Slurry shield tail brush replacement liquid nitrogen freezing safety protection device and method under high water pressure condition

A technology of safety protection device and shield tail brush, which is applied in the field of shield machines, can solve the problems of affecting the sealing effect, rubber tube aging, water seepage, etc., and achieve the effect of ensuring the safety of personnel and equipment, easy operation, and rapid freezing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

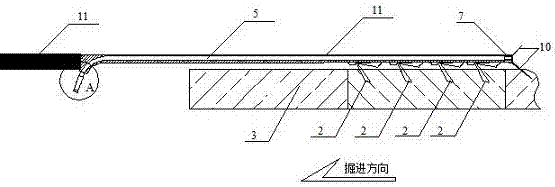

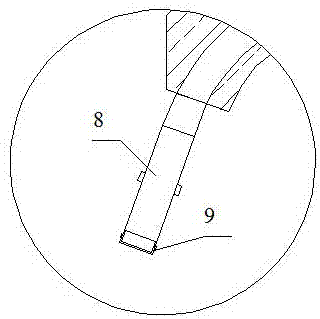

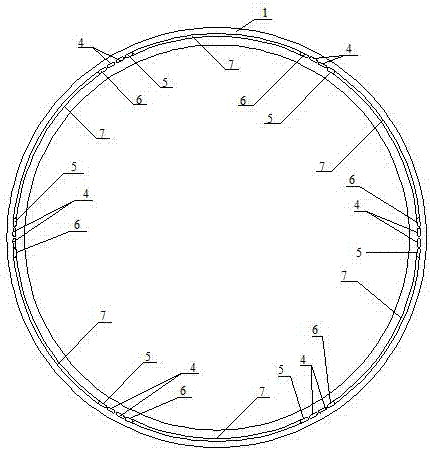

[0035] A safety protection method for replacing the liquid nitrogen freezing of the shield tail brush of the muddy water shield under the condition of high water pressure: including the following steps:

[0036] 1) Stop the shield machine, stop working and check the leakage point of the shield tail;

[0037] 2) The stainless steel hoses of the liquid inlet pipe and the liquid outlet pipe are connected to the liquid nitrogen system, and the liquid nitrogen is fed in, and the pressure of the liquid nitrogen feeding is 0.1MPa, and the temperature is measured;

[0038] 3) Continuously inject liquid nitrogen at a pressure of 0.1MPa to freeze and monitor the temperature to detect the leakage of the leak point, and the final temperature is -18°C;

[0039] 4) After the leakage is eliminated, continue to feed liquid nitrogen at a pressure of 0.08 MPa to maintain freezing;

[0040] 5) Carry out the plan implementation of the removal and replacement of the shield tail brush at the leaka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com