngineering

The invention provides a safety valve plate buffer mechanism. The safety valve plate buffer mechanism comprises a valve body, a water inlet pipe, a water outlet, a buffer module and an auxiliary blockage module; the water inlet pipe is arranged at the left part of the annular side surface of the valve body; the water outlet is formed in the middle part of the lower end surface of the valve body; the buffer module is arranged at the middle part in the valve body; the buffer module comprises a valve handle, a first lead screw, a first nut base, a valve plate body, a rubber pad, a right spring, acarrier plate, a water leakage hole, a sealing plug and a left spring; the auxiliary blockage module is arranged on the left side of the upper part in the valve body; and the auxiliary blockage module comprises a first bevel gear, a second bevel gear, a base, a connecting rod, a third bevel gear, a second lead screw, a guide groove, a second nut base, a sealing plate and a fourth bevel gear. Compared with the prior art, the safety valve plate buffer mechanism has the beneficial effects of achieving the buffer function of a valve plate body and achieving the blockage function of the water inlet pipe.

Owner:中山达鼎精密工业有限公司

Electronic three-dimensional virtual shutter glass

ActiveCN110529027BEasy to useGuarantee throughElongate light sourcesLighting elementsRotational axisShutter

The invention provides electronic three-dimensional virtual louver glass which comprises a frame body, wherein light transmission glass is respectively assembled at the front side and the back side ofthe frame body; more than two rows of mutually parallel louver blades are assembled between two layers of light transmission glass; the louver blades and the frame body are rotationally assembled; the louver blades are made of atomization glass; the louver blades are connected with a control circuit arranged in the frame body through rotating shafts at two ends; more than two rows of lamp stripsparallel to the louver blades are assembled at the back surfaces of the louver blades; more than five independent lamp heads at equal distances are designed on each lamp strip; the luminous surface ofeach lamp strip is attached to the back surface of the louver blade; and the lamp strips are connected into the control circuit through the rotating shafts arranged at two ends of the louver blades.When the louver glass is used, the sight line blocking function can be realized through the atomization glass; and meanwhile, a three-dimensional pattern with a multilayer structure can be formed in the three-dimensional space.

Owner:连云港感瓷电子科技有限公司

A fiber grating soil pressure testing device for civil engineering

ActiveCN110231113BEasy to assemble and disassembleEasy to retractForce measurement by measuring optical property variationFiberArchitectural engineering

The invention discloses an optical fiber grating soil pressure testing device for civil engineering, which includes a base body, a support foot, a retractable structure, a detection head and a disassembly structure. A retractable structure is provided on the side wall, and a detection head is arranged inside the retractable structure, a plate body is provided at one end of the detection head, and a disassembly structure is fixed on the end of the plate body close to the detection head, and the The other end is provided with a connecting wire, and the end of the connecting wire far away from the plate body is connected to the base body, a clamping structure is fixed on the side wall of the retractable structure on the side of the detection head, and the outer wall of the base body outside the retractable structure is installed There are occluded structures. The present invention not only realizes the function of easy disassembly and assembly of the pressure testing device, realizes the function of convenient retraction of the pressure testing device, but also realizes the function of dust shielding of the pressure testing device.

Owner:大连海蓝通信信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com