Patents

Literature

56results about How to "Does not affect opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

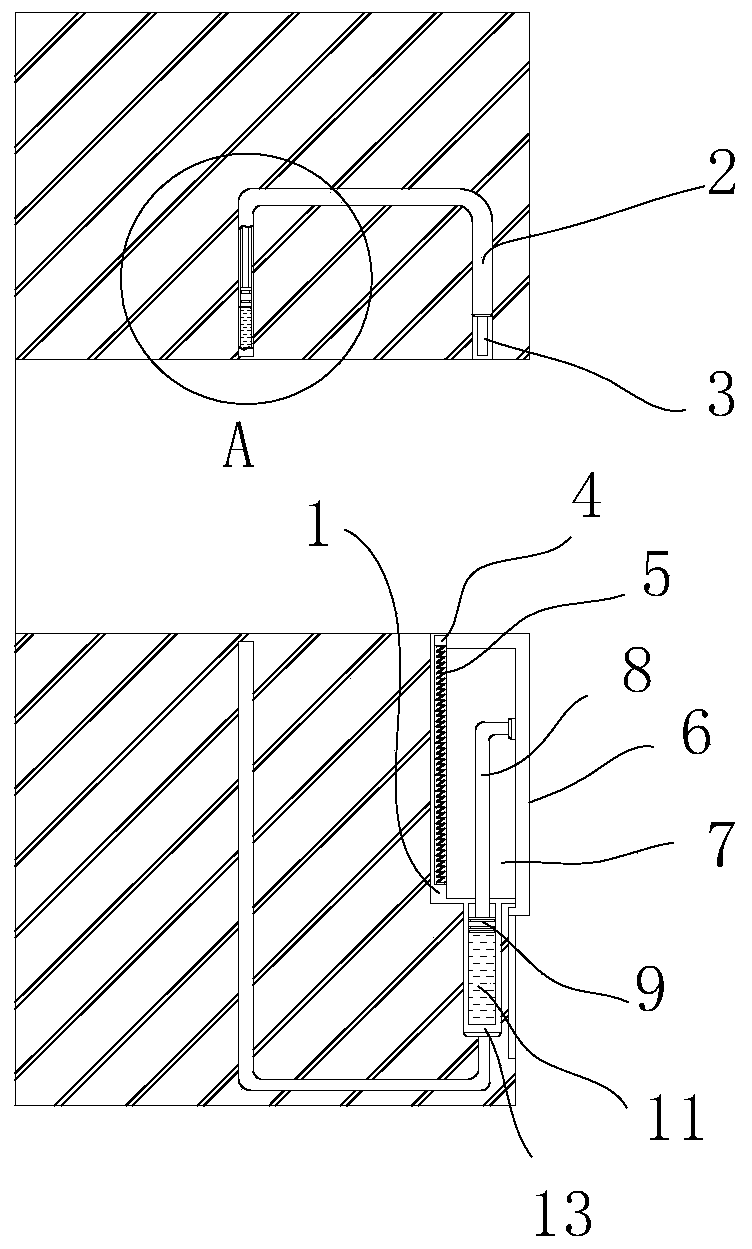

Multi-stage fracturing sliding sleeve device and using method thereof

ActiveCN102704904AEasy to openTurn on the implementationFluid removalWell/borehole valve arrangementsPetroleum engineeringBarrel Shape

The invention relates to a multi-stage fracturing sliding sleeve device and a using method thereof. The multi-stage fracturing sliding sleeve device is characterized by comprising an upper pipe column joint, a sleeve body, a lower pipe column joint, a switch sleeve and a reducing tee, wherein the lower part of the upper pipe column joint is connected with the upper part of the sleeve body; the lower part of the sleeve body is connected with the upper part of the lower pipe column joint; the sleeve body is in a circular barrel shape; a plurality of side holes are formed at the circumference near the upper position of the sleeve body at intervals; a circle of steps are formed at the inner side near to the lower position of the sleeve body; the switch sleeve which is also in a circular barrel shape is arranged in the sleeve body and below the upper pipe column joint and is fixed with the sleeve body through a plurality of pins; the inner diameter of the lower part of the switch sleeve is larger than that of the upper part of the switch sleeve; the reducing tee is arranged at the inner lower part of the switch sleeve; the circumference of the upper part of the reducing tee is fixedly connected with the switch sleeve through the plurality of pins; a plurality of cutting slits are formed at the lower part of the reducing tee; sealing mediums are filled in each cutting slit; the top of the lower pipe column joint is in a taper shape; a circle of steps bulging inwards are arranged at the bottom of the reducing tee, and the outer diameter of the top of the lower pipe column joint is smaller than that of the bottom of the reducing tee.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Hydraulic opening four-link type top cap device

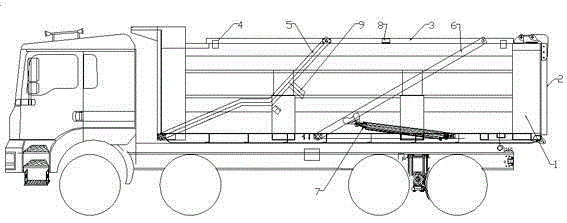

A hydraulic opening four-link type top cap device comprises a compartment. The rear end of the compartment is provided with a rear door, the top of the compartment is provided with an overturning top cap, the front and rear sides of the compartment are provided with top cap overturning devices which comprise front overturning arms and rear overturning arms, the upper ends of the front overturning arms and the rear overturning arms are connected with the side edge of the top cap through revolving axles, the lower ends of the front overturning arms and the rear overturning arms are connected with the compartment through revolving axles, overturning oil cylinders are arranged on the outer side of the rear end of the compartment, telescopic rods in the overturning oil cylinders are hinged to the rear overturning arms through joints, overturning positioning blocks are arranged on the side edge of the top cap, the front overturning arms are provided with support blocks at the positions corresponding to the overturning positioning blocks, and after the top cap is overturned through the top cap overturning devices, the overturning positioning blocks and the support blocks are mutually matched to limit the overturned top cap, to make the top cap to be positioned above the cab. The device is simple in debugging, high in reliability, good in stability, convenient to install and use and easy in maintenance.

Owner:驰田汽车股份有限公司

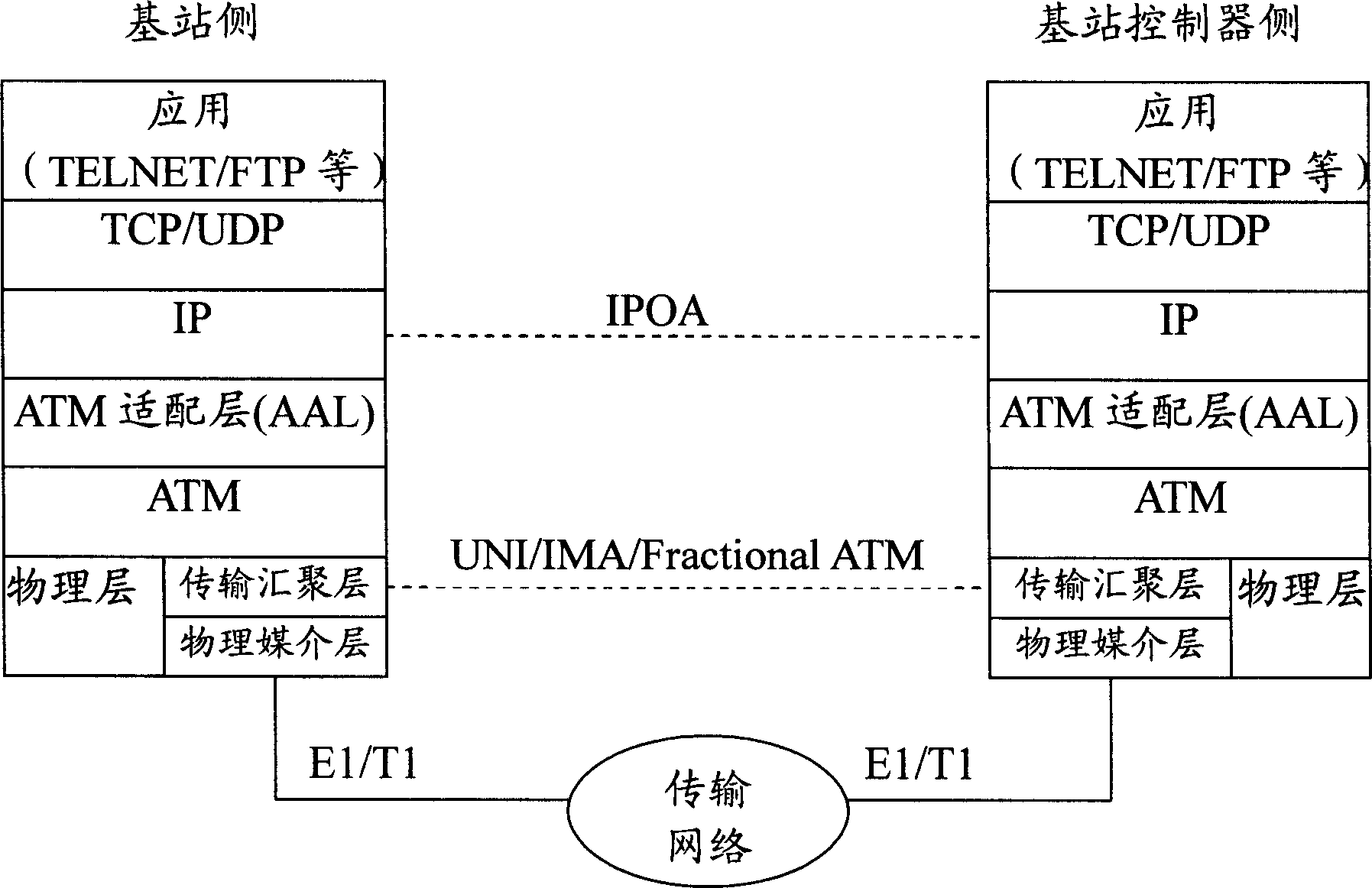

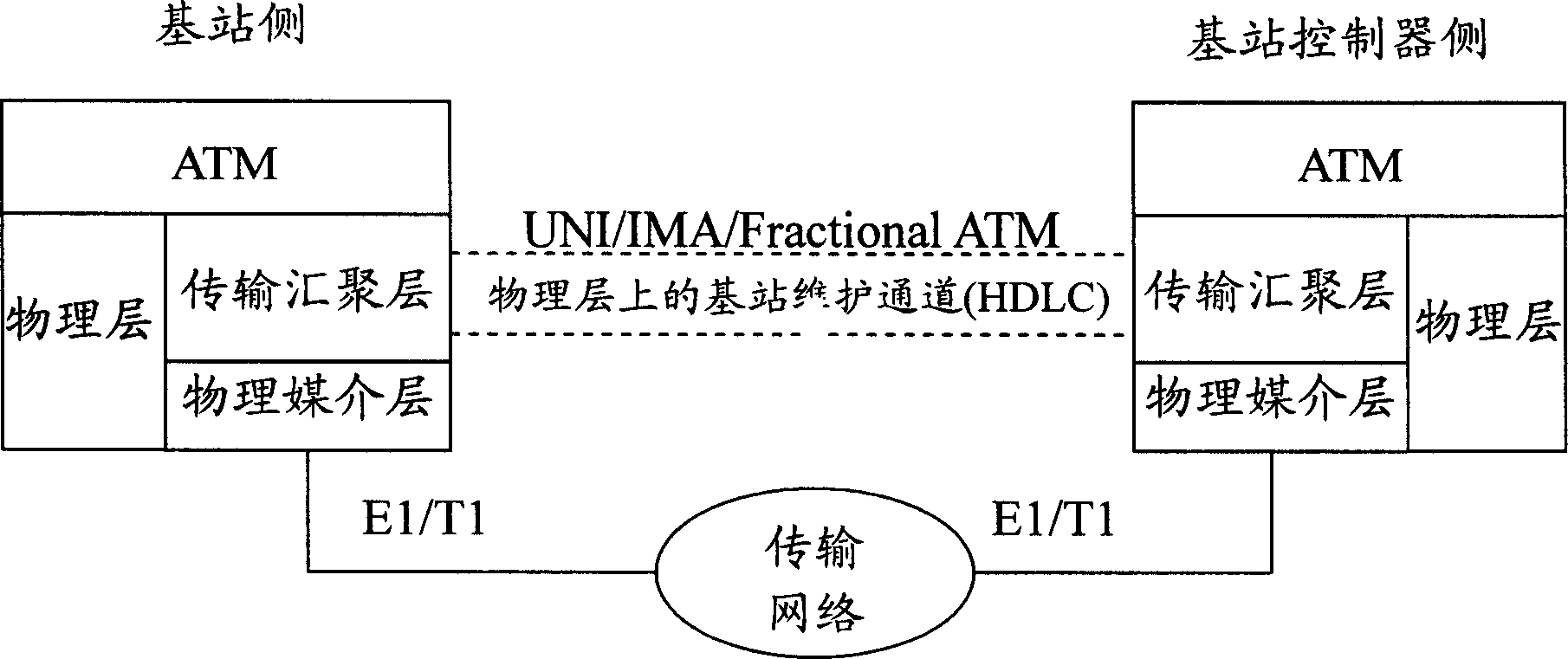

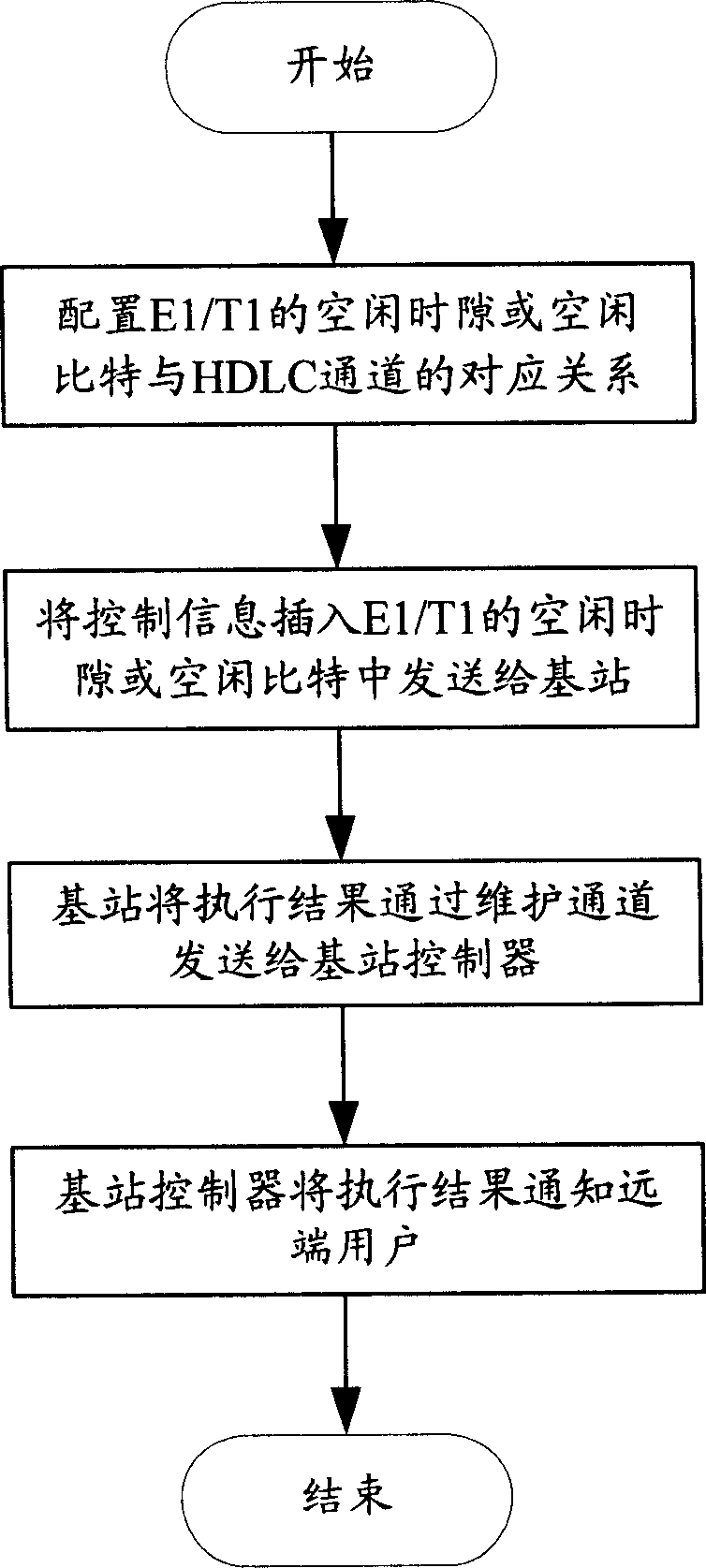

Method for remote maintaining 3G base station

InactiveCN1845629ADoes not affect openingDoes not affect the IPOA maintenance channelRadio/inductive link selection arrangementsWireless communicationThird generationData link

The disclosed method to remote maintain 3G base station comprises: configuring the correlation between advanced data link and control link to free time slot or bit on E1 / T1 port of base station; for maintenance, inserting maintenance information between normal free time slot or bit by RNC to send to the base station by the data link and control link. This invention has no effect to current IUB and IPOA, and has well performance with low cost.

Owner:GLOBAL INNOVATION AGGREGATORS LLC

Soft box for packaging cigarette capable of opening and closing repeatedly

InactiveCN101037158ARepeated opening and closing will not affectDoes not affect openingContainers for flexible articlesStampsManufacturing technologyAdhesive glue

The invention provides a cigarette packaging soft box capable of being opened and closed repeatedly, belonging to the cigarette package manufacturing technology field. The invention comprises a layer of lining paper, a layer of trademark paper, and a layer of transparent paper with an unsealing pull tape from inside to outside, the opening end of the trademark paper is fixed by a seal which seals the opening end of the trademark paper through a connecting device capable of repeatedly opening and closing. The connecting device capable of repeatedly opening and closing can be an adhesive button or a snap or a magnetic button. The invention changes adhesion manner of the soft package cigarette seal from the disposable adhesion into the adhesive glue adhering for multiple times, and the unsealing position of the transparent paper is adjusted correspondingly, the adhesive glue layer employs special raw material particularly suitable for the special weather of the North, and the invention has advantages of easily being opened, moderate adhesion degree, strong stability, reasonable structure, convenient manufacturing and being opened and closed repeatedly.

Owner:CHINA TOBACCO SHANDONG IND

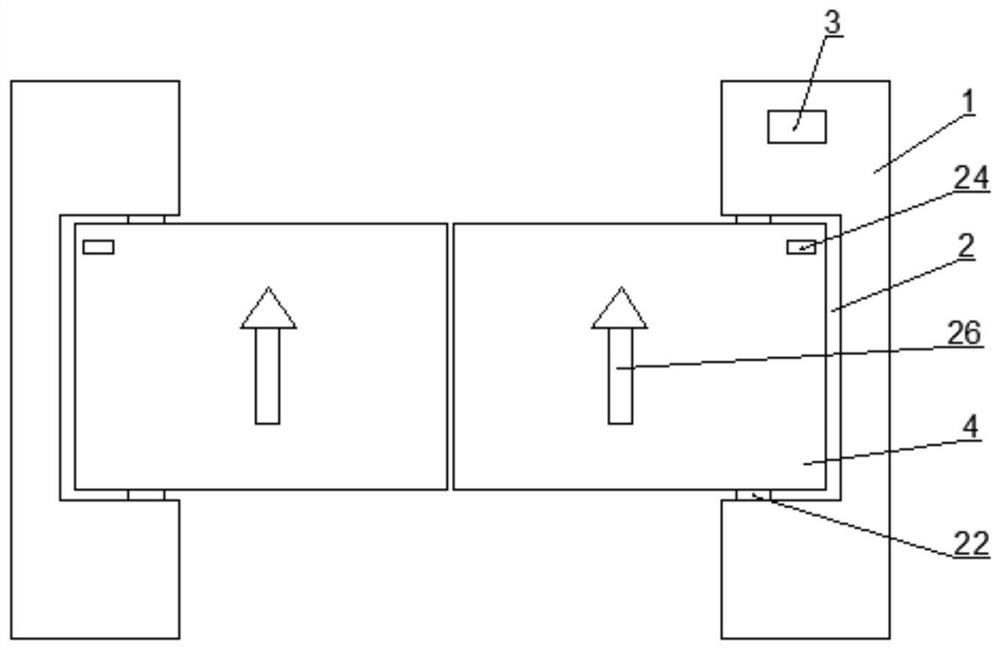

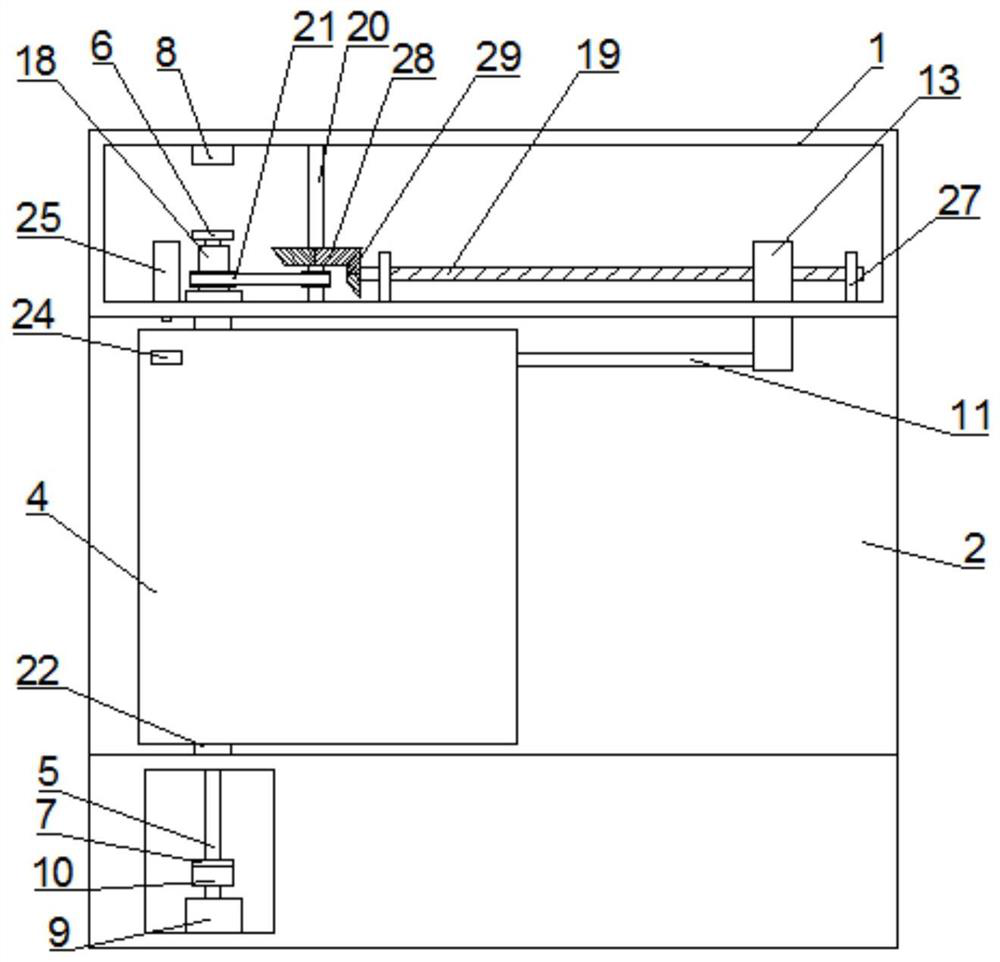

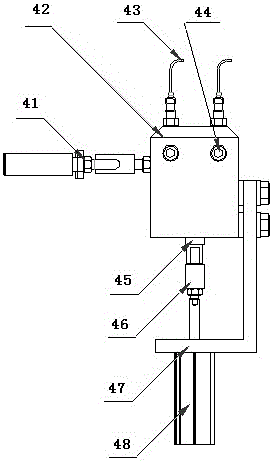

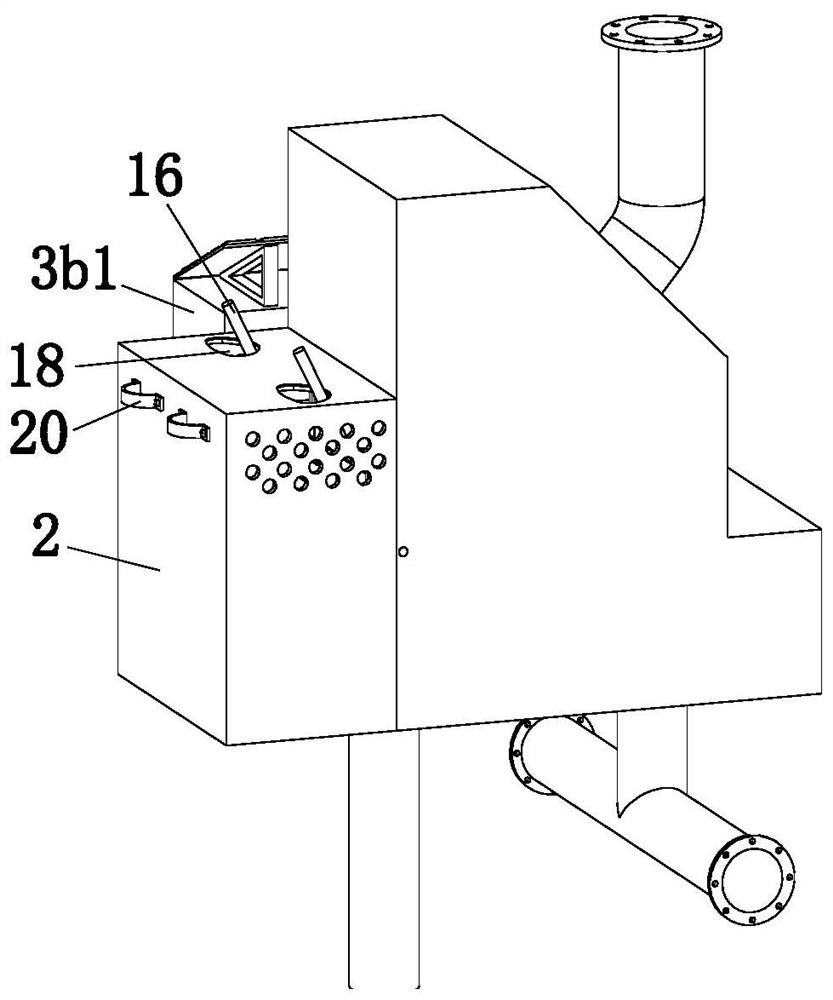

Mixing equipment for coating material dilution

ActiveCN111013435AControl the amount of injectionAvoid residueTransportation and packagingRotary stirring mixersProcess engineeringMechanical engineering

The invention relates to mixing equipment, particularly to mixing equipment for coating material dilution. The technical problem to be solved by the invention is how to provide mixing equipment used for coating material dilution and capable of accurately controling the injection amount of a diluent and preventing the diluent from being too much or too little. The mixing equipment comprises a box body frame, a stirring box and the like, wherein a placing groove for placing a container is formed in the box body frame, and the stirring box is fixedly connected to the box body frame. According tothe invention, a proper amount of a diluent can be injected into the stirring box through a quantitative feeding assembly, so that the injection amount of the diluent can be accurately controlled, andthe diluent is prevented from being too much or too little; the inner wall of the stirring box can be cleaned through a cleaning mechanism, so that the coating material is prevented from remaining inthe stirring box so as not to affect the next use; and the upward moving distance of a pull rod can be adjusted through an adjusting mechanism, so that a proper amount of the diluent can be sucked inaccurately.

