Patents

Literature

204results about How to "Ensure equipment security" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method suitable for width measurement and centering of rough rolling slab in hot rolling mill

InactiveCN101811140AAccurately measure the actual widthAvoid misuseGuiding/positioning/aligning arrangementsRoll mill control devicesContact pressureEngineering

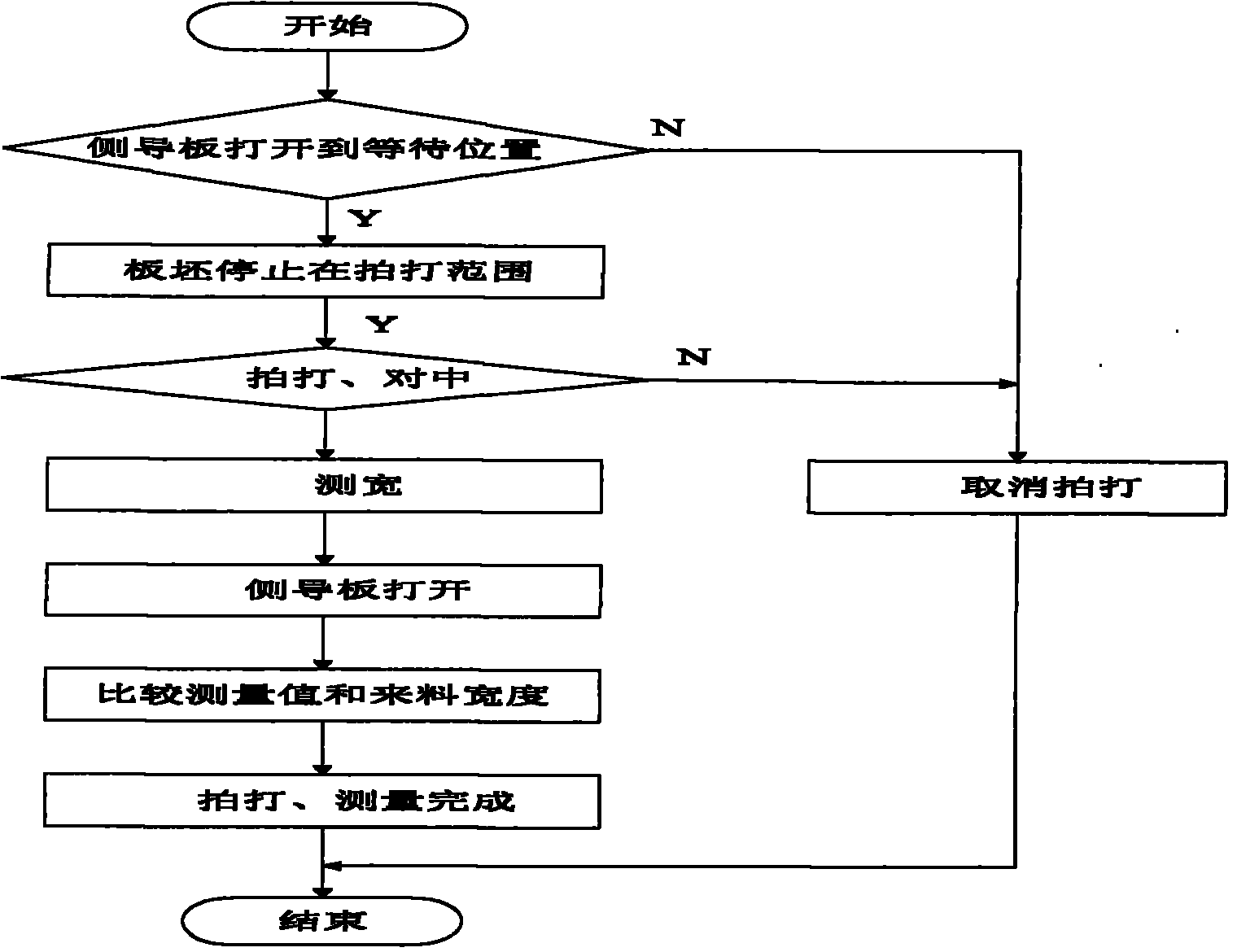

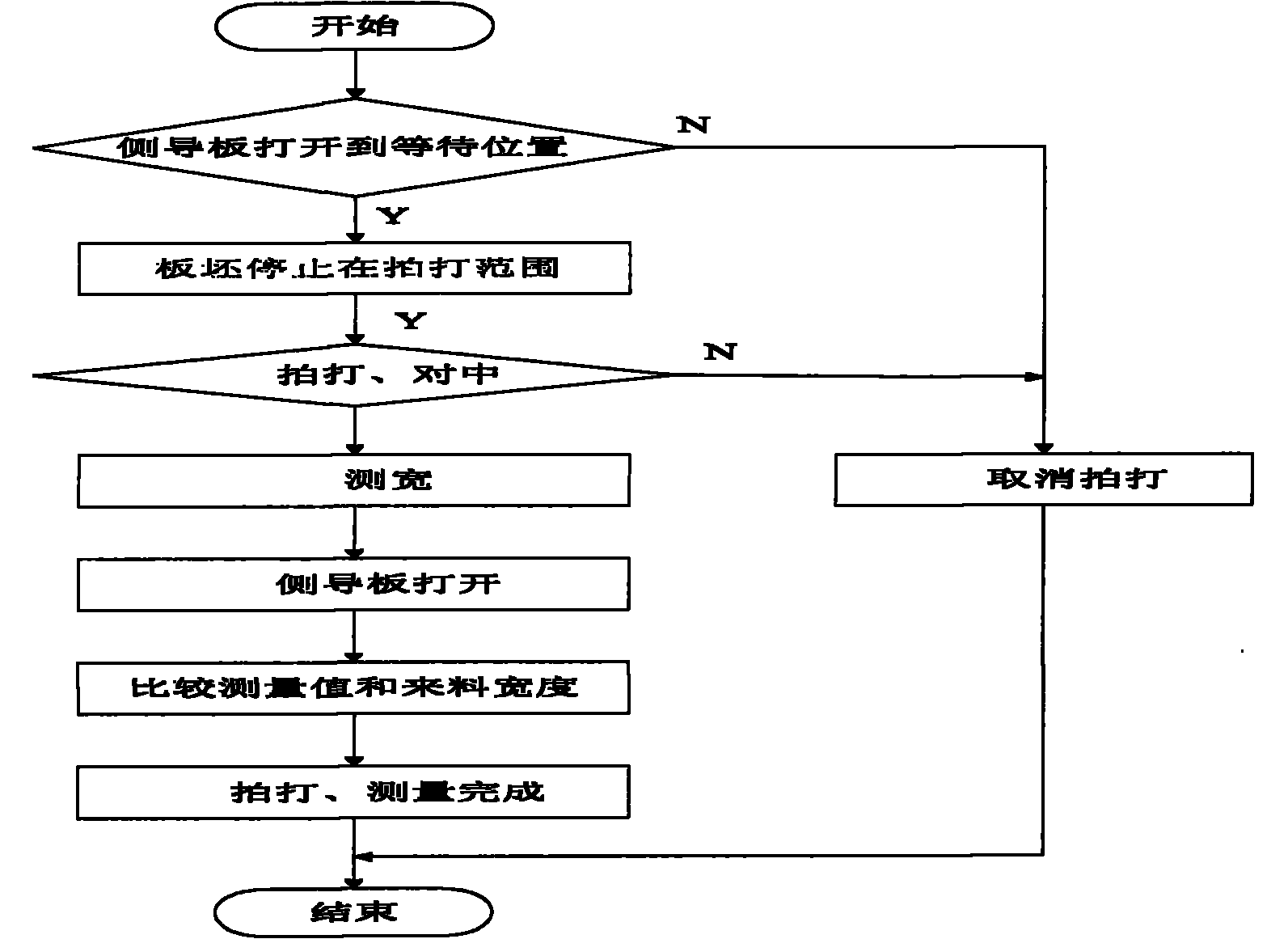

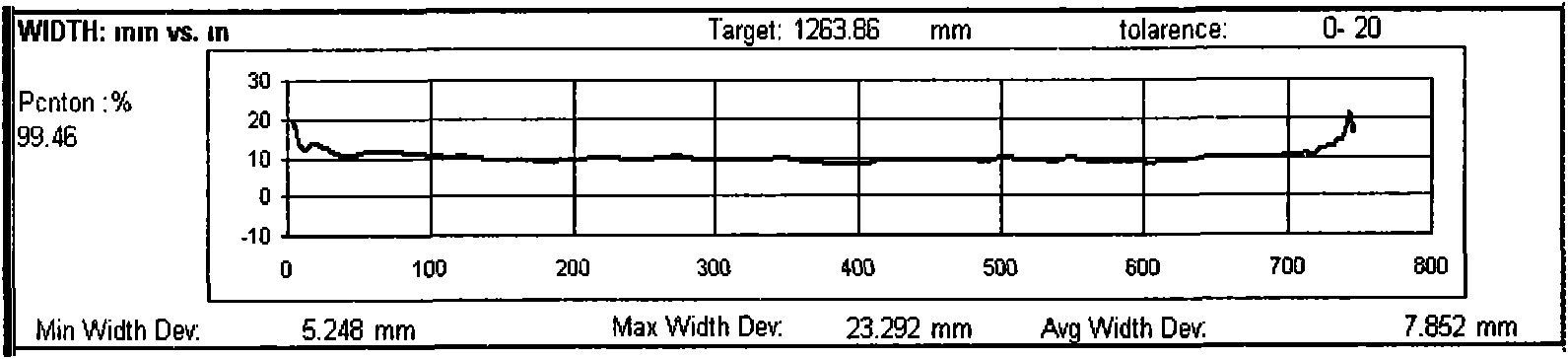

The invention relates to a method suitable for width measurement and centering of a rough rolling slab in a hot rolling mill, which belongs to the technical filed of steeling rolling computer control. The method mainly comprises the following steps of: 1, controlling a left guide plate and a right guide plate to arrive holding positions; 2, controlling the left guide plate and the right guide plate to move towards the direction of a rolling central line synchronously until contacting and patting a blank plate; 3, when the contact pressures of the left guide plate and the right guide plate, and the blank plate reach a predetermined value; recording the distance between the left guide plate and the right guide plate and the blank plate; 4, taking the recorded distance value as an actual width measurement value of the blank plate which is used for performing on-line control on rolling parts including a vertical roller; and 5, controlling the left guide plate and the right guide plate to return to guide positions. By adopting the method of the invention, original side plates which only have a guiding effect can play a role in patting the blank plate and ensuring the blank plate to be centered, and can be used as a detection device for measuring the actual width of the blank plate accurately, so that an error action caused by data error is avoided and the performance of equipment is remarkably enhanced without adding equipment investment hardly.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

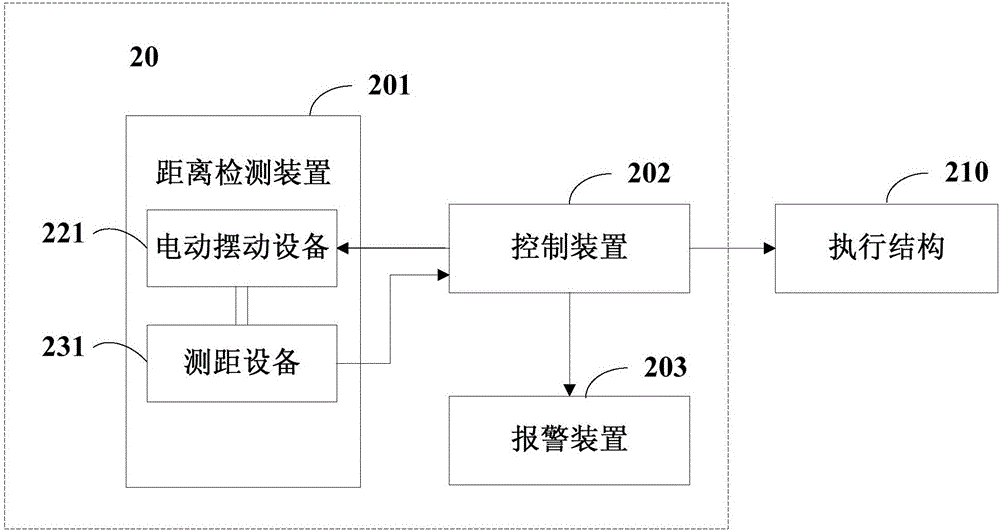

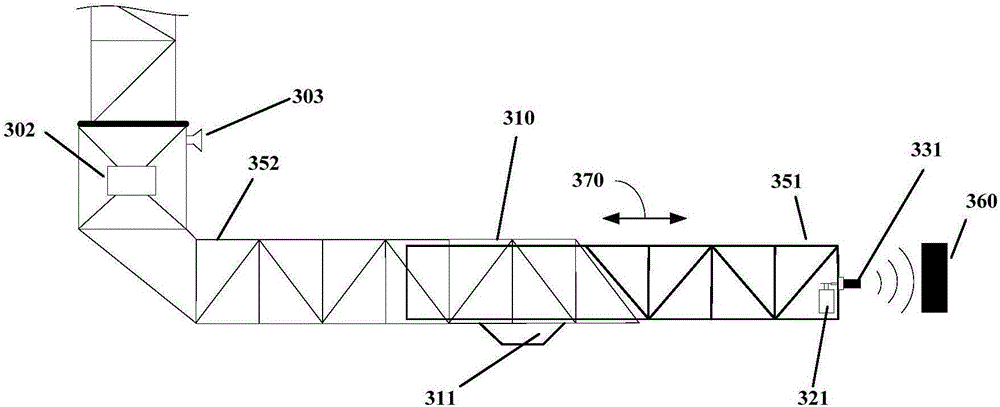

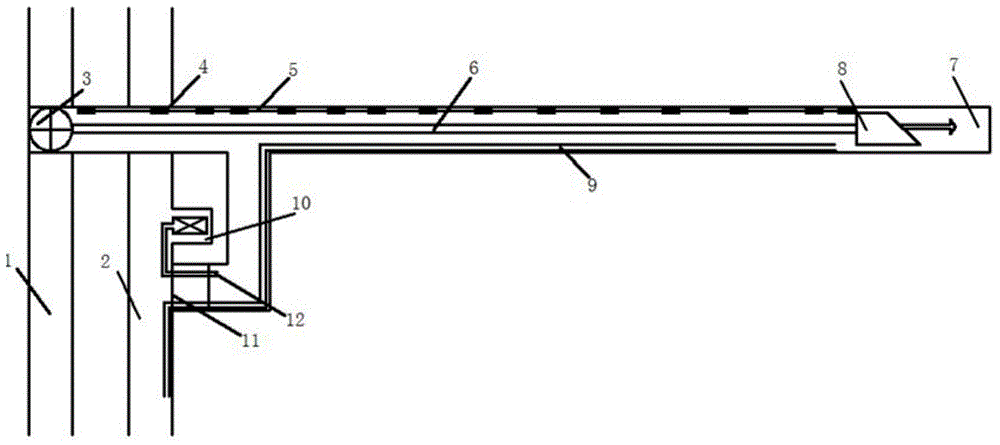

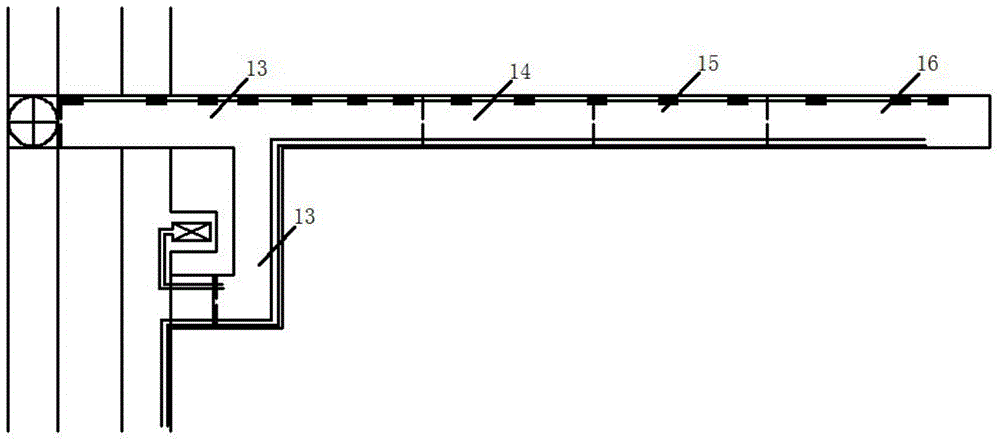

Control system and method of telescopic device, and telescopic device

PendingCN106502137AEnsure personal and equipment safetyTo achieve the purpose of anti-collisionProgramme control in sequence/logic controllersControl zoneDistance detection

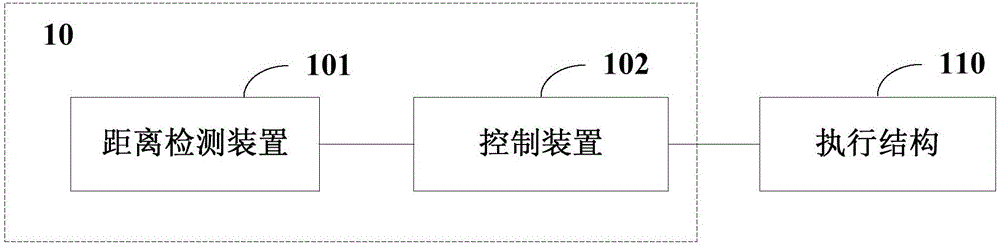

The invention, which relates to the engineering machinery field, discloses a control system and method of a telescopic device, and a telescopic device. The control system comprises a distance detection device and a control device. The distance detection device arranged on an arm head of the telescopic device is used for measuring a distance between the arm head and a surrounding obstacle and transmitting the measured distance value to the control device. The control device is used for controlling the telescopic device to make a corresponding telescopic motion after receiving the distance value according to a control zone where the distance value is located. Therefore, the corresponding telescopic motion can be made according to the control zone where the distance value is located, so that the collision between the telescopic device and the obstacle is avoided.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

