Sand spreading device of bullet train unit

A technology for EMUs and sandboxes, applied in locomotives and other directions, can solve the problems of sand discharge speed control, inability to guarantee uniformity, etc., to ensure uniformity, reduce the number of dismantling and cleaning work, and reduce the difficulty and cost of daily maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

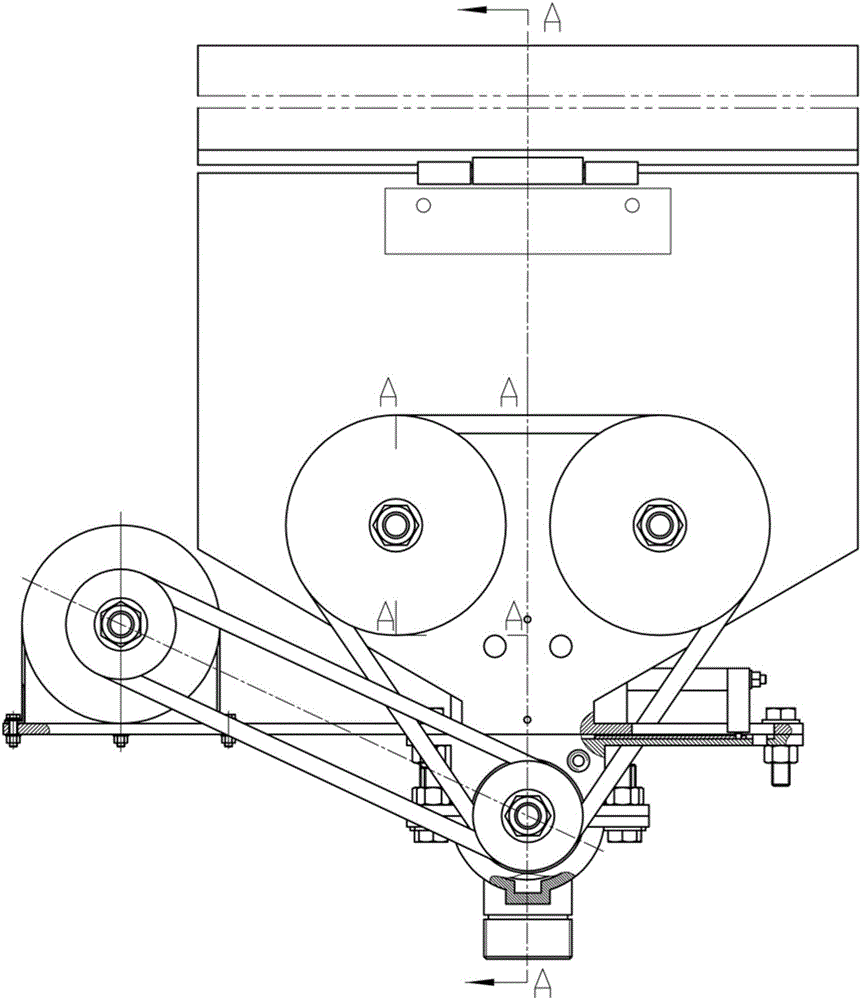

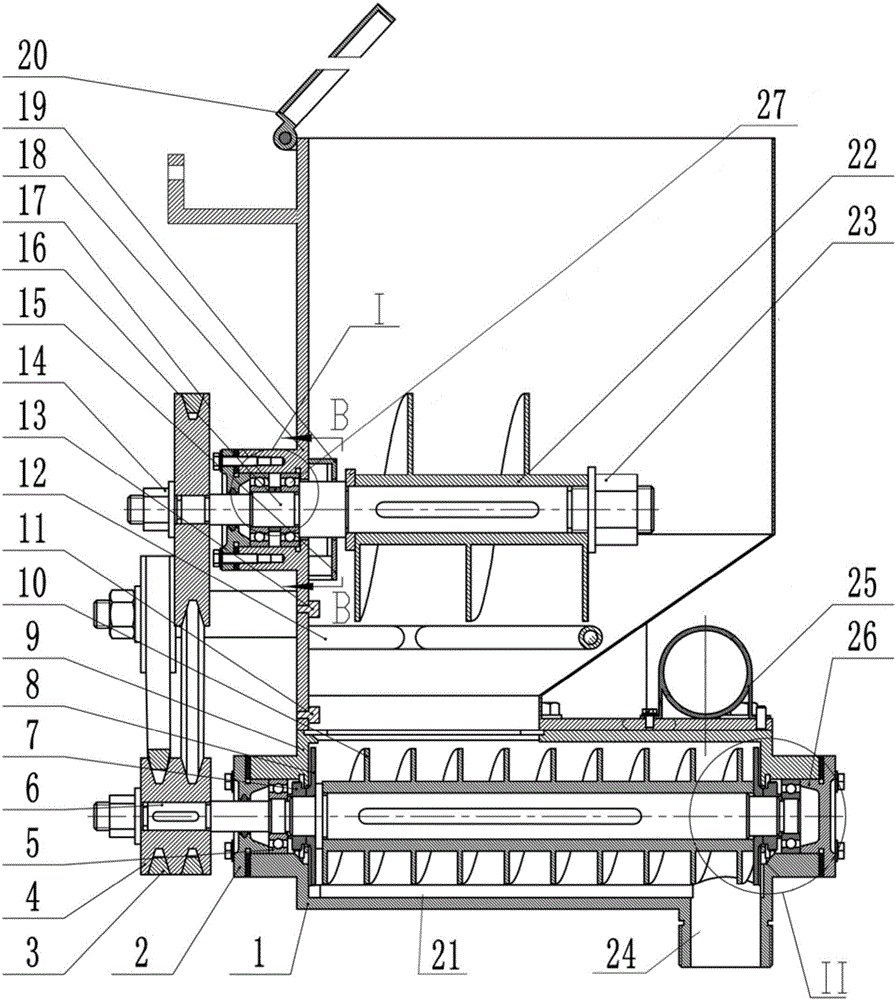

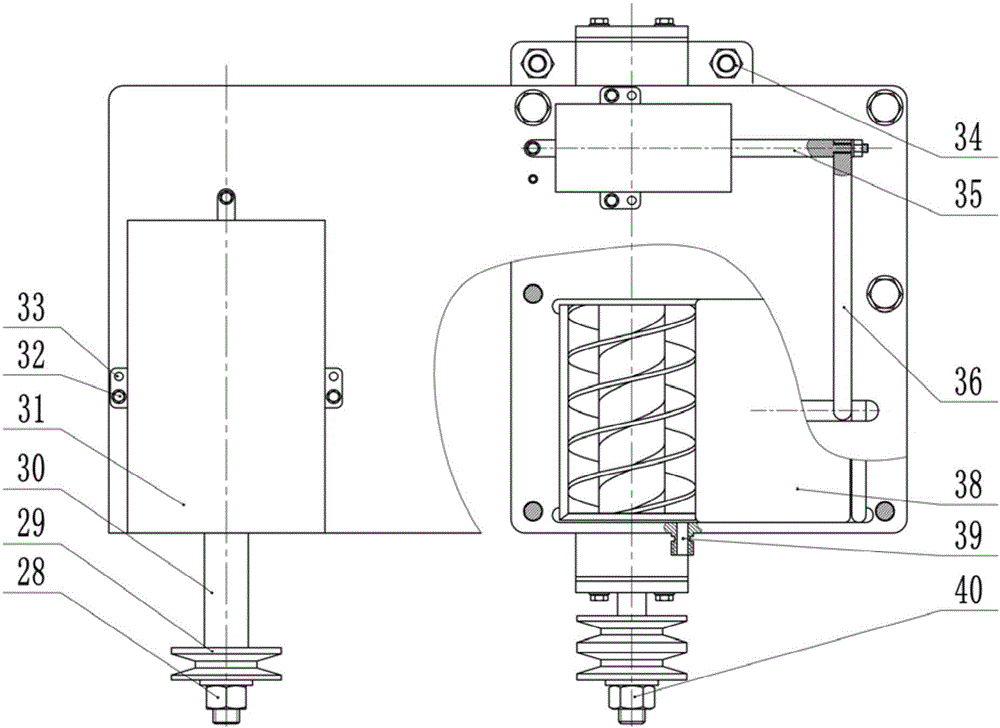

[0023] Such as figure 1 , 2 , 3, 4, 5, 6, and 7 show a kind of EMU sand spreading device, including sand box body Ⅰ1, through cover 2, belt 3, pulley Ⅰ4, ball bearing Ⅰ5, sand sending shaft 6, and sand prevention ring Ⅰ7 , anti-sand ring Ⅱ8, sand box body Ⅱ9, spiral piece Ⅰ10, temperature sensor 11, heater 12, position sensor 13, bolt 14, sealing box Ⅰ15, sand mixing shaft 16, pulley Ⅲ17, sand box body Ⅲ18, sealing box Ⅱ19 , sand box cover 20, long groove 21, screw piece II 22, nut 23, sand sprinkling port 24, air cylinder 25, end cover 26, ball bearing II 27, nut 28, pulley II 29, motor shaft 30, speed regulating motor 31, Bolt 32, pin 33, bolt 34, cylinder rod 35, push rod 36, sand return tank 37, baffle plate 38, hot air source interface 39, nut 40, rubber ring 41, sealing box guide rail groove 42, described sand box body Ⅰ1, sandbox body Ⅱ9, and sandbox body Ⅲ18 are sequentially fastened and connected by bolts 34 to form a sandbox body. A reversible sandbox cover 20 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com