Owner:陕西龙义泽环保建材有限公司

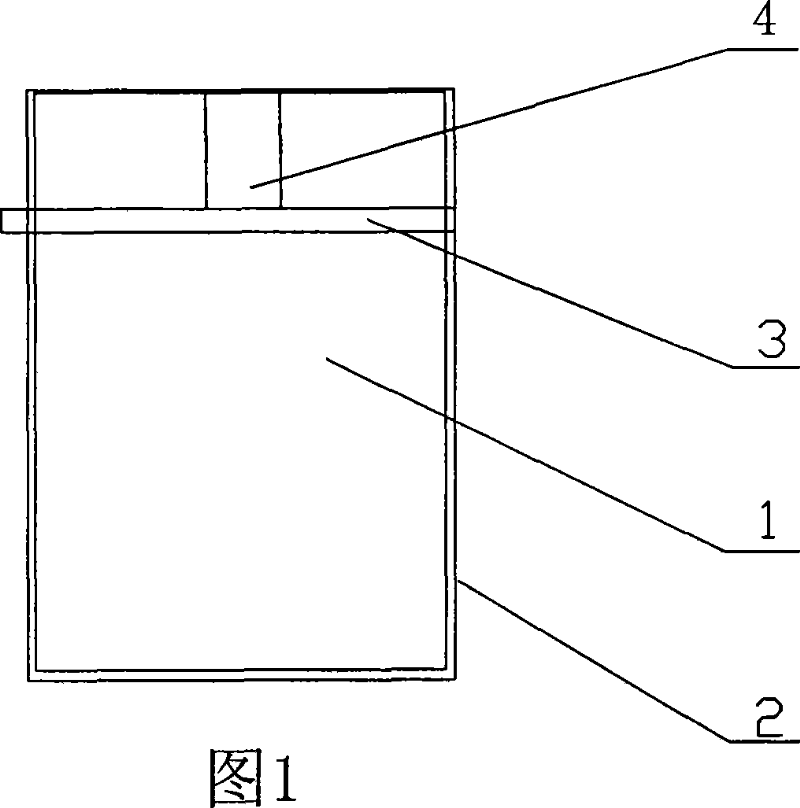

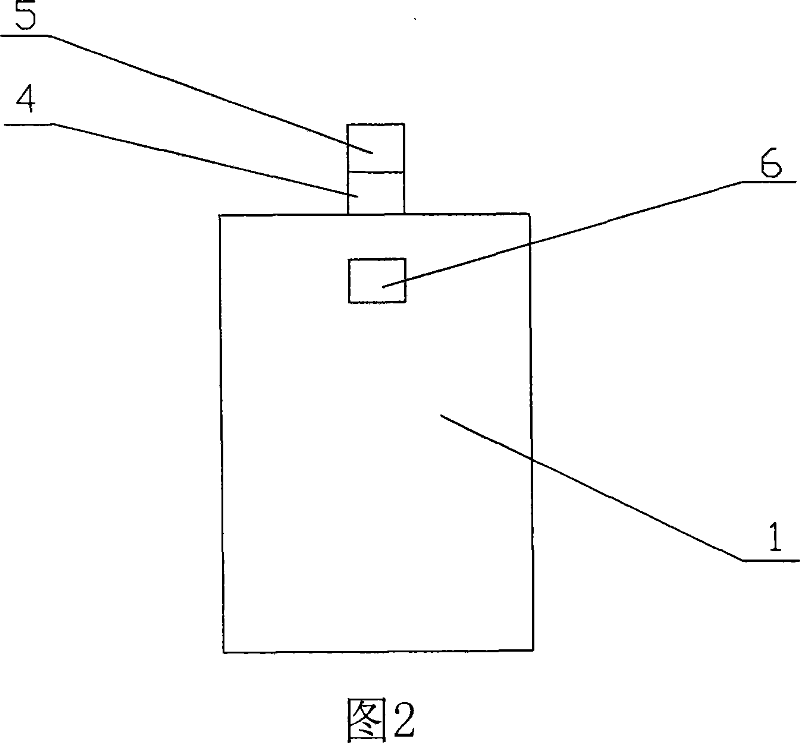

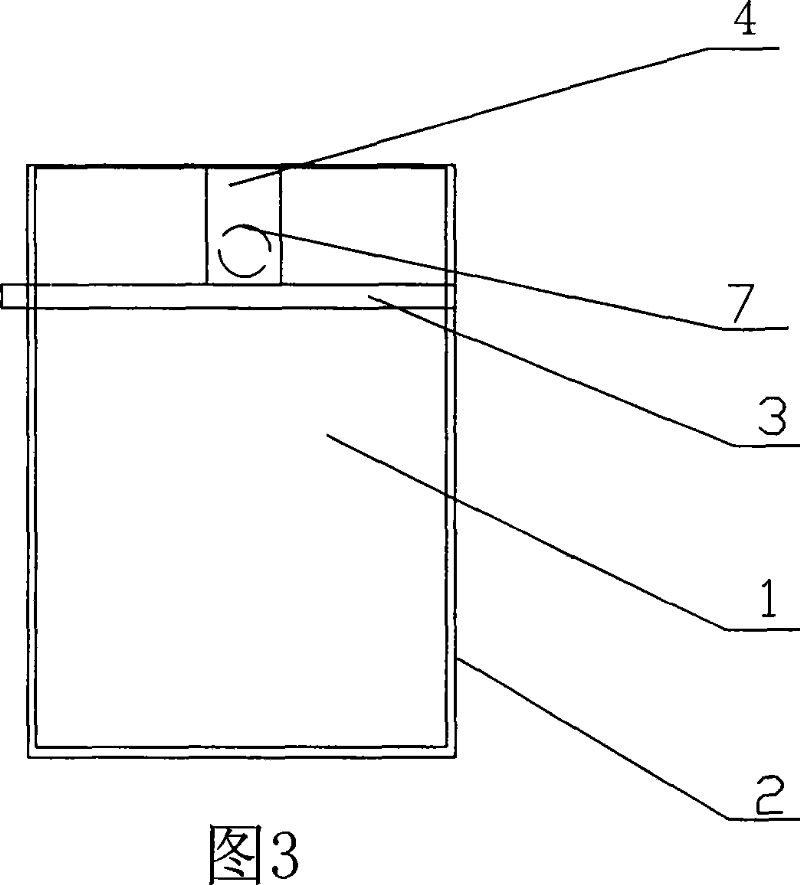

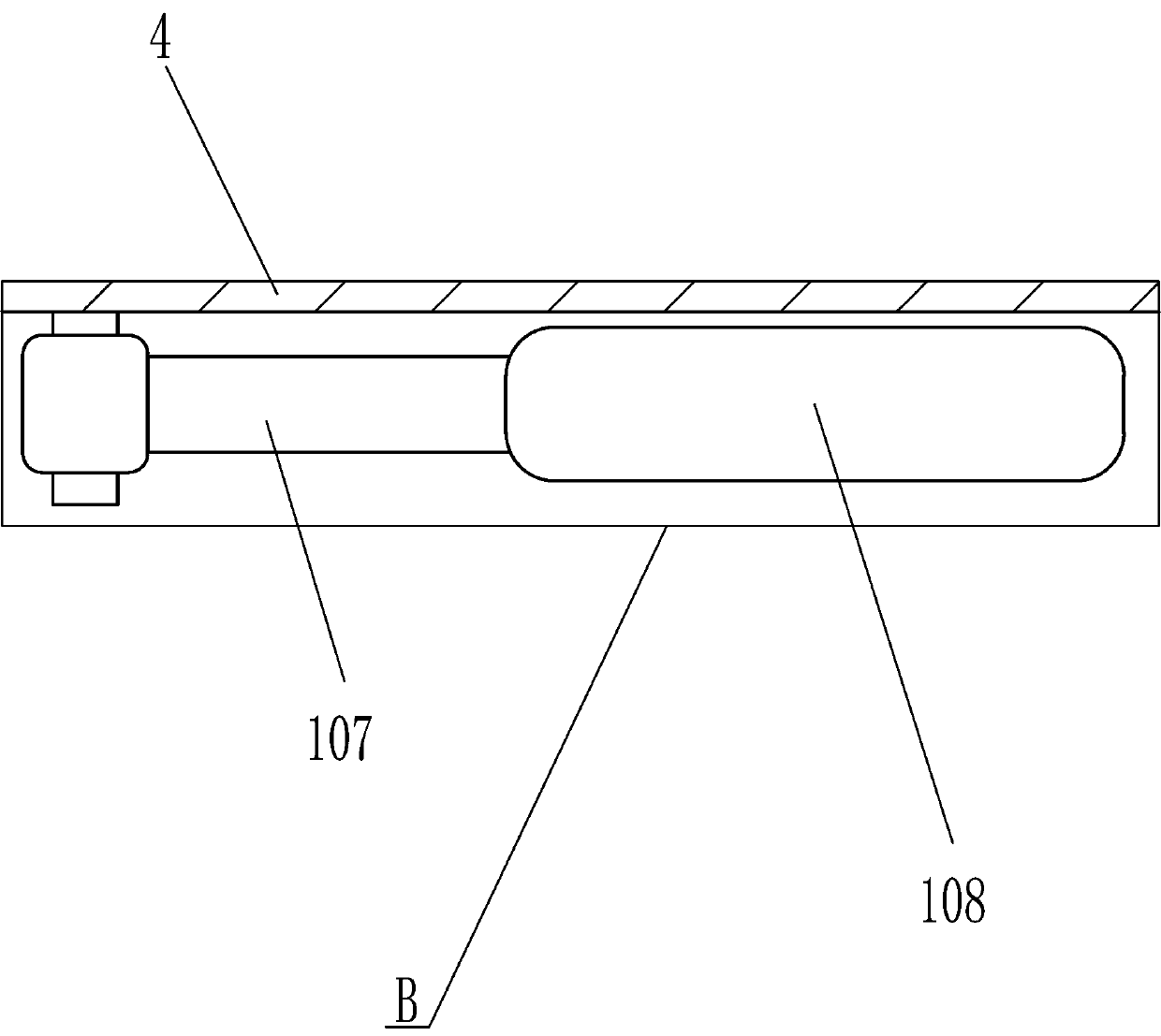

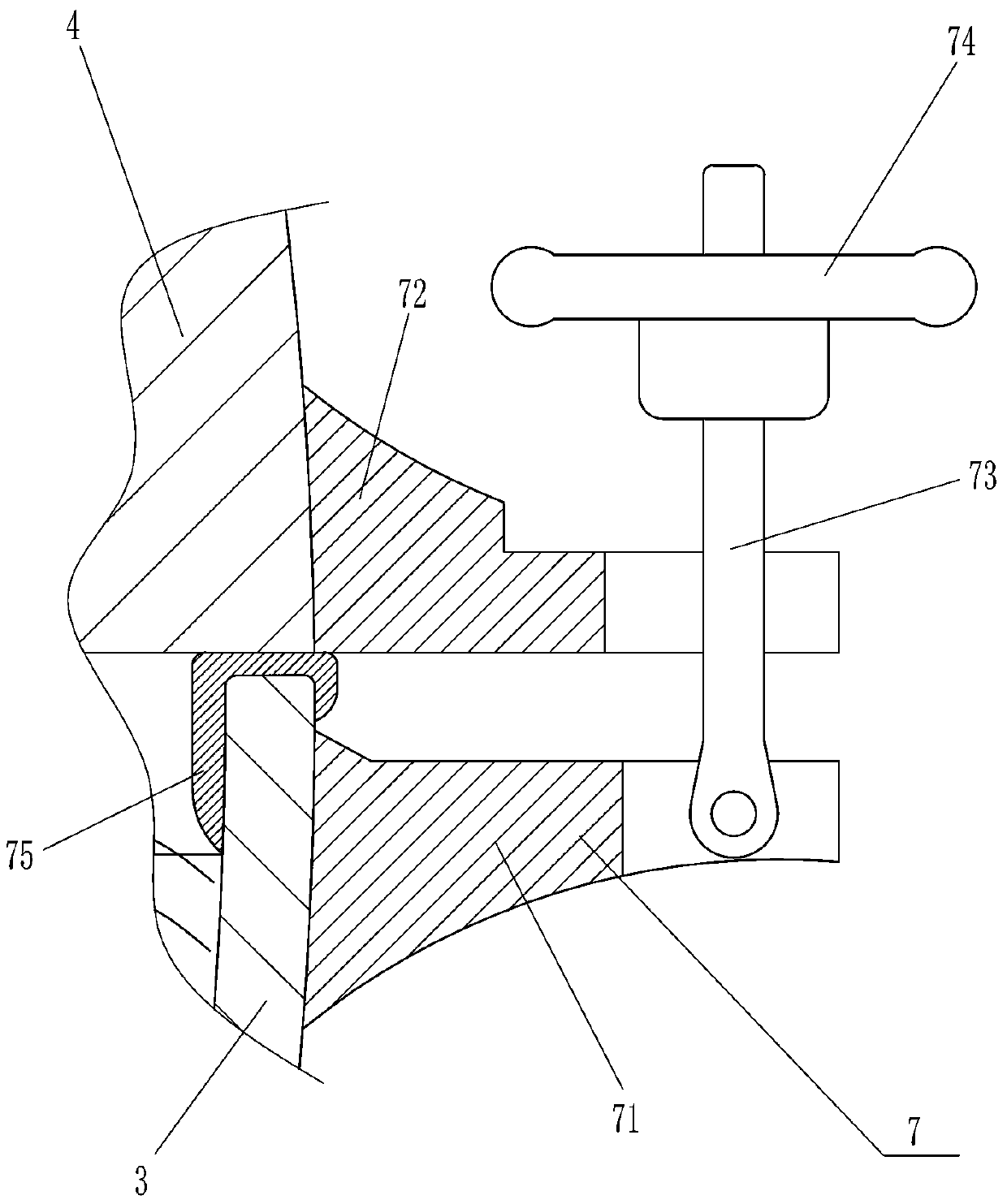

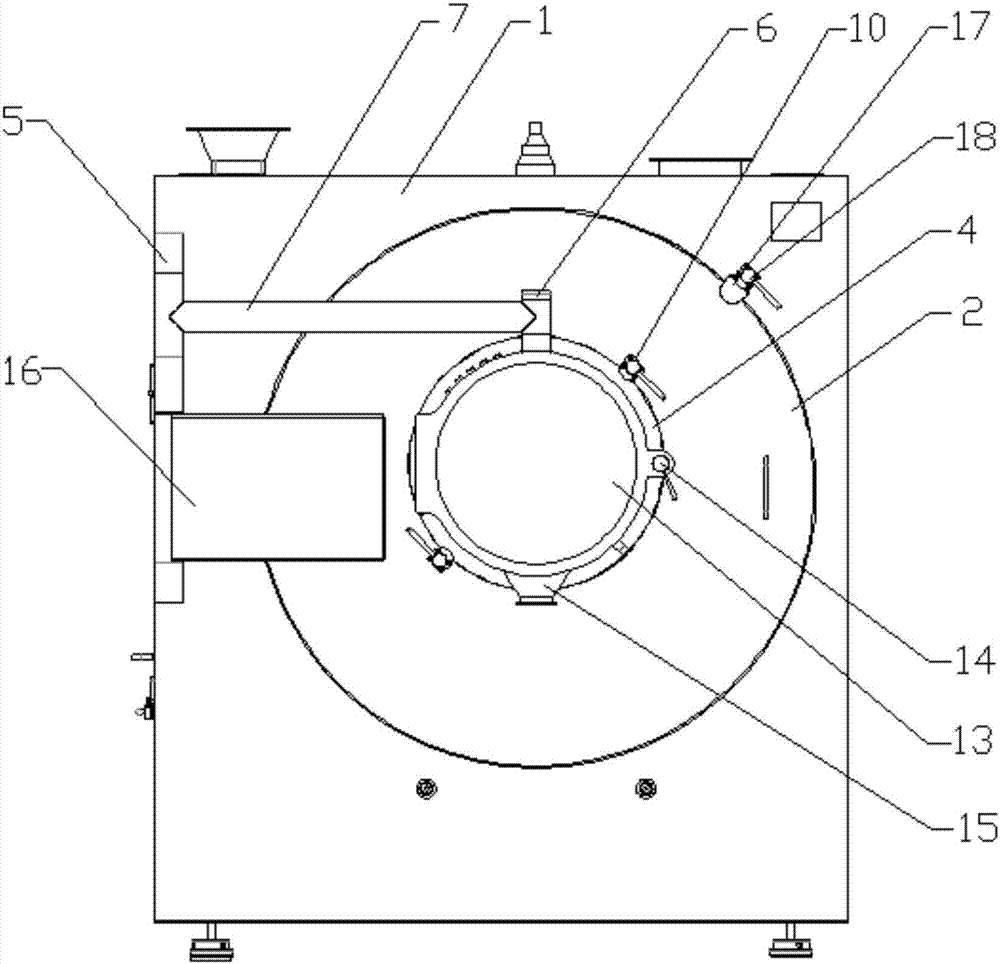

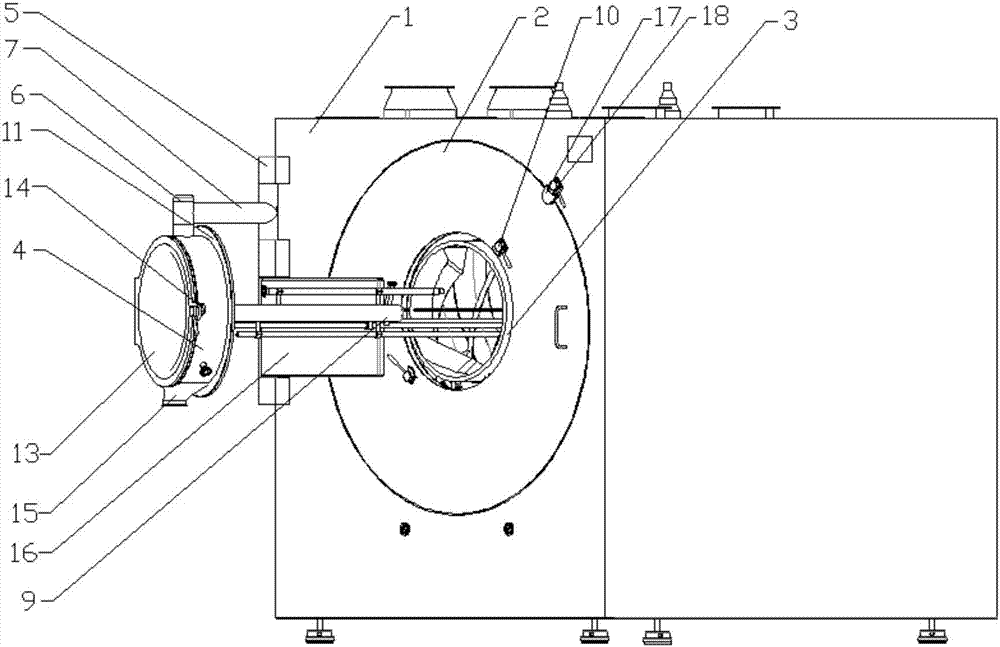

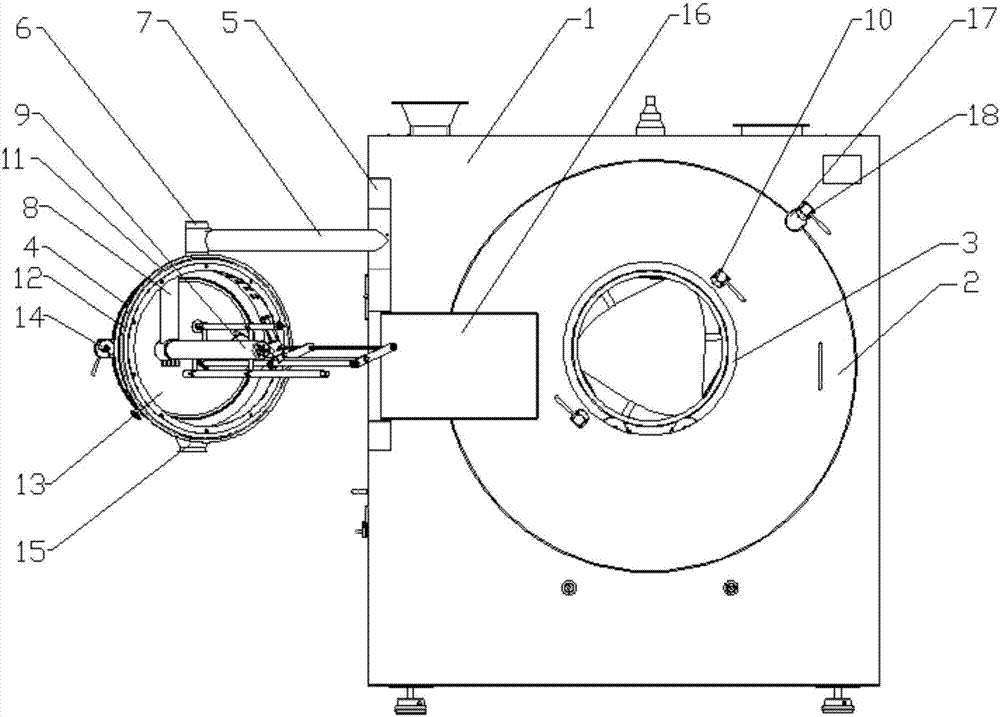

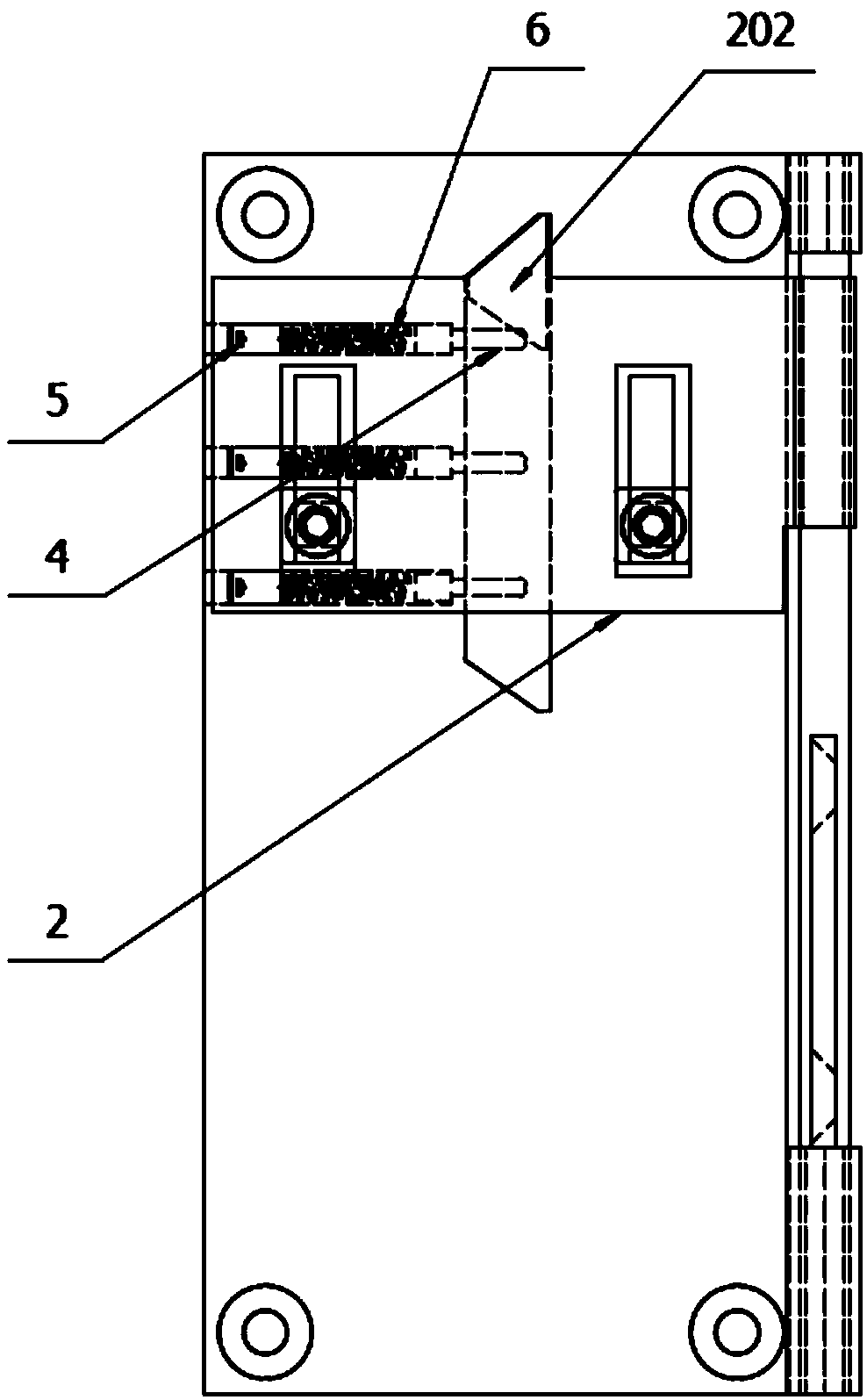

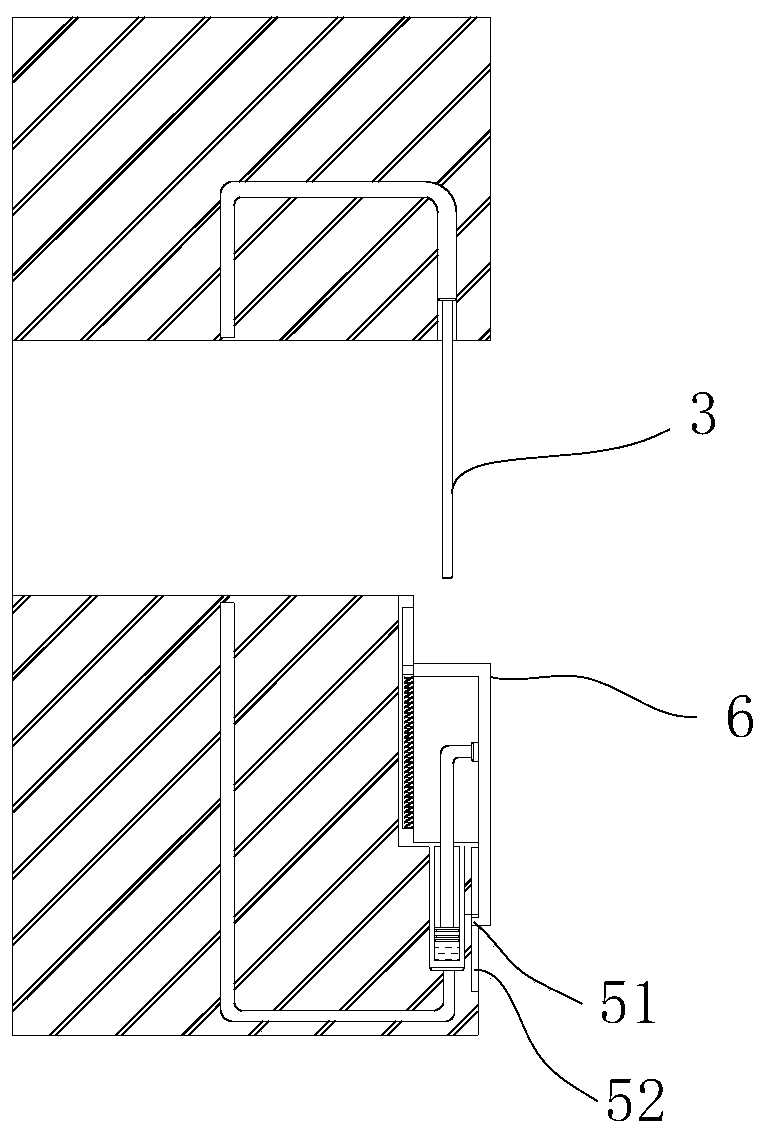

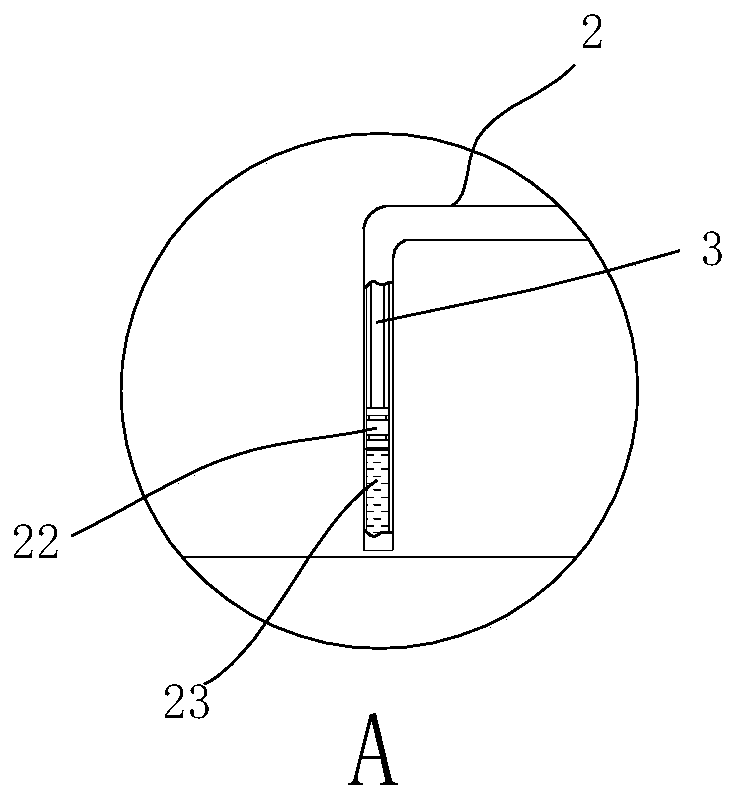

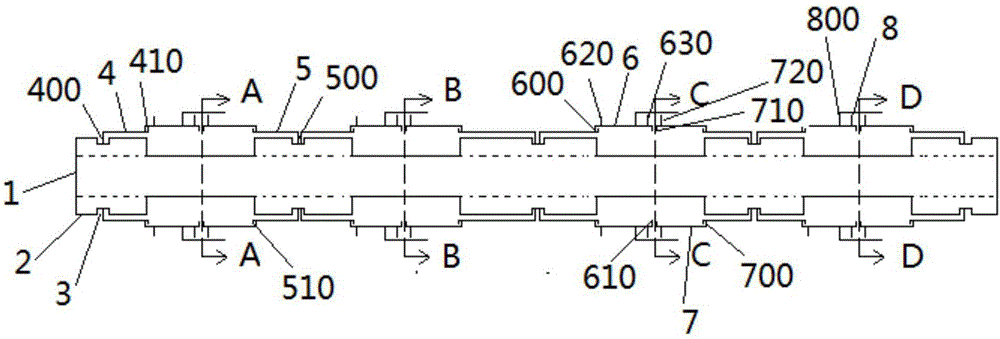

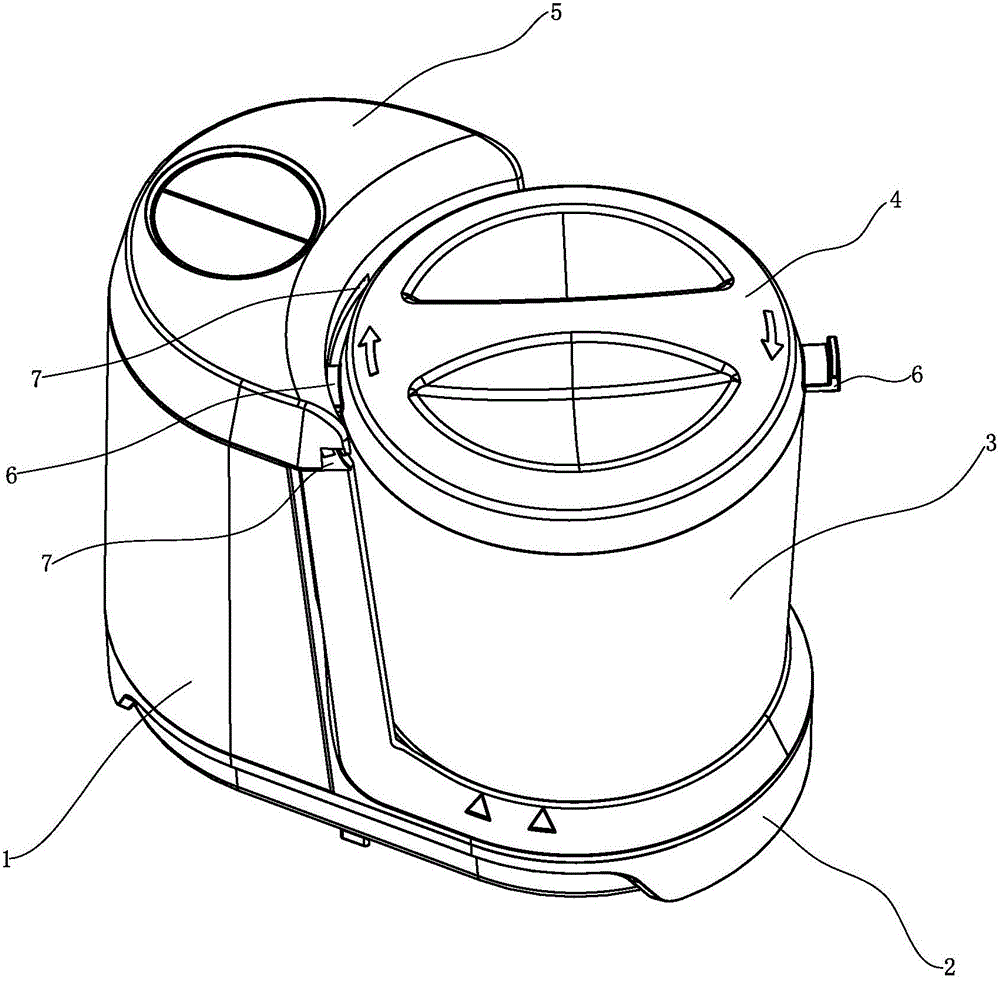

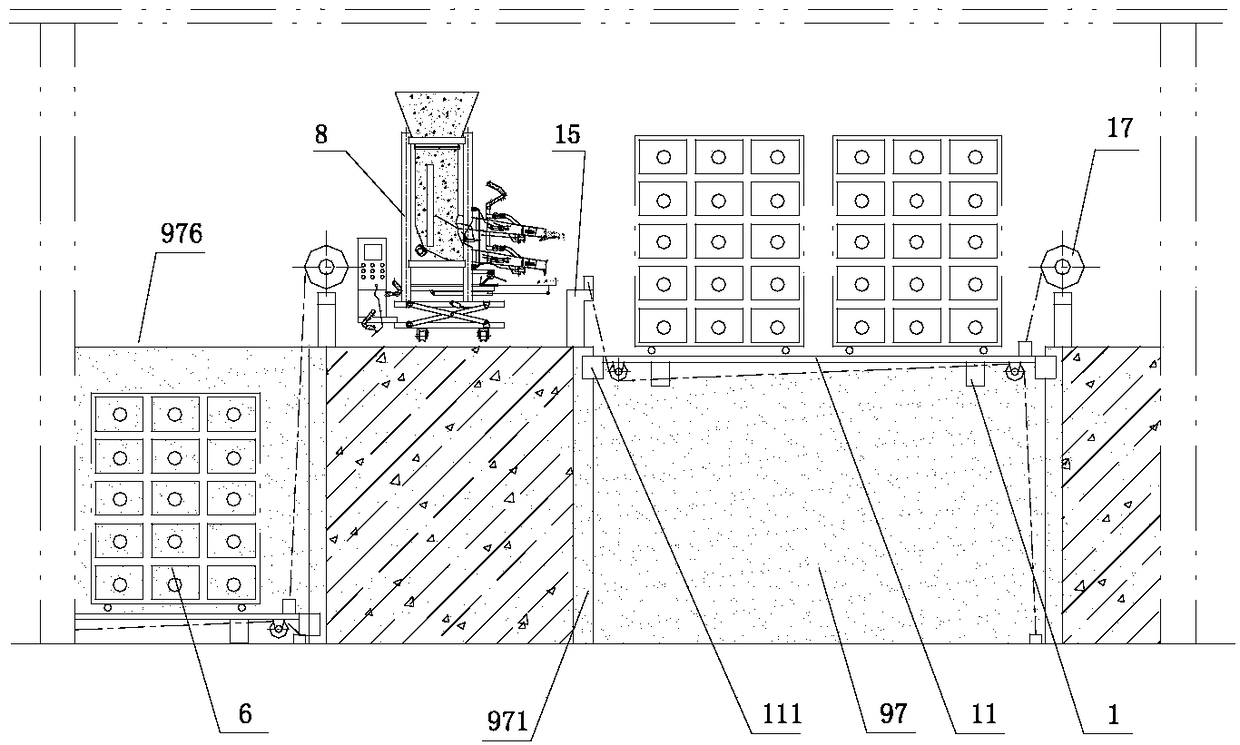

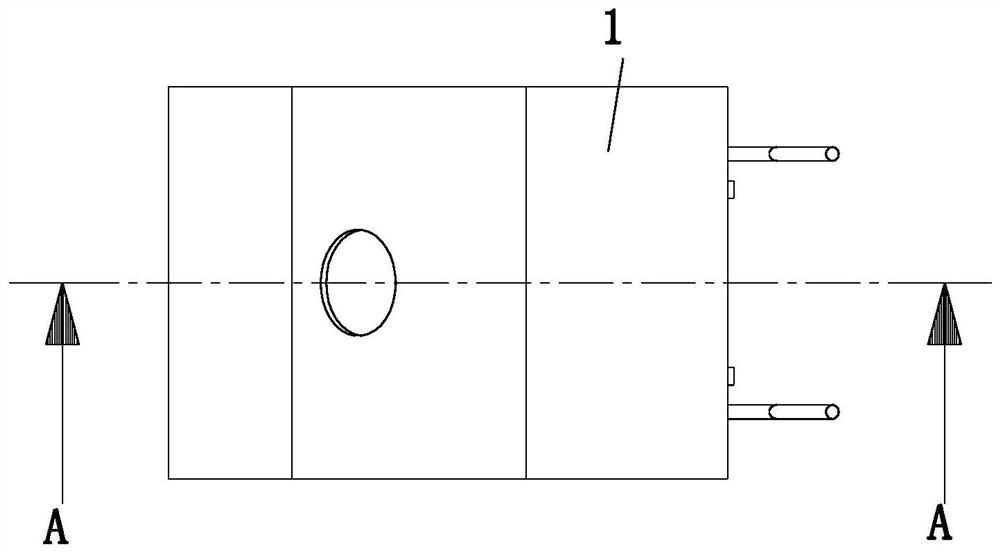

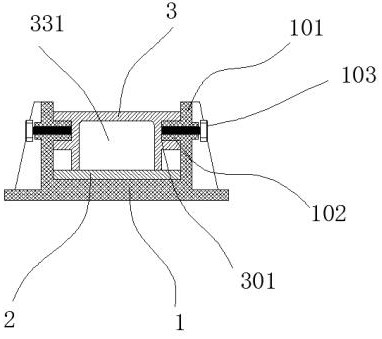

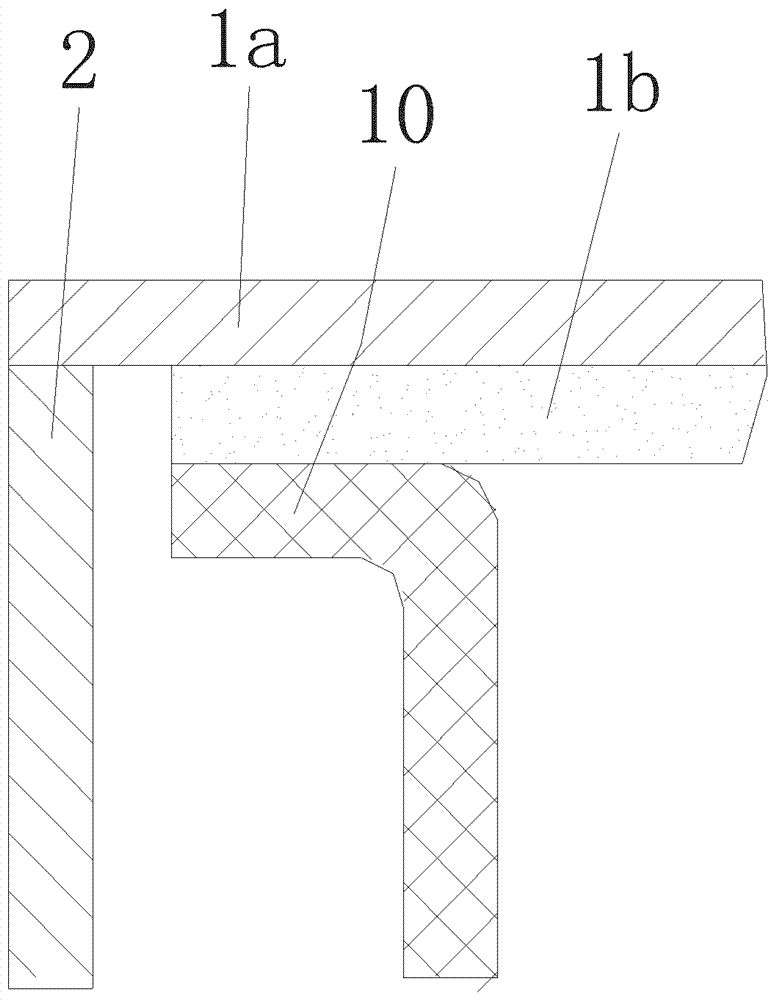

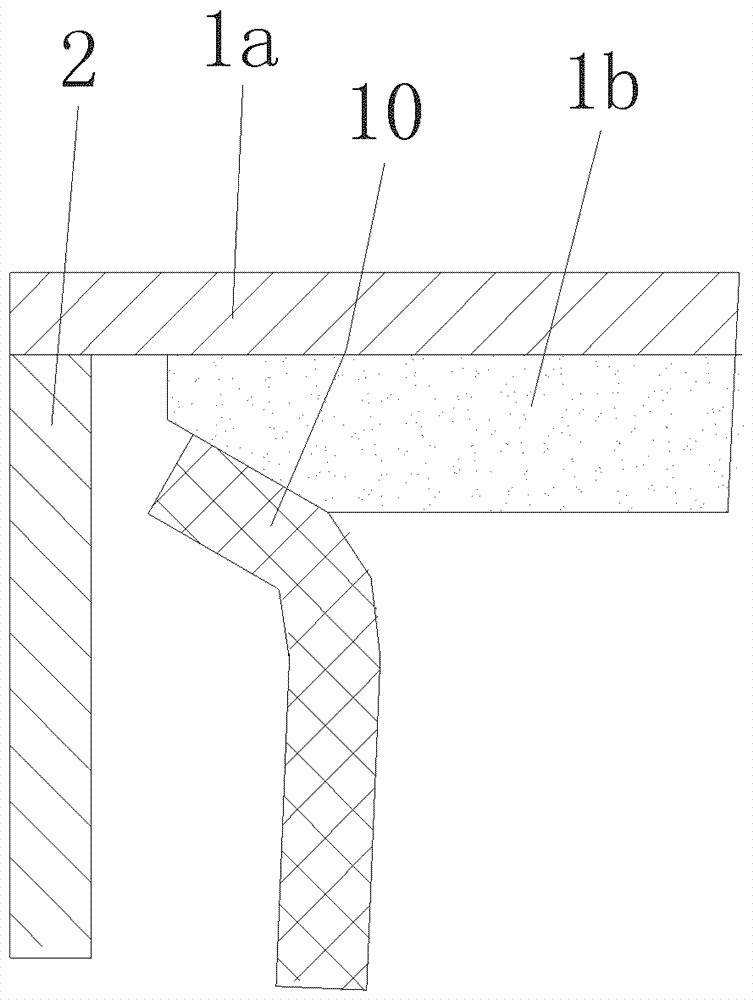

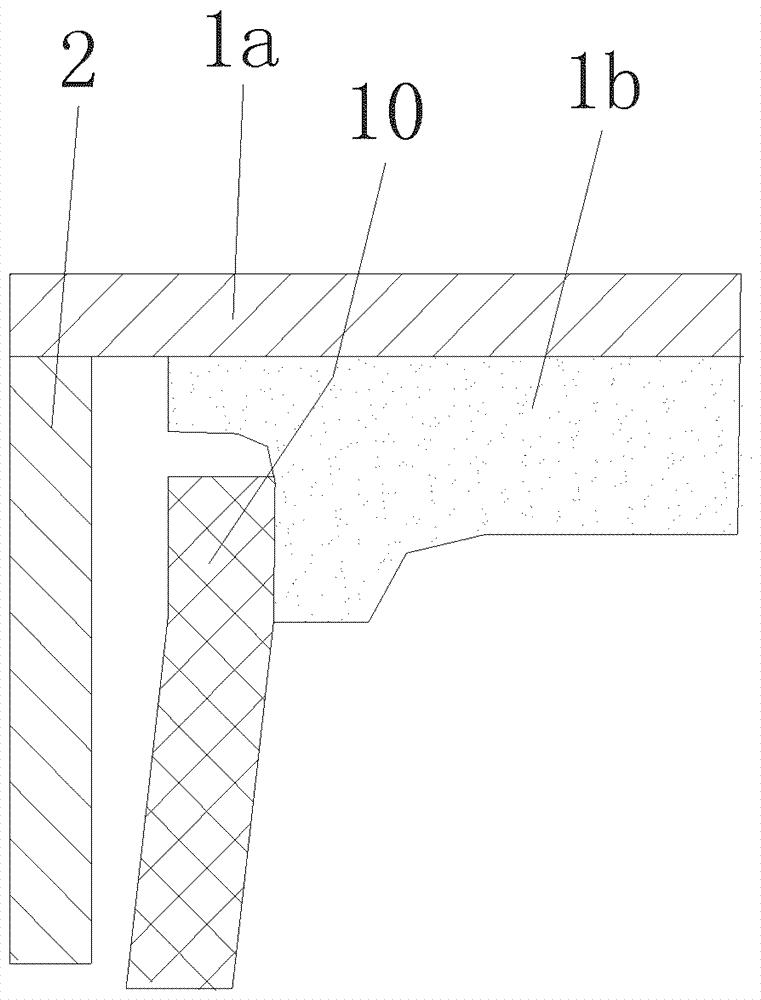

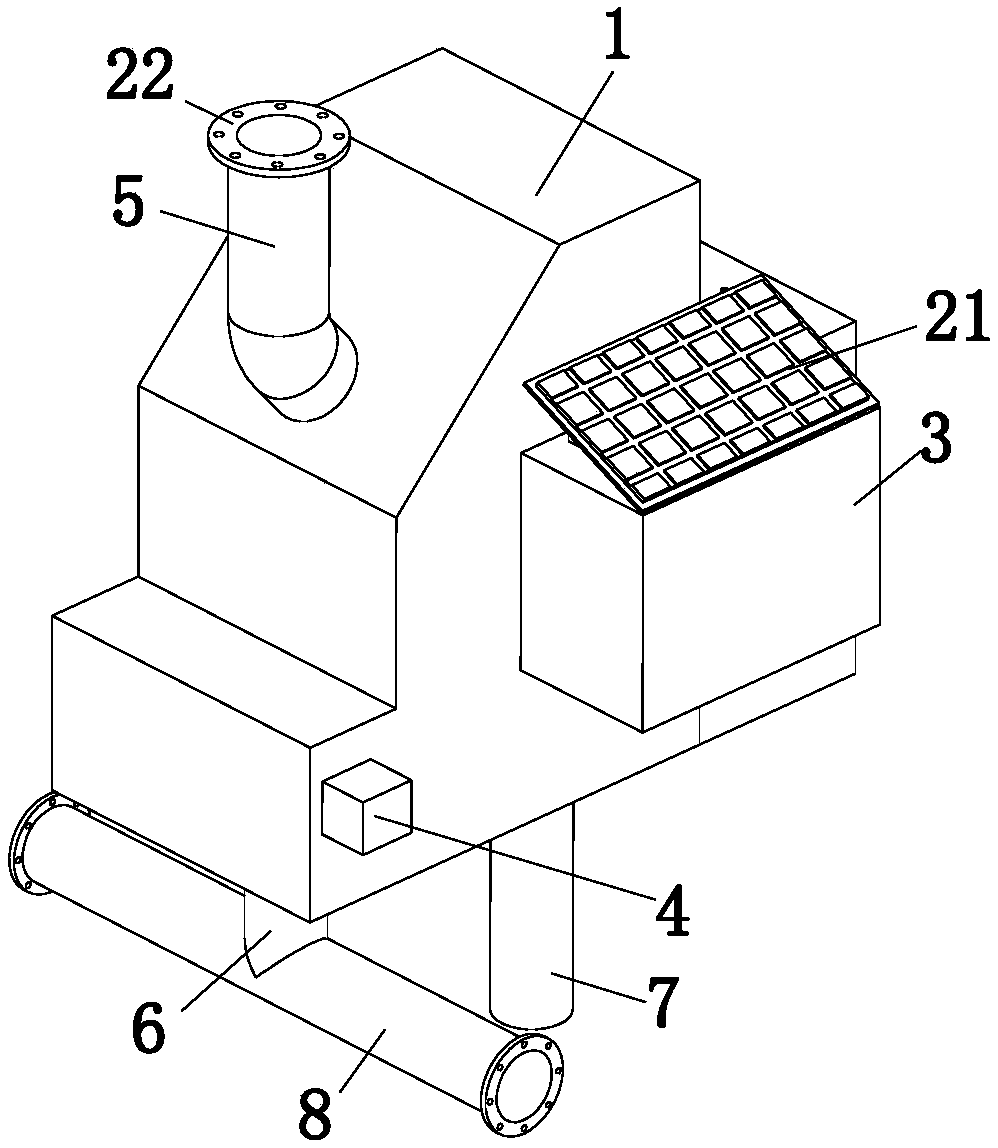

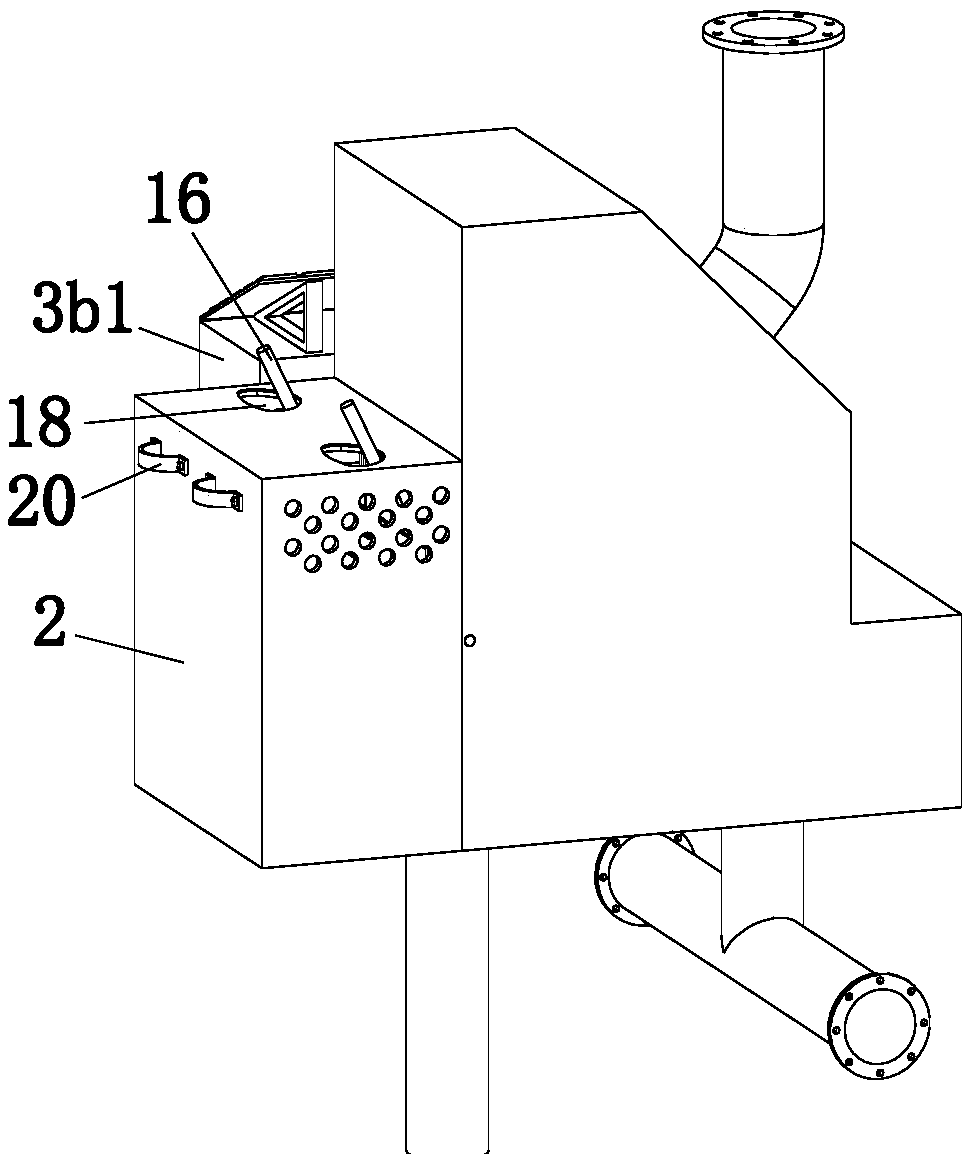

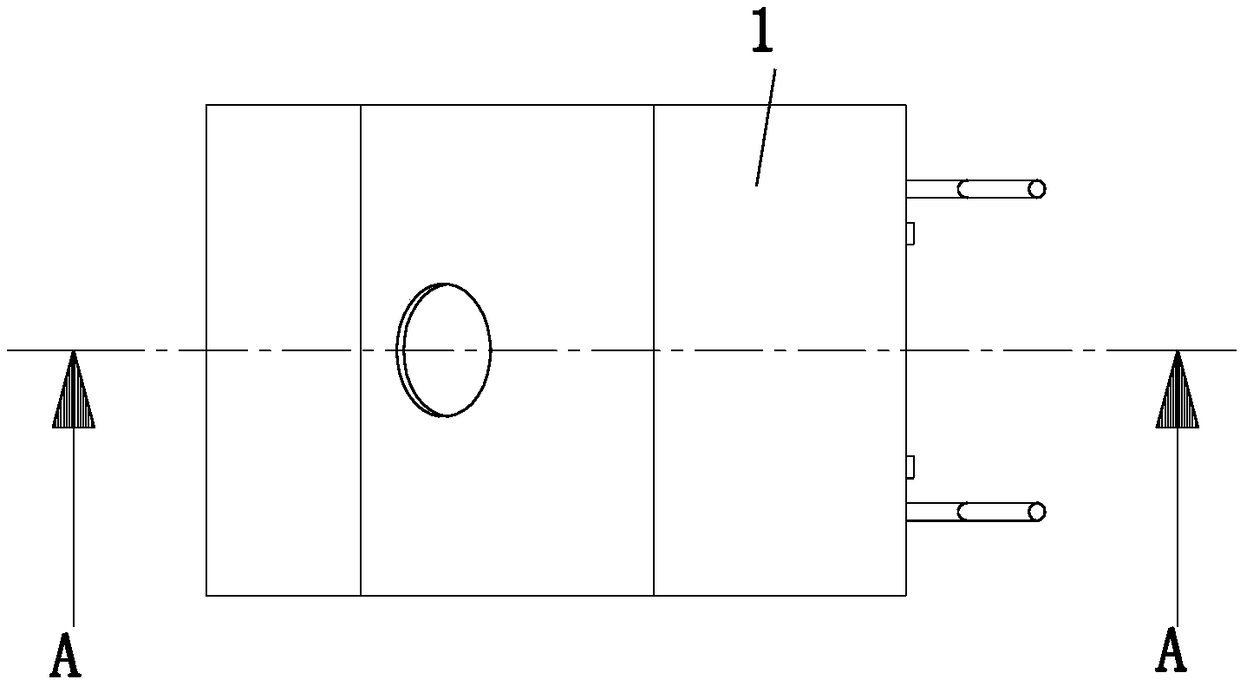

Spraying-gun-installing-frame clothes wrapping roller in-out mechanism of roller-replaceable clothes wrapping machine

ActiveCN107260548AEasy to pull outDoes not affect replacementPharmaceutical product form changeCoatingsStructural engineeringMechanical engineering

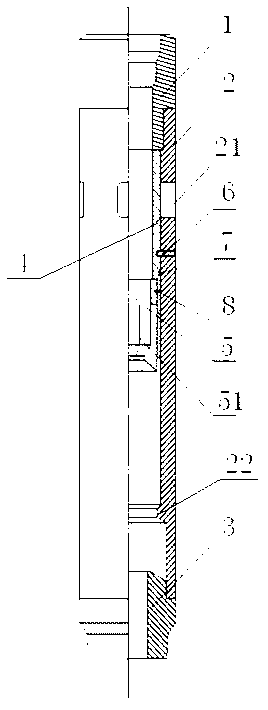

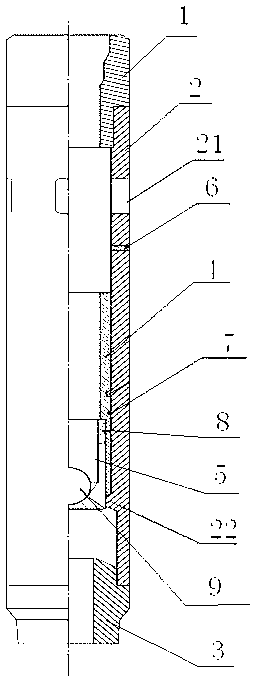

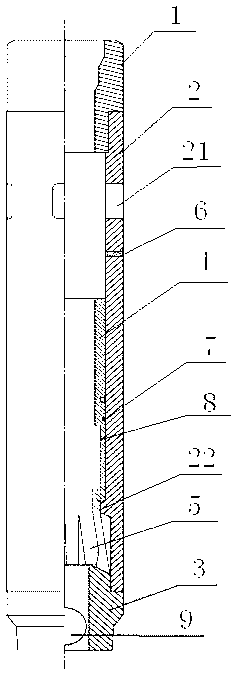