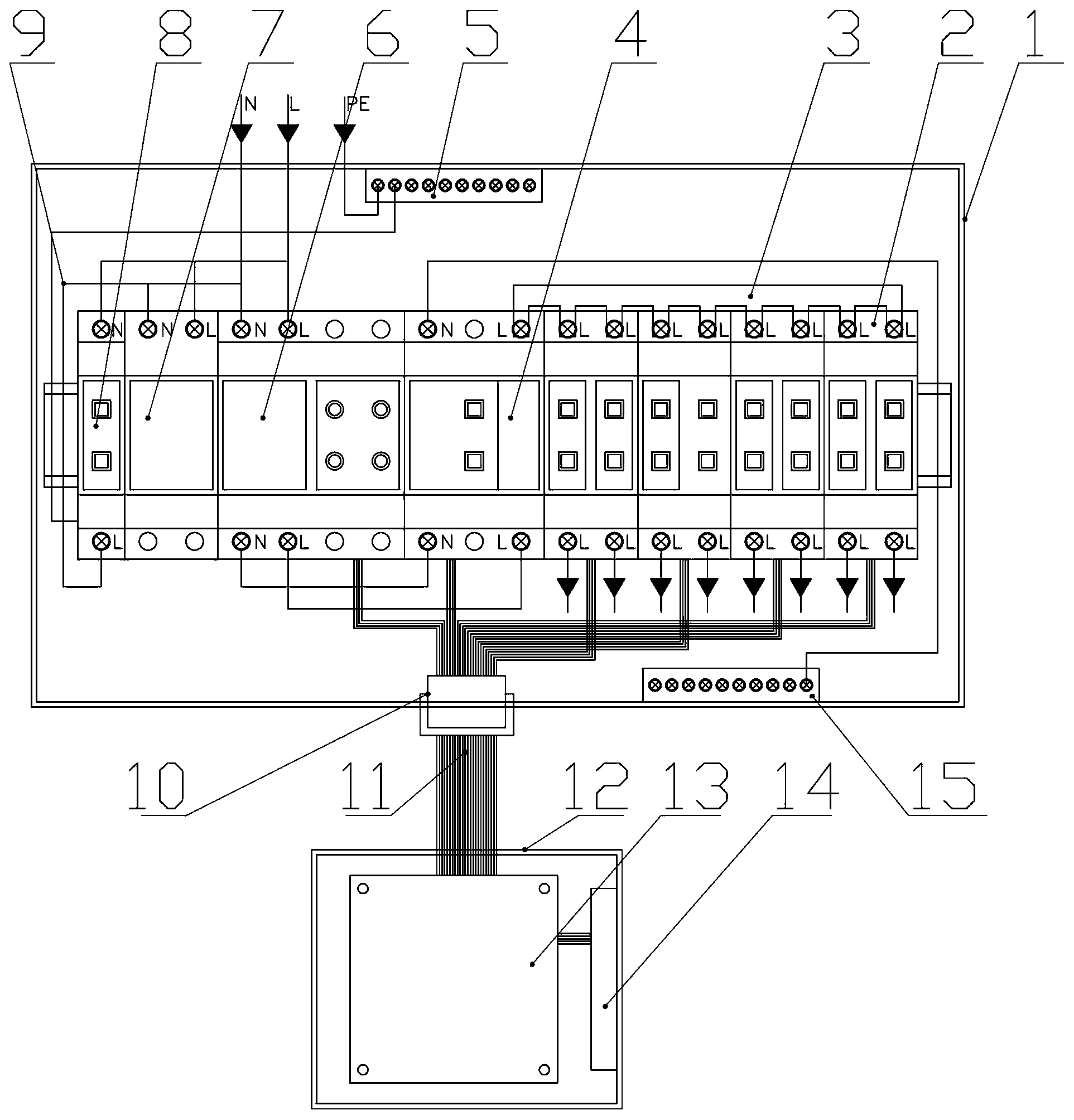

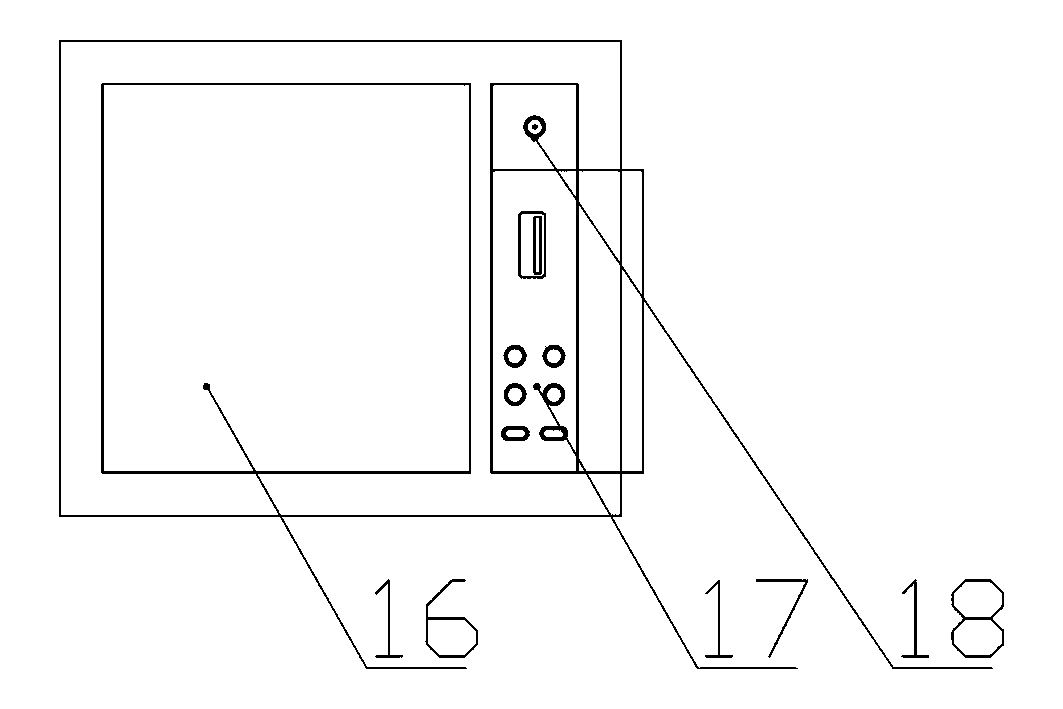

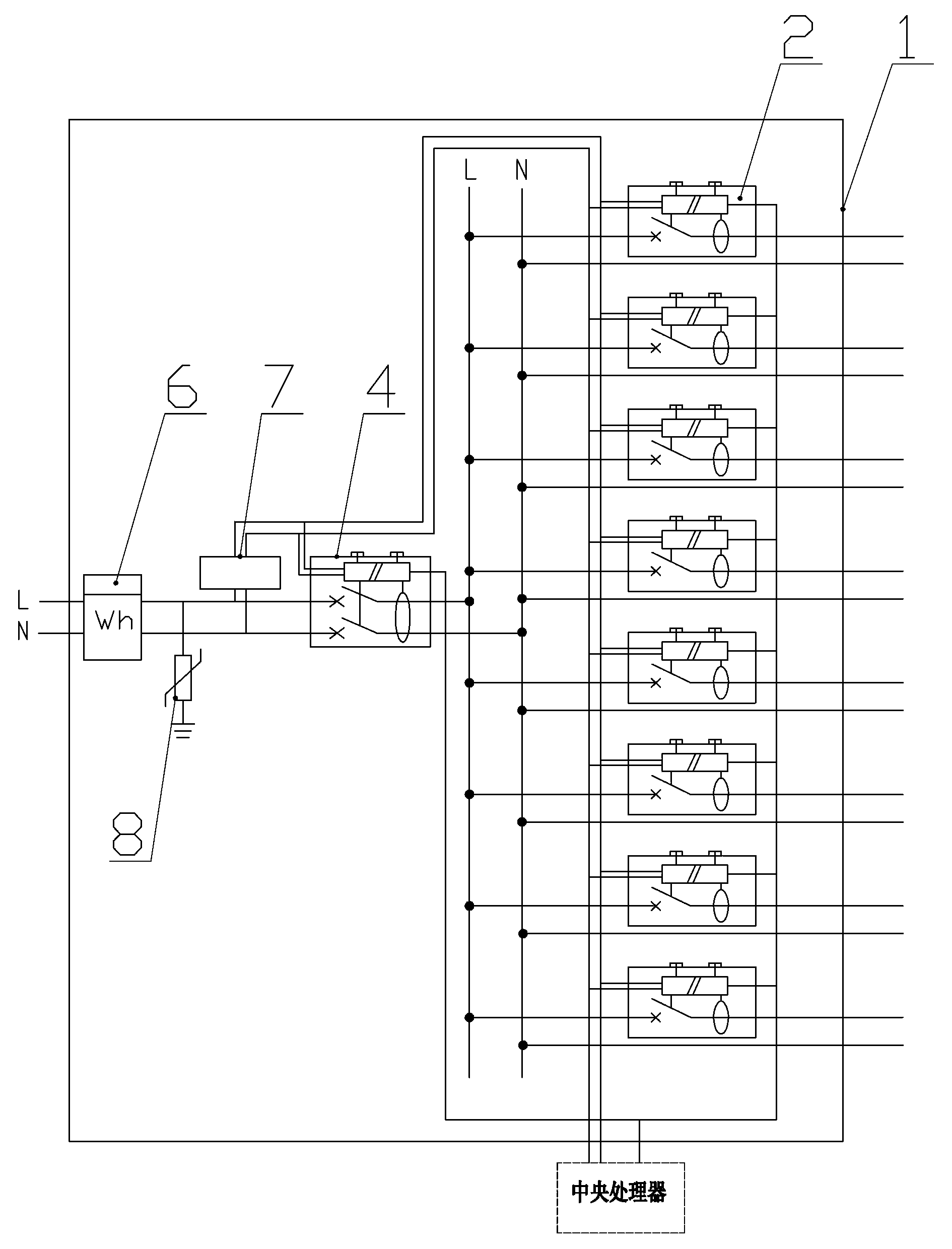

Domestic digital intelligent power distribution box

InactiveCN103854464AImprove the level of intelligenceEnsure equipment securityBoards/switchyards circuit arrangementsTransmission systemsMobile WebElectric energy

The invention provides a domestic digital intelligent power distribution box which has power supply receiving, distribution, control and protection functions of a traditional power distribution box, and also has intelligent functions of remote operation, digital setting, monitoring, power utilization promotion and the like. The domestic digital intelligent power distribution box comprises a power distribution switch box, a touch screen controller and externally-arranged equipment, wherein the power distribution switch box is internally provided with a metering prompting module, a DC12V power supply module, an anti-thunder module, a digital circuit breaker general switch and a digital circuit breaker branch switch. The domestic digital intelligent power distribution box applies equipment and technologies including a digital circuit breaker, the touch screen controller, cell phone operation software and a mobile network and the like so that the remote intelligent operation of power distribution equipment is realized and the intelligent level of domestic power distribution is improved. The domestic digital intelligent power distribution box can be used for carrying out real-time control on consumption of electric energy; under the condition of not reducing the life quality of residents, power utilization time periods of domestic electric appliances are reasonably planned; meanwhile, the electric energy waste caused by the reason that a power supply of electric appliance equipment is forgotten to be switched off when people go outside is also avoided.

Owner:STATE GRID CORP OF CHINA +2

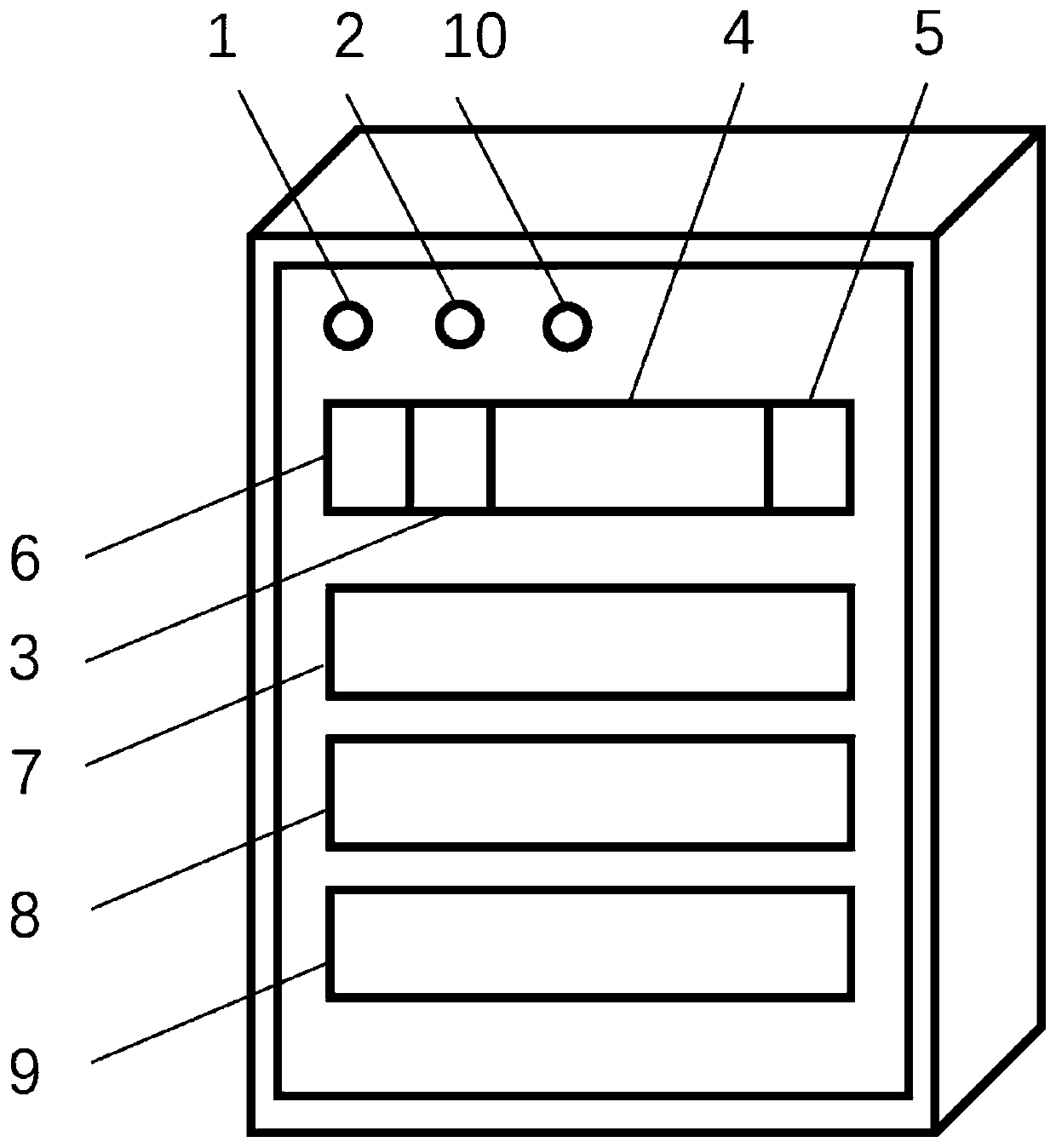

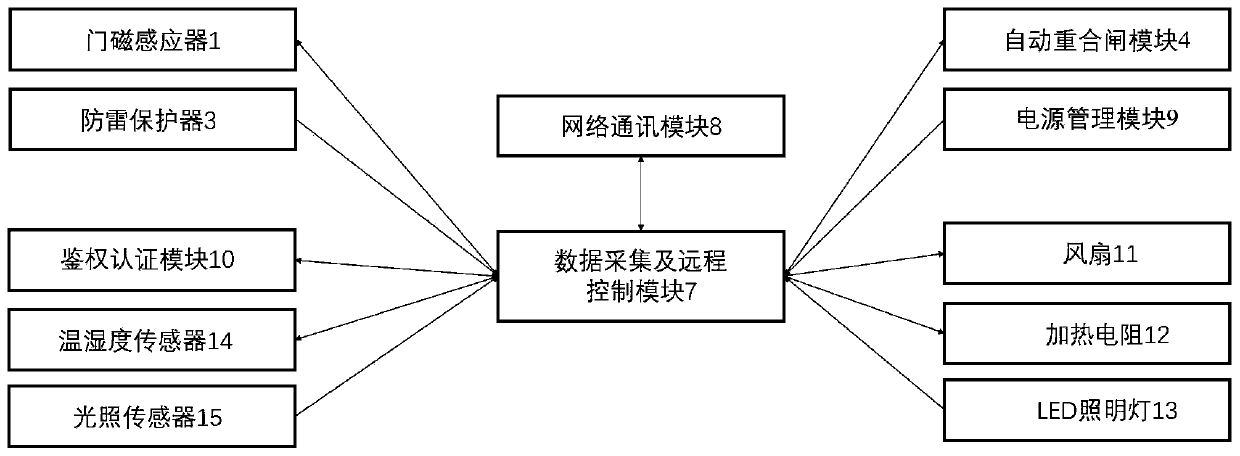

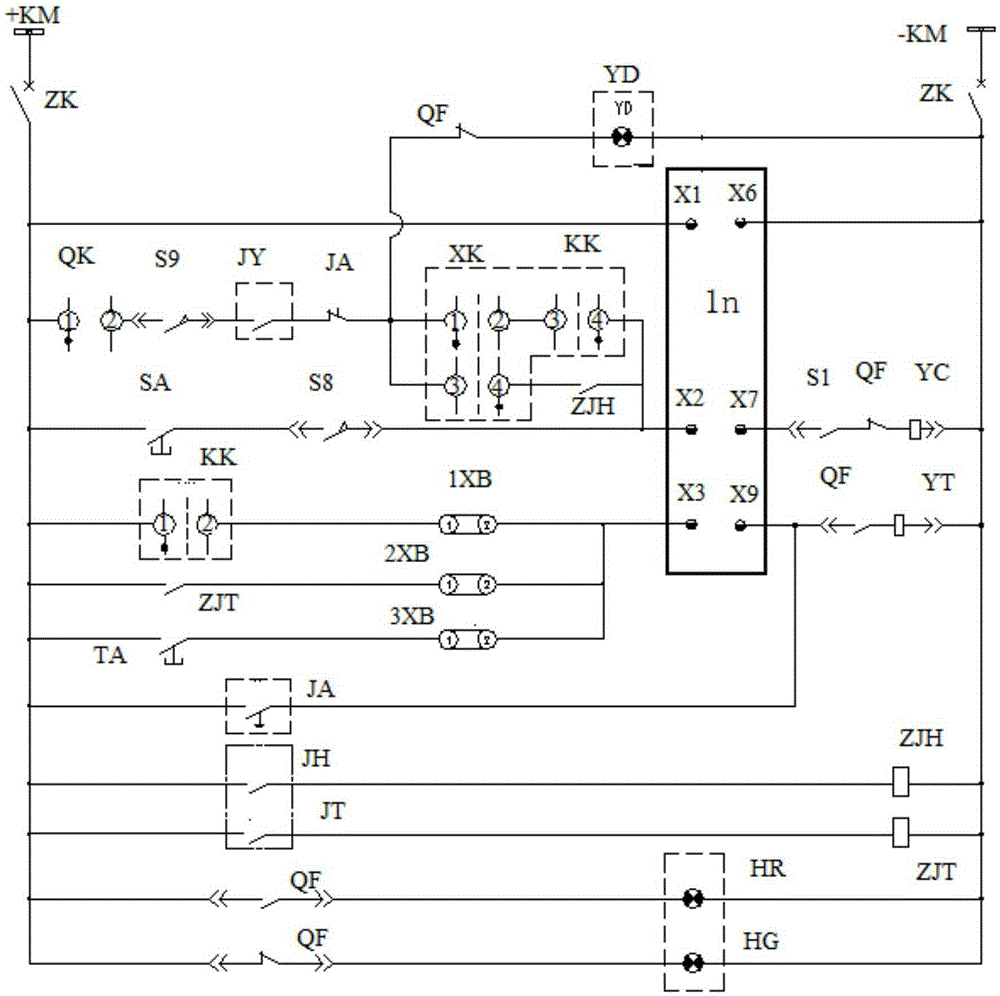

Internet-of-Things operation and maintenance monitoring box for multi-channel video monitoring integration

InactiveCN110784688AEnsure equipment securityGuaranteed versatilityClosed circuit television systemsProgramme control in sequence/logic controllersMoisture sensorNetwork communication

The invention provides an internet-of-things operation and maintenance monitoring box for multi-channel video monitoring integration. The internet-of-things operation and maintenance monitoring box comprises a door magnetic sensor, a lightning protection device, an automatic reclosing module, a data acquisition and remote control module, a network communication module, a power management module, atemperature and humidity sensor, an illumination sensor and an authentication module. The modular layout is adopted, versatility is kept, diversified configurations are provided to adapt to differentapplication scenes, and function expansibility is achieved; the Internet of Things communication technology is adopted, a series of sensors are combined, state detection of the monitoring box is achieved, the state and fault data of the monitoring box are uploaded to an operation and maintenance center in real time, and multiple remote control functions such as fan starting and stopping, camera remote restarting, heating resistor starting and stopping, remote power on and off and network restarting are supported. The operation and maintenance center realizes standard management for each operation and maintenance monitoring box, guarantees equipment safety, realizes effective authentication verification for remote and field operation of the monitoring boxes, and has an effective tracing mechanism for maintenance of the monitoring boxes.

Owner:深圳市中广控信息科技有限公司

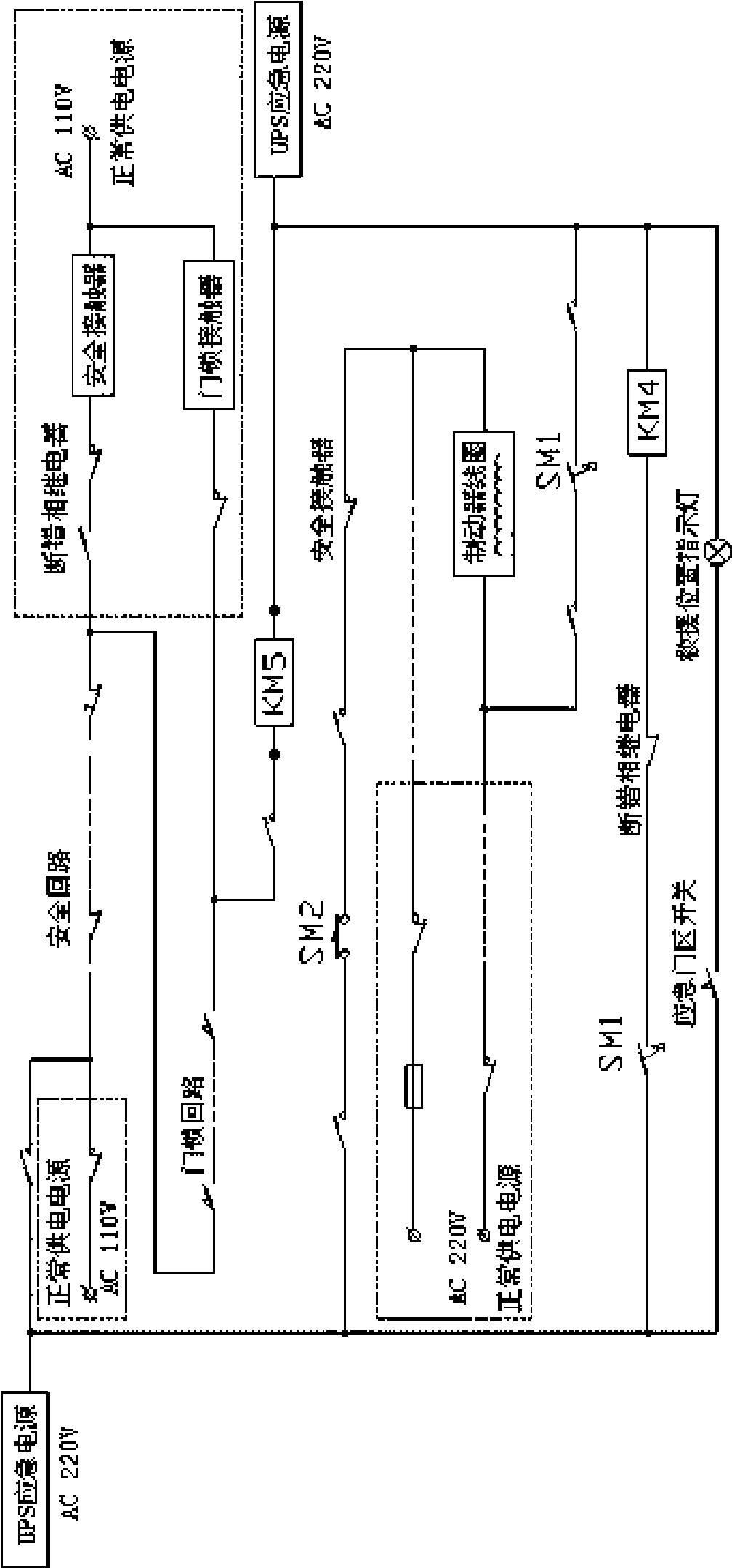

A control method and control device of remote switching-off of elevator without machine room

The invention discloses a control method and control device of remote switching-off of elevator without machine room. The method uses UPS emergency power supply to exert power to the brake coil, realizes switching-off by supplying power to the brake coil and realizes switching-on by breaking power to the brake coil. The control device includes an emergency power supply UPS, a control loop, a brake coil, wherein, the control loop includes an emergency start key switch SM1, an emergency switching-off button SM2; the emergency power supply UPS is connected to the brake coil through the emergency start key switch SM1 and the emergency switching-off button SM2. The invention uses UPS emergency power supply to supply power, realizes by controlling normal power supply switching-off and breaking power switching-on to the brake coil, has advantages of simple operation, easy switching off and the like features, which does not need prodigious manpower to open during mechanical remote switching-off and does not require special switching-off spatial position.

