Safety valve plate buffer mechanism

A technology of buffer mechanism and safety valve, applied in sliding valve, valve details, valve device and other directions, can solve the problems of limited service life, deformation of valve plate, weak resistance to impact force of valve plate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

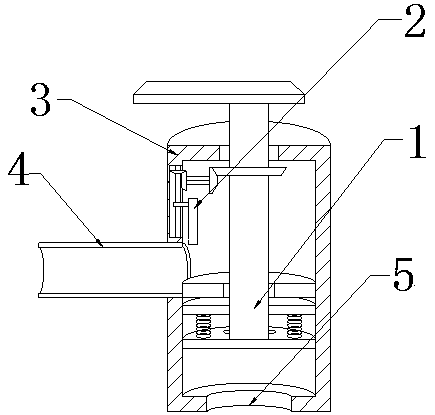

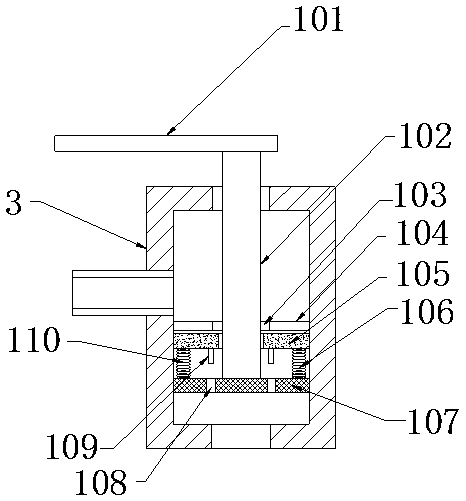

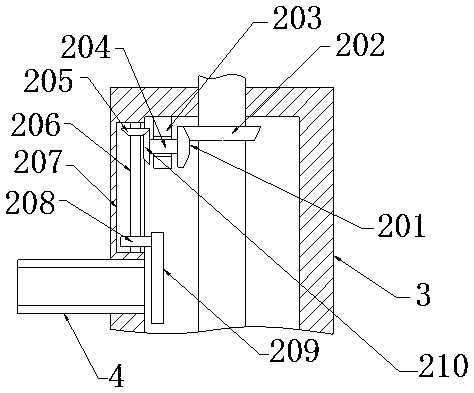

[0019] see Figure 1-Figure 3 , the present invention provides a technical solution: a safety valve plate buffer mechanism, including a valve body 3, a water inlet pipe 4, a water outlet 5, a buffer assembly 1 and an auxiliary sealing assembly 2, and the water inlet pipe 4 is arranged on the valve body 3 in an annular On the left side of the side, the water outlet 5 is set in the middle of the lower end of the valve body 3, and the buffer assembly 1 is arranged in the middle of the valve body 3. The buffer assembly 1 includes a valve handle 101, a screw rod 102, a nut seat 103, and a valve plate Body 104, rubber pad 105, right spring 106, carrier plate 107, leak hole 108, sealing plug 109 and left spring 110, auxiliary sealing assembly 2 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com