The invention discloses a spraying-gun-installing-frame clothes wrapping roller in-out mechanism of a roller-replaceable clothes wrapping machine, and relates to spraying-gun-installing-frame clothes wrapping roller in-out mechanisms. The spraying-gun-installing-frame clothes wrapping roller in-out mechanism aims at solving the problems that a clothes-wrapping-machine spraying gun installing frame and the clothes wrapping roller in-out mode of a spraying gun arranged on the spraying gun installing frame in the prior art cannot be suitable for the roller-replaceable clothes wrapping machine. A front door (2) of the spraying-gun-installing-frame clothes wrapping roller in-out mechanism is arranged on a machine body (1), a feeding port (3) is formed in the front door (2), a front mouth ring (4) is in a cylinder shape, a first hinge base (5) is arranged on one side of the front wall of the machine body (1), a second hinge base (6) is arranged on the outer side wall of the front mouth ring (4), and the two ends of a first connecting rod (7) are hinged to the first hinge base (5) and the second hinge base (6) respectively, one end of a supporting rod (8) is installed on the inner side wall of the front mouth ring (4), and the other end of the supporting rod (8) is detachably connected with the spraying gun installing frame (9) in a matched mode. The spraying-gun-installing-frame clothes wrapping roller in-out mechanism can be used for the roller-replaceable clothes wrapping machine.