Owner:ZHEJIANG ELLY ELEVATOR

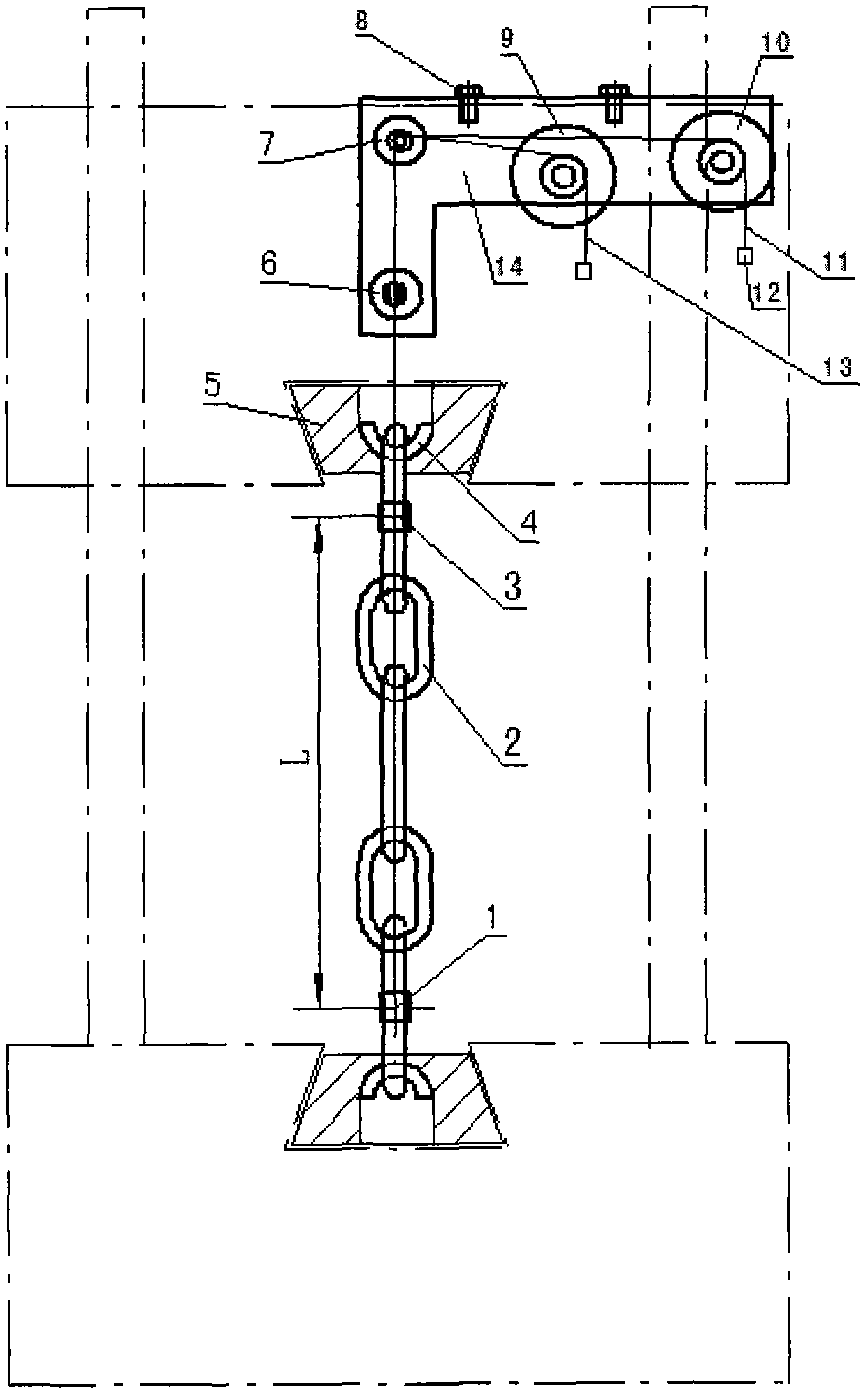

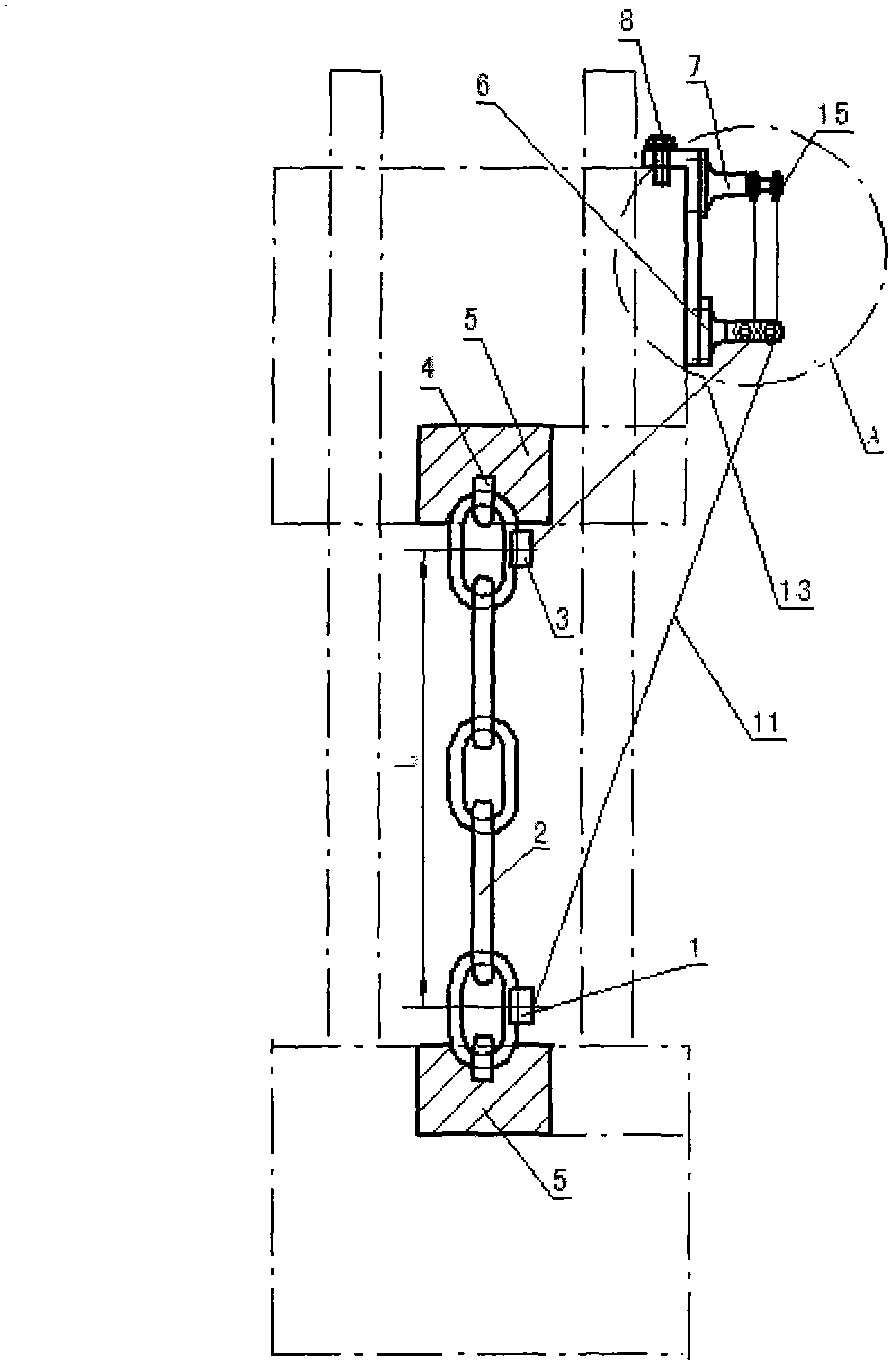

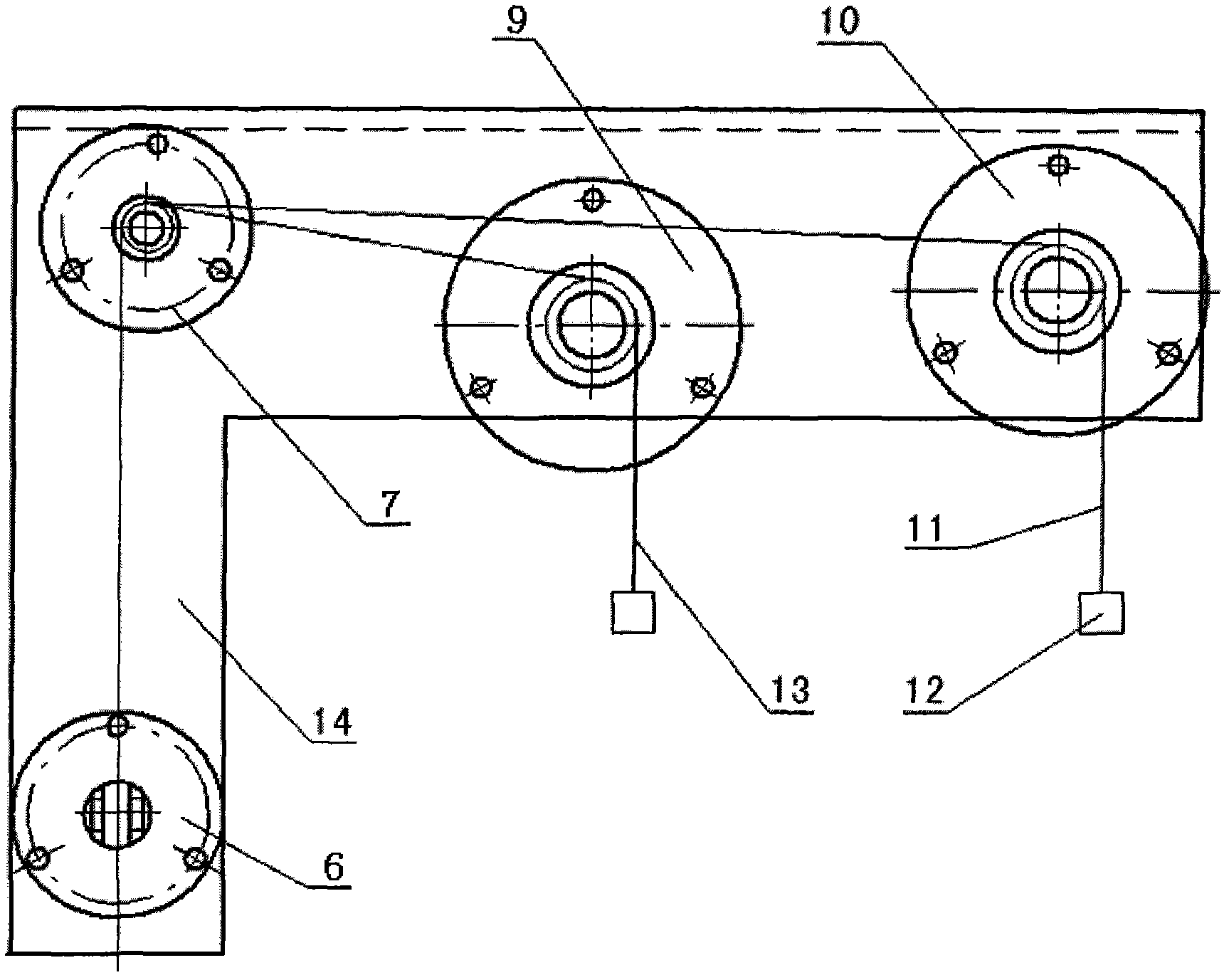

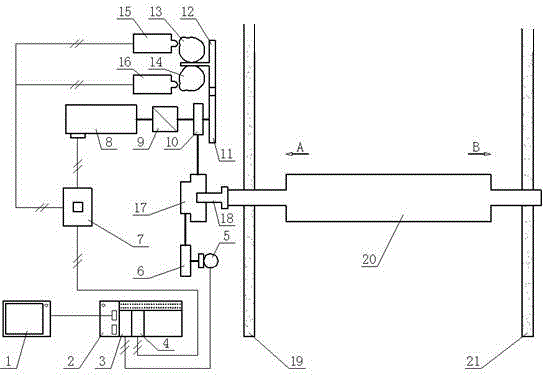

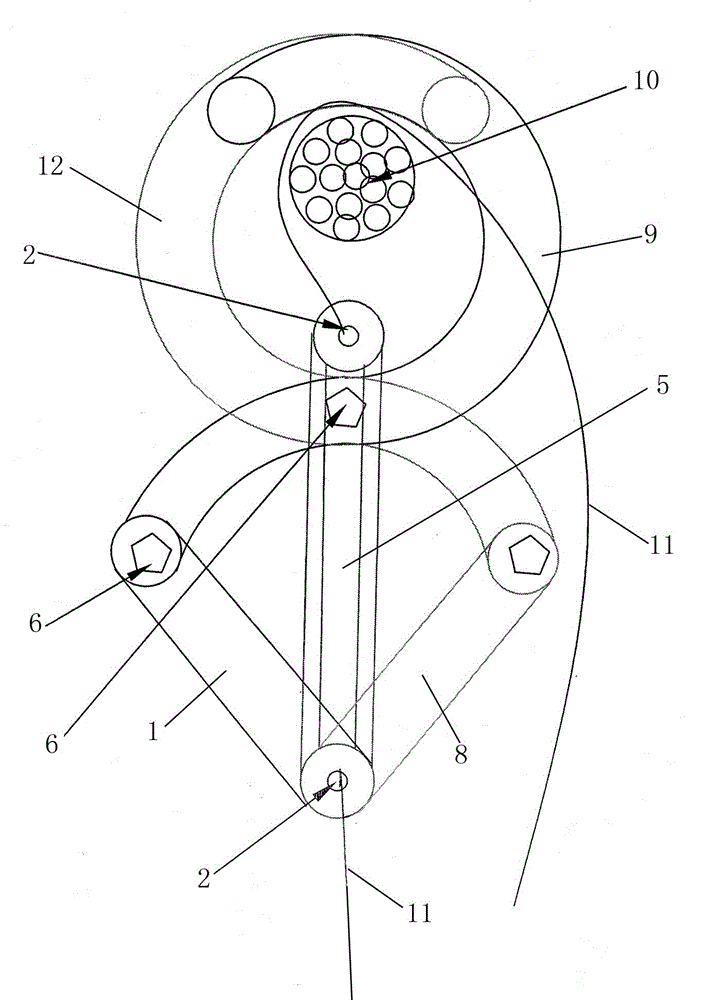

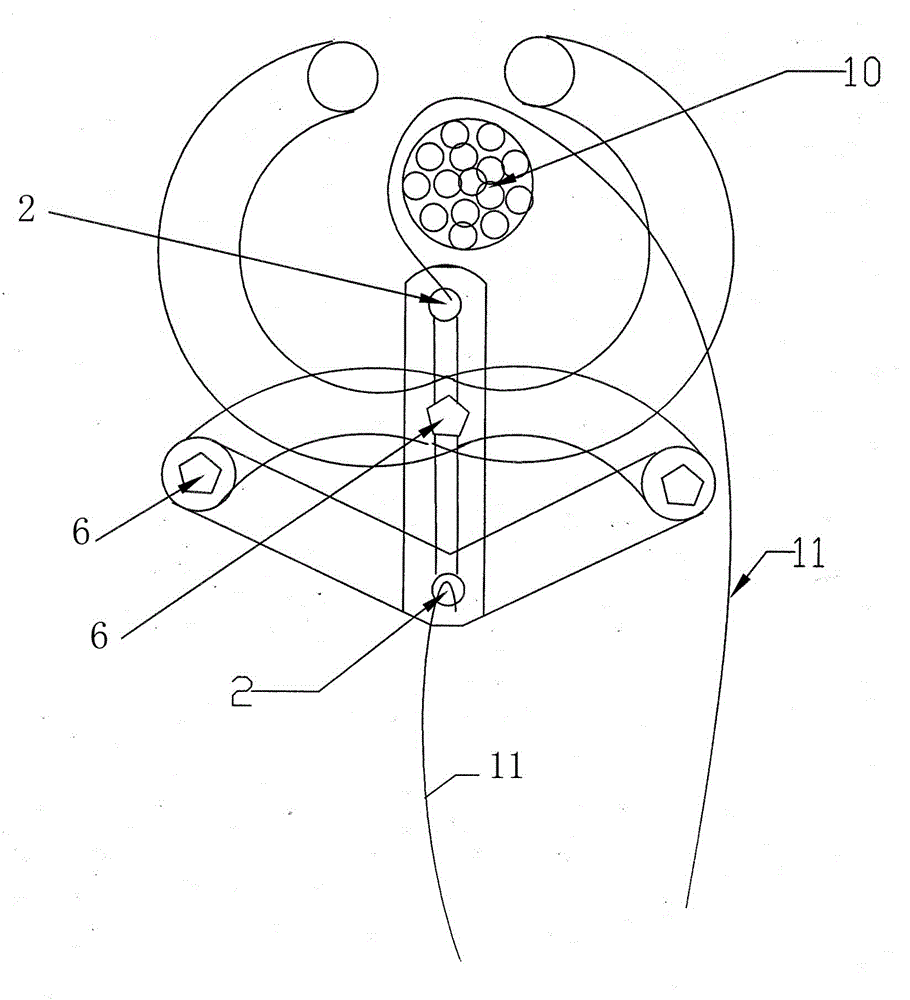

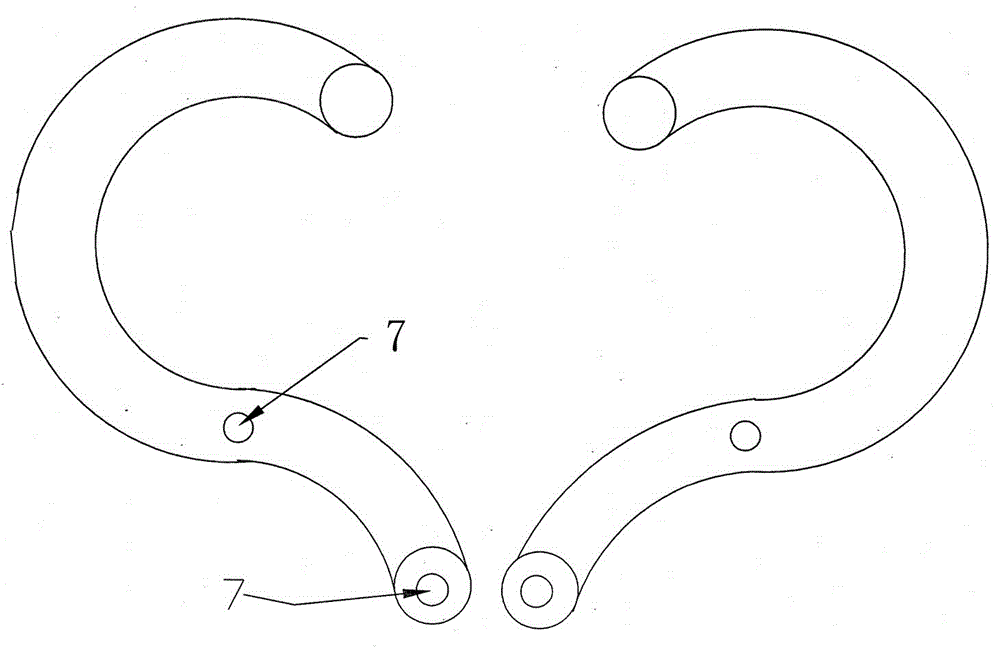

Elongation automatic testing apparatus and testing method of stretcher

ActiveCN102426139AAccurate collectionEnsure personal safetyMaterial strength using tensile/compressive forcesEngineeringTest fixture

The invention relates to the technical field of metal material mechanical property testing, and specifically relates to an elongation automatic testing apparatus and a testing method of a stretcher. Currently, a data collecting method of a maximal elongation under a test load is an artificial dotting and marking method which requires an operator to get approach to a test sample. When the quality of the sample is substandard, and brittle fracture is happened in advance, the personal safety of the operator is directly endangered. According to the invention, a right-angle frame assembled with a guide wheel support, a turning wheel support, and displacement sensors A and B is fixed on a top crossbeam of a stretching tester by using bolts; high-duty magnet absorption pedestals A and B are absorbed on a gauge length of the test sample; through the extension and the contraction of pull ropes A and B, the wheel hubs of the displacement sensors A and B rotate under driving, and an electrical signal with a certain proportion to the displacement distance of the pull ropes is outputted, such that the data of the maximal elongation under the test load is automatically collected during the stretching test. Therefore, artificial dotting measuring is replaced, and the securities of personnel and equipment are ensured.

Owner:CHINA COAL ZHANGJIAKOU COAL MINING MACHINERY

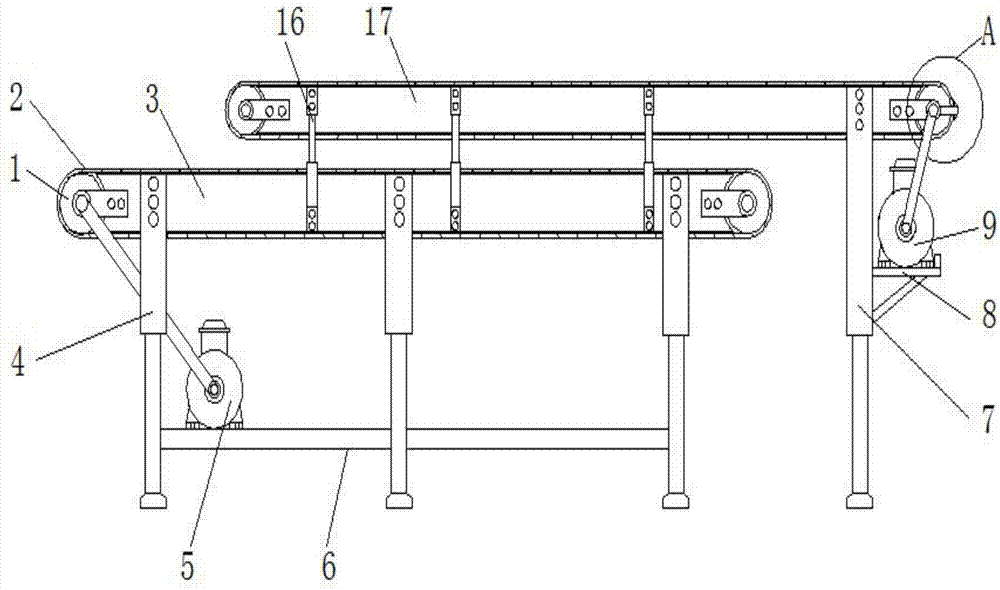

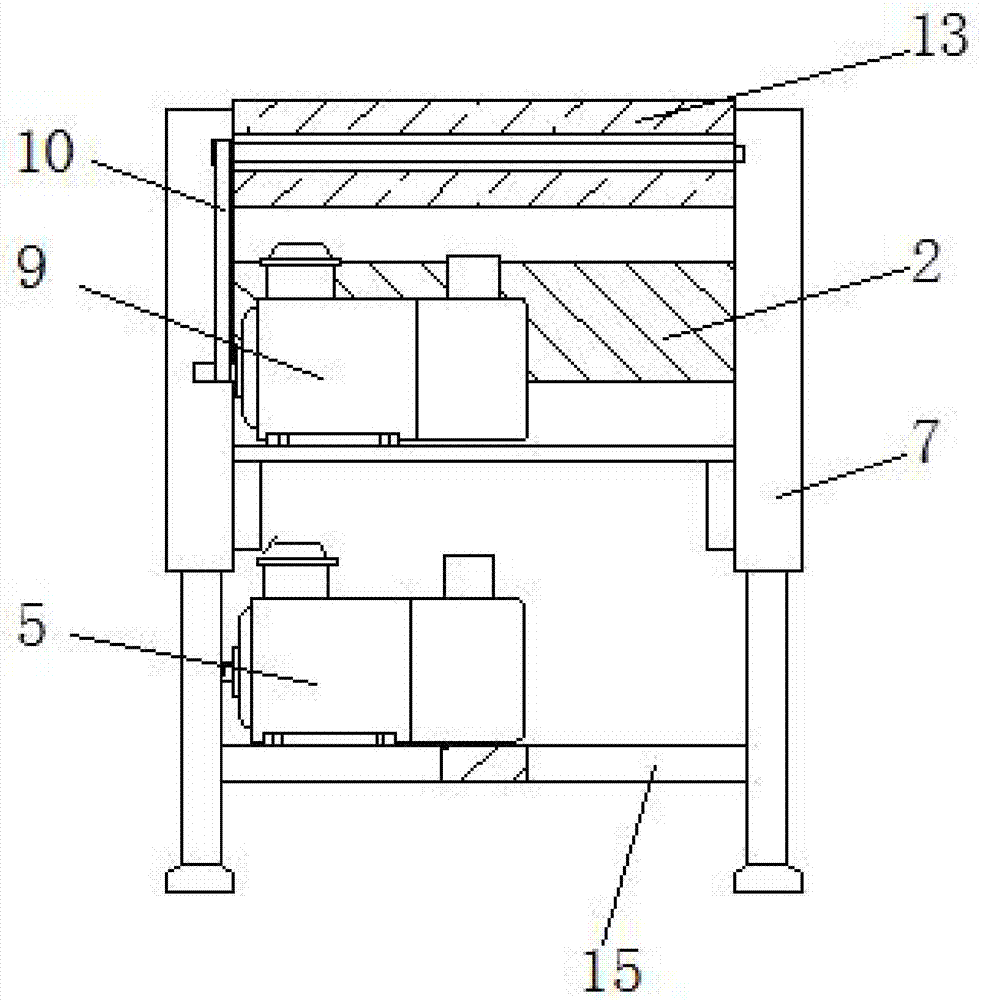

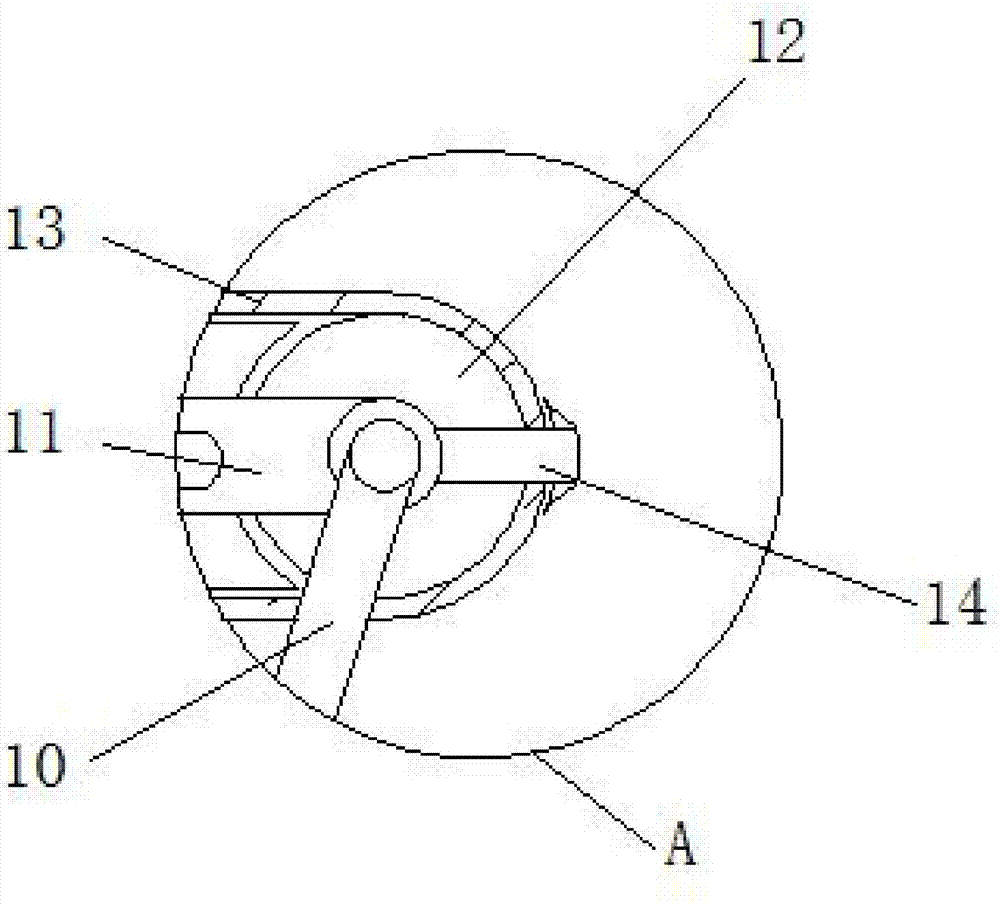

Metal garbage classification conveyor belt

InactiveCN107539703AEnsure equipment securityEasy to adjustConveyorsCleaningAustenitic stainless steelEngineering

The invention relates to a metal garbage classification conveyor belt, which mainly comprises a main driving wheel and a second fixed support rod. A first fixed support rod is arranged, so that the height of equipment can be freely adjusted when the equipment is used; a magnetic conveyor belt is arranged, and a magnetism principle is adopted, so that metal garbage can be metal-classified accordingto the magnetism principle, and the magnetic conveyor belt can be applicable to classifying metal and plastic garbage of household garbage containing metal; an assisting scraper is arranged, so thatthe metal can be ensured to be scraped by the assisting scraper when running on the magnetic conveyor belt, and the stability of the equipment is ensured; and an auxiliary support frame adopts austenitic grade stainless steel, so that the occurrence of the phenomenon that the magnetic conveyor belt cannot be adsorbed onto the auxiliary support frame during running is ensured to be avoided, and thesafety of the equipment is ensured.

Owner:ZHONGSHAN YAXI ENVIRONMENTAL PROTECTION TECH

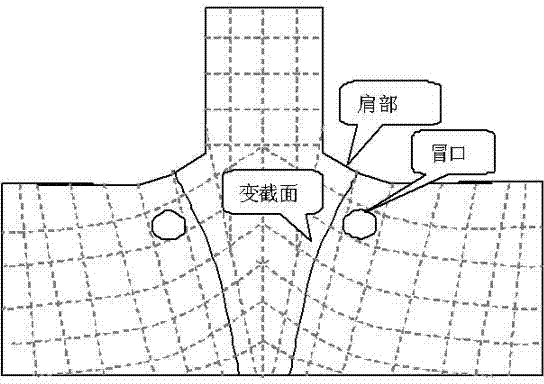

Magnetic powder detection method for large cast valve

ActiveCN103076389AIncrease contrastUniform contrast backgroundMaterial magnetic variablesEngineeringVALVE PORT

The invention relates to a new technique method for magnetic powder detection of a large cast valve, which comprises the following steps: 1), processing the surface of the valve body; 2), uniformly spraying contrast sensitivity on the surface of the valve body; 3), detecting whether the equipment is in the check validity period or not; 4), configuring a magnetic suspending liquid with the concentration within 10-25g / L; 5), fixing a Al-30 / 100 sensitivity test piece in a detected part through a standard test piece fixing device so as to assess the comprehensive performance of a detecting system; 6), wetting the surface of the workpiece by the magnetic suspending liquid, magnetizing the surface of the workpiece, and detecting the valve body according to a special magnetized path graph for the valve body inspection via an AC magnetic yoke continuous method; 7), utilizing an air pressure type sprinkling can with a lighting function and suitable for magnetic powder detection, directly performing observation once magnetic marks are formed, and achieving that magnetization, magnetic suspending liquid spraying and observation are performed at the same time; 8), recording detection parameters and defect magnetic marks, grading the workpiece quality according to the detection technique standard based on the displayed defect magnetic marks, and then determining whether the workpiece is qualified or not according to the acceptance quality level. Moreover, in case of reinspection, the sensitivity of the detecting system is readjusted, and the workpiece is detected again until the requirements are met. The method can be effectively used for detecting the magnetic powder of the large valve.

Owner:STATE GRID HEBEI ELECTRIC POWER RES INST +2

Oxygen-free outburst-prevention green and efficient tunneling technology suitable for gas-outburst coal road

InactiveCN104790958ARealize transportationRealize in and outMining devicesGas removalIntrinsic safetyEconomic benefits

The invention provides an oxygen-free outburst-prevention green and efficient tunneling technology suitable for a gas-outburst coal road and belongs to the technical field of mining safety. The oxygen-free outburst-prevention green and efficient tunneling technology mainly relates to the outburst predicting and forecasting technique, an intrinsic-safety tunneling device, an intrinsic-safety transportation device, a noxious gas monitoring system, a dynamic variable-frequency gas drainage system, the inert gas blocking technique, and the accident emergency rescue technique. By the adoption of the oxygen-free outburst-prevention green and efficient tunneling technology suitable for the gas-outburst coal road, harm caused by coal and gas outburst accidents can be effectively controlled and eliminated, safe and efficient tunneling is achieved, asphyxia, fires and explosion caused by gas can be effectively avoided, the situation that people are injured by coal and rock flow can be prevented, life safety of personnel and equipment safety are guaranteed, gas emission is reduced, and environmental friendliness is achieved; meanwhile, production efficiency is improved, production cost is reduced, and economic benefit of enterprises are increased.

Owner:UNIV OF SCI & TECH BEIJING

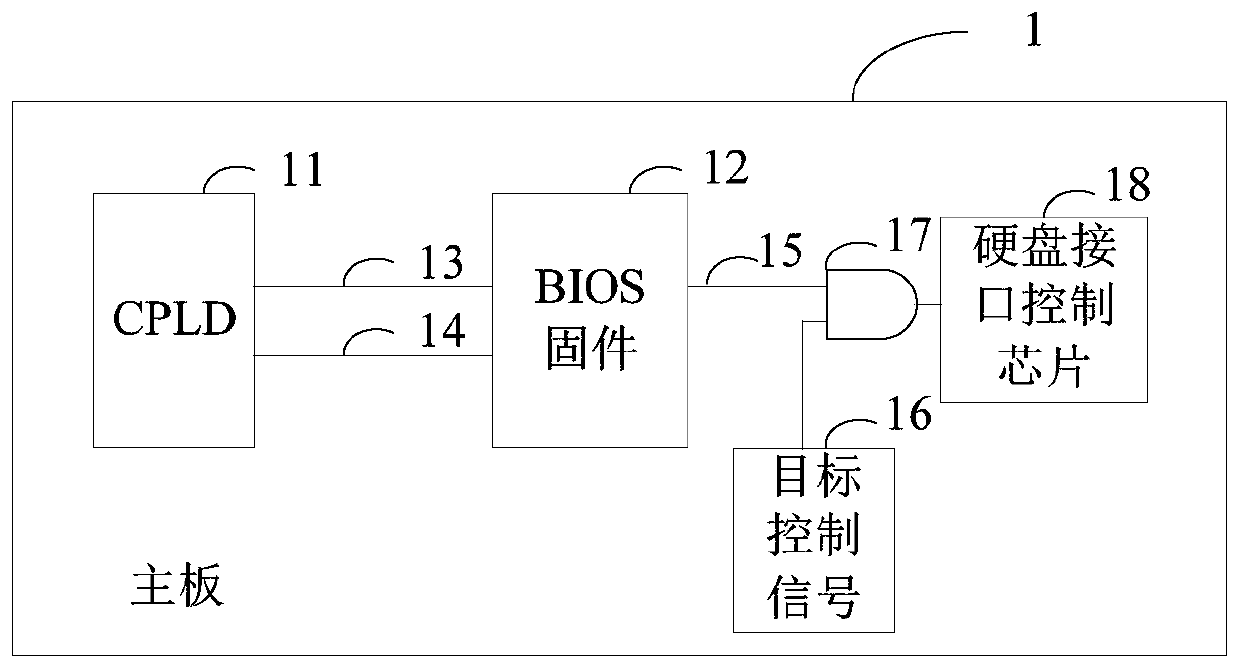

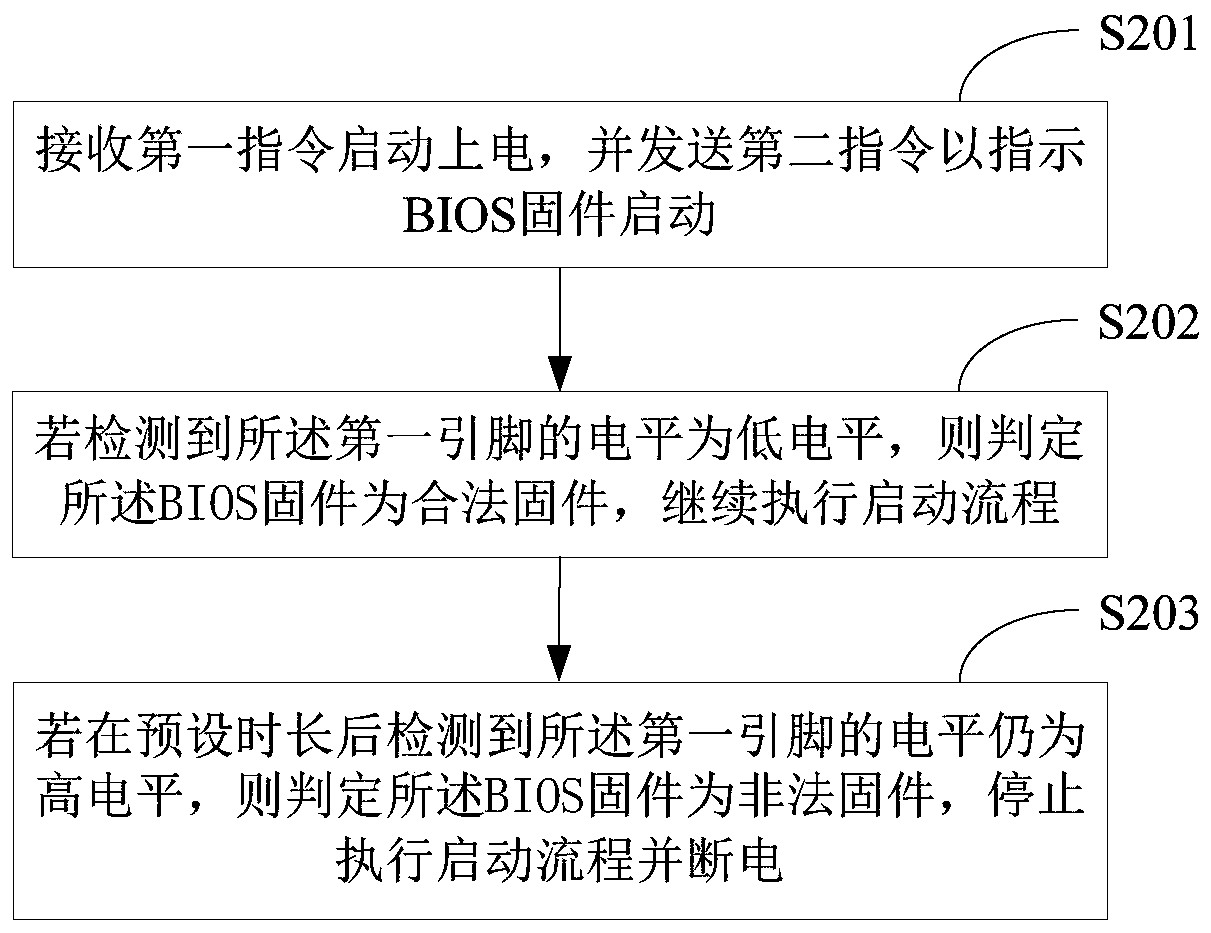

Mainboard, firmware safety detection method and terminal equipment

ActiveCN110472421AEnsure equipment securityEnsure safetyPlatform integrity maintainanceStart signalTarget control

The invention is applicable to the technical field of computers and provides a mainboard, a firmware safety detection method and terminal equipment. According to the method, a CPLD is connected with BIOS firmware through a first pin and a second pin. The legal BIOS firmware can set the first pin to be at a low level when being started, and the legal CPLD can set the second pin to be at a low levelwhen detecting that the first pin is at the low level and set a target control signal initially at the low level on the mainboard to be at a high level; the BIOS firmware is also connected with the third pin; a signal of the third pin and the target control signal are used as input signals of a specified AND gate; wherein the output signal of the designated AND gate is used as a hard disk starting signal of a hard disk interface control chip, the legal BIOS firmware can set the third pin to be at a high level when detecting that the second pin is at a low level, and the hard disk interface control chip can be started when the hard disk starting signal is at a high level. According to the embodiment of the invention, firmware safety detection can be carried out to guarantee equipment safety.

Owner:深圳中电长城信息安全系统有限公司

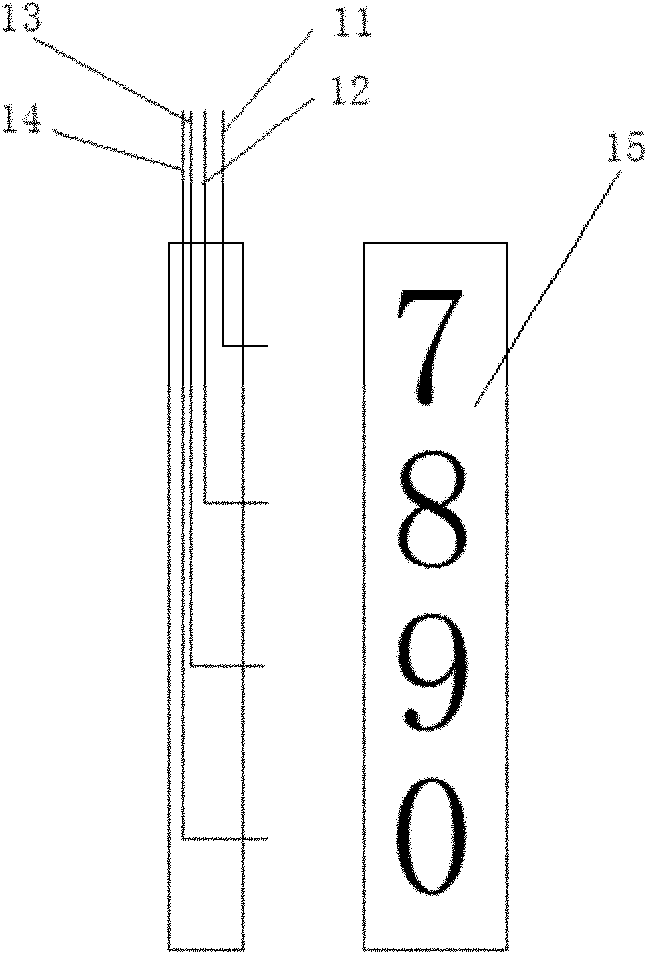

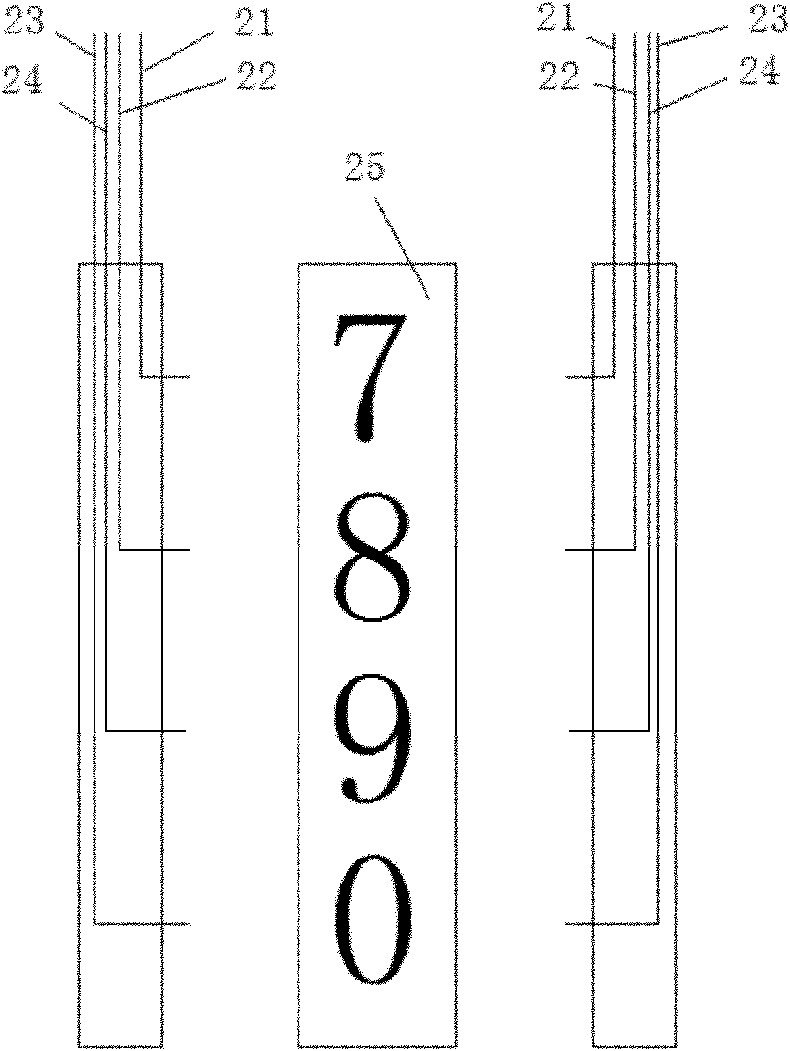

Character-wheel-type meter reading method and character-wheel-type direct-reading meter

InactiveCN102147279AGuarantee the safety of useEnsure equipment securityVolume indication and recording devicesDirect readingElectromagnetic interference

The invention discloses a character-wheel-type meter reading method and a character-wheel-type direct-reading meter. With respect to a photoelectric direct-reading type meter, at an optical pulse emitting end, a coded optical pulse is transmitted in optical fibers; the coded optical pulse irradiates to a specific position on a character wheel, wherein the specific position is provided with a light reflection or transmission area corresponding to characters on the character wheel; at an optical pulse receiving end, the coded optical pulse from the light reflection or transmission area is received by optical fibers and decoded by a decoding module so as to finally obtain the corresponding characters of the character wheel; the optical fibers at the optical pulse emitting end and the opticalfibers at the optical pulse receiving end are arranged in pairs and are opposite in positions; and in accordance with the system of the character wheel, a corresponding number of pairs of the opticalfibers at the optical pulse emitting / receiving ends are arranged so as to meet a condition that the emitted coded optical pulse and the received coded optical pulse in each pair of optical fibers areconsistent. By means of the invention, the problems of susceptibility to optical pollution, large optical interference between adjacent meters, large electromagnetic interference, poor safety, low reliability, high reading error rate and the like of the traditional direct-reading type meter are solved.

Owner:南京邦耀科技发展有限公司

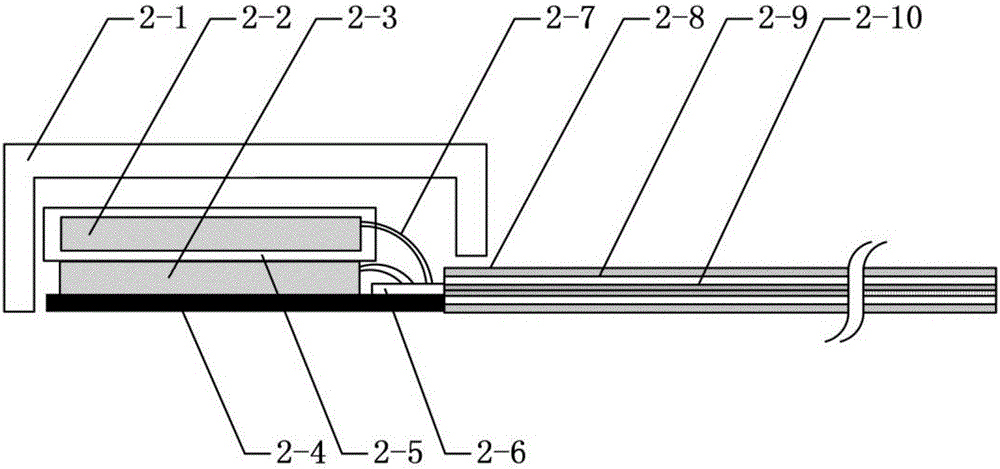

Strain measuring system resisting strong electromagnetic interference

InactiveCN106248045AReduce the impactEnsure equipment securityStrength propertiesPhysicsStrain gauge

The invention discloses a strain measuring system resisting strong electromagnetic interference. The strain measuring system mainly comprises a front-end magnetic field compensation strain probe, a double-layer shielded cable, a rear-end signal processing circuit and recording equipment, wherein the front-end magnetic field compensation strain probe mainly comprises an operating plate, a compensating plate and a shielding shell, and is used for compensating for strong electromagnetic interference and temperature interference in the environment; the shielding shell is used for protecting a strain gage, reducing high-frequency electromagnetic interference, and improving measurement accuracy; the rear-end signal processing circuit and the recording equipment include a Wheatstone double-arm bridge, a fifth-order Butterworth low-pass filter, a voltage follower, an A / D converter and terminal recording equipment; the cut-off frequency of the fifth-order Butterworth low-pass filter is 10kHz, and the fifth-order Butterworth low-pass filter is used for further filtering out high-frequency electromagnetic interference; and the voltage follower is used for isolating electromagnetic pulse surge to protect rear-end equipment. The strain measuring system realizes safe and accurate measurement of strain signals through adopting three technical means of front-end compensation, transmission shielding and back-end filtering.

Owner:XI AN JIAOTONG UNIV

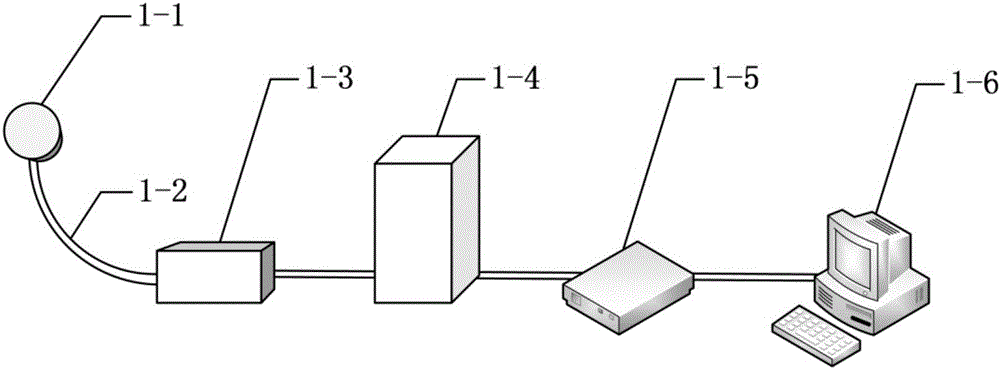

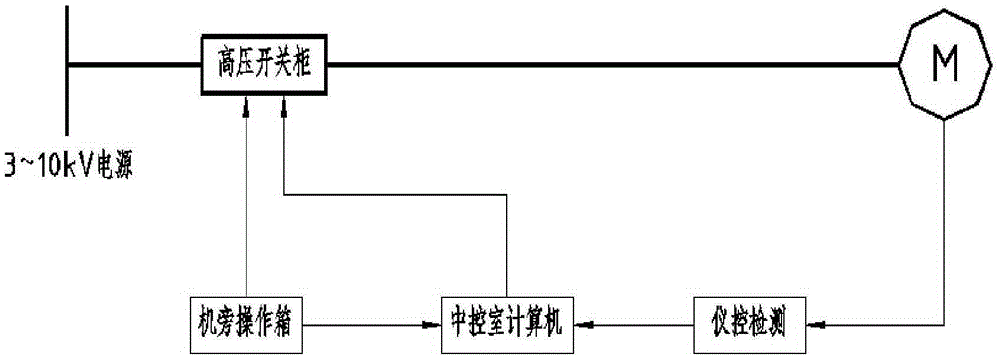

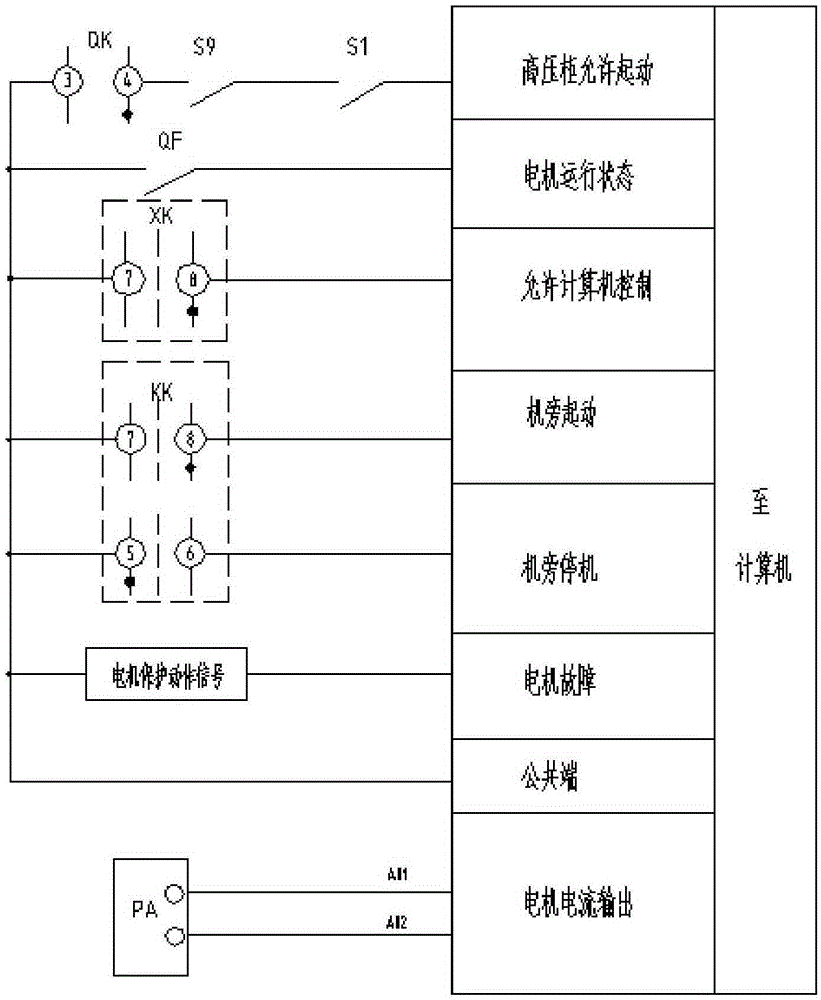

On-off control circuit for 10kV motor

ActiveCN105334761APerfect start preparationIncrease operational pertinenceProgramme control in sequence/logic controllersMicrocomputerAutomatic control

The invention discloses an on-off control circuit for a 10kV motor, and belongs to the field of high-voltage motor control. The on-off control circuit comprises automatic air switches ZK, a microcomputer integrated protection device 1n, breakers QF, a control switch KK, a selection switch XK, intermediate relays ZJT and ZJH, indicator lamps, a selector switch QK and emergency stop buttons JA. The positive end of one automatic air switch ZK is connected with the terminal X1 of the microcomputer integrated protection device 1n, and the terminal X6 of the microcomputer integrated protection device 1n is connected with the negative end of the corresponding automatic air switch ZK to form a power source loop of the microcomputer integrated protection device 1n; the negative end of one automatic air switch ZK is connected with one end of the switching-on allowing signal lamp beside the motor, the other end of the automatic air switch ZK is connected with one end of a normally closed auxiliary contact of the corresponding breaker QF, and the other end of the normally closed auxiliary contact of the corresponding breaker QF is connected with a control contact of the selection switch XK to form a loop allowing the corresponding indication lamp to be turned on. Manual control and automatic control can be switched through the on-off control circuit.