Owner:NANO PHARM TECH MACHINERY EQUIP

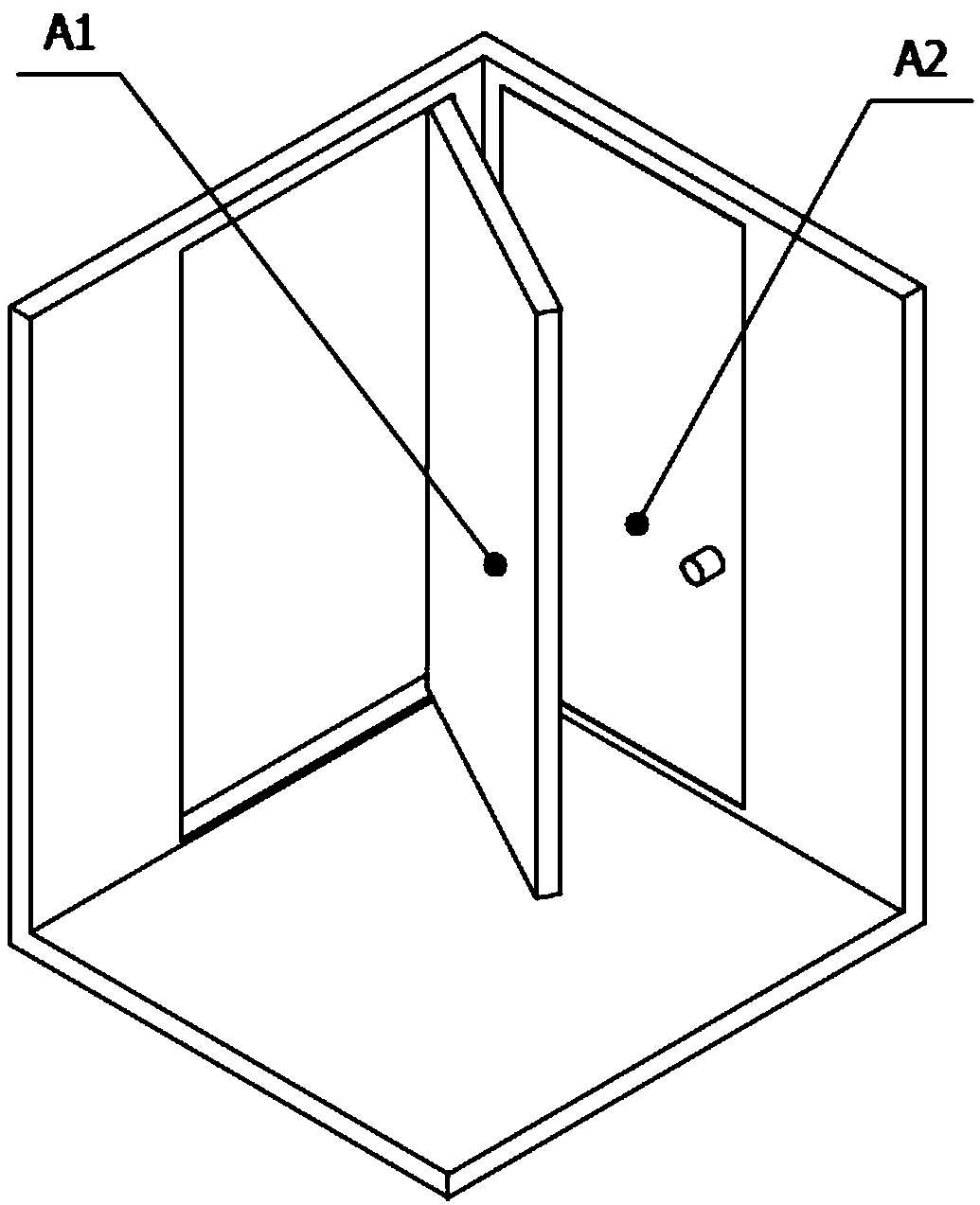

Swing gate with anti-collision function

ActiveCN113756229ADoes not affect openingDoes not affect shutdownTraffic signalsRoad signsElectric machineClassical mechanics

The invention discloses a swing gate with an anti-collision function. The swing gate comprises a case which is provided with a groove on one side surface, a swing gate vertically and rotatably arranged in the groove, a vertical rod vertically arranged in the swing gate and slidably connected with the swing gate in the vertical direction, a first electromagnet, a servo motor, a supporting rod and a control unit, wherein the upper end and the lower end of the vertical rod are located in the case, and a first electromagnet attraction piece and a second electromagnet attraction piece are fixedly arranged at the upper end and the lower end of the vertical rod correspondingly; the first electromagnet is arranged right above the first electromagnet attraction piece; an output shaft of the servo motor is vertically arranged, and the servo motor is fixedly provided with a second electromagnet located under the second electromagnet attraction piece; the supporting rod is horizontally arranged on the back surface of the swing gate, one end of the supporting rod is slidably connected with the swing gate through a first sliding block, and the other end of the supporting rod is slidably connected with the case through a second sliding block; and the two ends of the supporting rod are hinged to the first sliding block and the second sliding block correspondingly. Damage to the motor can be effectively reduced, and the beneficial effects of prolonging the service life and reducing the operation cost are achieved.

Owner:北京中成科信科技发展有限公司

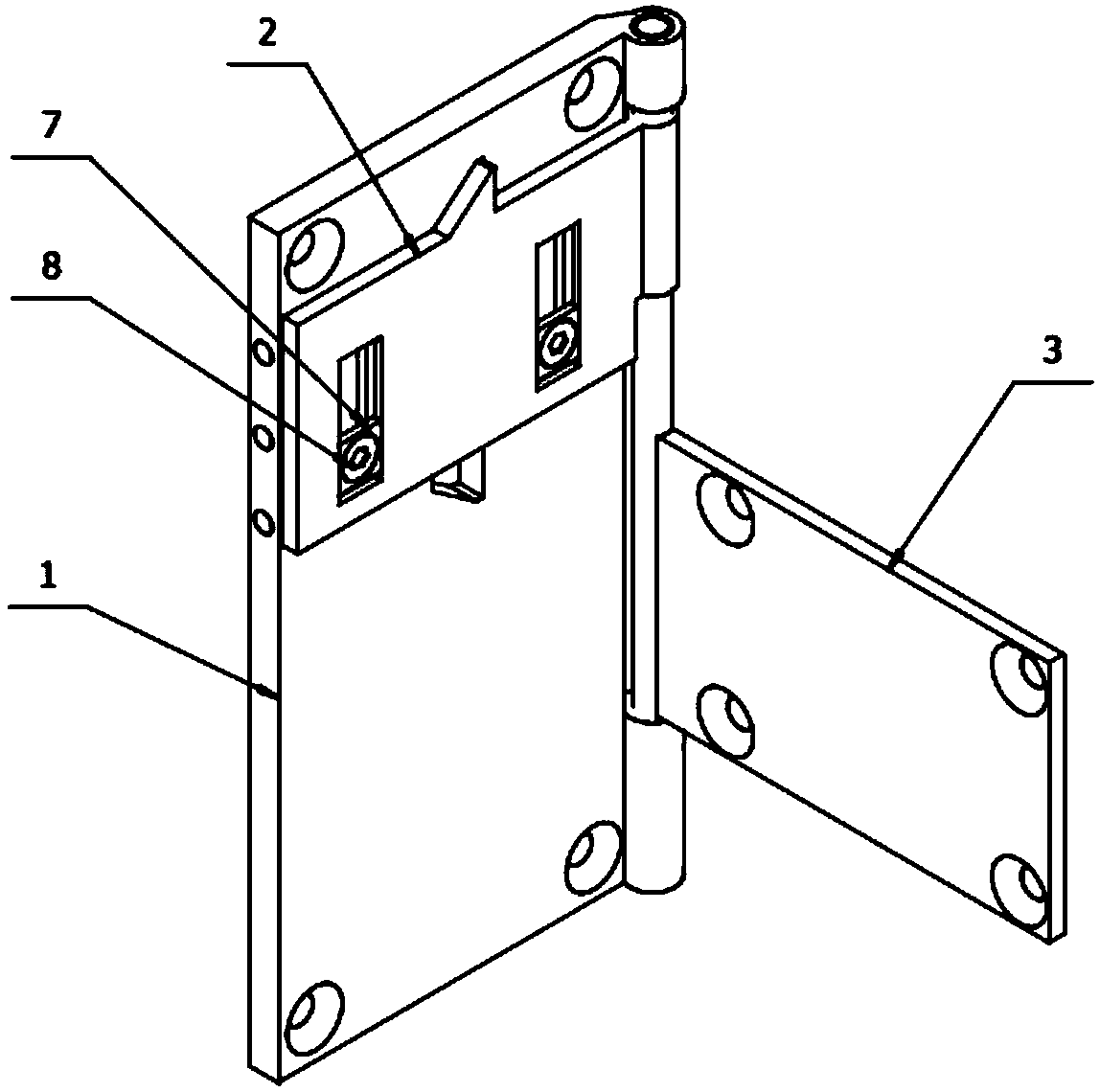

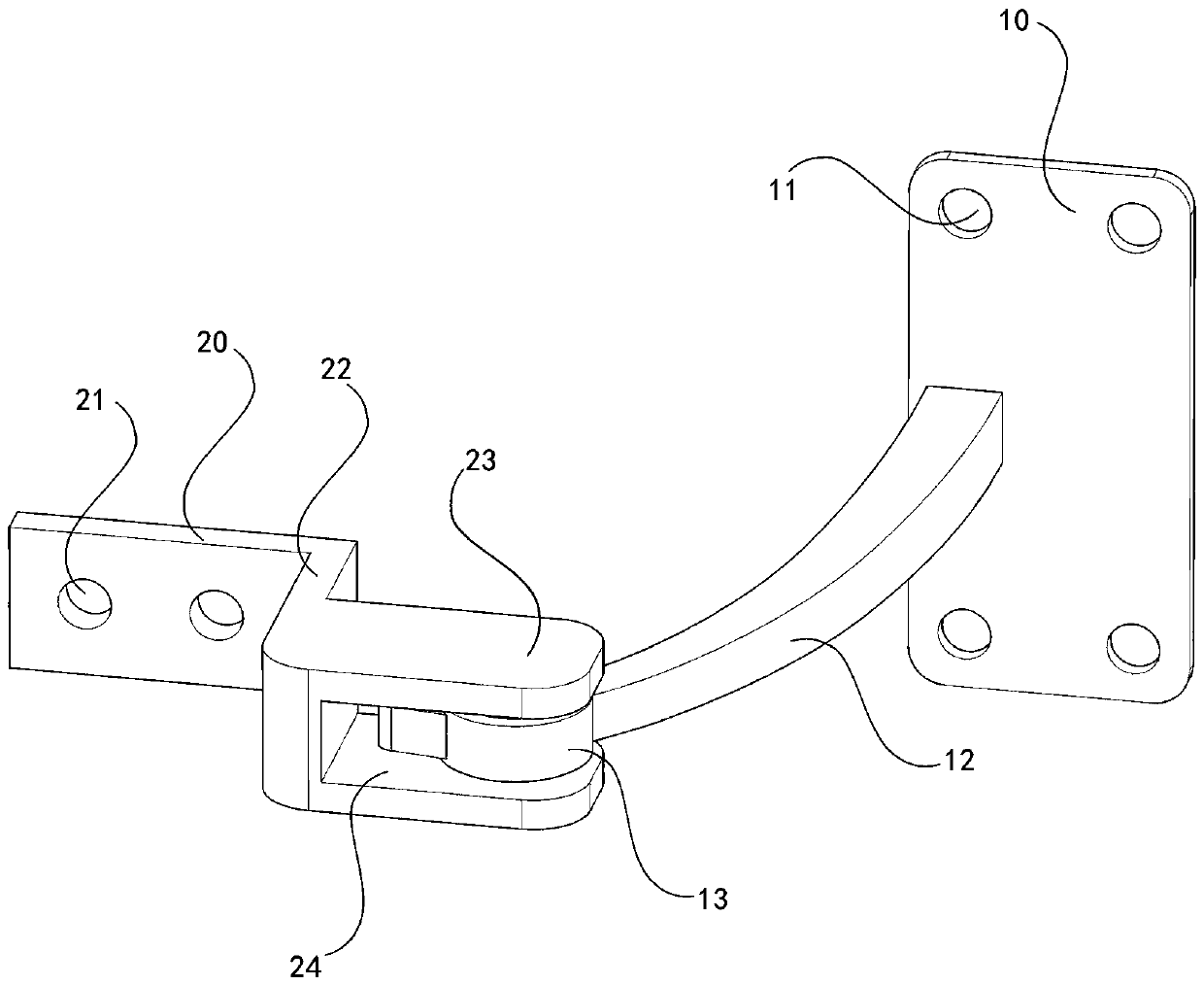

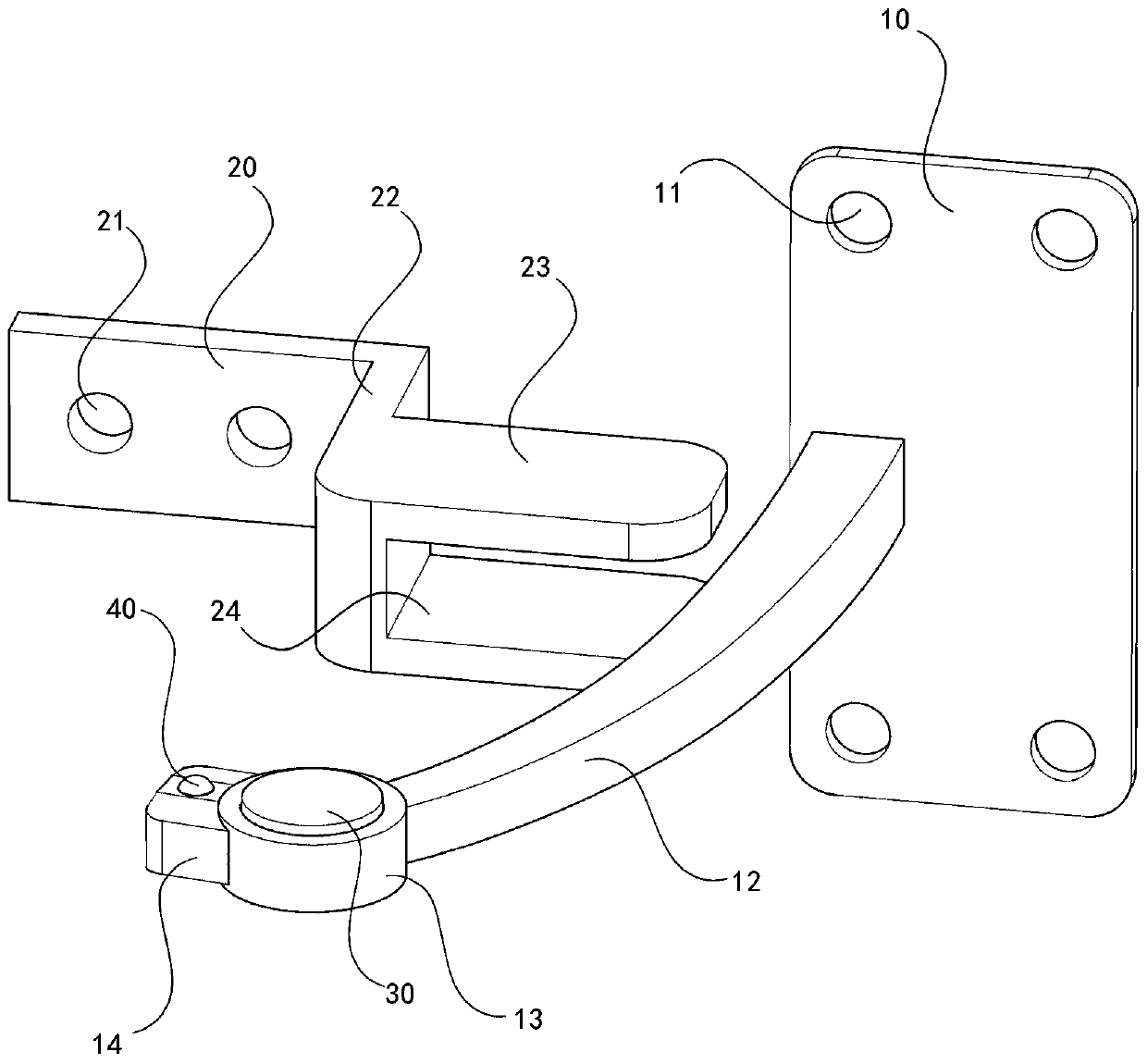

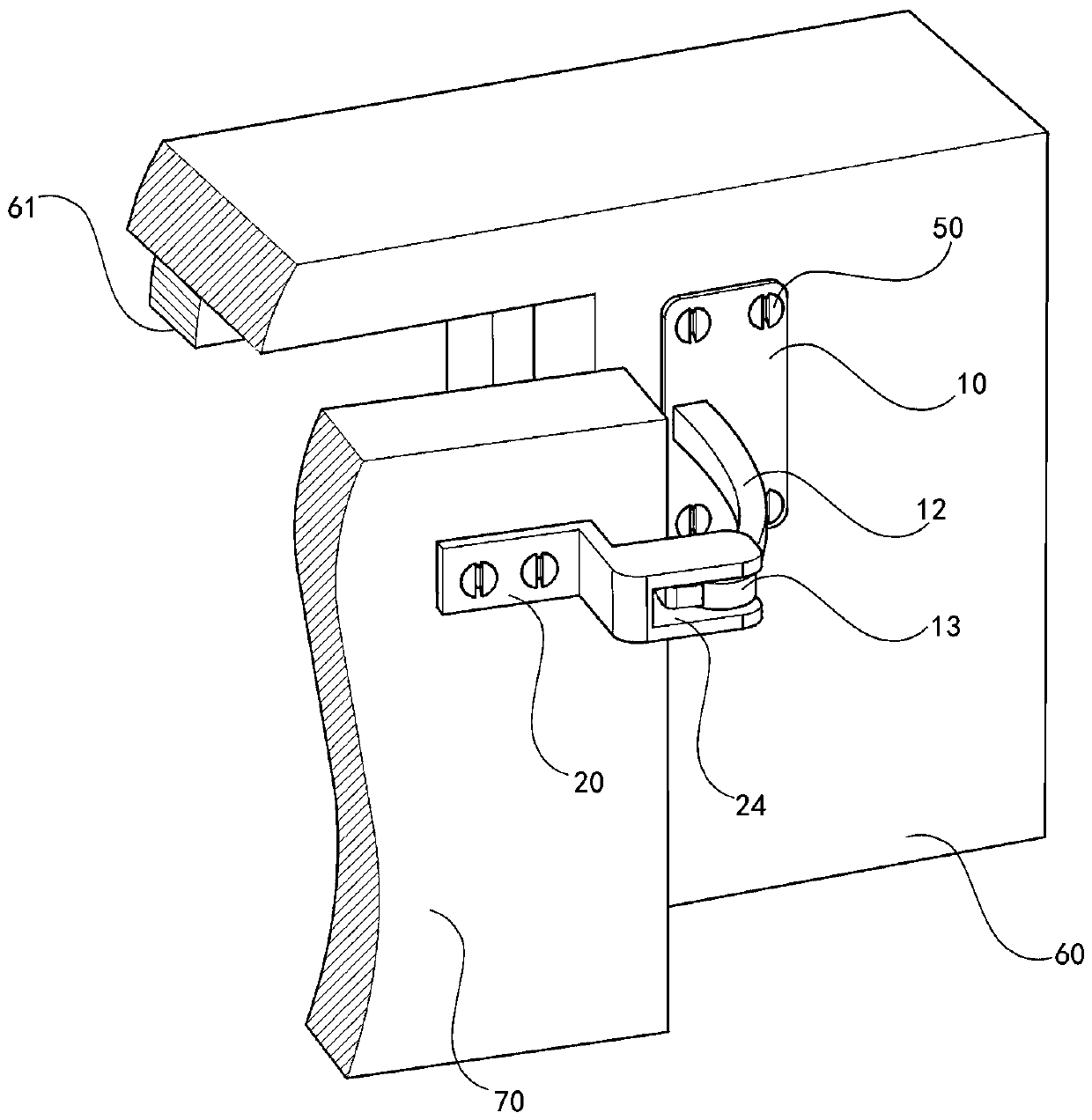

Multi-pose stop control hinge lock and door provided with same

ActiveCN108915451AImprove securityDoes not affect openingWing accessoriesHingesSlide plateEngineering