Owner:ANHUI MASTEEL ENG & TECH GRP

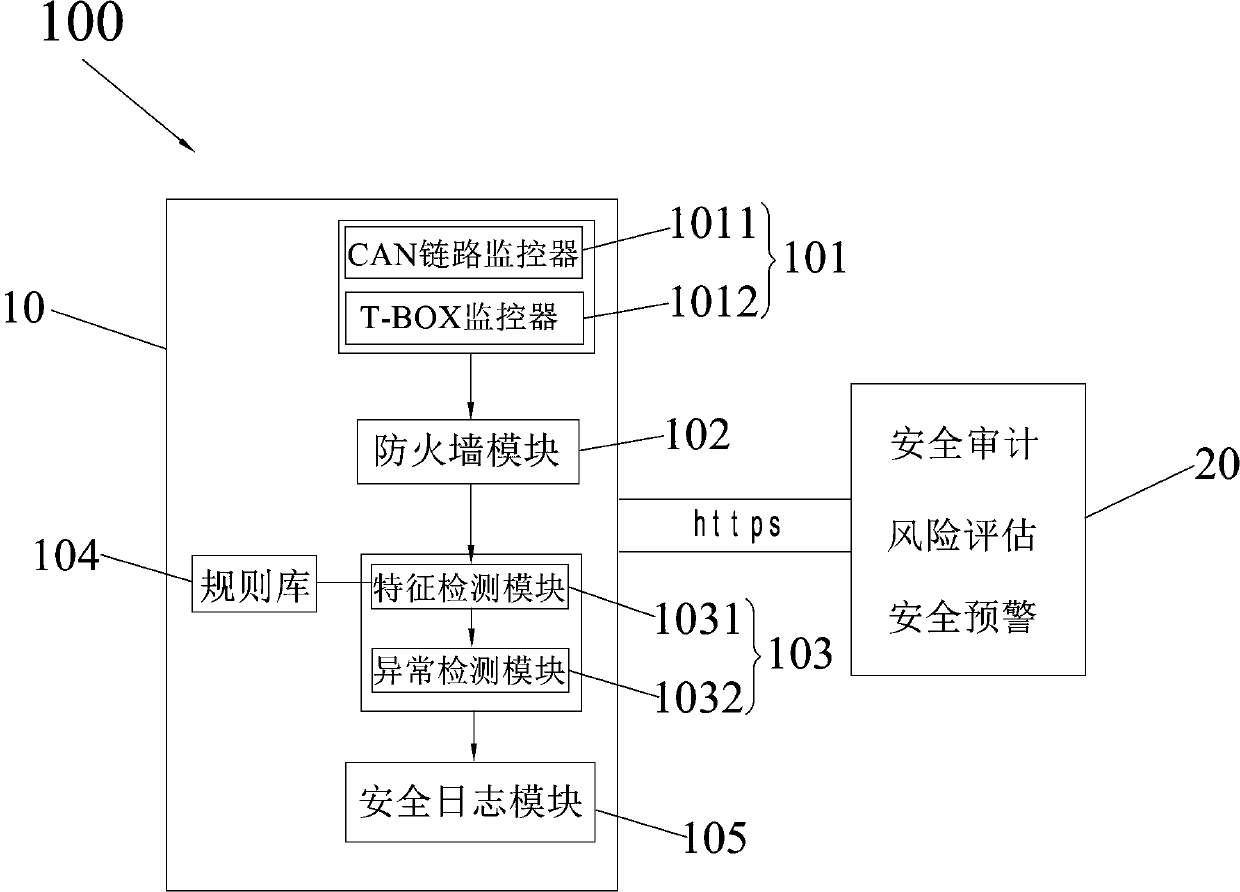

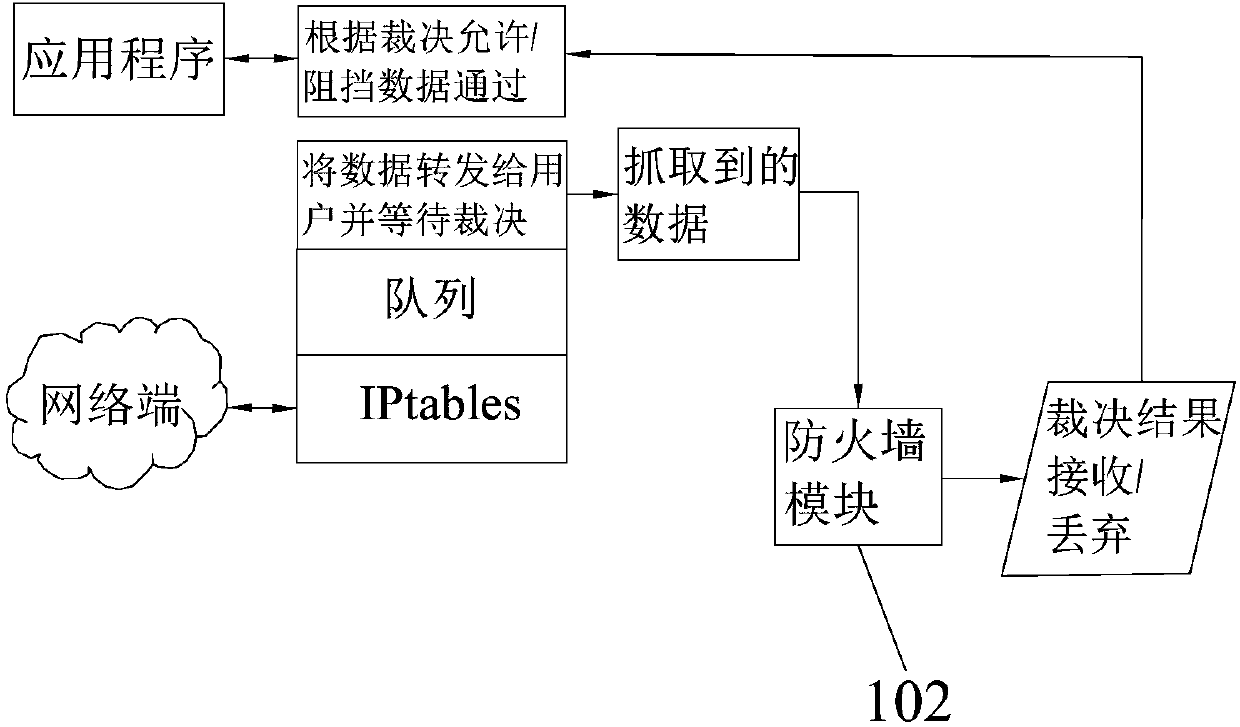

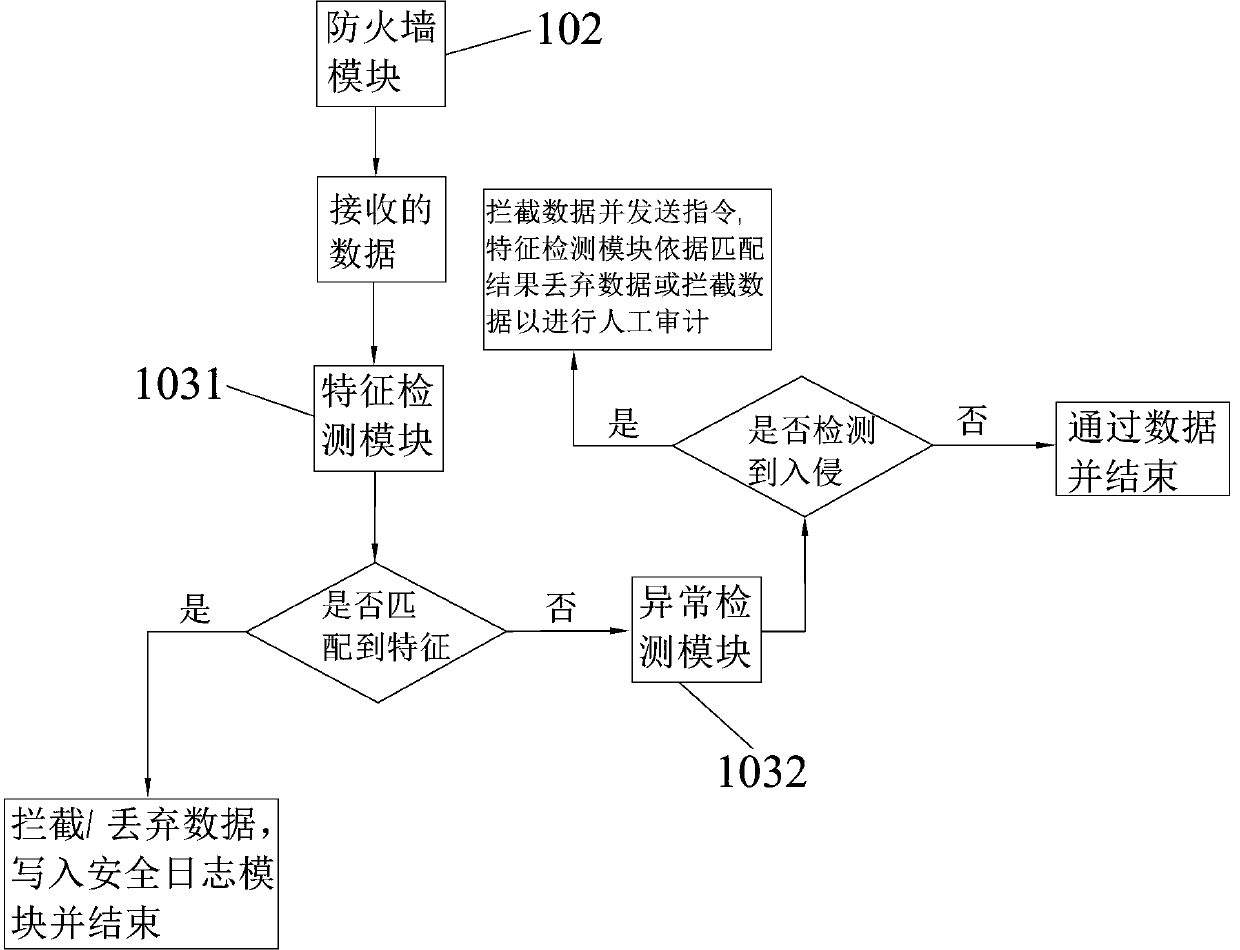

Internet of Vehicles monitoring system, method and device and readable storage medium

InactiveCN111431864AEnsure equipment securityReduce detection calculationsMachine learningTransmissionEmbedded systemEngineering

The invention discloses an Internet of Vehicles monitoring system, which comprises a data collector, a firewall module, an intrusion detection module and a rule base, and is characterized in that thedata collector is used for collecting communication data; the firewall module is used for filtering the communication data so as to discard attack data / abnormal request data or receive normal communication data; and the intrusion detection module is used for matching the communication data received by the firewall module with a preset rule in a rule base, carrying out anomaly detection on the communication data with a legal matching result, and executing corresponding operation according to a detection result. Double protection levels are set by combining the firewall and the intrusion detection technology, an intrusion prevention mechanism is optimized, the firewall module operates before the intrusion detection module works, meaningless detection calculation of the intrusion detection module can be reduced, and the working efficiency of the Internet of Vehicles monitoring system is improved. In addition, the invention further discloses an Internet of Vehicles monitoring method and device and a computer readable storage medium.

Owner:SECZONE TECH CO LTD +1

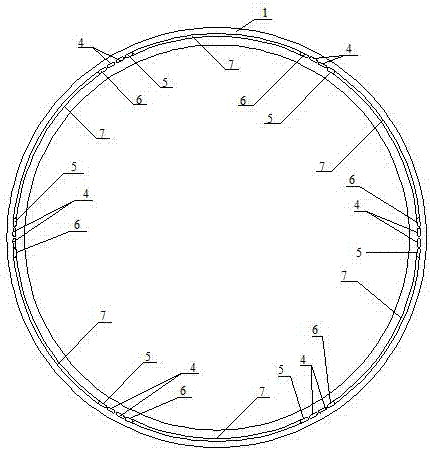

Soft sealing device for converter mouth and fume hood

InactiveCN102605136AAvoid Explosion HazardsGuaranteed shrink volumeManufacturing convertersSteelmakingElectricity

The invention relates to a steelmaking process control device for a steel making factory, in particular to a soft sealing device for an LD (linz-donawitz) converter mouth and fume hood. The periphery of the inlet of the fume hood is provided with a ring pipe; the ring pipe is provided with a nitrogen inlet pipe; and a plurality of nitrogen spraying nozzles are annularly distributed on the ring pipe at intervals. During each period of production of a converter, a nitrogen sealing curtain is formed between the inside fume and the outside air of the fume hood, and the fume is separated from the outside air without contacting. Because the fume is separated from the outside air without contacting, the secondary combustion of a system is avoided, the hidden danger of explosion of a dedusting system is avoided, the calorific value of gas is improved, the rear dedusting fume is reduced, the purity and the yield of gas are improved, and water and electricity are saved. The soft sealing device for the LD converter mouth and fume hood can be used safely and reliably, and radically solves the problem on the sealing of the converter mouth and fume hood.

Owner:北京五一环保科技股份有限公司

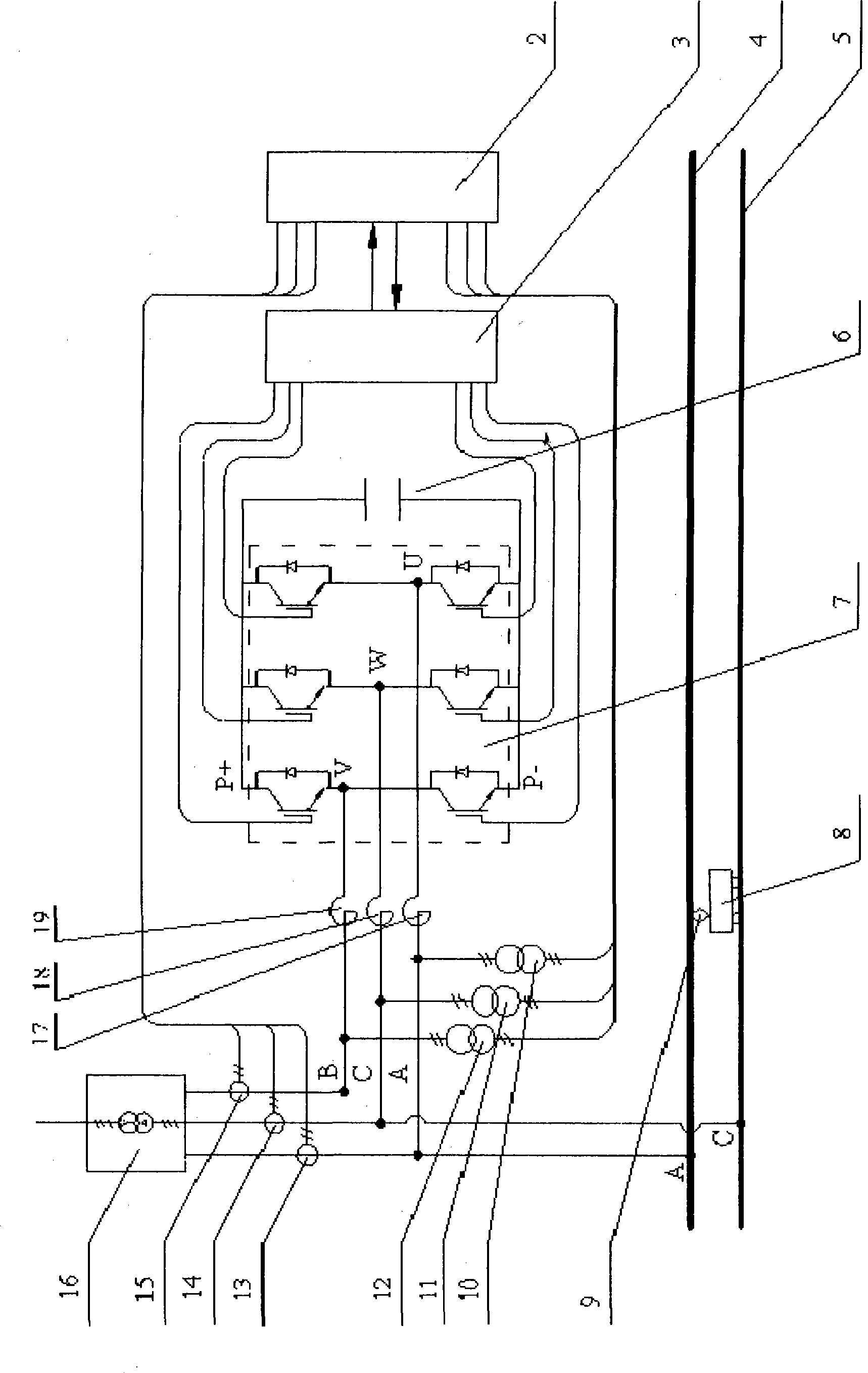

Non phase separation type traction power supply equipment for railway locomotive

InactiveCN101503065AEnsure equipment securityRun efficientlyPower supply linesSingle network parallel feeding arrangementsCapacitanceEnergy partitioning

A non-split-phase type traction power supply device used for rail vehicles belongs to technical field of railway electric traction power supply. The device comprises a traction transformator and an energy distribution regulating machine which mainly consists of a main controller, a driver, an electronic power switch bridgearm, a support capacitance arm, three electric current sensors, three voltage transducers and three reactors, wherein, the driver is connected between a control terminal of the electronic power switch bridgearm and the main controller, the electric current sensors and the voltage transducers are respectively connected between the main controller and A phase, B phase and C phase of an output end of the traction transformator, and the reactors are connected between the center of the bridgearm and the A phase, the B phase and the C phase of an output end of the traction transformator. The invention has the advantages that split-phase power supply is changed into non-split-phase power supply, great run-through of the traction contact network can be realized, and power phase position exchange for power supply again caused by frequent power failure can be avoided, so that safe, high speed and high-efficiency running of train can be guaranteed.

Owner:四川省佳灵电气有限公司

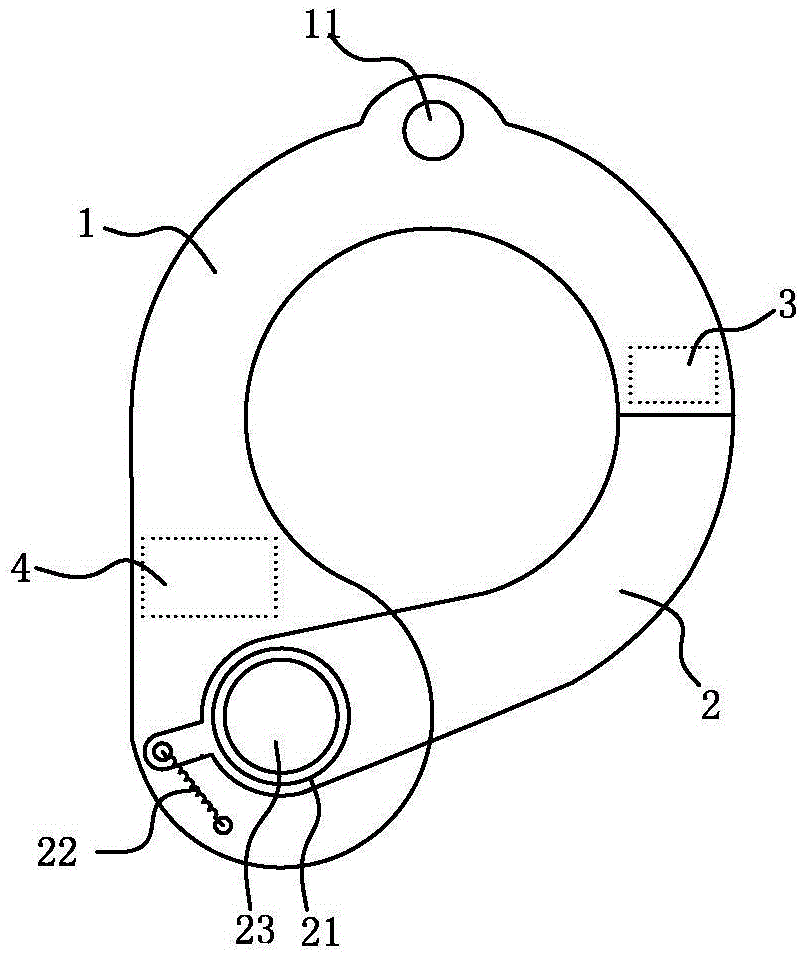

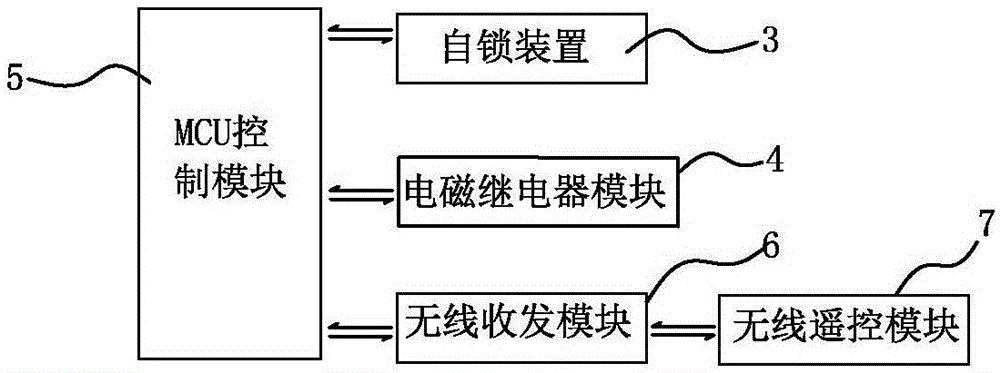

Intelligent rescuing high-altitude pothook device

InactiveCN105107100AHigh degree of intelligenceRealize remote wireless remote controlSafety beltsRemote controlComputer module

The invention discloses an intelligent rescuing high-altitude pothook device which comprises a pothook body and a retaining arm, wherein the retaining arm is pivoted to the pothook body and can be opened or closed relative to the pothook body; a self-lock device matched with the retaining arm is arranged at the upper end of the pothook body; a sling hole is arranged at the lower end of the pothook body; an electromagnetic relay module for controlling the retaining arm to be opened or closed relative to the pothook body, an MCU control module electrically connected with the electromagnetic relay module, as well as a wireless transceiving module and a wireless remote control module electrically connected with the MCU control module are further arranged at the lower end of the pothook body; the wireless transceiving module is connected with the wireless remote control module. The intelligent rescuing high-altitude pothook device is high in intelligent degree, can realize wireless remote control to control the open-close state of the pothook, and also can cooperate with an unmanned aerial vehicle to haul a rope to high altitude and fix the rope onto a corresponding object without manual floor climbing, so that the safety of high-altitude field operation can be improved, and personal and equipment safety are ensured.

Owner:DONGGUAN TIANNAN OPTICAL TECH

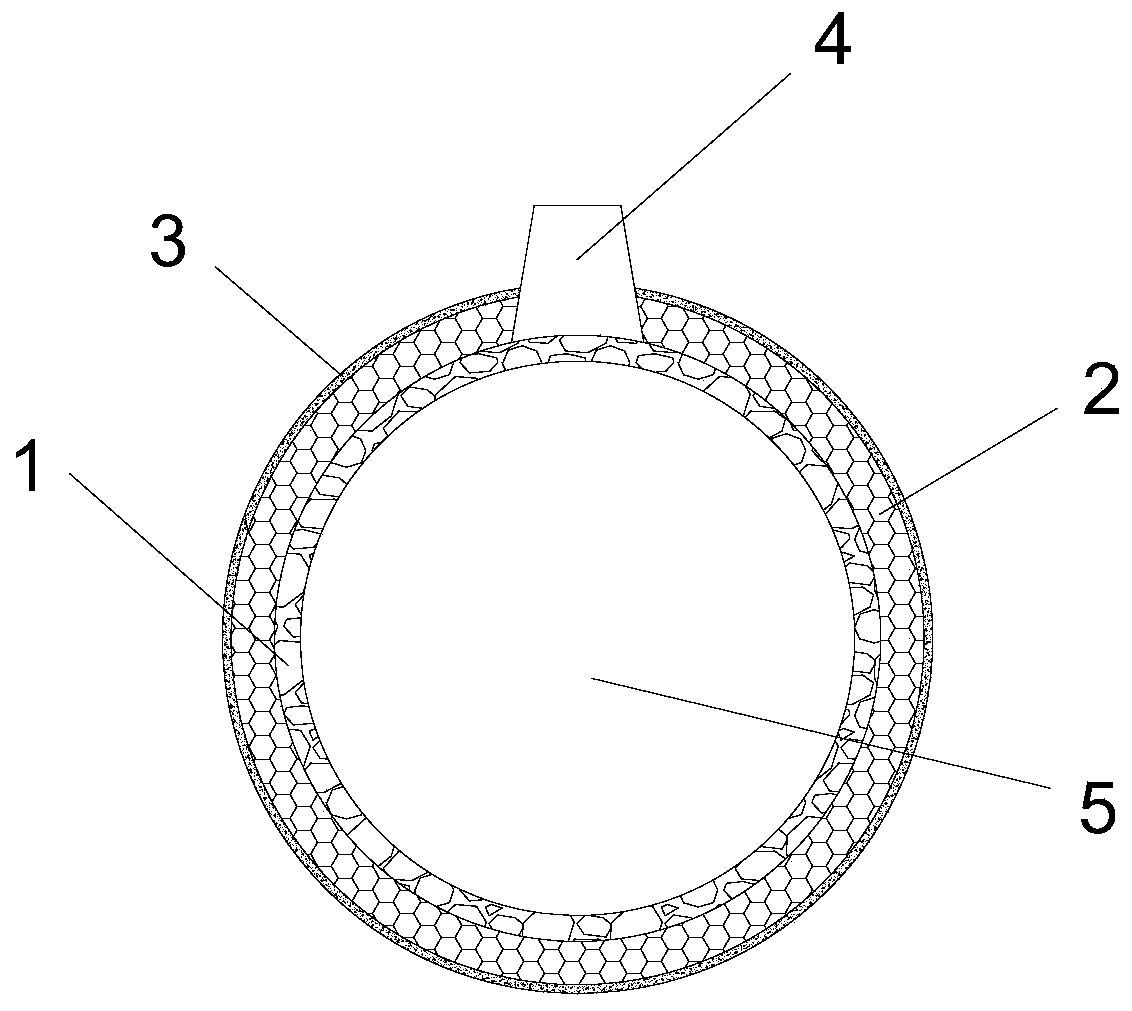

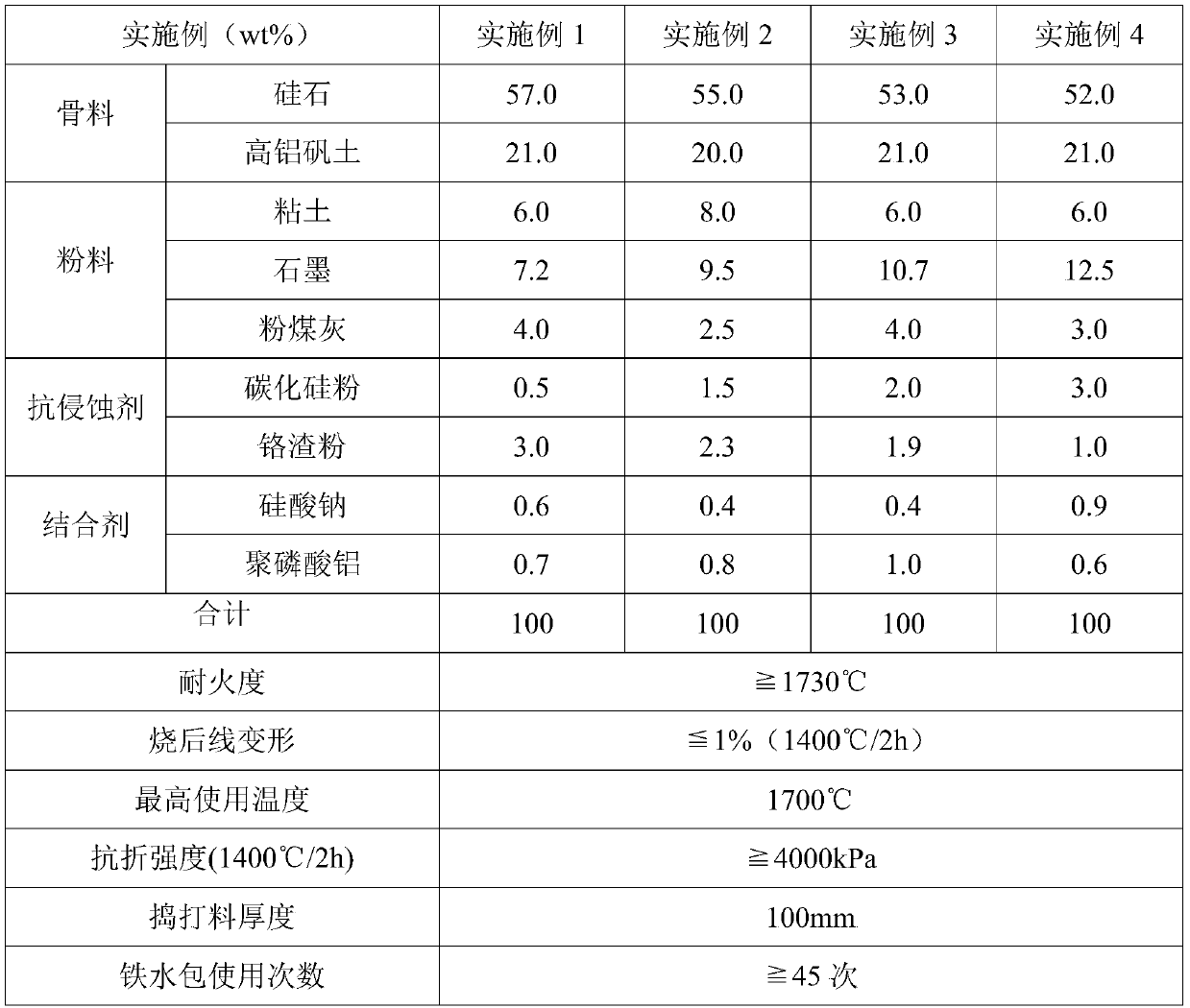

Ramming material for ladle lining and preparation method thereof

The invention relates to a ramming material for a ladle lining and a preparation method thereof. The ramming material comprises the following raw materials: 52 to 57 percent of silica, 20 to 23 percent of high-alumina bauxite, 5 to 10 percent of clay, 5 to 15 percent of graphite, 0.1 to 5 percent of fly ash, 0.2 to 5 percent of silicon carbide power, 0.1 to 3 percent of chromium slag powder, 0.1 to 1 percent of sodium silicate and 0.1 to 1 percent of aluminum polyphosphate. Advantages of the invention are as follow: as that structure strength is high in the use process, it will not cause ladleleakage accidents due to loosening, peeling and other damages in the use process, thus ensuring the safety of people and equipment around the ladle during lifting and transporting, preventing molteniron from sticking to the ladle, preventing wrapping of molten iron in slag, improving the recovery rate of molten iron, and greatly improving the safety and economy.

Owner:鄂尔多斯市瀚博科技有限公司

Electrified spanning construction method for high-voltage line

InactiveCN111355188APrevent fallingAvoid damageApparatus for overhead lines/cablesBlock and tackleEngineering

The invention provides an electrified spanning construction method for a high-voltage line. The electrified spanning construction method comprises the following steps that A, ground anchors are buriedin two sides of a spanned line respectively; B, iron towers of the high-voltage line serve as a crossing frame, holding poles is arranged below wire cross arms of the iron towers, and bearing tacklesis installed on the holding poles; C, a first bearing rope is pulled; D, a hanging basket is mounted to form an insulating sealing net; E, a second bearing rope is arranged between the wire cross arms of the two iron towers in a traction mode according to the method in the step C; F, a stay wire pulley block is assembled, the stay wire pulley block comprises a plurality of upper pulleys, and eachupper pulley is connected with a lower pulley; the stay wire pulley block is pulled to the position below the second bearing rope, and all the upper pulleys are installed on the second bearing rope;G, a wire is pulled, and the two ends of the wire is anchored on a wire cross arm; and H, the stay wire pulley block, the second bearing rope, the hanging basket and the first bearing rope are removed. The method is not limited by terrains and is suitable for crossed crossing pay-off and take-up construction of crossed lines which are high and cannot be powered off.

Owner:SICHUAN NO 2 ELECTRIC POWER CONSTR CO

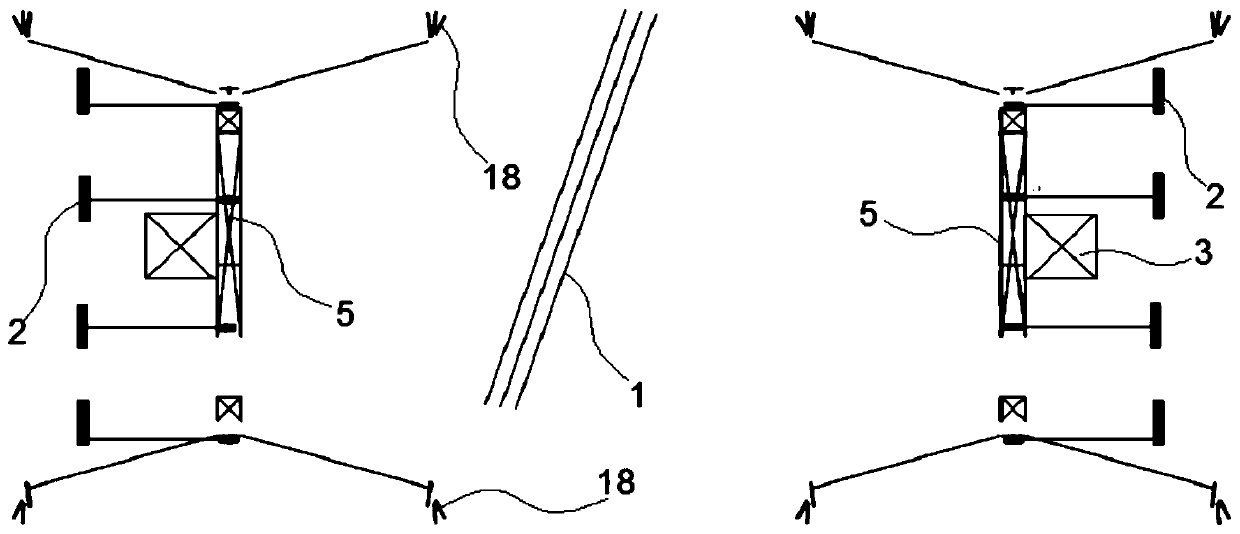

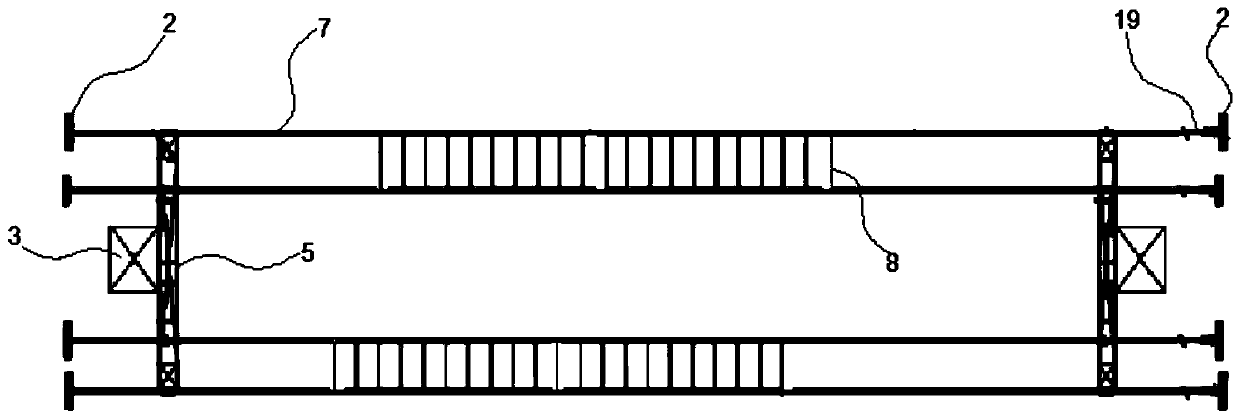

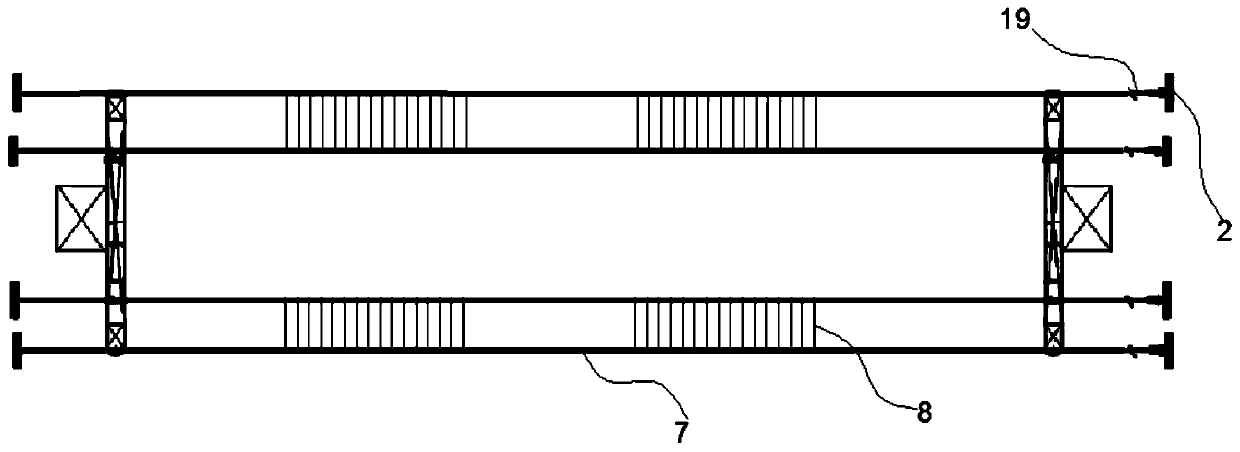

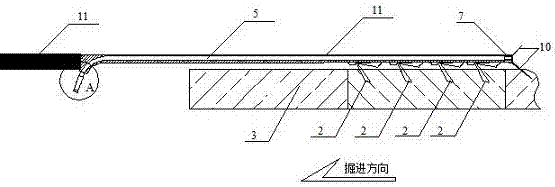

Method for protecting edge heaters during hot rolling of stainless steel

InactiveCN103240276AAssurance controlEnsure equipment securityRoll mill control devicesRolling safety devicesAutomatic controlNormal conditions

The invention belongs to the field of automatic control of hot continuous rolling strip steel rolling lines and particularly relates to a method for protecting edge heaters during hot rolling of stainless steel. A first metal detector, a second metal detector and a third metal detector are installed on a roller way from a roughing mill to a connecting point of the roughing mill and a finishing mill, edge heaters are installed on two sides of the roller way behind the connecting point of the roughing mill and the finishing mill, during hot rolling of the stainless steel, strip steels move from the roughing mill to the finishing mill along the roller way, first-stage speed reduction is conducted when heads of strip steels move to the first metal detector, second-stage speed reduction is conducted when heads of strip steels move to the second metal detector, and when heads of strip steels move to the third metal detector, if edge heaters detect abnormalities, strip steels moving on the roller way are subjected to wandering control till strip steels return to normal conditions. By the aid of the method, the safety usage of edge heaters during rolling of the stainless steel is guaranteed.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