Owner:江苏金迪木业股份有限公司

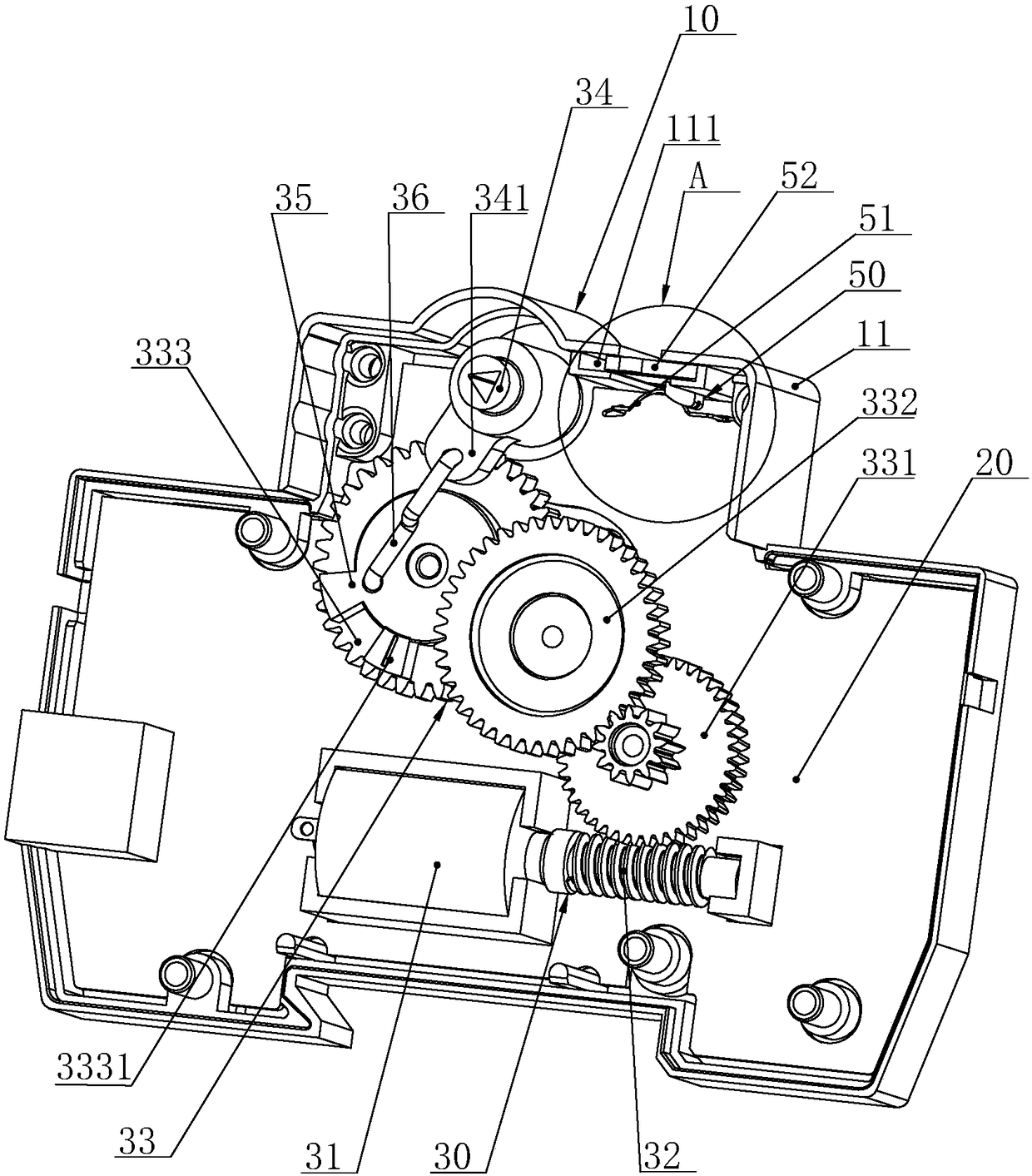

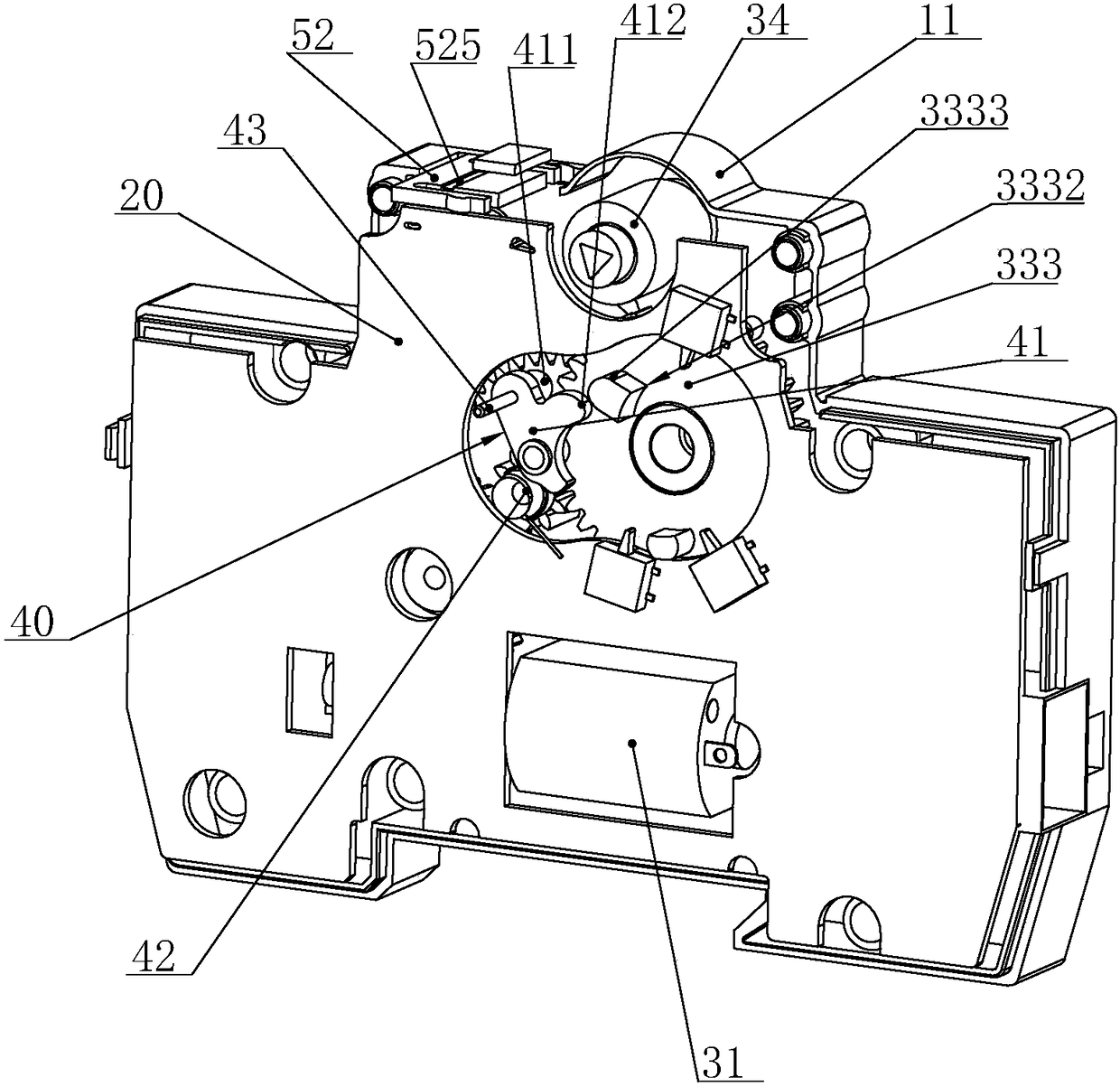

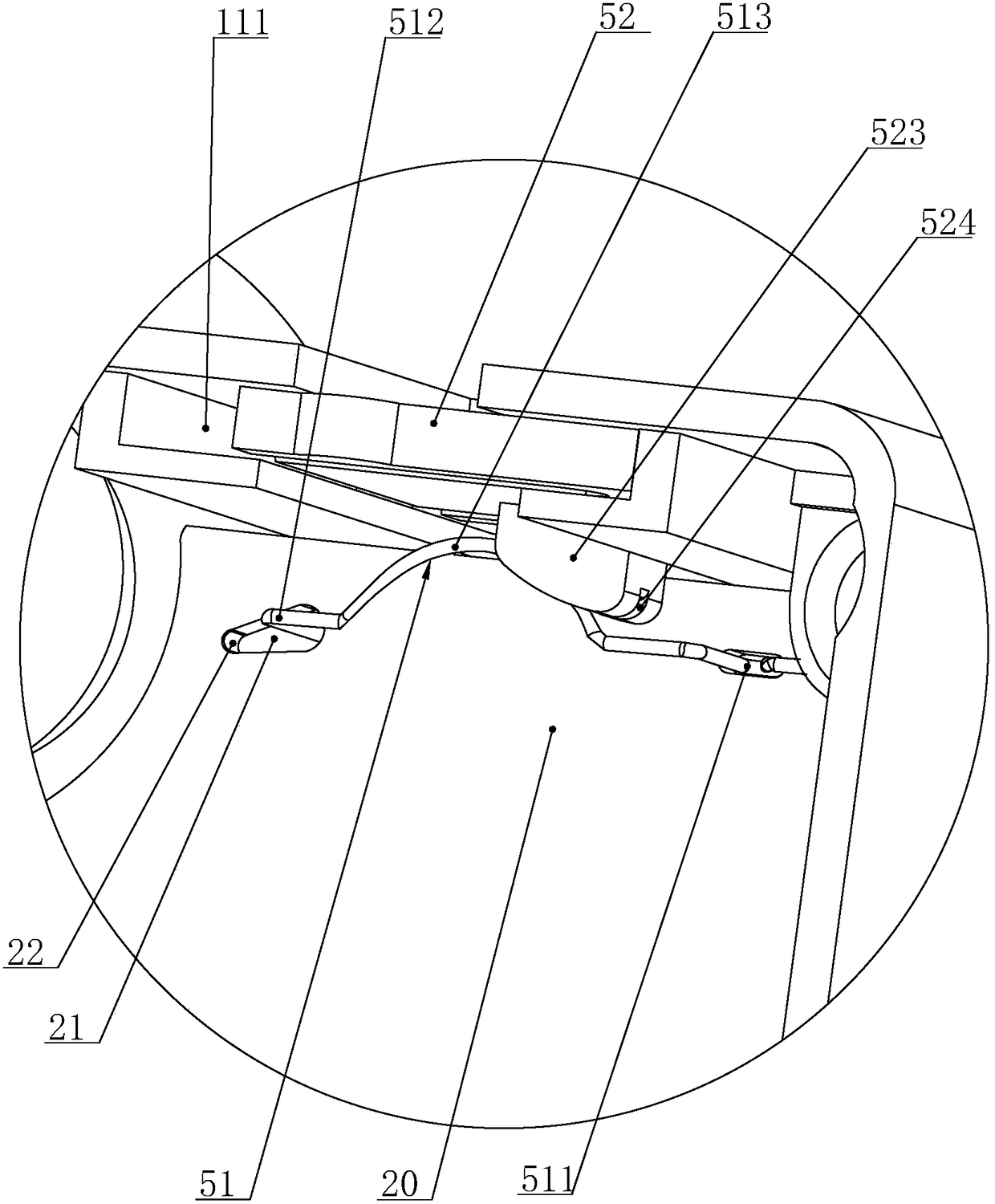

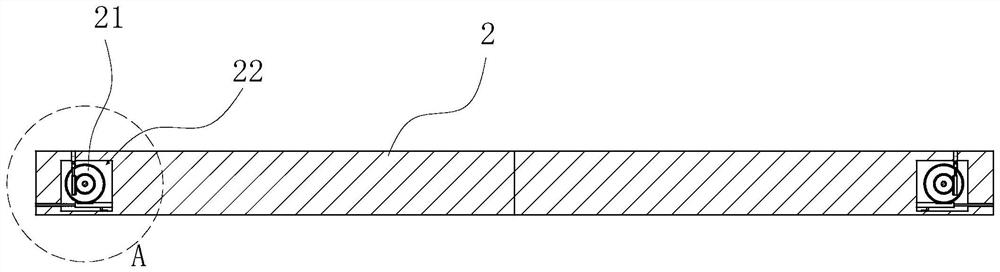

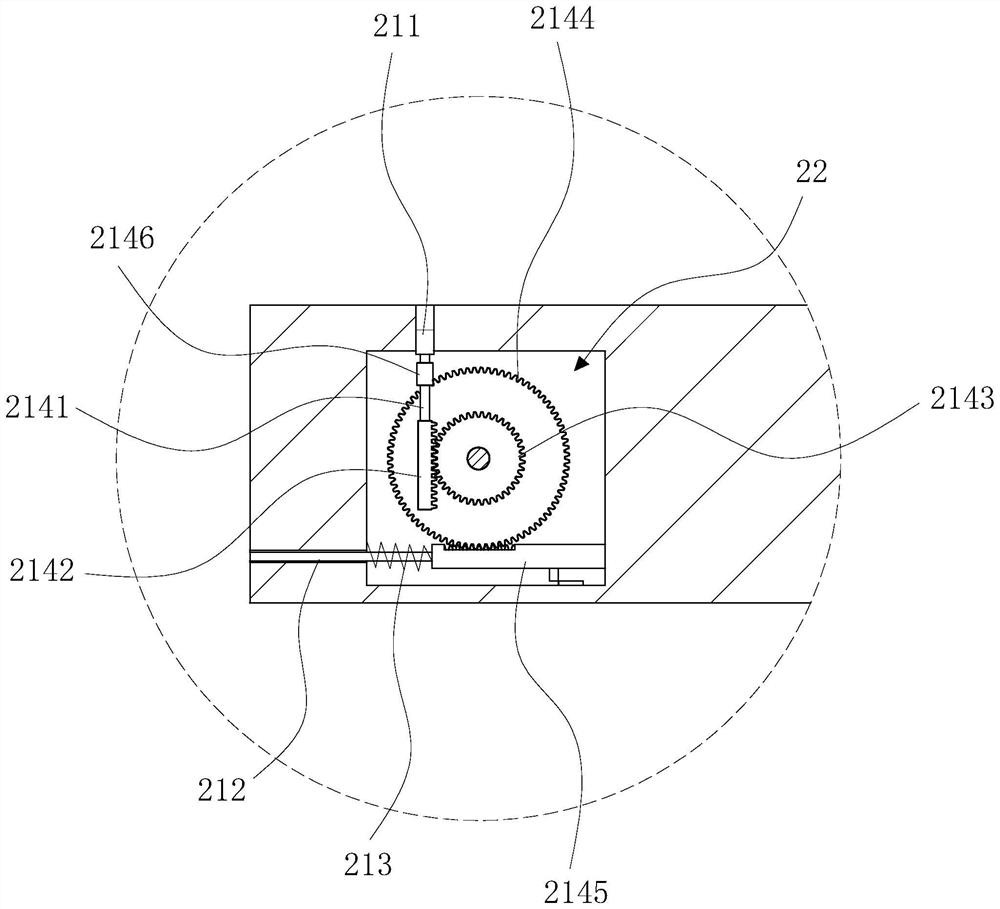

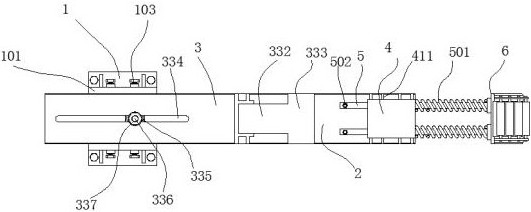

Electric operating mechanism of miniature circuit breaker

ActiveCN108695119ASimple structureImprove reliabilityProtective switch operating/release mechanismsEngineeringCircuit breaker

The invention relates to an electric operating mechanism of a miniature circuit breaker. The electric operating mechanism comprises a housing, a circuit board, a transmission group and a tripping assembly; the transmission assembly comprises a motor, a worm, a gear set and a rotating shaft; the gear set includes a first-stage gear engaged with the worm, a second-stage gear engaged with the first-stage gear, and a third-stage gear engaged with the second-stage gear; a transmission sleeve is movably disposed on the front surface of the third-stage gear; the rotating shaft is provided with a connecting portion corresponding to the transmission sleeve; the connecting portion and the transmission sleeve are connected with each other through a pull rod; one side of the front surface of the third-stage gear, which is corresponding to the transmission sleeve, is provided with a shifting block which is matched with the transmission sleeve; when rotating towards the switching-on direction of thecircuit breaker, the third-stage gear is in linkage fit with the transmission sleeve; and when rotating towards the switching-off direction of the circuit breaker, the third-stage gear is in free fitwith the transmission sleeve. The electric operating mechanism of the invention has the advantages of simple structure, stable and reliable performance, low manufacturing cost and reliable realization of the switching-on and switching-off of the circuit breaker. .

Owner:SIQI TECH

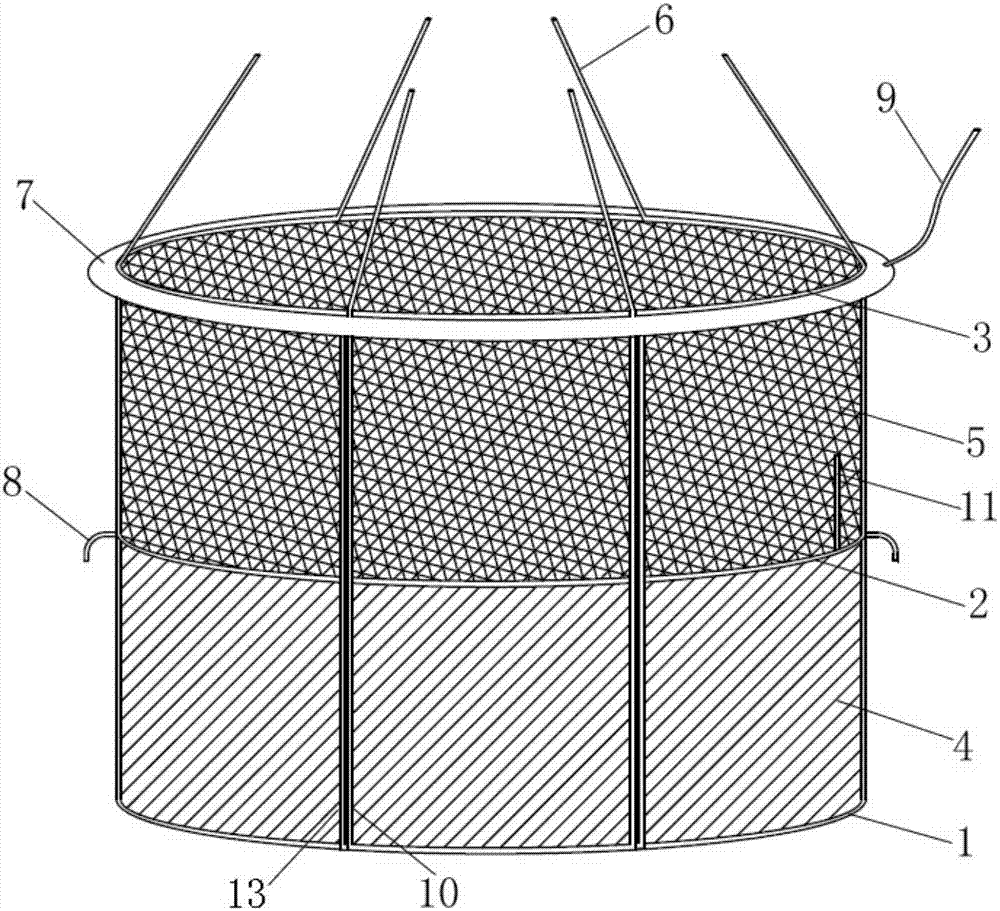

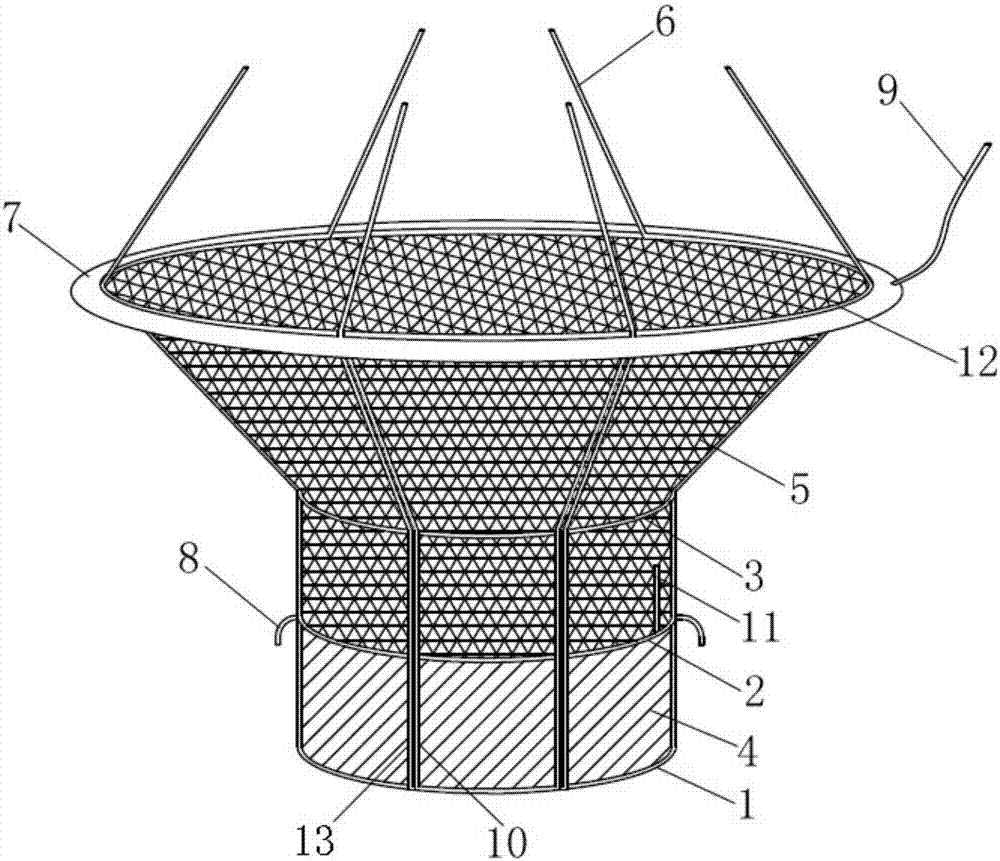

Live fish catching device

The invention relates to a live fish catching device, comprising a first support ring, a second support ring and a third support ring from bottom to top. The bottom of the live fish catching device is sealed. The first support and the second support ring are enclosed through waterproof cloth. The second support ring and the third support ring are enclosed through netting. The third support ring is connected with a plurality of ropes. The live fish catching device comprises an inflatable balloon at the top. The second support ring is provided with a support structure for keeping the waterproof cloth open to form a water storage space after catching. The live fish catching device can provide a gentle catching process and facilitated catching, with less injury caused to fish bodies, dewatering of fishes is avoided during catching, and live fish catching is guaranteed accordingly.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

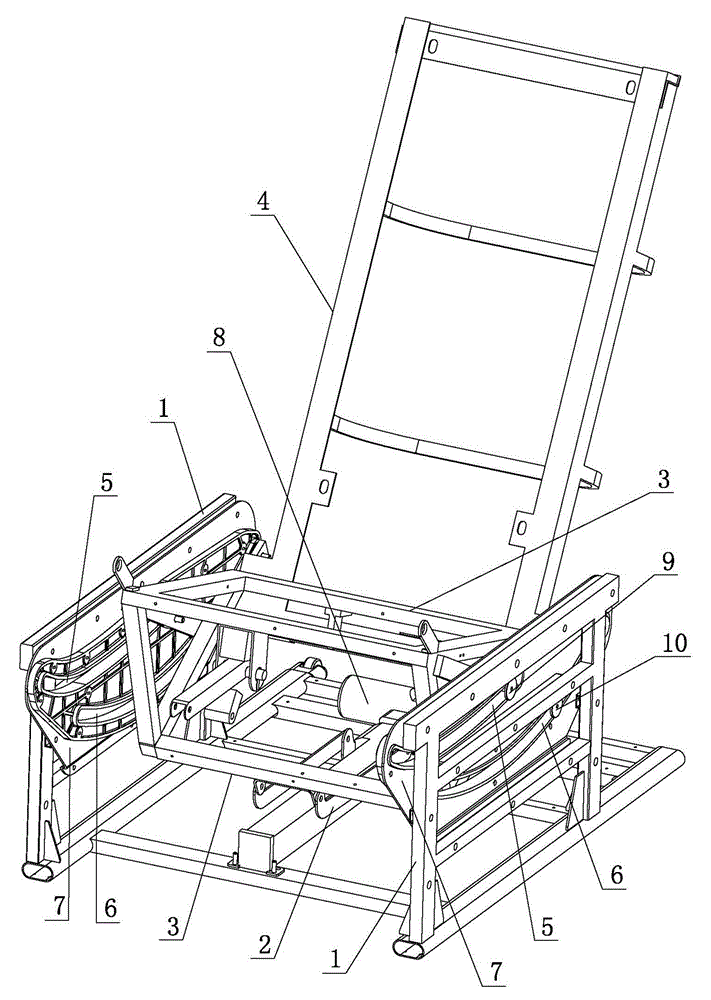

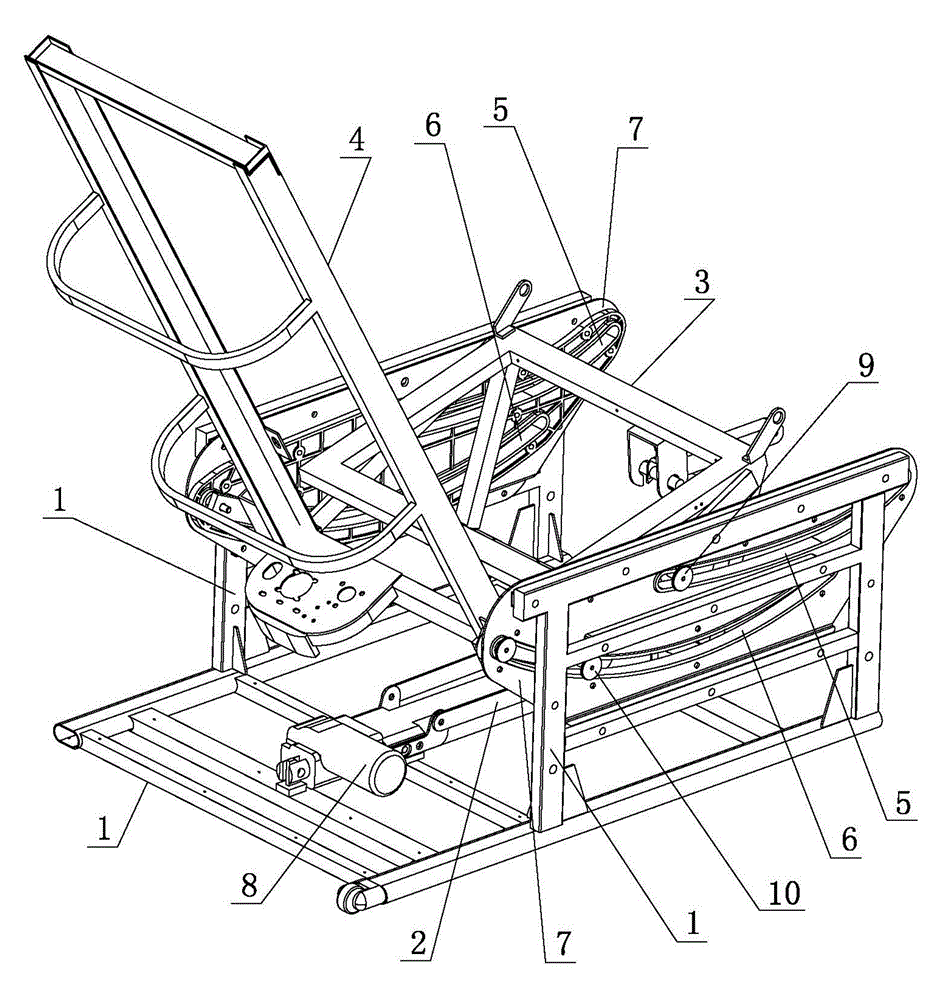

Zero space structure of massage chair

The invention discloses a zero space structure of a massage chair and belongs to the massage chair field. Large enough space is reserved at the back of the existing massage chairs to ensure that the back of the chairs can lean backwards, which causes inconvenience to people. The zero space structure comprises an underbed outer frame, an underbed inner frame, a back, a motor, a push rod and two guide rail installing plates. The back end of the underbed inner frame is connected with the lower end of the chair back; the output shaft of the motor is connected with a reducing mechanism; one end of the push rod is connected with the reducing mechanism and the other end of the push rod is connected with the lower end of the underbed inner frame; a first pulley and a second pulley are respectively arranged at the left side and the right side of the underbed inner frame; two guide rail installing plates are respectively arranged at the left inner side and the right inner side of the underbed outer frame; a first guide rail and a second guide rail are respectively arranged at two guide rail installing plates; the first pulley and the first guide rail are in sliding connection and the second pulley and the second guide rail are in sliding connection. The zero space structure can be applied to massage chairs to lead the distance between the back of the massage chair and the wall surface in a living room to be zero, thus the occupied space is small. In addition, the massage chair is convenient for staring, operation and shutting down.

Owner:广东生命动力按摩器材有限公司

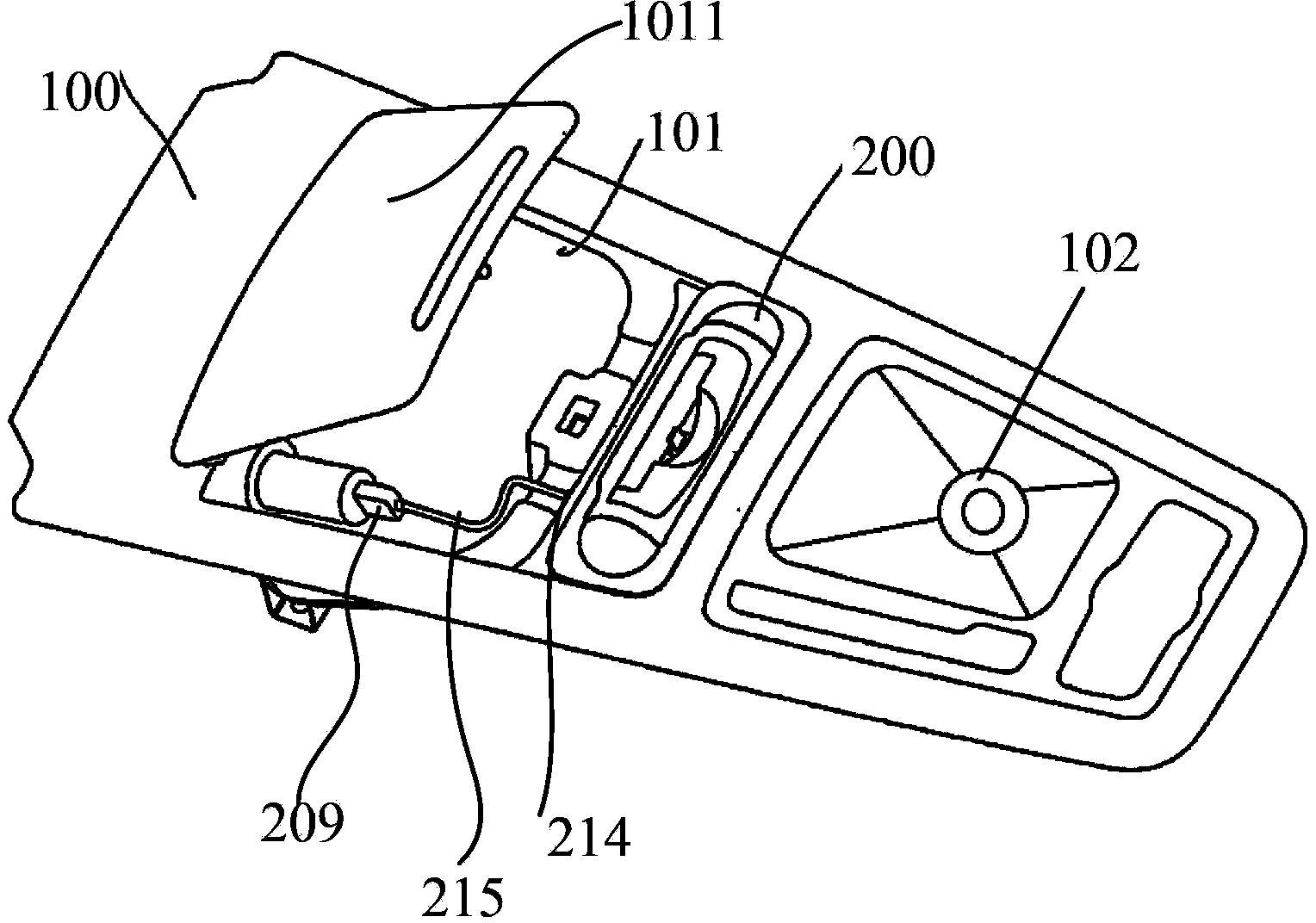

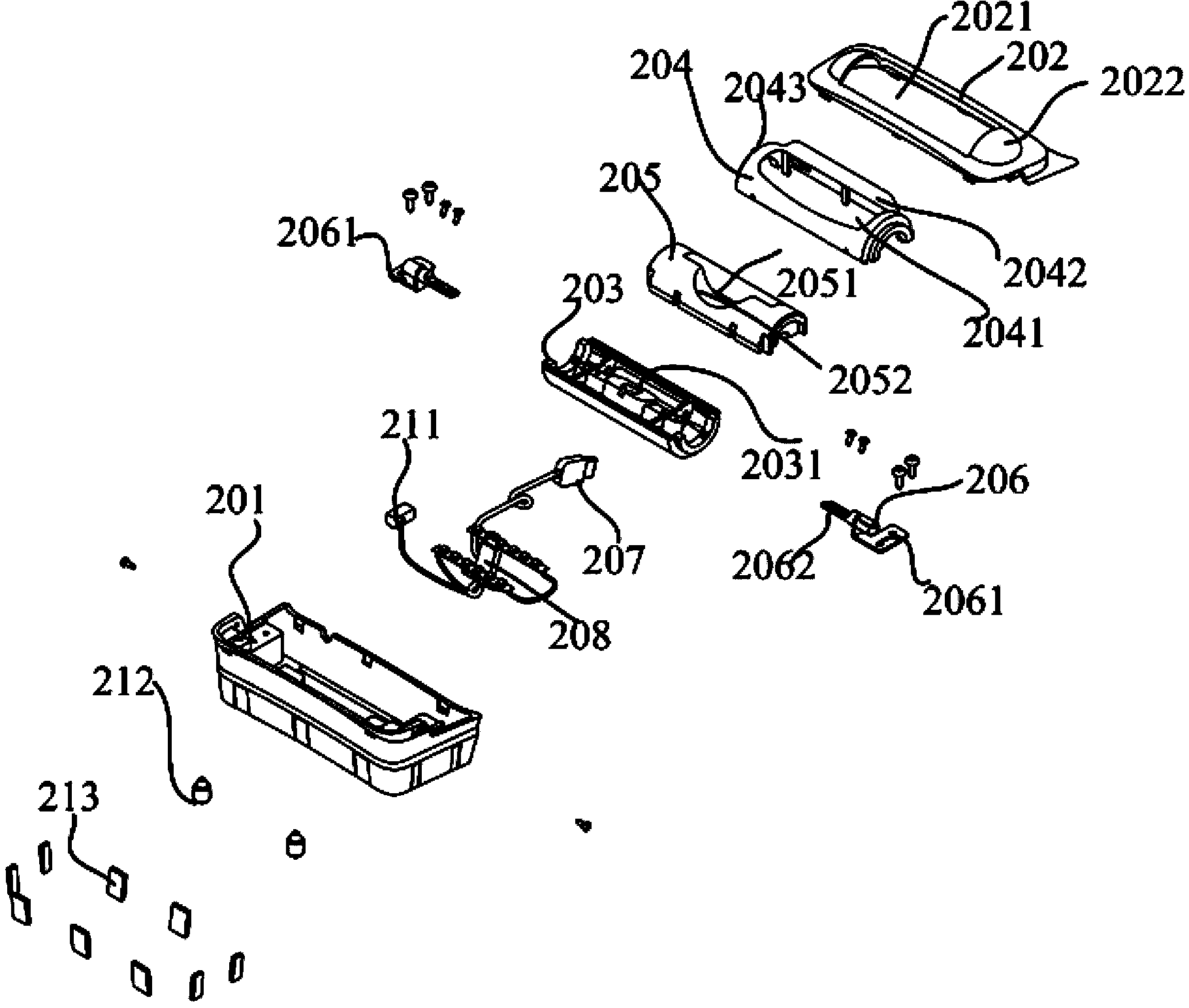

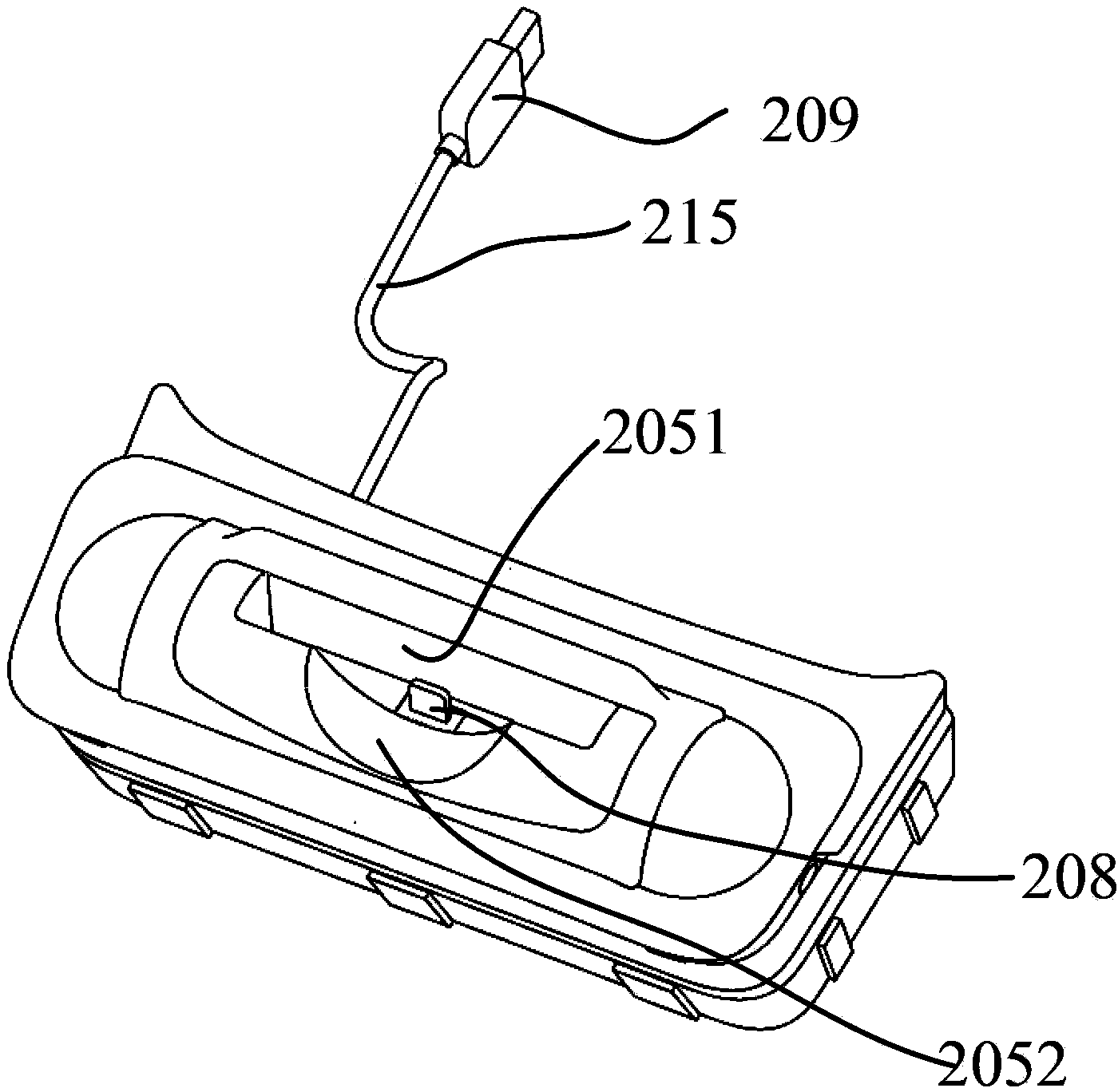

Vehicular portable terminal charging device and vehicular console

ActiveCN104108355ADoes not affect openingDoes not affect gear operationBatteries circuit arrangementsElectric powerComputer terminalEngineering