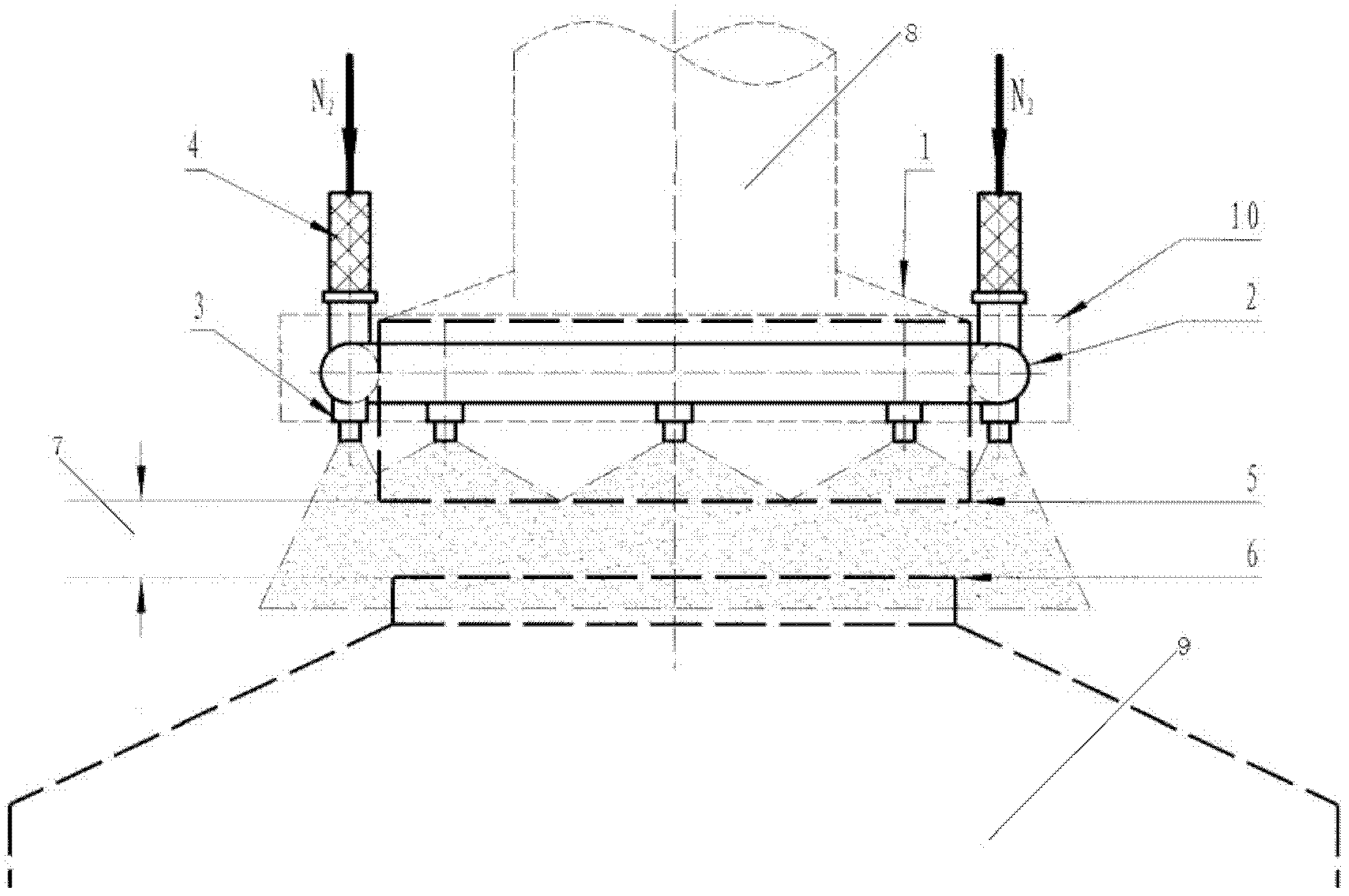

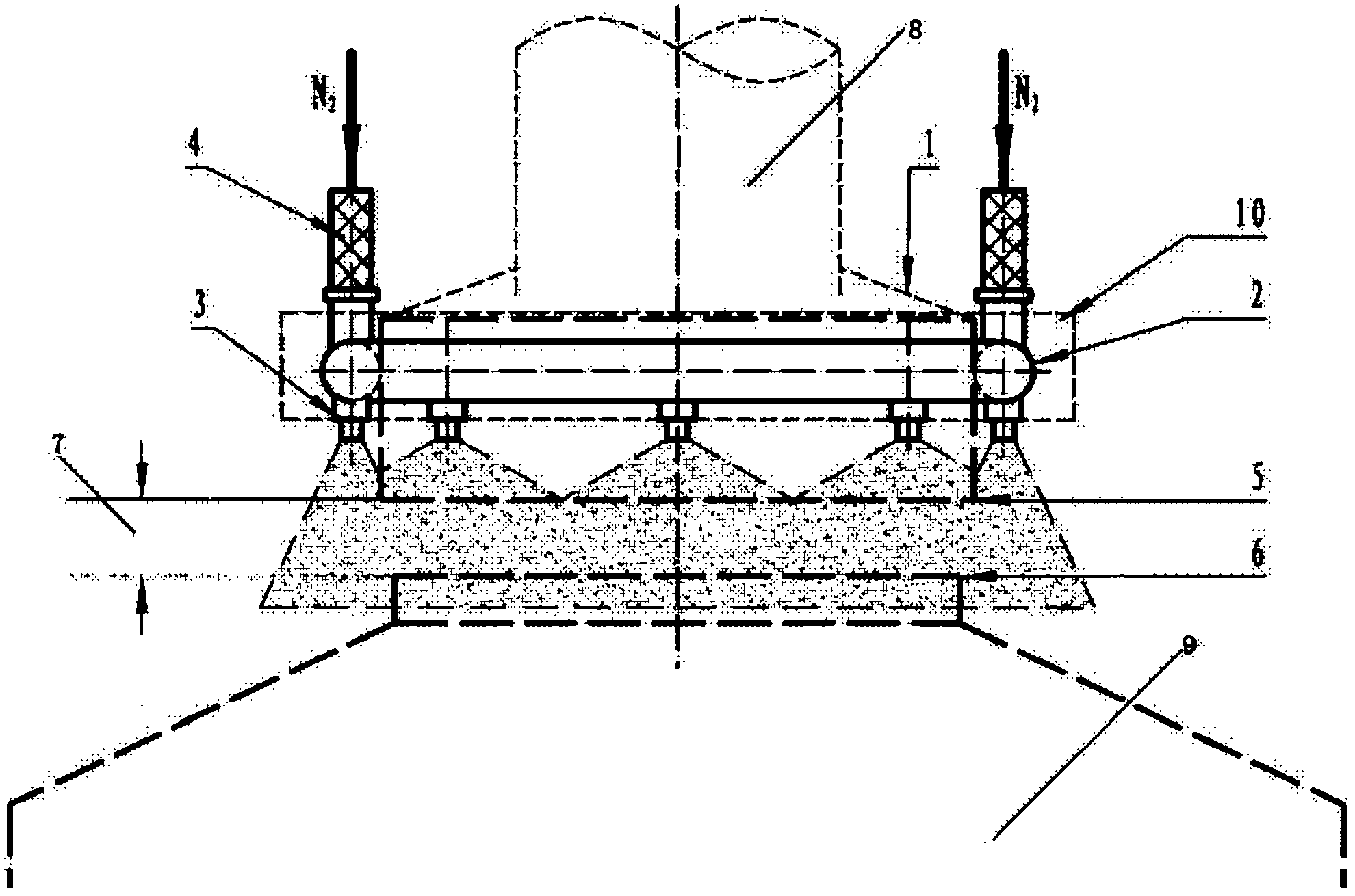

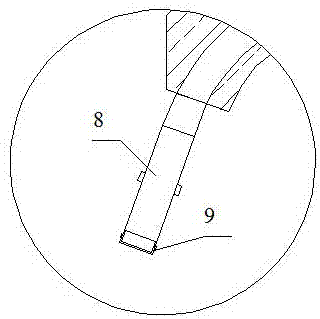

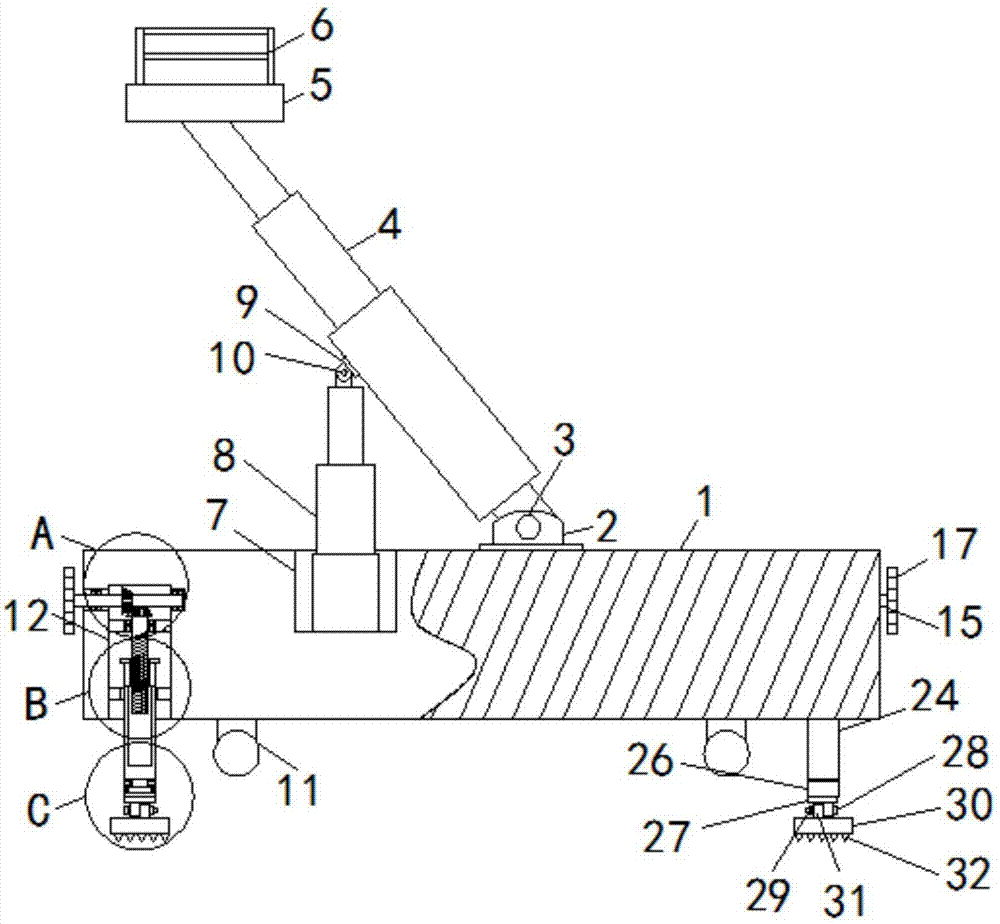

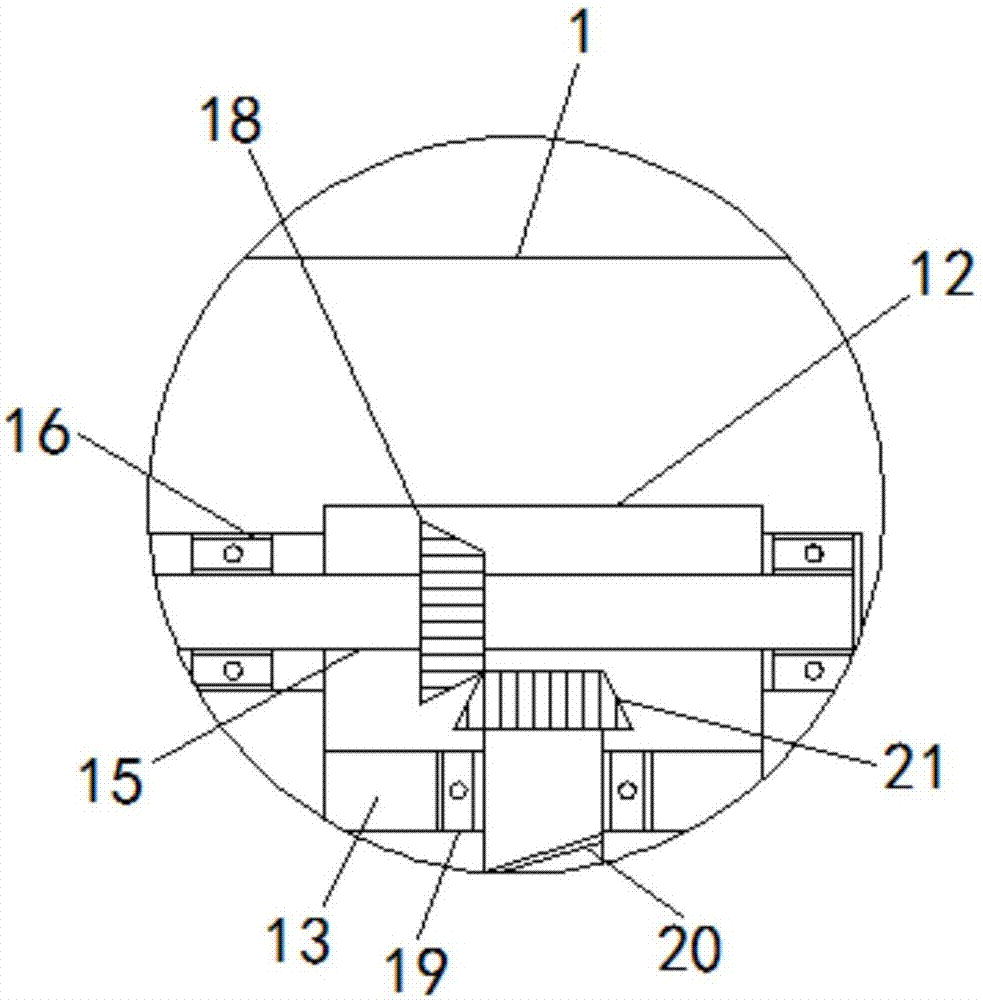

Slurry shield tail brush replacement liquid nitrogen freezing safety protection device and method under high water pressure condition

PendingCN106988752ASimple and efficient operationFreeze quicklyTunnelsShield machineElectrical and Electronics engineering

The invention relates to a slurry shield tail brush replacement liquid nitrogen freezing safety protection device under a high water pressure condition. The device comprises a shield tail shell, a shield tail brush and a duct piece which are arranged from outside to inside; mortar pipes are arranged inside the shield tail shell; the device further comprises at least one set of liquid nitrogen freezing device; each liquid nitrogen freezing device is arranged inside the shield tail shell and located between the adjacent mortar pipes; and each liquid nitrogen freezing device comprises a liquid inlet pipe, a liquid outlet pipe and an annular freezing pipe, wherein the annular freezing pipe is connected between the other ends of the liquid inlet pipe and the liquid outlet pipe. The device has the beneficial effects that the risk of hole drilling in the duct piece and destructive influences on the structure of the duct piece are avoided, the annular liquid nitrogen freezing pipes are arranged at the shield tail and form a liquid nitrogen circulation channel with the liquid inlet pipes and the liquid outlet pipes which are reserved in the middle shield position, circular liquid nitrogen in the channel can rapidly freeze a soil body at the shield tail, impurities like slurry and mortar are prevented from entering a shield machine, the device is easy and convenient to operate, freezing is rapid, and personnel and equipment safety in the shield tail brush replacement process can be effectively ensured.

Owner:CHINA RAILWAY SHISIJU GROUP CORP

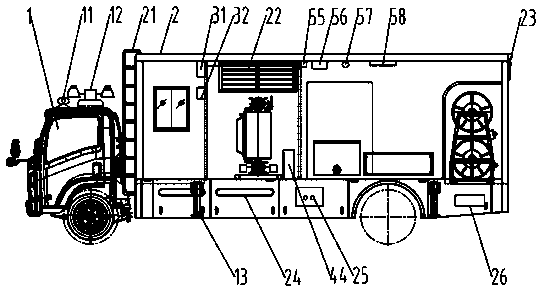

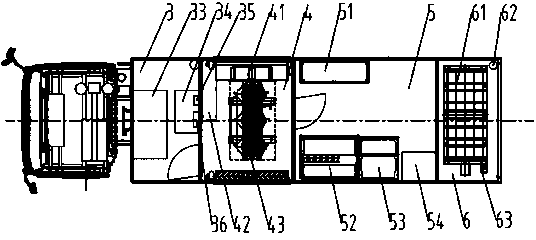

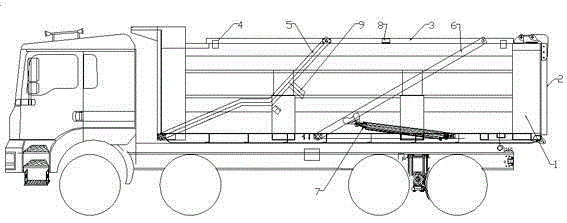

Intelligent power transformation truck

ActiveCN104210412ARealize non-stopWith boost functionDistribution substationsItem transportation vehiclesAutomatic controlTransformer

The invention relates to an outage-free operation device, in particular to an intelligent power transformation truck. The intelligent power transformation truck comprises a chassis truck, a carriage, a transformer, a ring network cabinet, a low voltage cabinet and a cable winch, wherein an operating chamber, a power transformation chamber, a high-low voltage chamber and a winch chamber are formed inside the carriage; an electrical control screen and an operation control screen are mounted in the operating chamber; an air exhaust window and a radiating fan are mounted in the power transformation chamber; a smoke sensor and a temperature and humidity sensor are mounted in the power transformation chamber and the high-low voltage chamber; an integrated control device is arranged in the high-low voltage chamber. The environment work condition of the carriage can be automatically controlled, and the optimum operation efficiency state of various pieces of equipment is achieved. The intelligent power transformation truck has a boost-buck function and a ring network function, is easy to mount, convenient, reliable and reasonable to configure, and good in integration effect, and can reach a repair scene immediately, so that outage-free maintenance, failure repair and equipment replacement can be emergently, flexibly, quickly and safely performed.

Owner:LONGYAN HAIDEXIN AUTOMOBILE

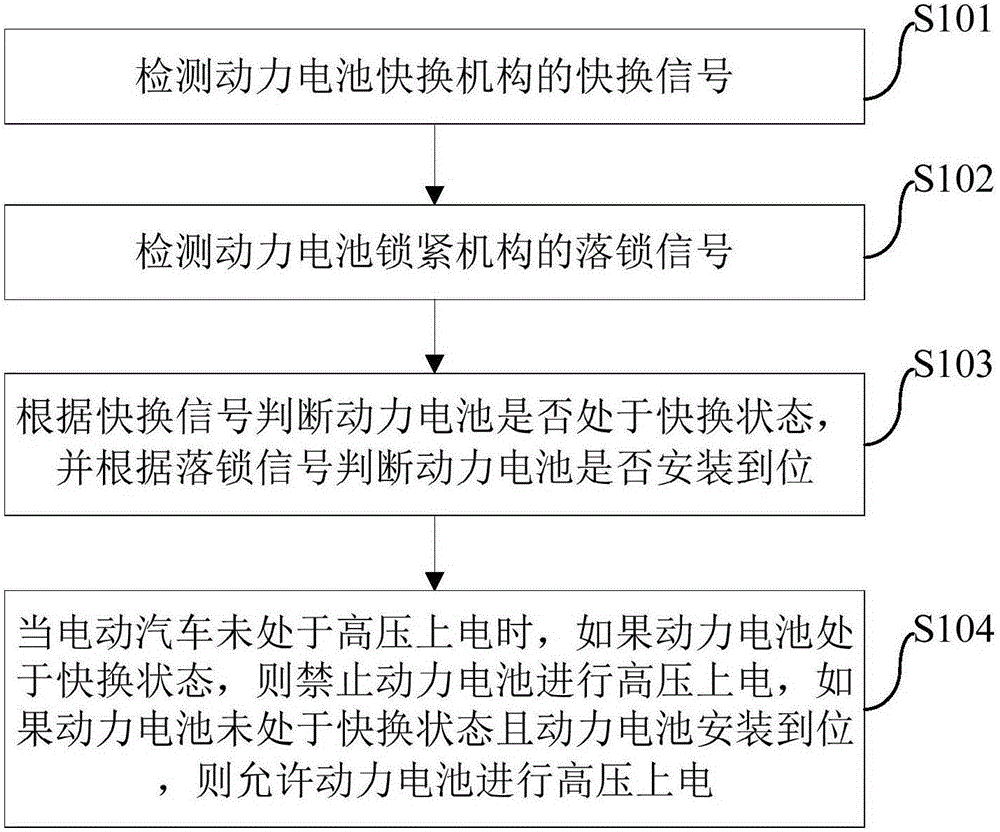

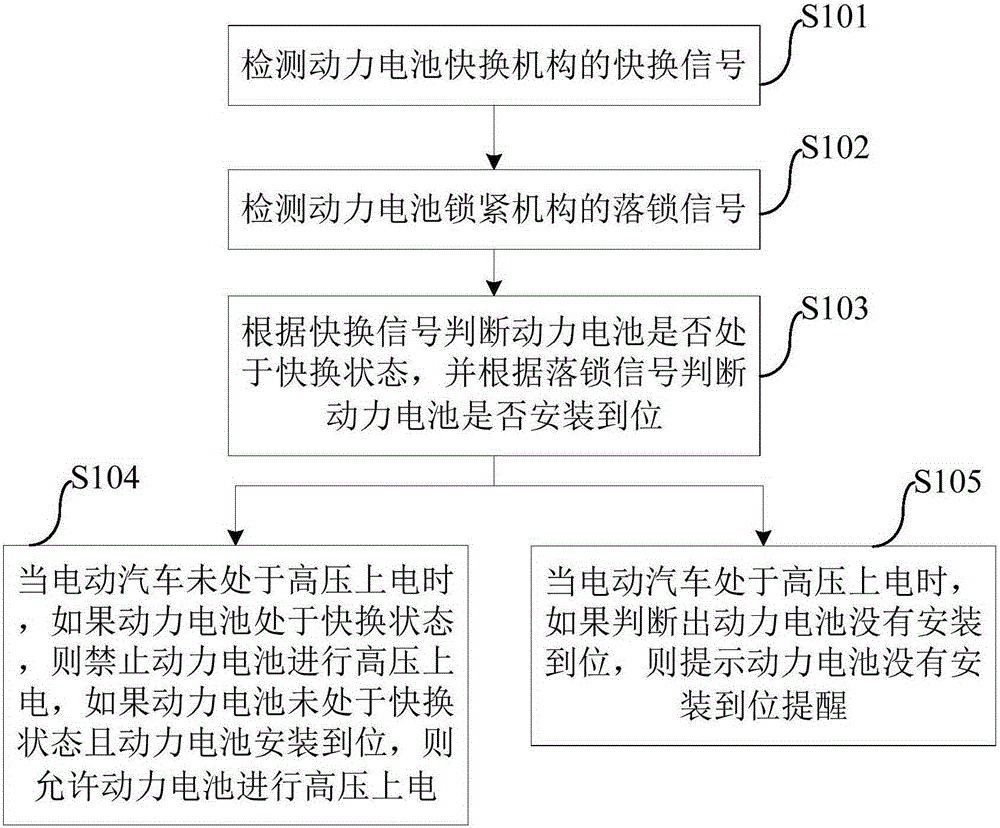

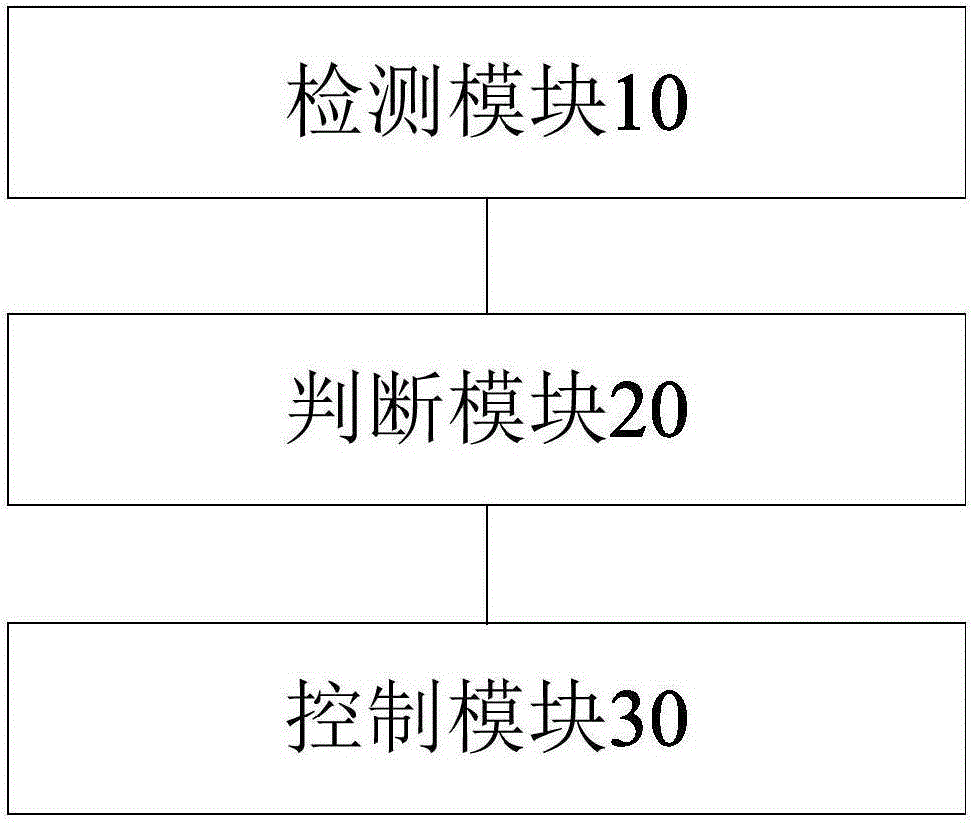

High-voltage control method and system of electric vehicle and electric vehicle

InactiveCN105216635AEliminate potential safety hazardsEnsure equipment securityElectric devicesElectrical batteryElectric vehicle

The invention discloses a high-voltage control method and system of an electric vehicle and the electric vehicle. The method comprises the following steps: detecting a quick-change signal of a power battery quick-change mechanism; detecting a locking signal of a power battery locking mechanism; judging whether a power battery is in a quick-change state or not, and judging whether the power battery is mounted in place or not according to the locking signal; and when the electric vehicle is not powered on with a high voltage, prohibiting the power battery from being powered on with a high voltage if the power battery is in a quick-change state, while allowing the power battery to be powered on with a high voltage if the power battery is not in a quick-change state and is mounted in place. Through the high-voltage control method and system of the electric vehicle according to the embodiment of the invention, the high-voltage safety in a quick-change process of the power battery can be guaranteed.

Owner:BEIJING ELECTRIC VEHICLE

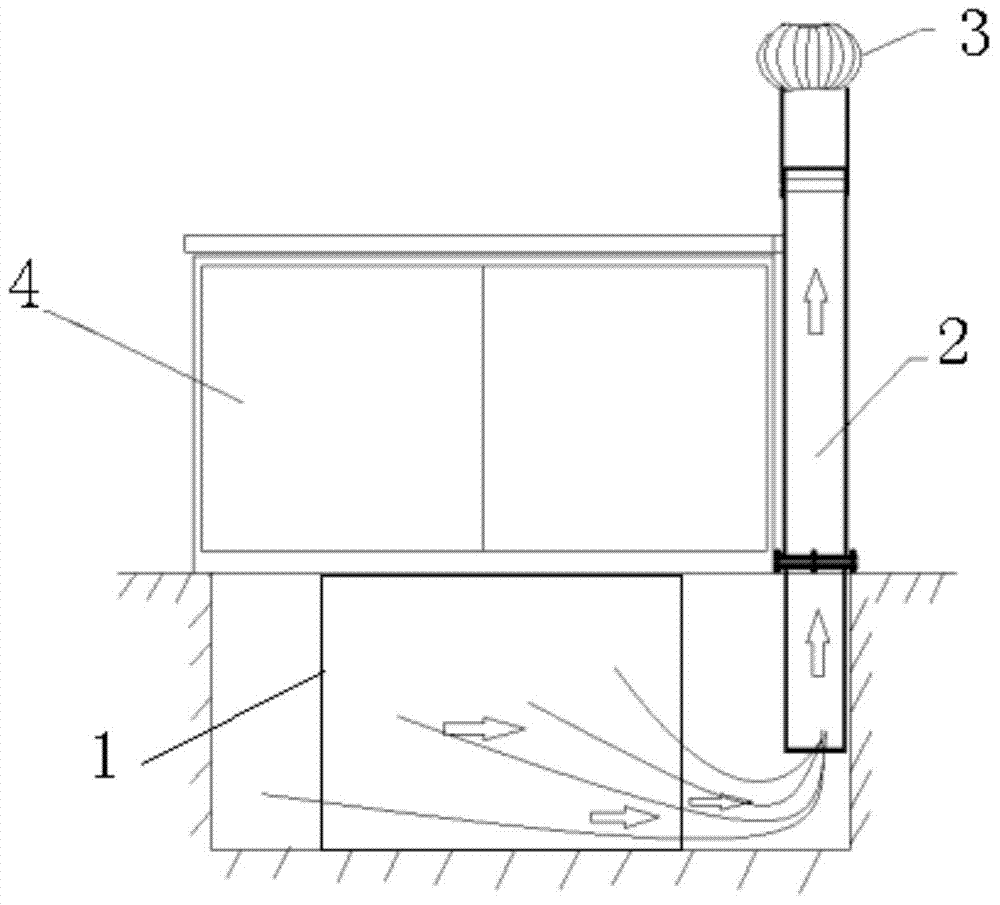

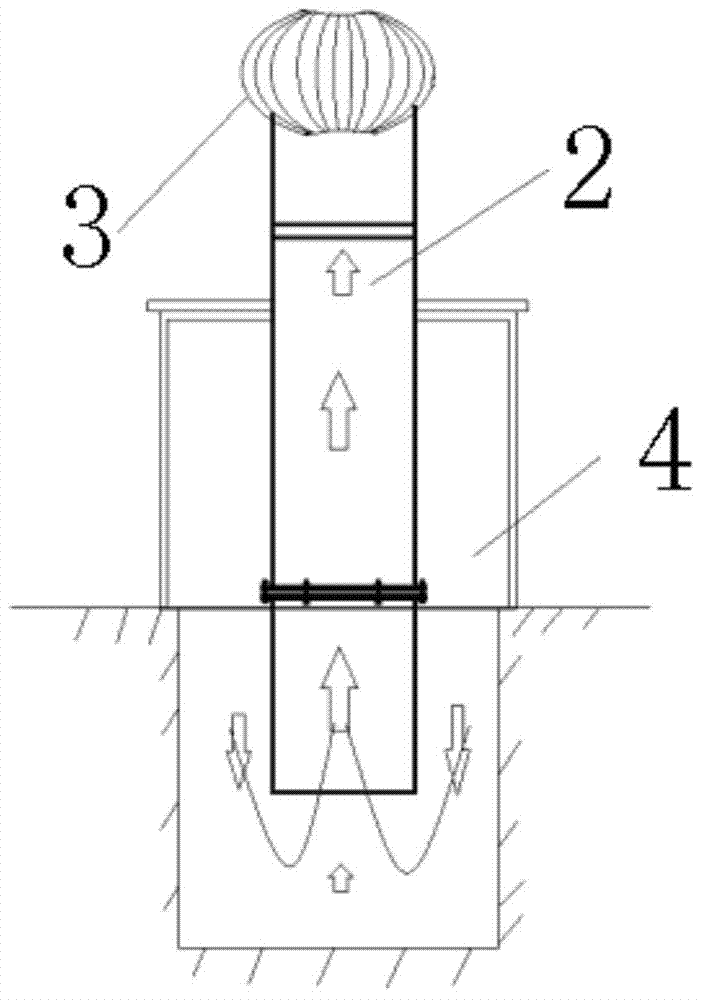

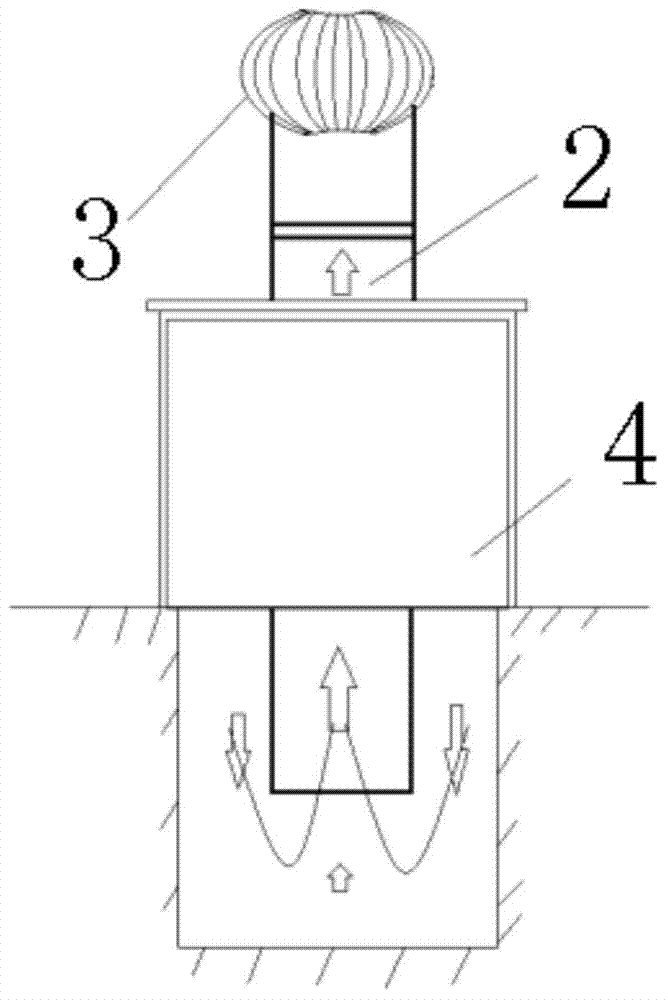

Field cabinet body anti-condensation device for electric power system

InactiveCN103762509AEnsure equipment securityAvoid condensationSubstation/switching arrangement cooling/ventilationEngineeringCold air