Owner:QOROS

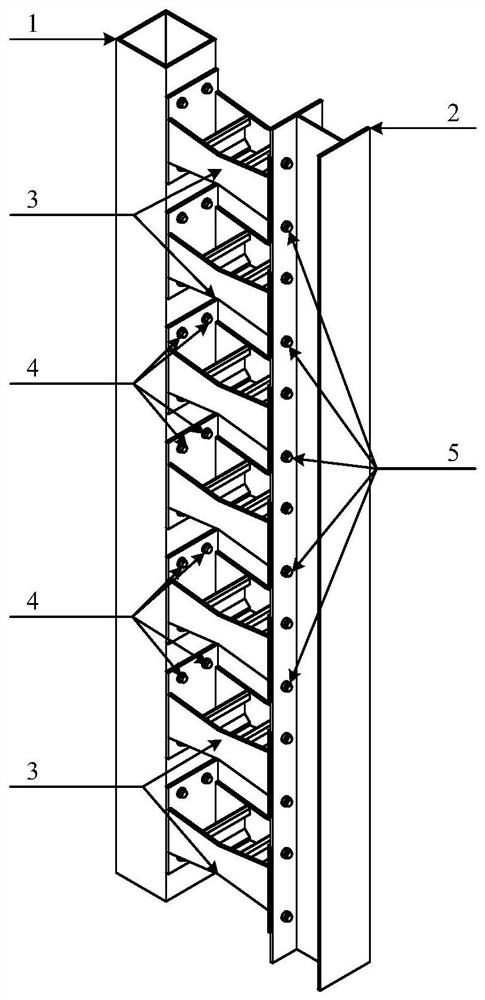

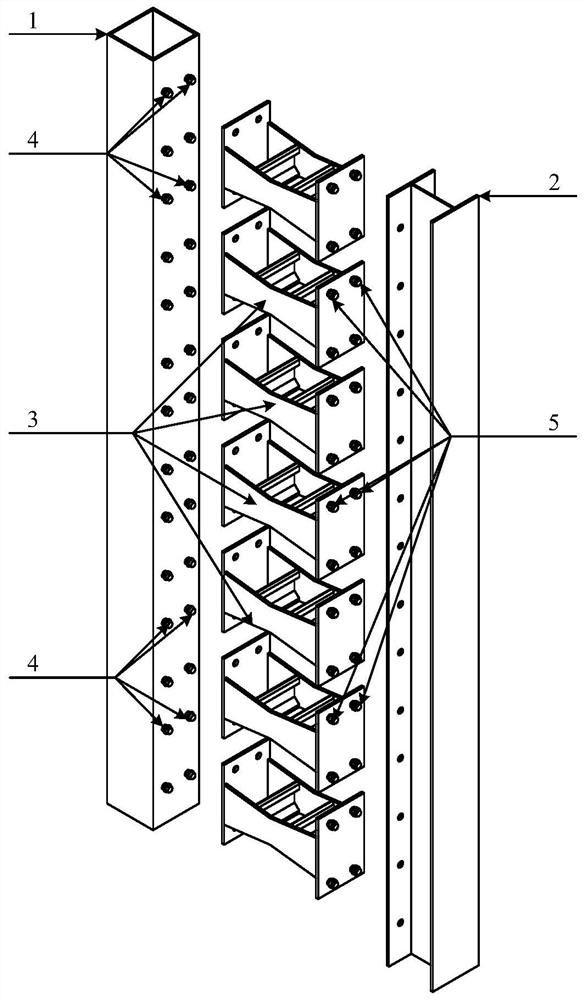

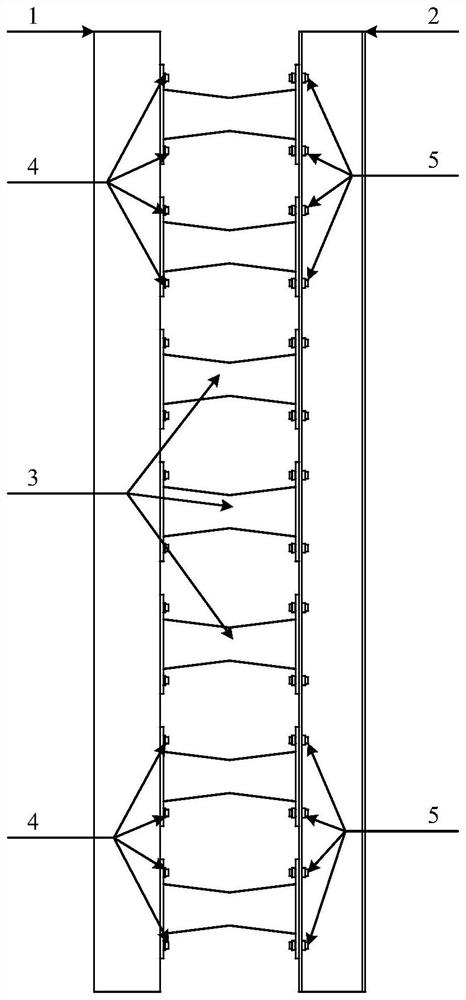

Post-earthquake repairable assembly type latticed column with shear type energy dissipation dampers

ActiveCN112302252ASufficient lateral stiffnessReduce sidewaysStrutsProtective buildings/sheltersArchitectural engineeringSteel columns

The invention discloses a post-earthquake repairable assembly type latticed column with shear type energy dissipation dampers, and belongs to the technical field of structural engineering. The latticed column comprises a steel column, the shear type energy dissipation dampers, a first unilateral bolt group and a second high-strength bolt group. All the steel components are manufactured in a factory, the welding quality is easy to control, all the steel components only need to be hoisted and connected in a bolt assembly mode on a construction site, and the industrialization level and construction efficiency are high. The latticed column has the advantages of mechanical property and practical property at the same time, specifically, in the aspect of the mechanical property, the shear type energy dissipation damper structure is adopted to increase the height of the anti-side section of the latticed column, so that the lateral capacity and the energy dissipation capacity of the latticed column are improved; and in the aspect of practical performance, corrugated tie plates are used for being connected with the shearing energy dissipation plates, the steel consumption of the damper is reduced, good economical efficiency is achieved, and the function of an original structure can be recovered only by replacing the damaged damper after an earthquake.

Owner:BEIJING UNIV OF TECH

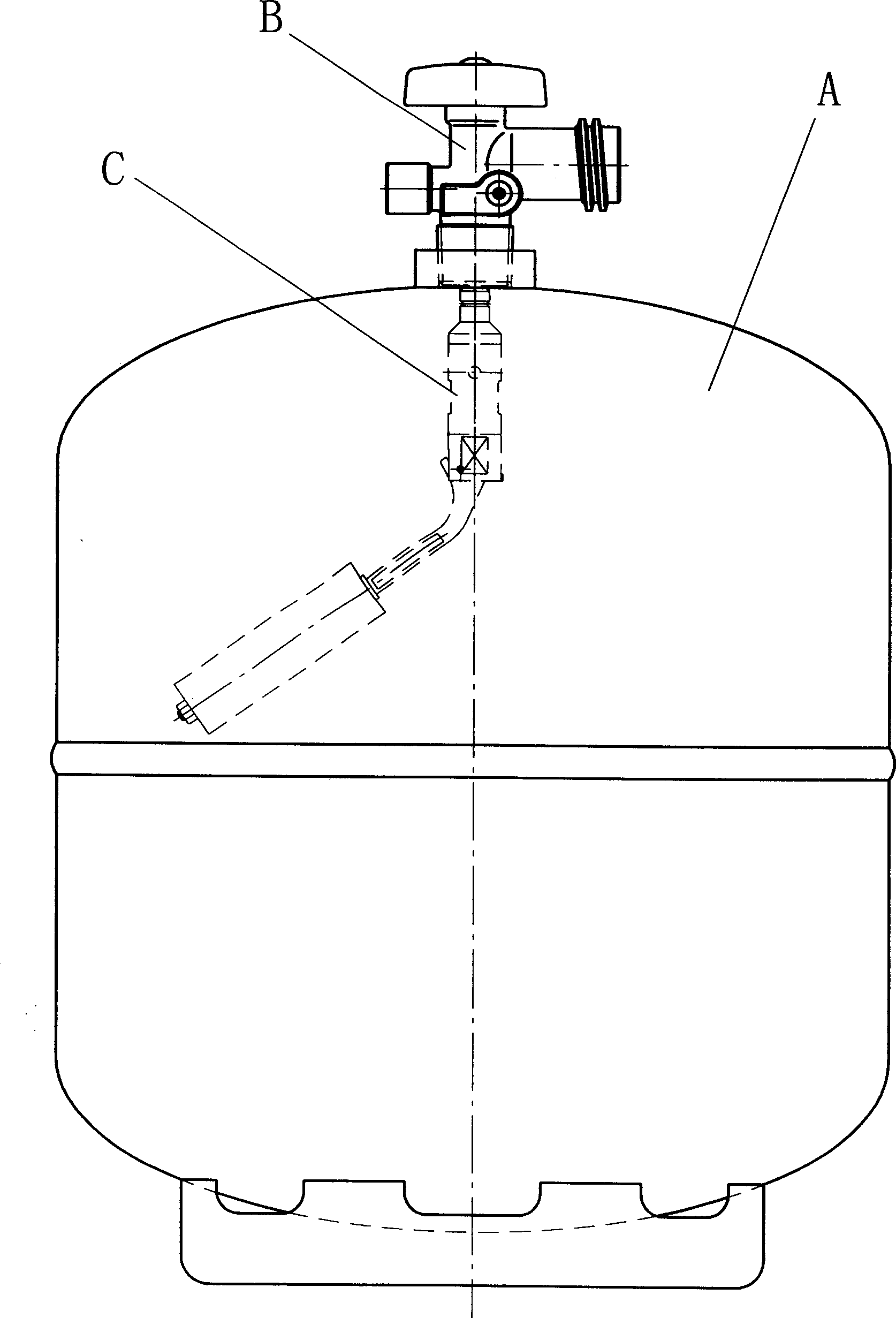

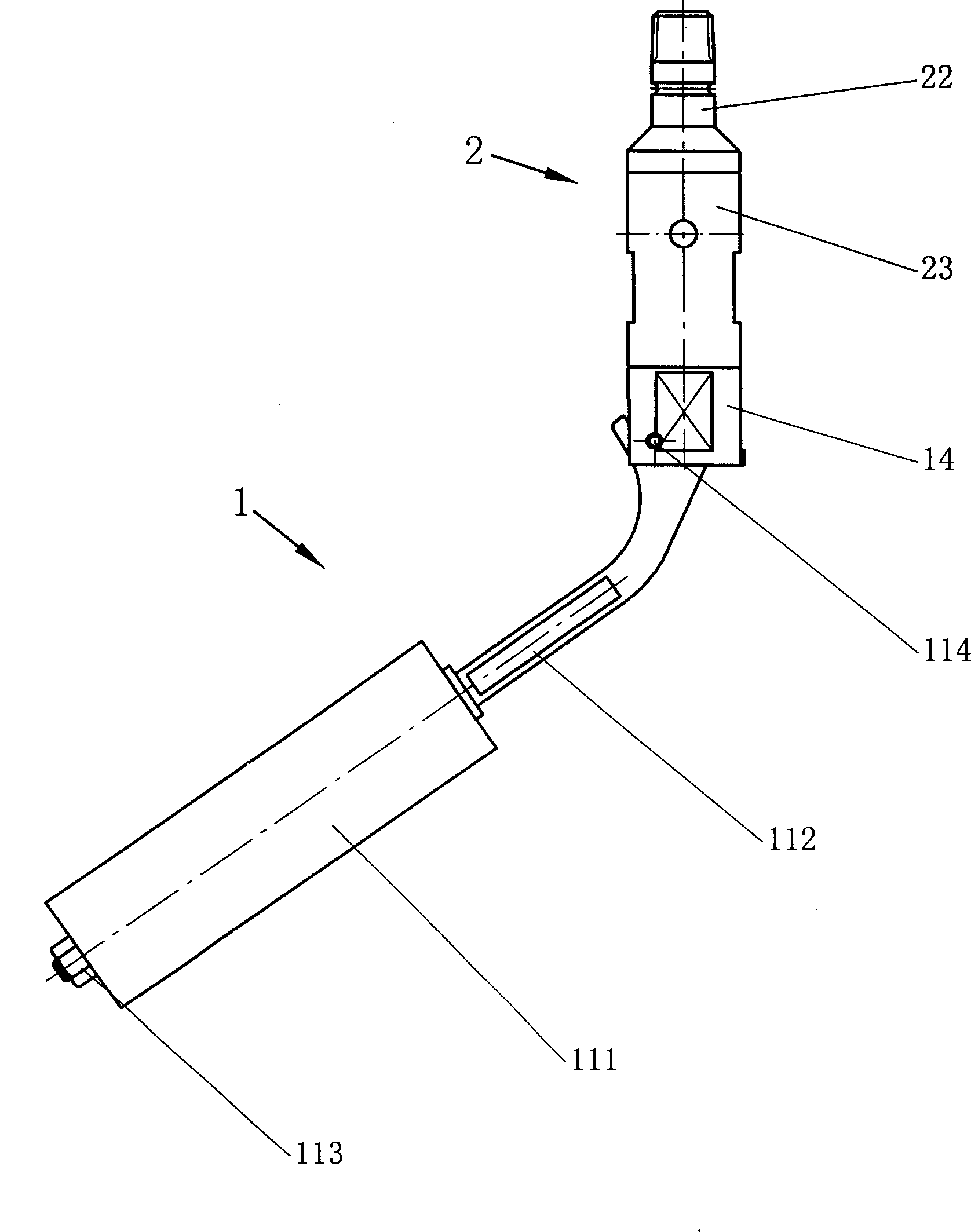

Over-inflation protecting apparatus

InactiveCN1566742AFast fillQuick closeOperating means/releasing devices for valvesEqualizing valvesGas cylinderMagnetic poles

An excess charging protector mounted in a liquified petroleum gas pot comprises a state assembly and an on-off assembly. The state assembly has a connecting rod with a float mounted thereon. The connecting rod is hinged with a lower end cover and connects a magnetic loop support. The magnetic loop support with a builtin magnetic loop is mounted in an annular recess of the lower end cover. A valve core rod is mounted in a closedended round meshed pipe of the lower end cover. A magnetic core is mounted at the bottom of the valve core rod. The magnetic core upper plane magnetic pole has identical polarity with that of the magnetic loop. The on-off assembly barrel has a valve port pore communicated with a radial pore. There are axial inflow pores around the valve port pore. A piston cushion on a piston body mounted in lower inner cavity of the valve port pore aligns said valve port pore. Inner bores of the piston body and the barrel are sealed sliding fit. The radial pore communicated with the barrel inner cavity is in inner cavity of the piston body. The barrel underpart is rigidly coupled to the lower end cover. The state assembly applies the two-magnetism repulsion principle to act, and the action can be completed at pole momentarily, and the pole location can be converted exactly. The on-off assembly utilizes the big and small pore flow velocity pressure gradient principle of fluid, and the action is quick and reliable. It is suitable for fine accurate control, and has a good sealing effect.

Owner:李平安 +1

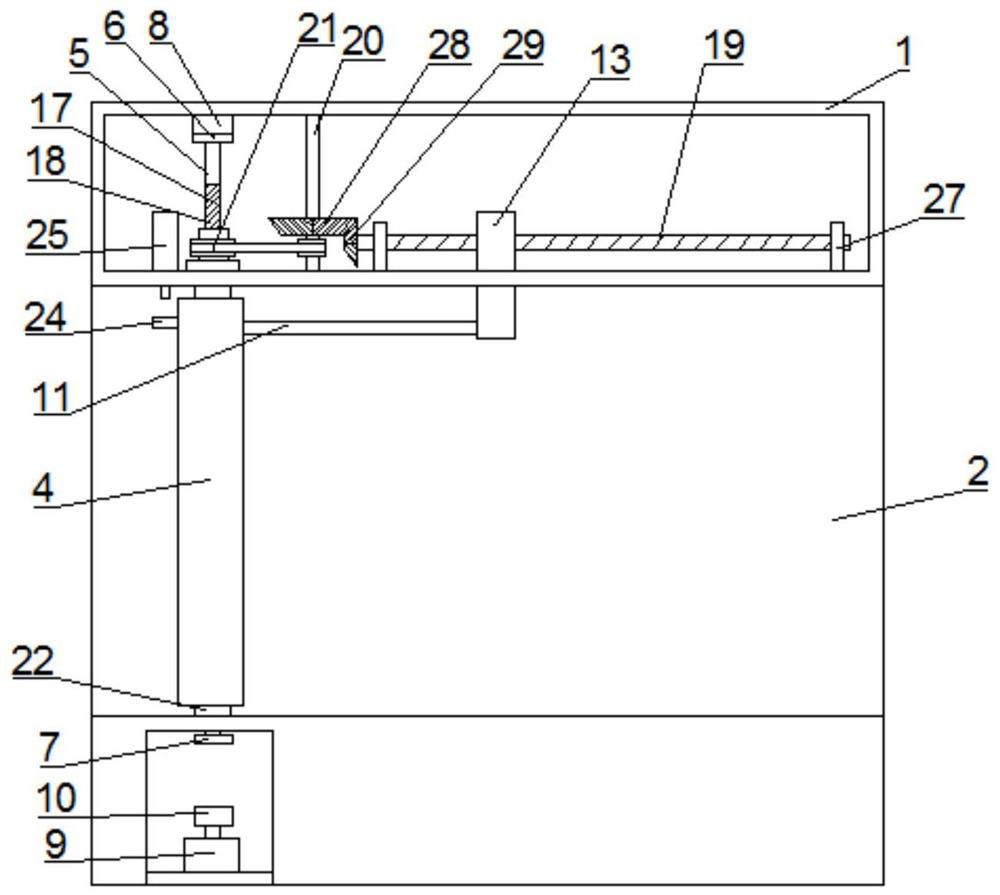

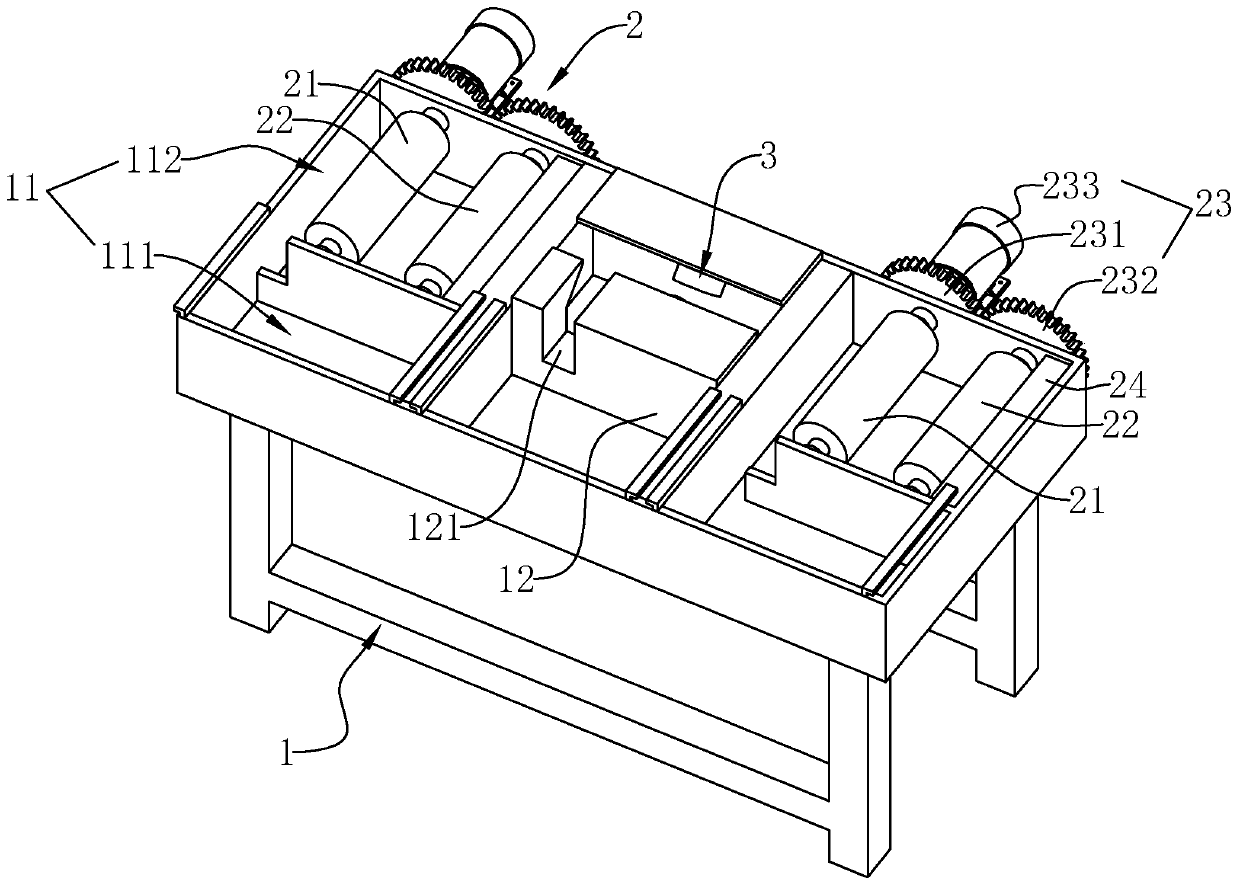

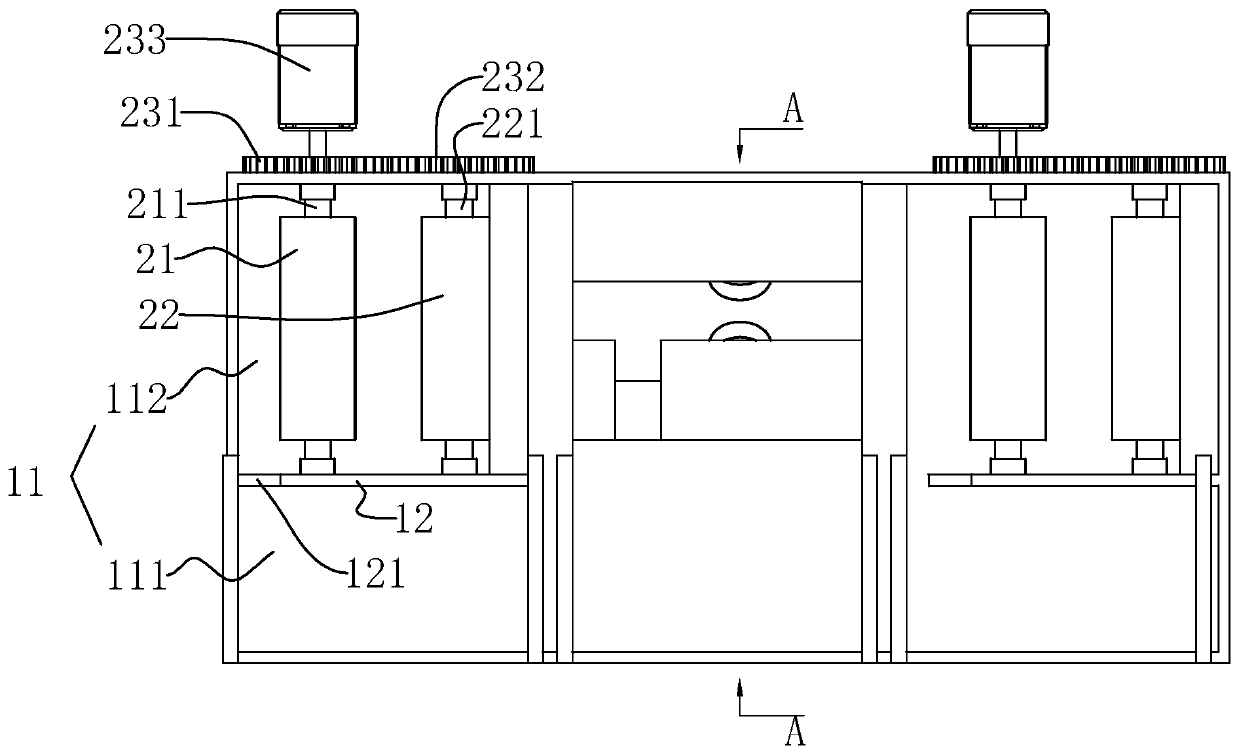

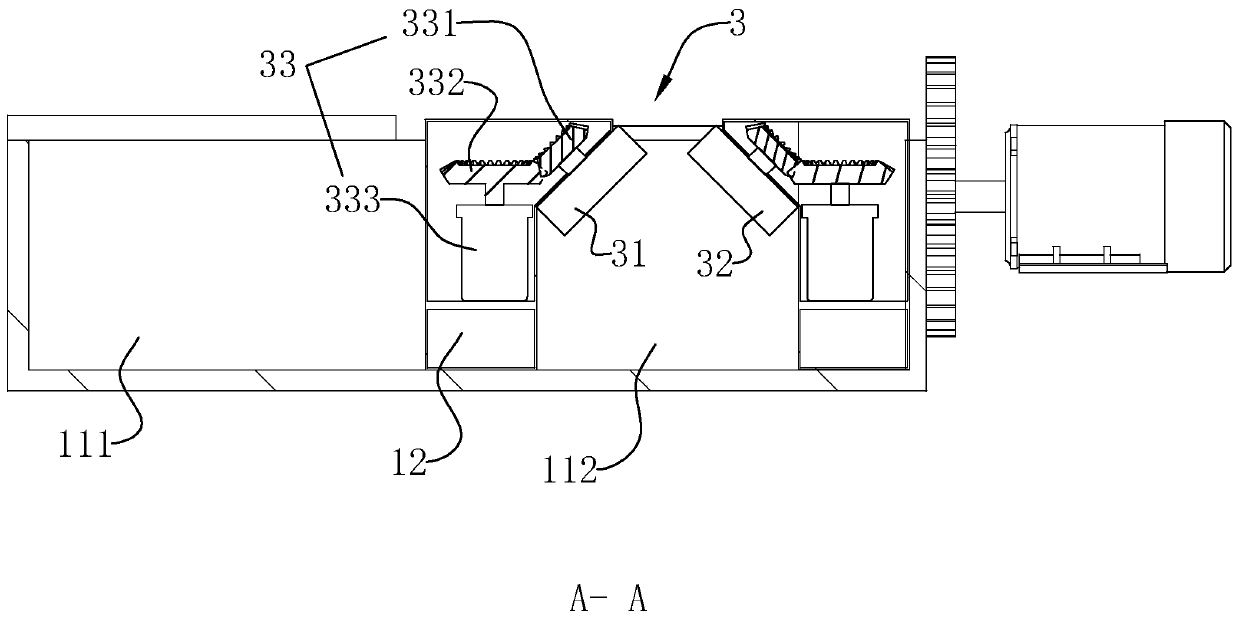

Gluing device for book perfect binding production line

InactiveCN108944139BGlue evenlyHigh bonding strengthToysBook making processesProduction lineElectrical and Electronics engineering

The invention discloses a gluing device of a book glue binding production line, and relates to gluing devices. According to the technical scheme, the gluing device is characterized by comprising a workbench, two sets of spine gluing device bodies arranged on the workbench and a side gluing device body which is arranged between the two sets of spine gluing devices and used for gluing the two sidesof one end, close to a spine, of a book, three gluing chambers are formed in the workbench at intervals, and the two sets of spine gluing device bodies and the side gluing device body are correspondingly arranged in the three gluing chambers. According to the gluing device of the book glue binding production line, when the book is produced, the spine can be automatically coated with glue, and theprocessing efficiency of the book is improved.