A field cabinet body anti-condensation device for an electric power system is characterized in that the field cabinet body anti-condensation device for the electric power system comprises a bottom frame supporting structure, an exhaust duct and an exhaust device, wherein a cabinet body is installed on the bottom frame supporting structure and the bottom frame supporting structure is placed in an underground pit; the exhaust duct is installed beside the bottom frame supporting structure, the lower end of the exhaust duct is 10 cm to 15 cm away from the bottom of the pit, and the upper portion of the exhaust duct is 20 cm to 30 cm higher than the cabinet body; the exhaust device is installed on the upper portion of the exhaust duct. The field cabinet body anti-condensation device for the electric power system has the advantages that the condensation phenomenon that cold air inside the cabinet body condenses into ice crystal attached to a device is avoided and a guarantee is provided for device safety.

Owner:STATE GRID CORP OF CHINA +1

Hydraulic opening four-link type top cap device

A hydraulic opening four-link type top cap device comprises a compartment. The rear end of the compartment is provided with a rear door, the top of the compartment is provided with an overturning top cap, the front and rear sides of the compartment are provided with top cap overturning devices which comprise front overturning arms and rear overturning arms, the upper ends of the front overturning arms and the rear overturning arms are connected with the side edge of the top cap through revolving axles, the lower ends of the front overturning arms and the rear overturning arms are connected with the compartment through revolving axles, overturning oil cylinders are arranged on the outer side of the rear end of the compartment, telescopic rods in the overturning oil cylinders are hinged to the rear overturning arms through joints, overturning positioning blocks are arranged on the side edge of the top cap, the front overturning arms are provided with support blocks at the positions corresponding to the overturning positioning blocks, and after the top cap is overturned through the top cap overturning devices, the overturning positioning blocks and the support blocks are mutually matched to limit the overturned top cap, to make the top cap to be positioned above the cab. The device is simple in debugging, high in reliability, good in stability, convenient to install and use and easy in maintenance.

Owner:驰田汽车股份有限公司

Axial adjusting and controlling system of printing plate roller of corrugated board printer

ActiveCN102975478AEnsure equipment securityConvenience for registering workRotary pressesPrinting press partsContactorRotary encoder

The invention provides an axial adjusting and controlling system of a printing plate roller of a corrugated board printer. The printing plate roller is arranged between a power side mechanical wall board and an operating side mechanism wall board. The roll shaft of the printing plate extends out of the operating side mechanism wall board to be in transmission connection with a mechanical reducing mechanism. The mechanical reducing mechanism is in transmission connection with a motor which is connected with a reversible contactor. The system is characterized in that double synchronous pulleys are arranged at the roll shaft of the printing plate. The double synchronous pulleys are respectively connected with a rotary coder and a mechanical transmission limiting system. Based on axial adjustment and electric control of current printing plate roller of the corrugated board printer unit, a mechanical axial limiting system is further arranged, so that when the axial device of the device changes out of the allowed range, the system can stop the machine under the effect of the mechanical axial limiting system to ensure the safety of the device.

Owner:ZHUZHOU SINOVAN PACKAGING TECH

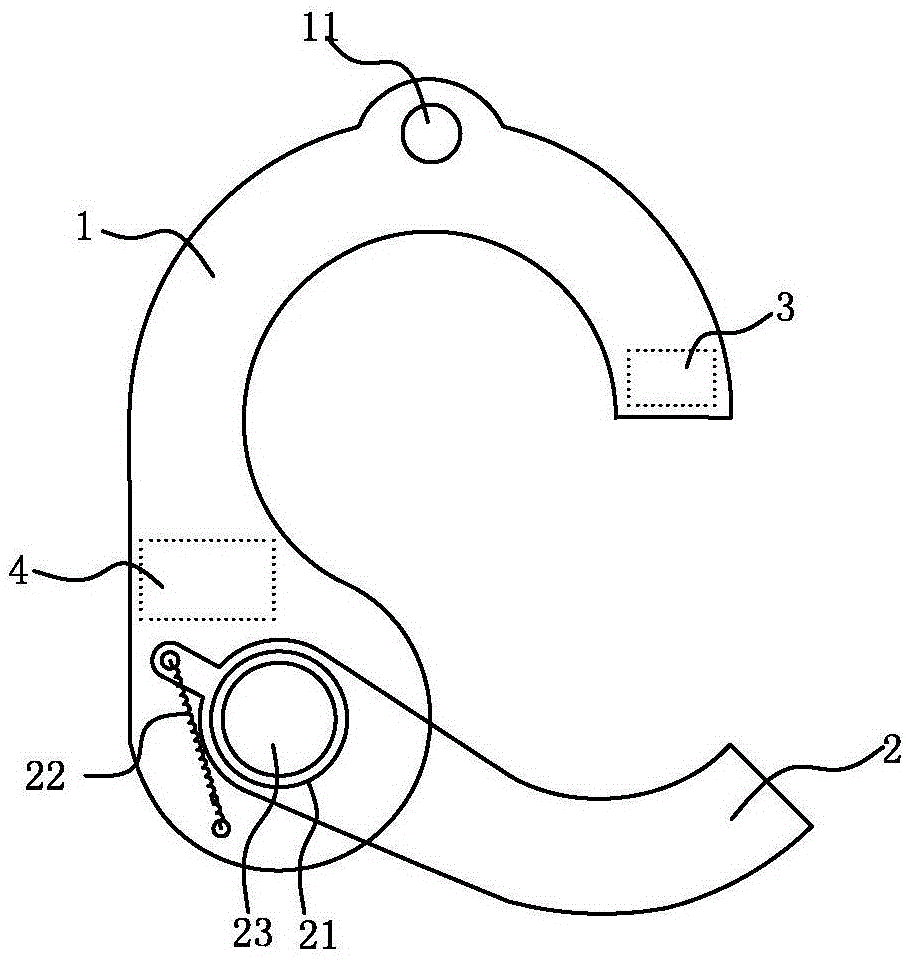

High-altitude operation automatic rope locking device

ActiveCN104064991APrevent prolapseImprove field safetyRopes and cables for vehicles/pulleyTextile cablesEngineeringOperation safety

The invention relates to a high-altitude operation automatic rope locking device. The device is characterized in that two sides of a sliding block is provided with a pull plate I and a pull plate II, the pull plate I, the pull plate II and one end of the sliding block are hinged through hinge shafts, the other ends of the pull plate I and the pull plate II are respectively hinged to one end of a closed door I and a closed door II, the other ends of the closed door I and the closed door II intersect, the closed door I and the closed door II are connected with the upper part of the sliding block through hinge shafts, two ends of the sliding block are respectively provided with traction rope holes, traction ropes pass through the traction rope holes, and the pull plate I and the pull plate II are provided with magnetic locks which are connected with the sliding block. According to the high-altitude operation automatic rope locking device, the sliding block is driven up and down by using the magnetic locks, the sliding block carries out driving downward to drive the pull plates to lock the closed doors, the sliding block carries out driving upward to drive the pull plates to open the closed doors, the release of a hook from a wire can be prevented, the site operation safety is improved, and the safety of people and equipment is ensured.

Owner:STATE GRID CORP OF CHINA +1

Electricity maintenance lifting operation platform

The invention relates to the technical field of electricity maintenance and discloses an electricity maintenance lifting operation platform. The electricity maintenance lifting operation platform comprises a bearing plate; a first positioning seat is fixedly mounted in the center of the top of the bearing plate; a first pin shaft is arranged on the first positioning seat in a penetrating and inserting mode; and the first positioning seat is movably connected with a first hydraulic telescopic rod through the first pin shaft. According to the electricity maintenance lifting operation platform, four rotary discs are rotated separately to adjust the lengths of hollow supporting rods, so that the hollow supporting rods adapt to the ground surfaces which are different in slope; the bottom of each hollow supporting rod is provided with a T-shaped cylinder and a rotary cylinder, so that supporting plates are effectively prevented from being driven to rotate when the hollow supporting rods rotate; and meanwhile bolts and tightening nuts can be adjusted, so that the supporting plates adapt to the ground surfaces which are different in slope, the problem that maintenance is inconvenient to conduct on the slopy ground surfaces is effectively solved, the working efficiency of maintenance on the slopy ground surfaces is effectively improved, and the personal safety of maintenance on the slopy ground surfaces is effectively improved.

Owner:武晓丹

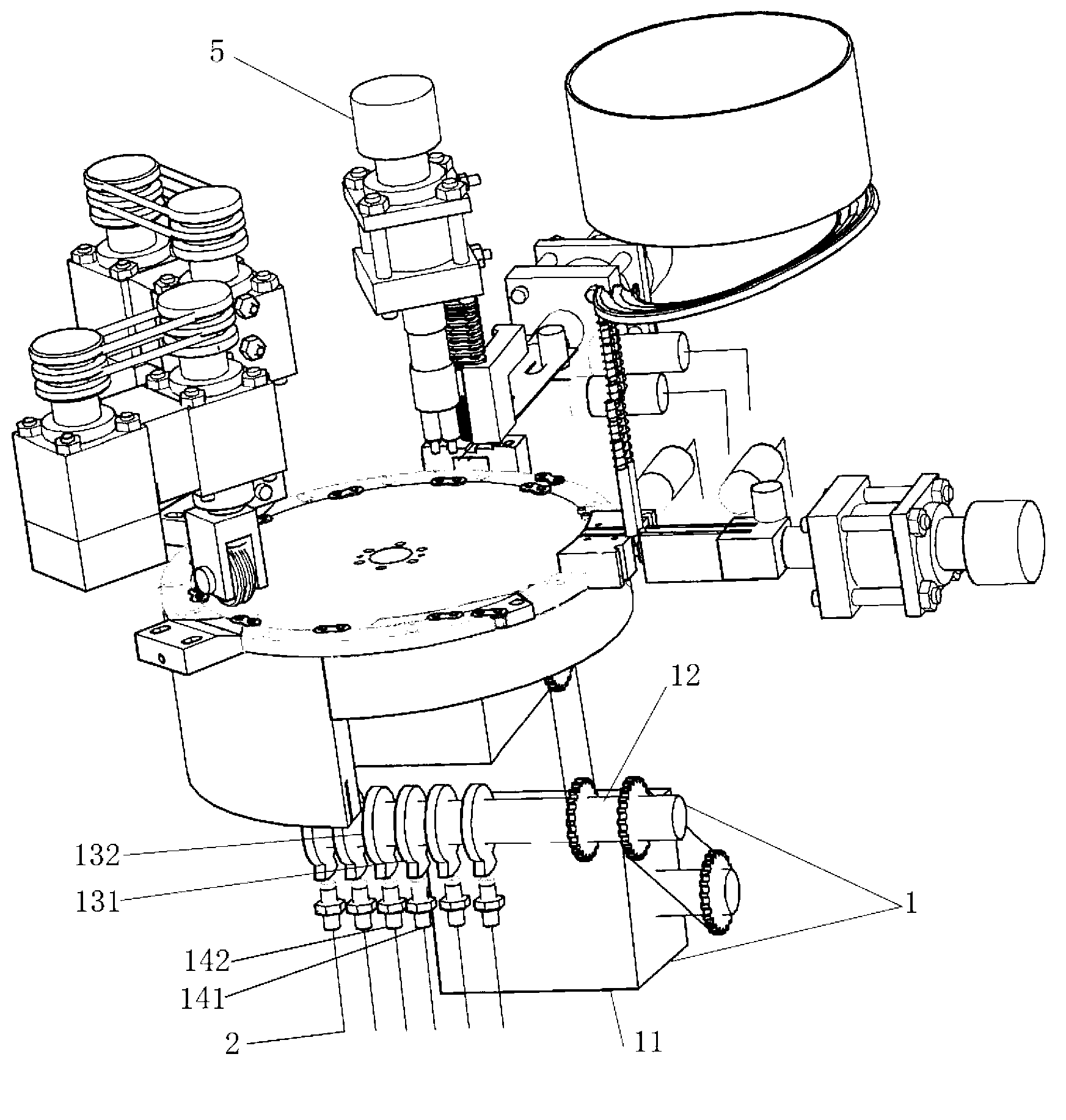

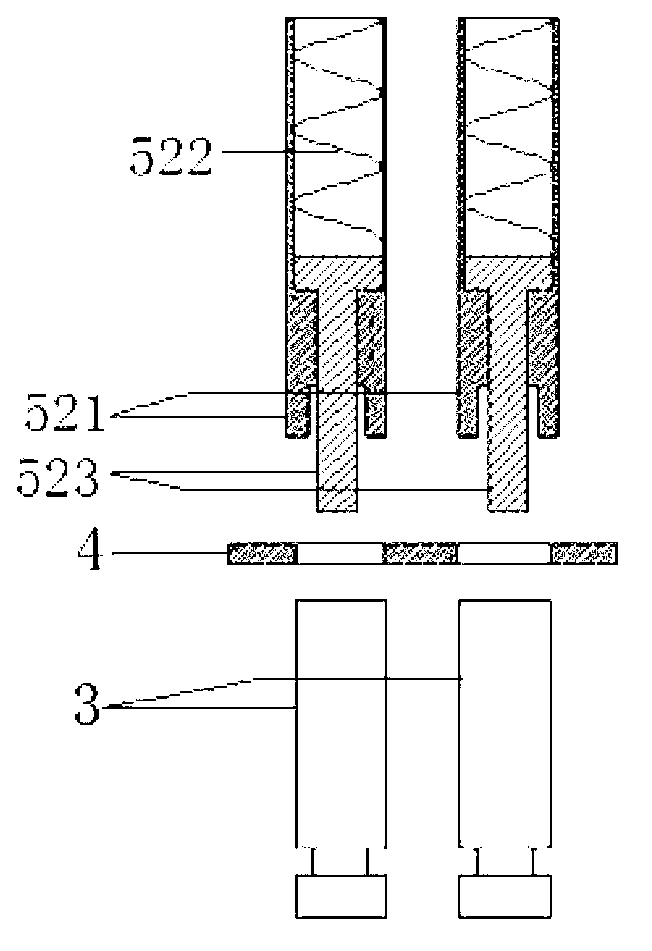

Piece assembly device used for chain assembly

The invention provides a piece assembly device used for chain assembly and relates to the field of chain production. The piece assembly device comprises a lifting device, a piece press device connected with the lower end of the lifting device, a control device, a first piece assembly cam, a sensor corresponding to the first piece assembly cam, a second piece assembly cam and a sensor corresponding to the second piece assembly cam. The lifting device is connected with the control device. The piece press device comprises a piece press mould and a pair of guide collision devices installed in the piece press mould and elastically connected with the piece press mould, and the sensors are connected with the control device. The piece assembly device has the advantages of being safe in production, high in efficiency, good in quality, high in stability and the like, thereby being a full automatic piece assembly device used for chain assembly.

Owner:SUZHOU CHUNMENG INTELLIGENT TECHNOLOGY CO LTD

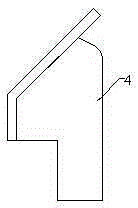

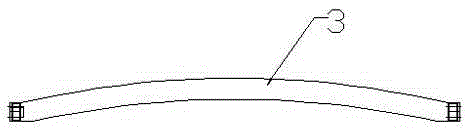

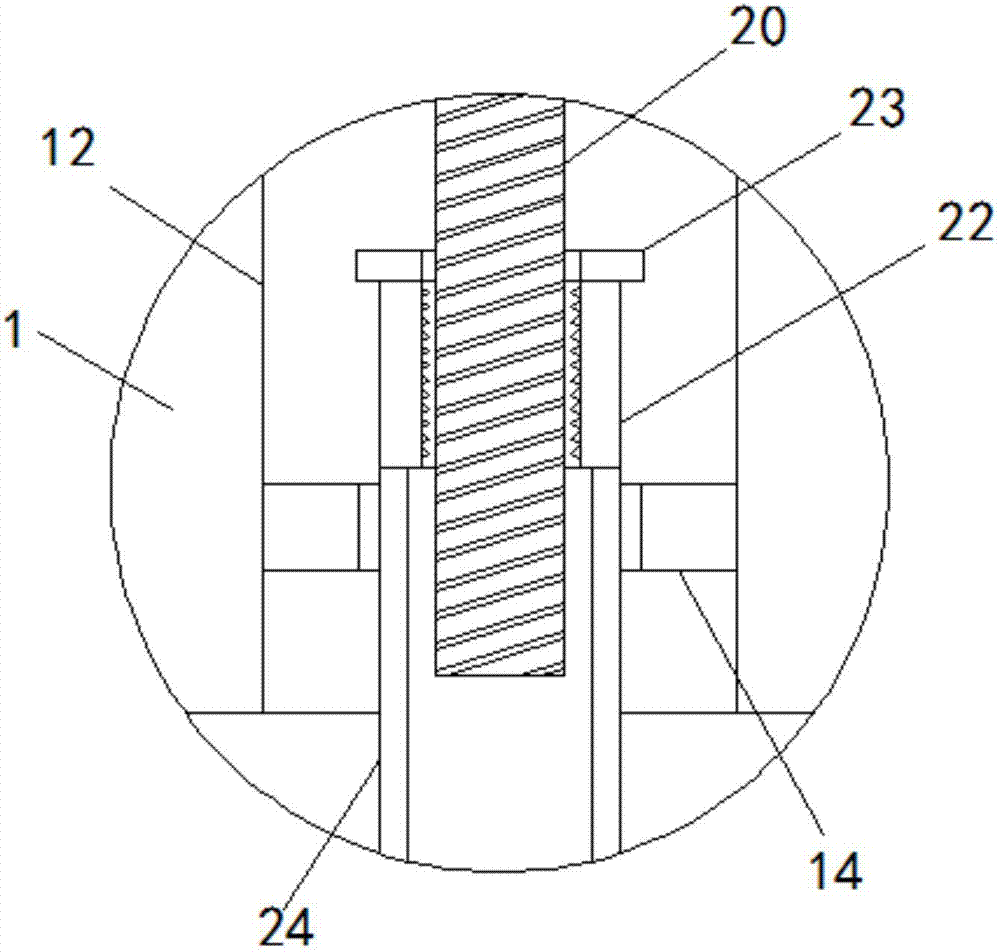

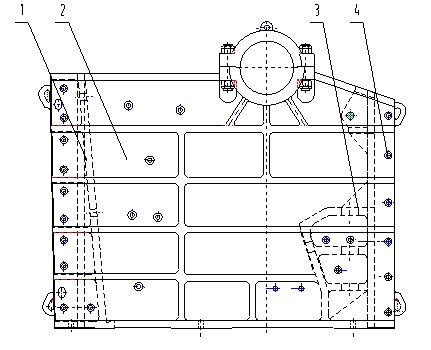

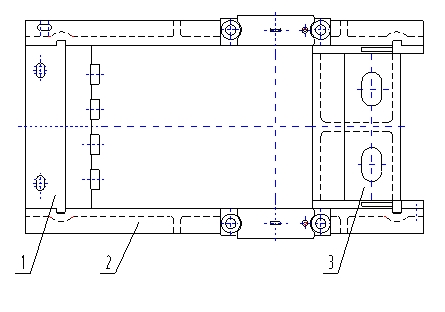

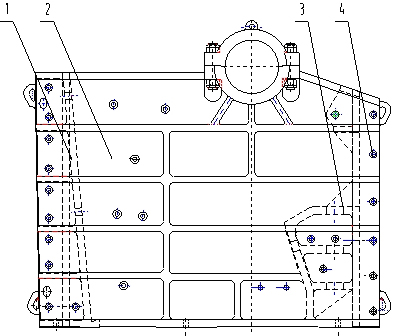

Large separable combined jaw crusher frame

The invention discloses a large separable combined jaw crusher frame. The frame comprises front box bodies (1), frame side plates (2), rear box bodies (3), and high strength hinged bolts (4). The front and the rear of the inner side of the frame side plate (2) are provided with wide grooves. Both side surfaces of the front box boy (1) and both side surfaces of the rear box body (3) are provided with convex benches, wherein the convex benches are corresponding to the shapes of the wide grooves. The convex benches are arranged in the wide grooves on the frame side plates (2). The frame side plates (2) and the front box bodies (1) are connected by the high strength hinged bolts (4), and the frame side plates (2) and the rear box bodies (3) are connected by the high strength hinged bolts (4), such that the whole frame is combined into a solid integration. According to the present invention, the separable combined structure is firm, and is convenient to install on site; the large separable combined jaw crusher frame has the following advantages that: 1, the large separable combined jaw crusher frame is easy to construct; 2, the large separable combined jaw crusher frame is firm and reliable; 3, the large separable combined jaw crusher frame is convenient to install and maintain on the site; 4, the large separable combined jaw crusher frame is convenient to transport; 5, the large separable combined jaw crusher frame is easily installed in a small space (such as underground); 6, the personal safety and the equipment safety are ensured.

Owner:朝阳重型机器发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com