Owner:北京昌联印刷有限公司

Magnetic type device for enabling side-hung door to be unlatched

A magnetic type device for enabling a side-hung door to be unlatched comprises a main positioning plate, an auxiliary positioning plate, a magnet, a door leaf and screws. The magnetic type device is characterized in that the main positioning plate is provided with main positioning plate through holes and a supporting rod; the top end of the supporting rod is provided with a ring, and the middle ofthe ring is provided with the magnet; the auxiliary positioning plate is provided with auxiliary positioning plate through holes and a strut, a fork head is arranged on the strut, and the middle of the fork head is provided with a fork opening; the magnet is fixed into the ring, and the two ends of the magnet protrude from the ring; the height of the magnet is smaller than the width of the fork opening; the screws enable the main positioning plate to be fixed to a door frame through the main positioning plate through holes; the screws enable the auxiliary positioning plate to be fixed to thedoor leaf through the auxiliary positioning plate through holes; and the door frame is provided with a door casing which is used for limiting the closing position of the door leaf. According to the magnetic type device, the door leaf is limited through the performance of the magnet.

Owner:CHONGQING PUBLIC TRANSPORTATION CAREER ACADEMY

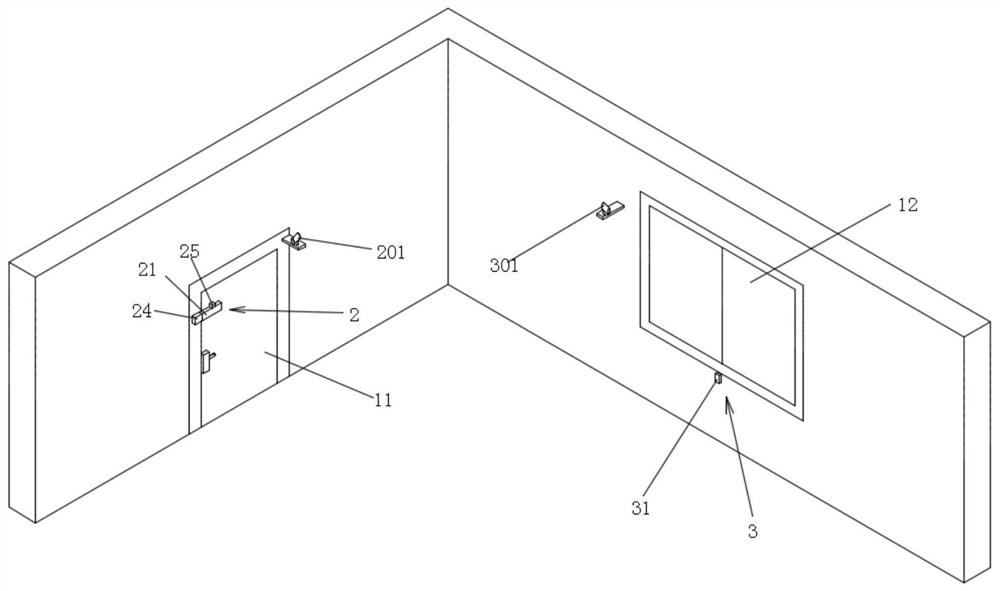

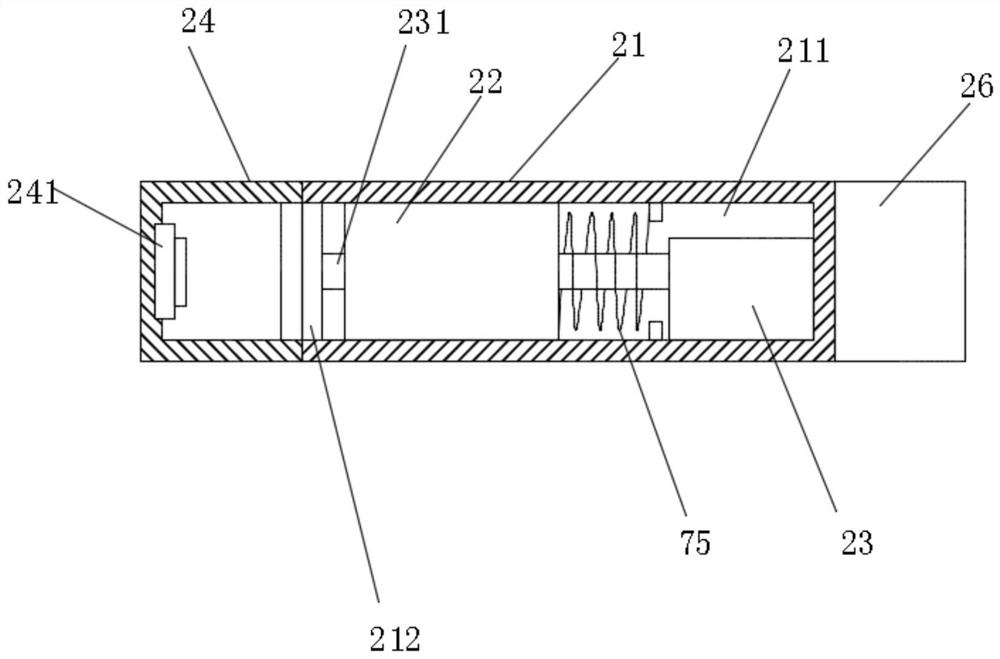

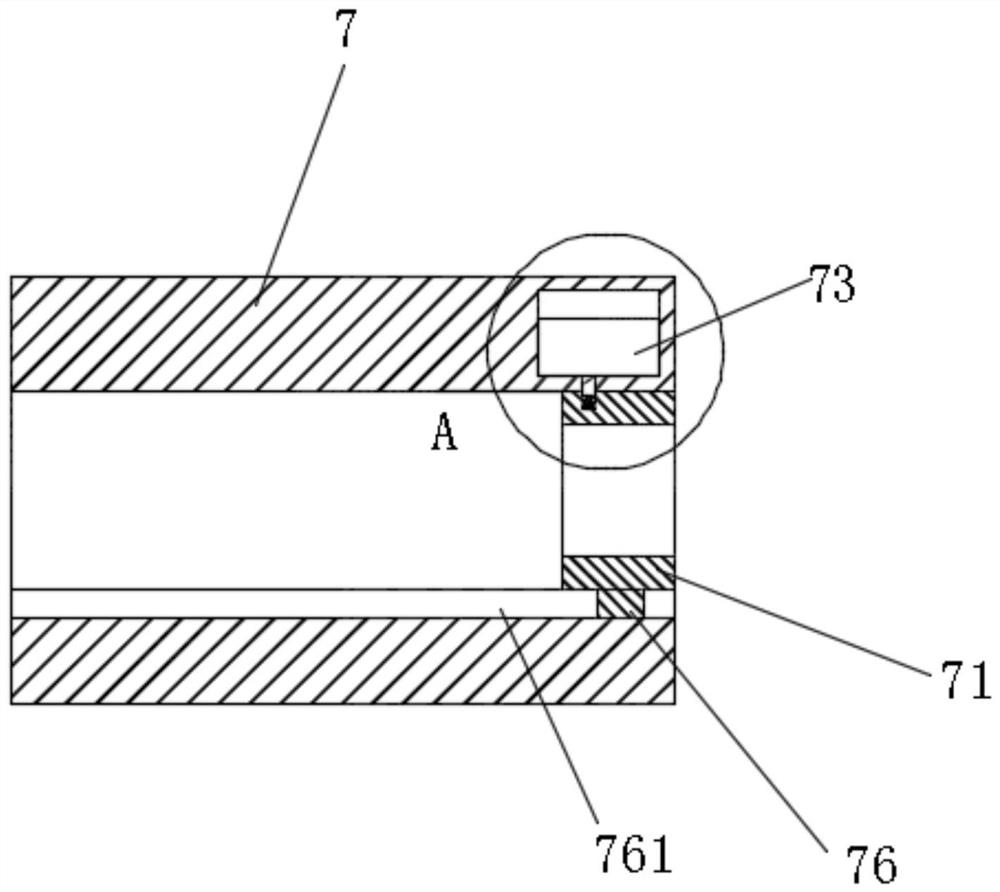

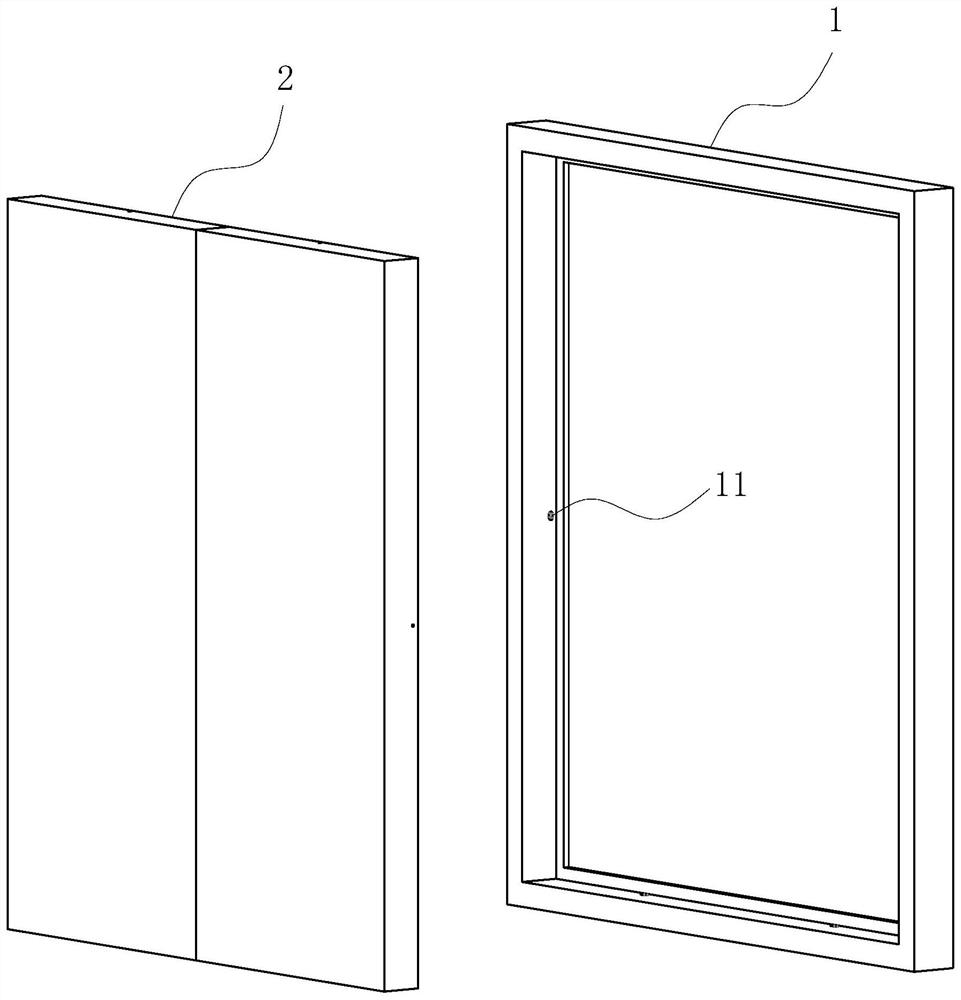

Anti-theft system for community users

ActiveCN109972993AAchieve functionDoes not affect openingBurglary protectionShutters/ movable grillesEngineeringPiston

The invention discloses an anti-theft system for community users. The anti-theft system for the community users includes an anti-theft system mounted at an window, the anti-theft system is arranged atthe outer edge of the window edge and includes a base and a base plate, the base is arranged in an groove in the outer side of the window edge in an embedded mode, the upper end surface of the base is flush with the upper end face of the window edge, the base plate is mounted on the base in a lifting mode, a hollow cavity is formed between the base plate and the base, one or more piston rods arearranged side by side at the inner side end of the base plate, sealing cylinders are embedded in the bottom surface, directly facing the piston rods, of the hollow cavity, and a sealing cavity is formed in each sealing cylinder. According to the anti-theft system for the community users, based on a windowsill structure, during climbing, descending can be realized, top jacking limiting is realizedat the same time to achieve the function of an anti-theft net, appearance is aesthetic during not in use, and outward opening of the window is not affected.

Owner:深圳市金地楼宇科技有限公司

Suspended ground pole and application method thereof

ActiveCN105720391AEasy to hangEffective contact areaConnection contact member materialElectrical conductorEngineering

The invention discloses a suspended ground pole and an application method thereof, and relates to the field of electric machinery. The ground pole comprises a conductive metal pole, wherein an insulating layer wraps the peripheral surface of the conductive metal pole; a plurality of annular grooves (3) are formed in the axial surface of the insulating layer at equal intervals; the depths of the annular grooves (3) are smaller than the thickness of the insulating layer; one segment of conductive metal pole free of the annular insulating layer is arranged on the peripheral surface of the insulating layer between two adjacent annular grooves (3); a stepped cylinder device is clamped between two adjacent annular grooves (3) in a sleeving manner; each stepped cylinder device comprises two pairs of stepped cylinders in one-to-one correspondence; and each two pairs of stepped cylinders sleeve the outer surface of the insulating layer between two adjacent annular grooves (3). The suspended ground pole can ensure sufficient and effective contact area of a wire drained to the ground and the ground pole, prevents the wire drained to the ground from sliding off, and simultaneously solves the problem of an electric wire suspension position set by a worker in a working area.

Owner:STATE GRID CORP OF CHINA +1

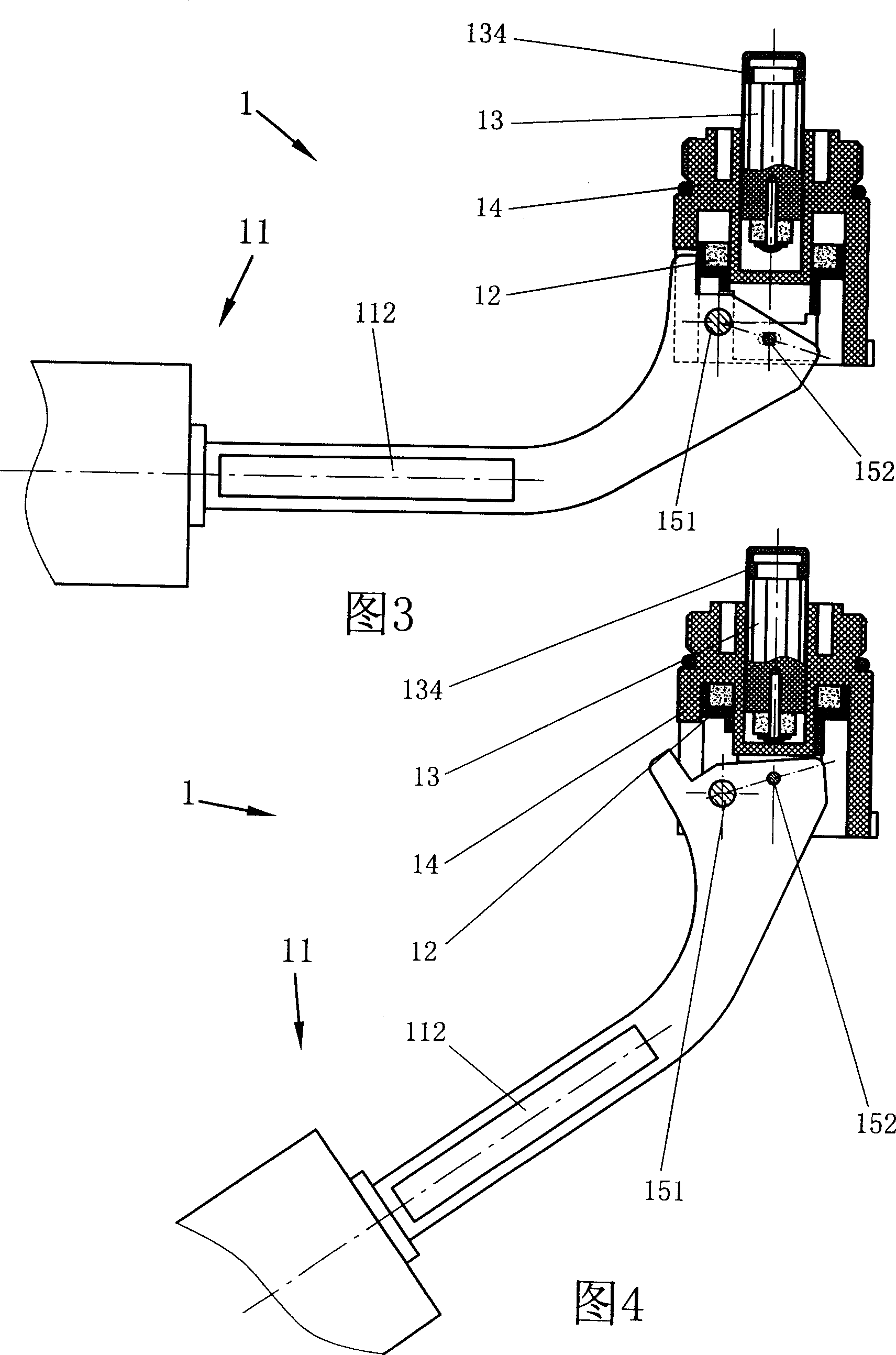

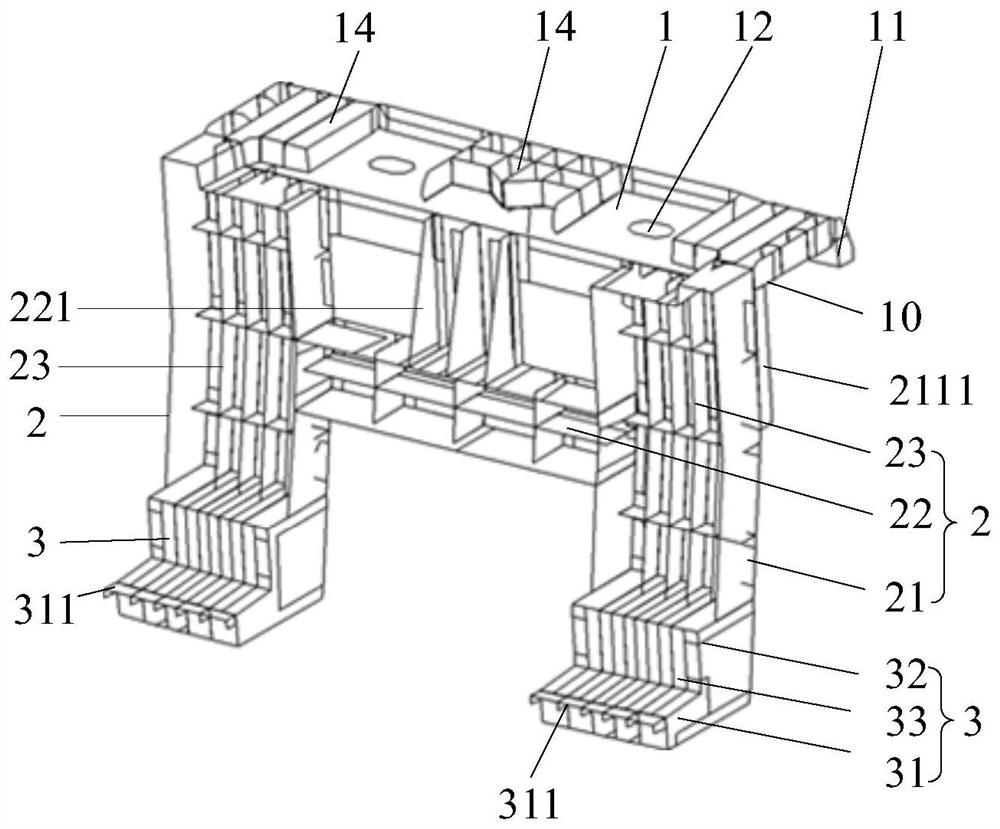

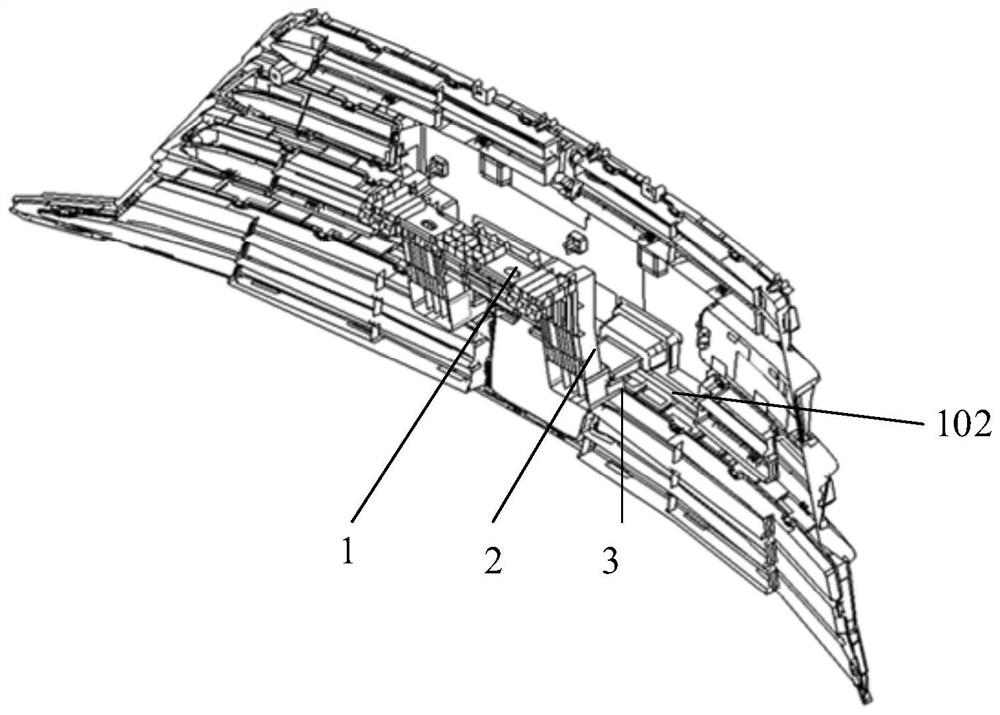

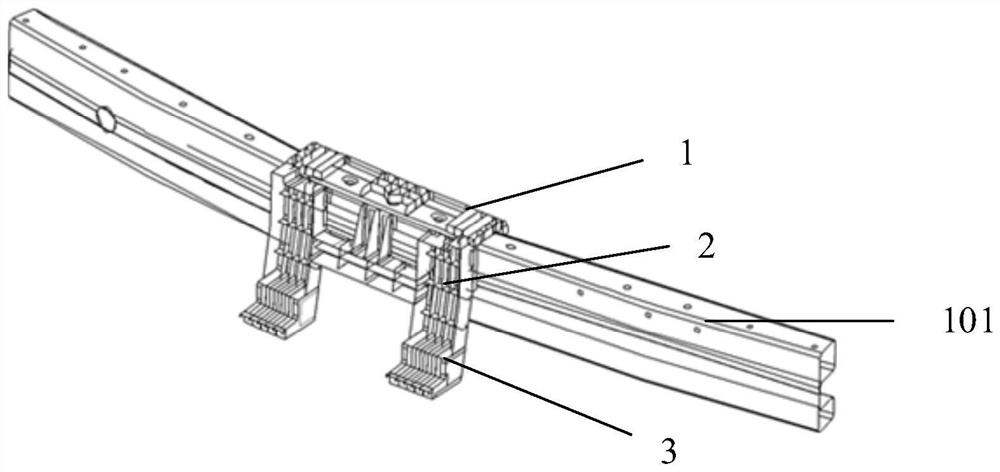

front support device

ActiveCN112373424BAchieve connectionPrevent sinkingPedestrian/occupant safety arrangementBumpersCar manufacturingStructural engineering

Owner:CHERY AUTOMOBILE CO LTD

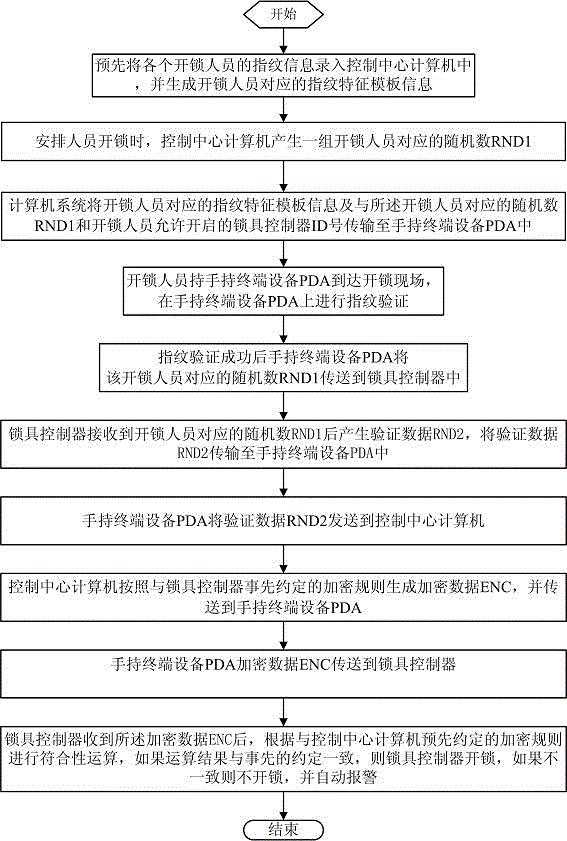

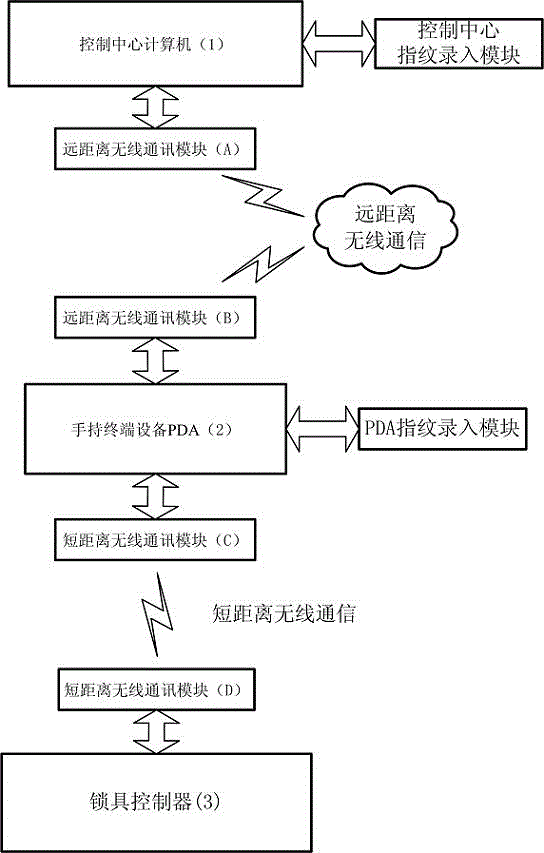

Unlocking method and system based on handheld terminal device pda and fingerprint recognition technology

ActiveCN103106714BDoes not affect openingSecurityIndividual entry/exit registersCommunication interfaceShortest distance

Owner:NANJING EASTHOUSE ELECTRIC CO LTD

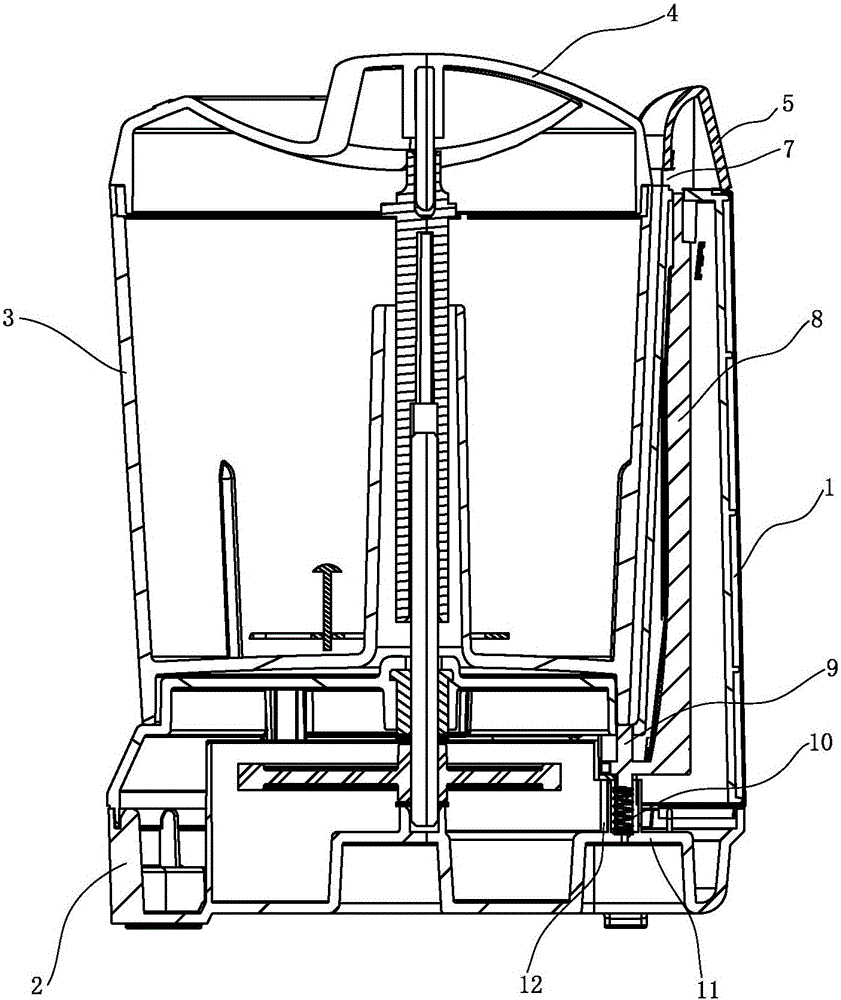

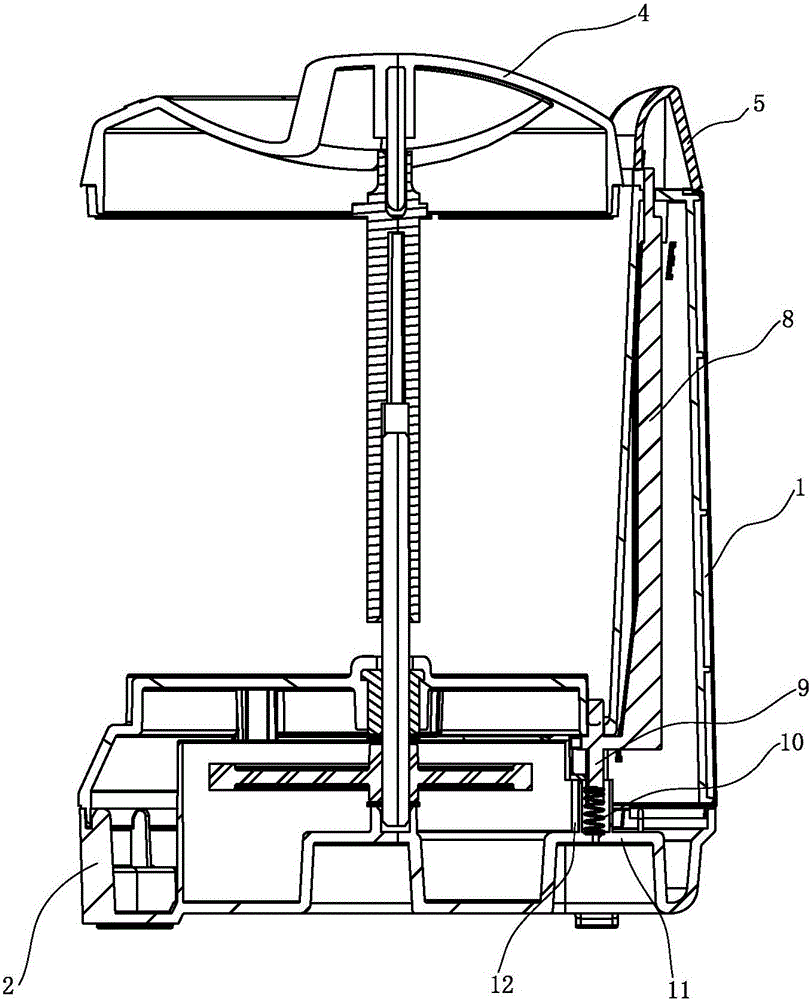

Food processor cover safety protection device

ActiveCN103767572BDoes not affect pick and placeDoes not affect slidingKitchen equipmentJoints typesEngineering

Owner:DONGGUAN BBK HOUSEHOLD ELECTRICAL APPLICANCES +1

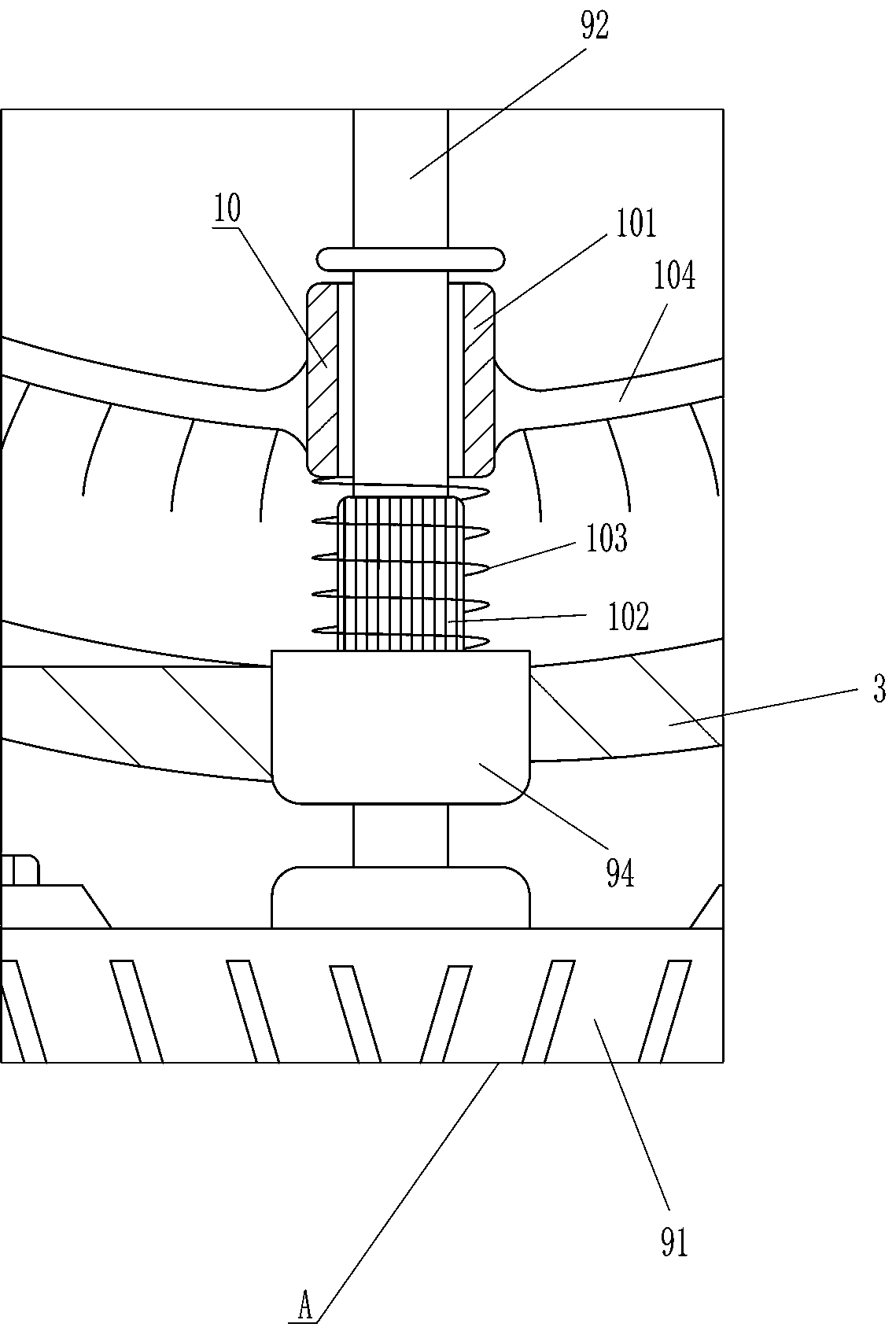

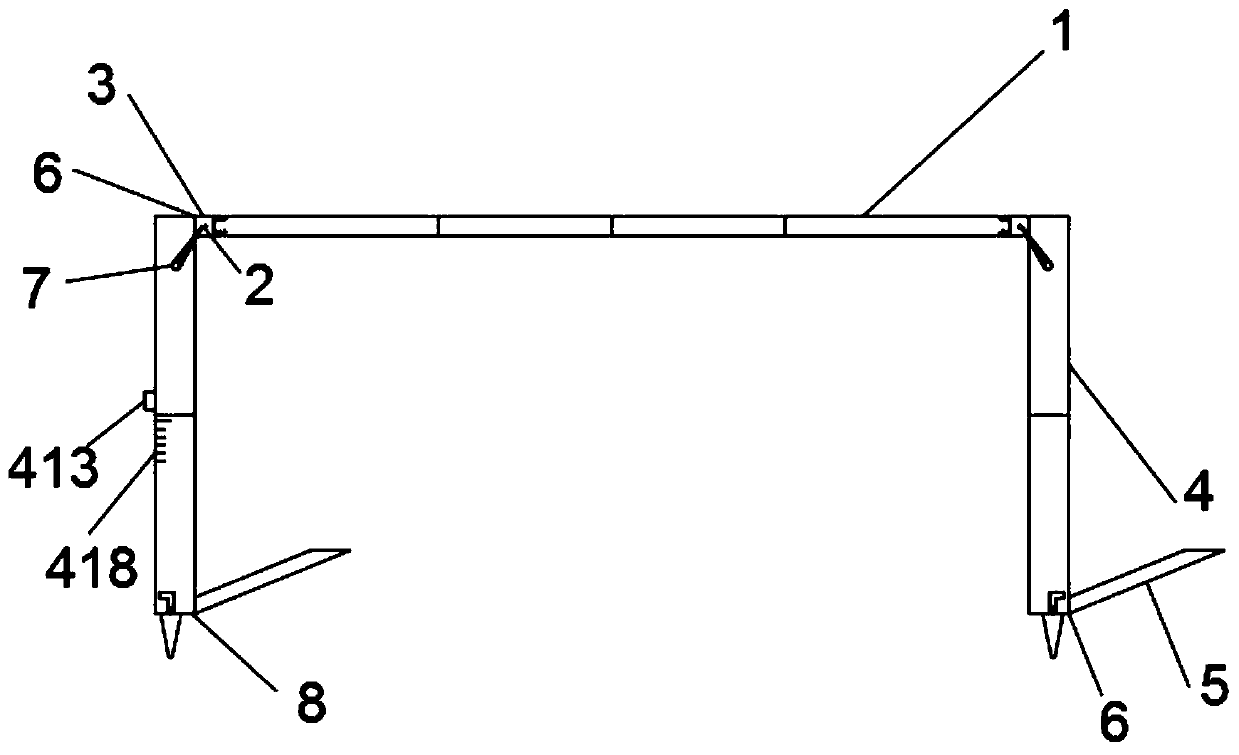

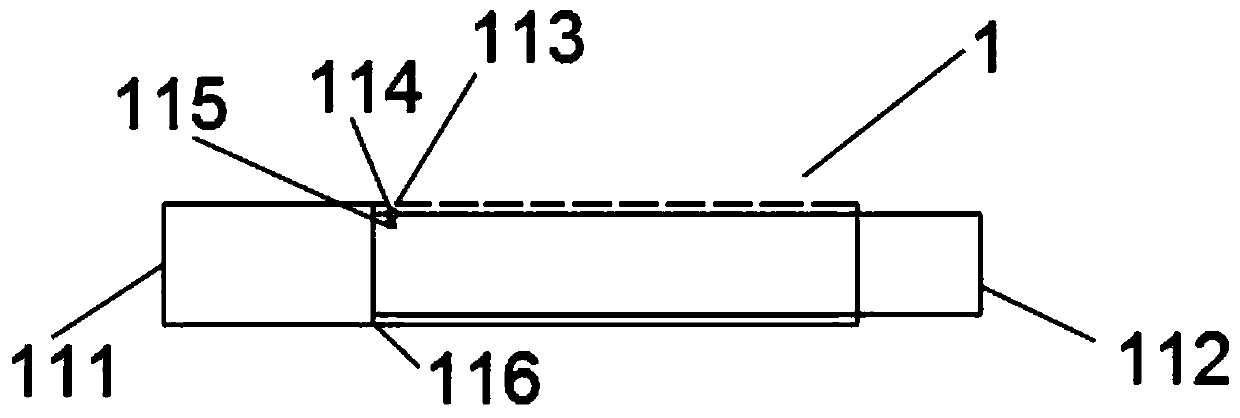

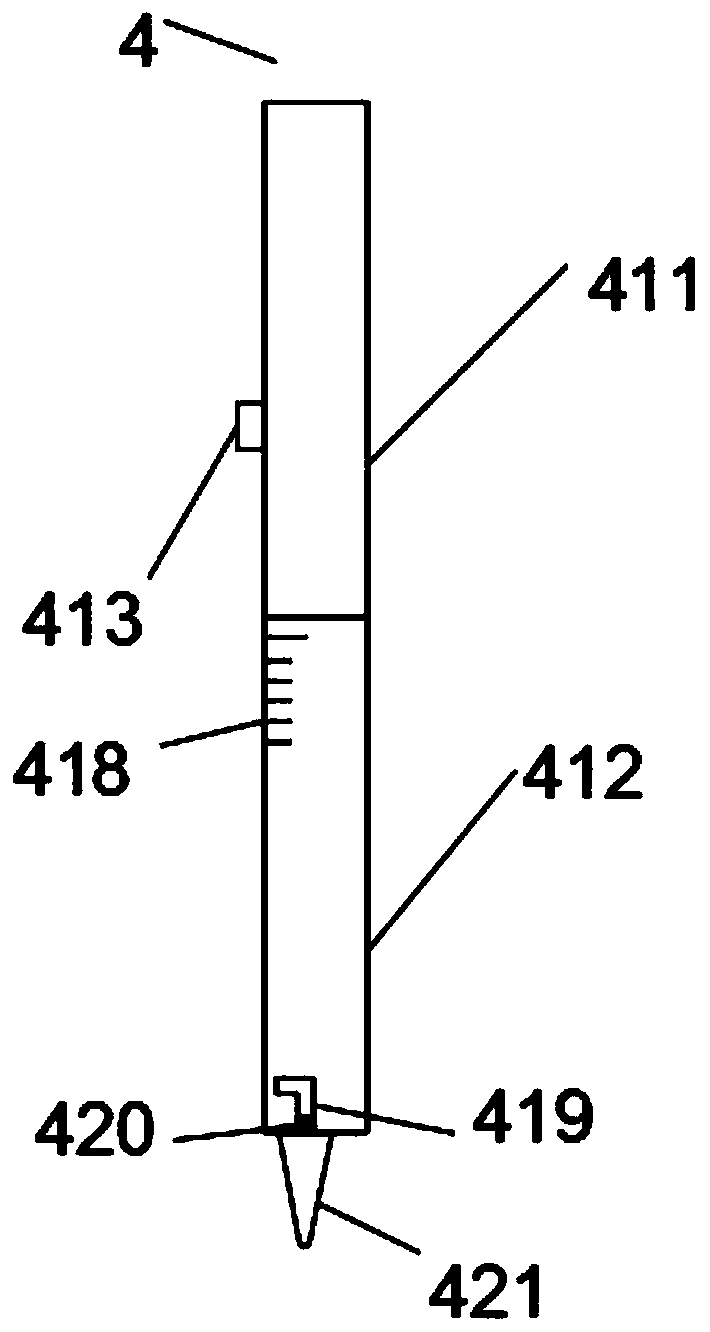

Sports hurdle frame

InactiveCN111084999AFolded size is smallOvercoming the problem of easy breakageRace-coursesRidingIndustrial engineeringForce direction

The invention provides a sports hurdle frame. The sports hurdle frame comprises a cross rod, connecting pieces, supporting pieces, stabilizing pieces and bearings. All the rods can be folded; the connecting pieces enable sleeve rods and fixing rods to be connected in a rotating mode. When a student hurdles a hurdle, the cross rod is touched; the cross rod can rotate along the force direction, so that the student is prevented from being stumbled; the problem that the joint is easy to break in the prior art is solved; the spring specially designed in the connecting piece can be used for limitingthe rotating angle, so the corner of the cross rod is prevented from being overlarge; the height of the hurdle is adjustable through cooperation of a gear and a rack, a matched ruler can be adjustedaccording to students of different ages or heights, the length is adjustable through cooperation of the sleeve rod and the sliding rod, the requirements of students of different ages are also met, andthe folding size can be smaller.

Owner:SHAANXI TECHN INST OF DEFENSE IND

Household monitoring system

PendingCN111970491ATimely processingReduce lossesClosed circuit television systemsMonitoring systemThe Internet

The invention relates to the technical field of household equipment, in particular to a household monitoring system, which comprises a first alarm mechanism, a second alarm mechanism, a control moduleand a terminal, and is characterized in that the first alarm mechanism comprises an access control device and a first camera which are arranged on a door; the access control device is used for acquiring a signal of whether the door body is normally opened or not; the first camera is used for shooting the environment of the door body; the second alarm mechanism comprises a window security device and a second camera which are installed on a window; the window security device is used for obtaining a signal whether an intruder exists in the window or not, and the second camera is used for shooting the environment at the window; the control module is used for data acquisition of the first alarm mechanism and the second alarm mechanism, and the control module is in communication connection withthe terminal based on the Internet. According to the home monitoring system, the condition that an intruder invades a house can be mastered in time, so that the property loss of residents is reduced.

Owner:NANNING COLLEGE FOR VOCATIONAL TECH

Rail transit double-opening sliding plug door

InactiveCN114033264AReduce the probability of automatic openingDoes not affect openingPower transmission/actuator featuresDoor arrangementEngineeringStructural engineering

The invention relates to a rail transit double-opening sliding plug door. The door comprises a door leaf and a door frame; the door leaf is installed on the door frame; a locking groove is formed in the door frame; a locking cavity is formed in the door leaf; a sliding hole and a locking hole are formed in the locking cavity; a high-speed locking device is installed in the locking cavity; the high-speed locking device comprises a piston, a linkage mechanism, a reset spring and a locking rod, the piston is installed in the sliding hole and connected with the locking rod through the linkage mechanism, the locking rod is installed in the locking cavity in a sliding mode, one end of the locking rod is installed in the locking hole and can penetrate out of the locking hole to enter the locking groove, the piston drives the locking rod to slide through the linkage mechanism, and the two ends of the reset spring are fixedly connected with the side wall of the locking cavity and the locking rod respectively. With the rail transit double-opening sliding plug door adopted, the defect that a sliding plug door is automatically opened in the high-speed running process of a vehicle is overcome.

Owner:广州康尼轨道交通装备有限公司

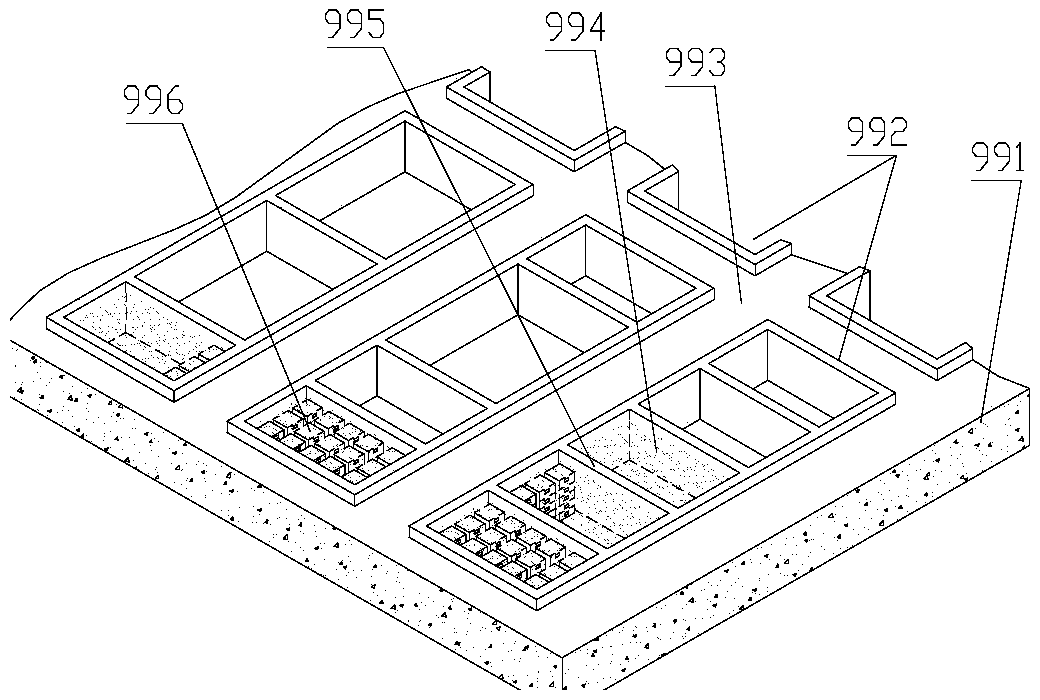

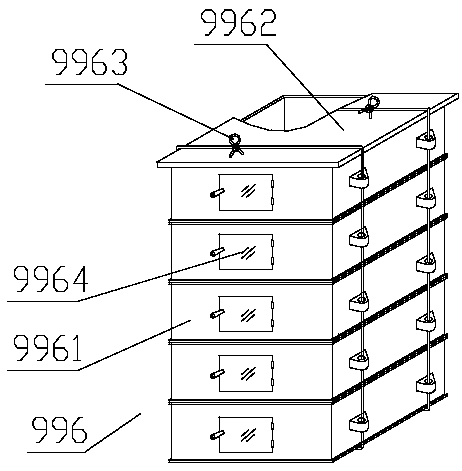

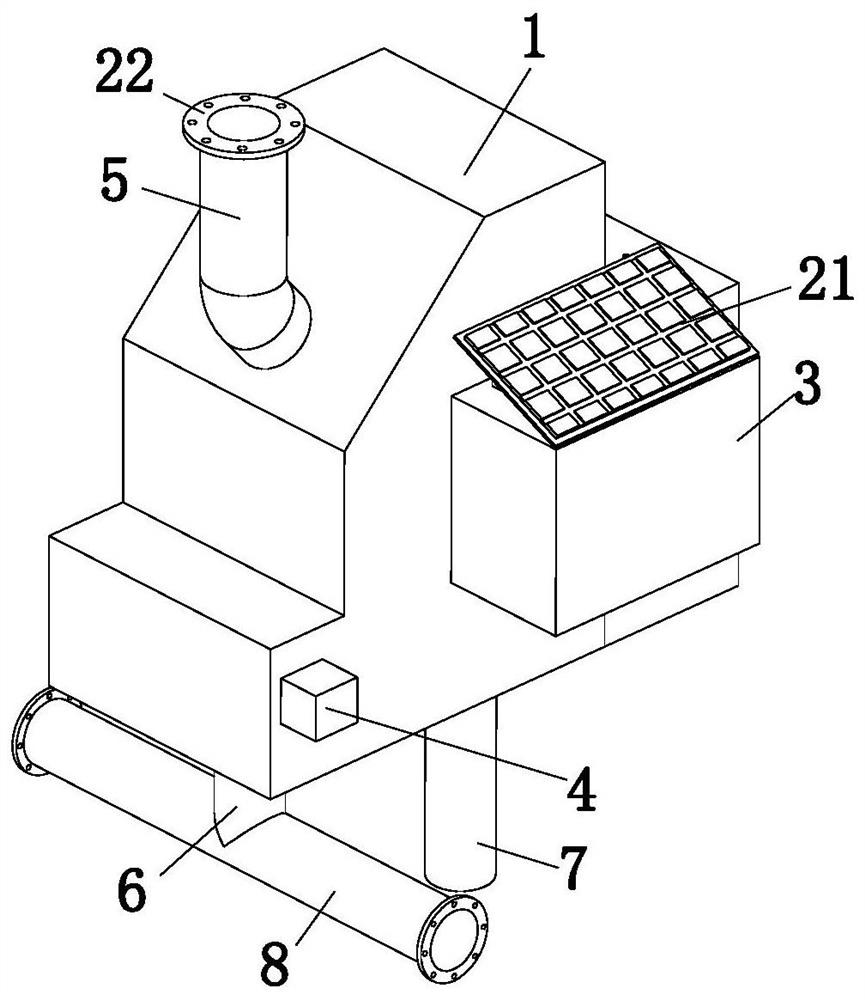

Land abalone culturing feeding system

InactiveCN109042444ANovel structureReduce manufacturing costClimate change adaptationPisciculture and aquariaZoologyGround level

The invention discloses a land abalone culturing feeding system. The system comprises a culturing pond, a culturing cabinet and a lifting and lowering machine; the culturing pond is arranged under theground of a workshop; the edge of the culturing pond is provided with a workshop walk paths one or more lifting and lowering machines is installed in the culturing pond, and a lifting and lowering platform in the lifting and lowering machine can perform up and down lifting and lowering in horizontal planes between the bottom and surface of the culturing pond; one or more culturing cabinets are placed on the lifting and lowering platform; moving wheels are arranged at the bottom of the culturing cabinet; the culturing cabinet is lowered into culturing water in the culturing pond to perform culturing, and the culturing cabinet is lifted to the surface of the pond from the culturing pond; an operator moves the culturing cabinet onto the workshop walk paths to feed, or the operator feeds by grabbing feed to the culturing cabinet on the lifting and lowering platform, or the operator feeds the culturing cabinet which is moved to the workshop walk path or the lifting and lowering platform through the feeding machine.

Owner:张达英

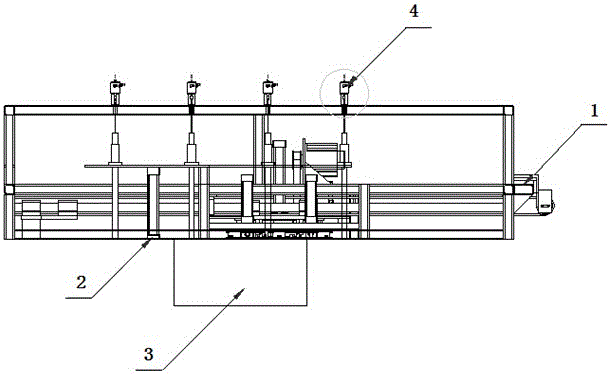

Four-head mouth-bonding unit for film-lined pouches

ActiveCN104475304BDoes not affect openingPrevent overflowLiquid surface applicatorsCoatingsEngineeringPiston rod

The invention provides a four-nozzle mouth adhesion device for a film package bags with a lining. The four-nozzle mouth adhesion device comprises a transverse moving mechanism, a longitudinal moving mechanism, a hot melt adhesive ejection machine and nozzle mechanisms, wherein each nozzle mechanism comprises an aeration one-way valve, an adhesive ejection head body, a nozzle needle tube, a heating rod, a thermal-insulating connecting sleeve, a cylinder mounting rack and a micro-cylinder; compressed air is provided into the aeration one-way valves through air pumps; channels through which an adhesive or compressed air passes are formed in the adhesive ejection head bodies; nozzle needle tube mounting holes are formed in the front parts of the adhesive ejection head bodies; piston holes are formed in the rear parts of the adhesive ejection head bodies; heating rod mounting holes are formed in two sides of the piston holes; the bases of the micro cylinders are arranged on cylinder mounting racks; piston rods of the micro cylinders are connected with the heating rods through the thermal-insulating connecting sleeves. Due to design of a piston mechanism for controlling the surplus adhesives of the nozzle needle tubes when adhesive ejection is started and stopped, the adhesive outlets of the nozzle needle tubes are controlled to prevent the surplus adhesives from overflowing outside bag mouths, the outer layers of the mouths of inner and outer bags can be adhered together, and inner bags can be opened easily.

Owner:JIANGSU WANLE AUTOMATION EQUIP

A drainage device for a bridge

Owner:绍兴柯桥富荣纺织有限公司

Protective device installed on rear portion of vehicle

The invention discloses a protective device installed on the rear portion of a vehicle. The protective device comprises connecting pieces installed on the two sides of a vehicle girder, and steel plates assembled in the connecting pieces. The connecting pieces are made of Q235 common carbon structural steel, the wall thickness of each connecting piece is 6 mm-12 mm, and the connecting pieces are fixed to the vehicle girder in a bolting or welding manner. An upper clamping plate and a lower clamping plate are formed on the surface of each connecting piece in a casting manner, wherein sliding blocks are arranged on the opposite faces of the two clamping plates, and screw holes penetrating through the sliding blocks are formed in the outer sides of the clamping plates. The device does not influence the use of the truck, and can perform buffering and energy absorption to protect a small vehicle when the small vehicle collides with the truck.

Owner:蔡金良

Battery capable of reducing or eliminating case voltage and method of making same

ActiveCN104282864BDoes not affect openingReduce case voltageCell seperators/membranes/diaphragms/spacersFinal product manufactureEngineeringElectrolyte

The invention provides a battery capable of reducing or eliminating the voltage of the casing, which includes a casing, a cell with a first tab and a second tab, and an insulating sheath arranged between the casing and the cell, with a first The electric cores of the tab and the second tab are assembled in the insulating sheath and the insulating sheath is connected to the upper cover of the casing in a sealed manner, and the assembled electric core with the first tab and the second tab, The insulating sheath and the upper cover of the housing are packaged together in the lower housing of the housing, and the lower housing of the housing is connected to the upper cover of the housing in a sealed manner. The invention also provides a method for preparing a battery capable of reducing the voltage of the casing, wherein an insulating sheath is arranged between the casing and the battery core. The advantage of the battery and the battery preparation method is that the electrolyte only contacts the positive and negative electrodes without contacting the shell of the battery due to the insulating sheath, thereby reducing or eliminating the voltage between the shell and the electrodes.

Owner:SAIC GENERAL MOTORS +1

Working method of bridge water drainage device

The invention relates to the field of bridge equipment, specifically to a bridge water drainage device. The bridge water drainage device comprises a treatment box, a dirt collecting box, a filtering mechanism and an oil removing mechanism; a filtering cavity, an oil suction cavity and an oil collecting cavity are formed in the treatment box; the filtering mechanism and the oil removing mechanism are correspondingly mounted in the filtering cavity and the oil suction cavity; the dirt collecting box is positioned on one side of the treatment box; a water inlet pipe is arranged at the upper end of the treatment box; an oil drain pipe and a water drainage pipe are arranged at the lower end of the treatment box; an oil collecting pipe communicating with the oil drain pipe is arranged at the lower end of the oil drain pipe; a material outlet is formed in one side of the treatment box; a material stopping component is arranged in the material outlet; the filtering mechanism comprises a filtering net and a swinging component; a hinging shaft is arranged at one end of the filtering net; and the filtering net is hinged to the treatment box through the hinging shaft. The bridge water drainagedevice has the beneficial effects that greasy dirt and sand stones in drained water can be drained to prevent pipeline blockage; and moreover, the structure is simple, and the manufacturing cost is lower.

Owner:佛山市市政建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com