On-off control circuit for 10kV motor

A switch control circuit and motor technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problem of single control mode, improve production efficiency and automation, improve work, and realize manual and The effect of automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

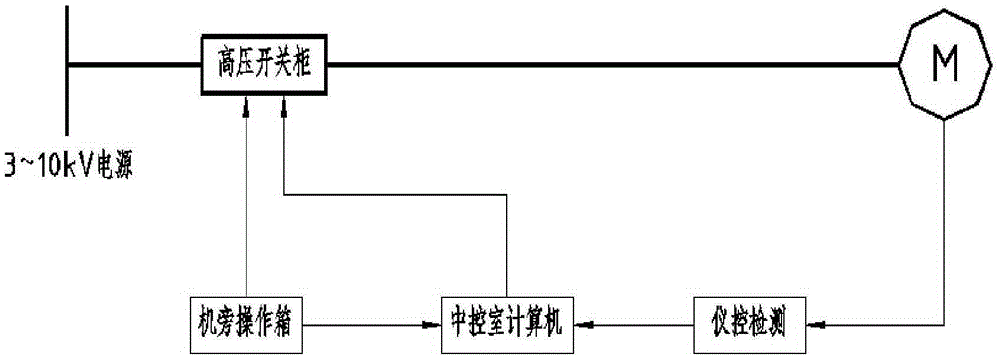

[0058] Such as figure 1 As shown, the 10kV high-voltage primary circuit is connected in series with a circuit breaker QF. The circuit breaker QF is installed in the switch cabinet. The circuit breaker QF is connected to the high-voltage motor. On the computer in the computer in the central control room, the computer in the computer in the central control room outputs signals to the switch cabinet, and the electrical signal in the operation box next to the machine is transmitted to the computer in the computer in the central control room on the one hand, and to the switch cabinet on the other hand.

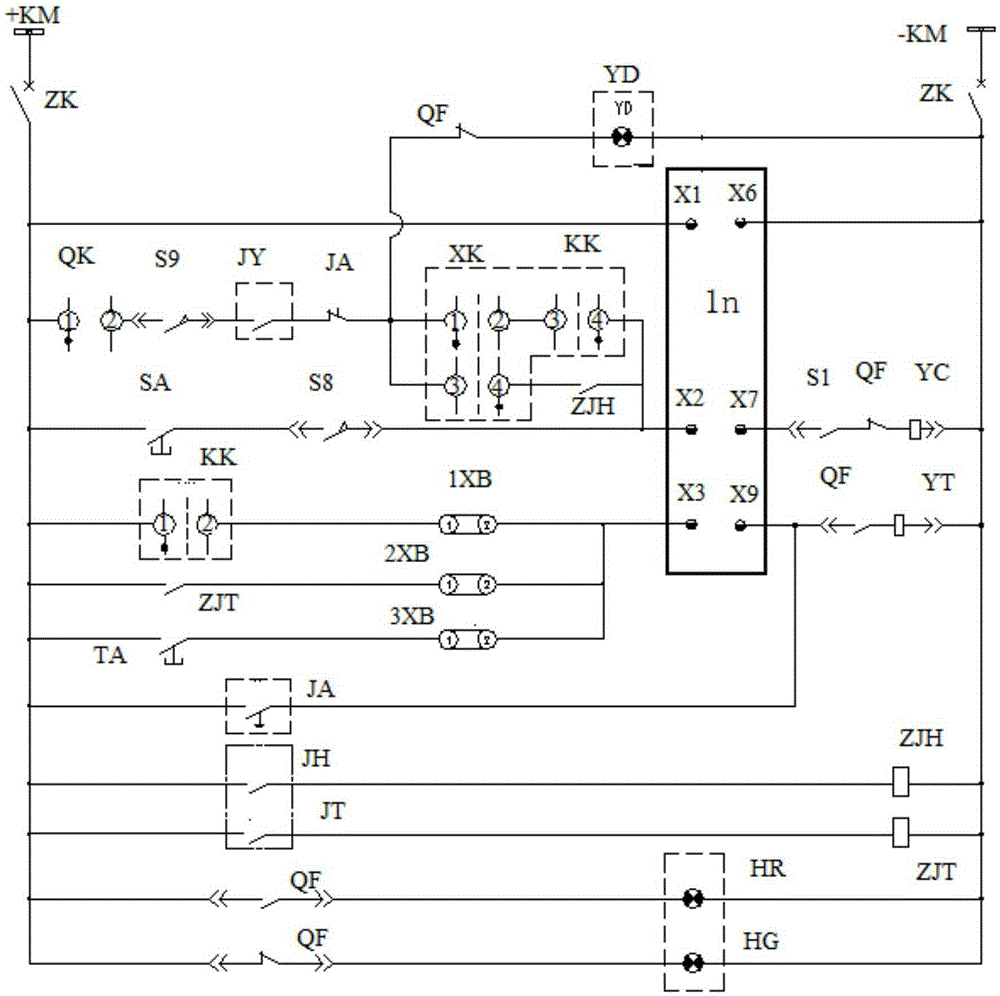

[0059] Button TA is on the switch cabinet, motor start indicator light YD, selection switch XK, control switch KK, emergency stop button JA, motor running signal lamp HR and motor stop signal lamp HG are all located in the operation box next to the machine. The selection switch XK on the operation box next to the machine adopts a three-position model, and it is placed in the middle...

Embodiment 2

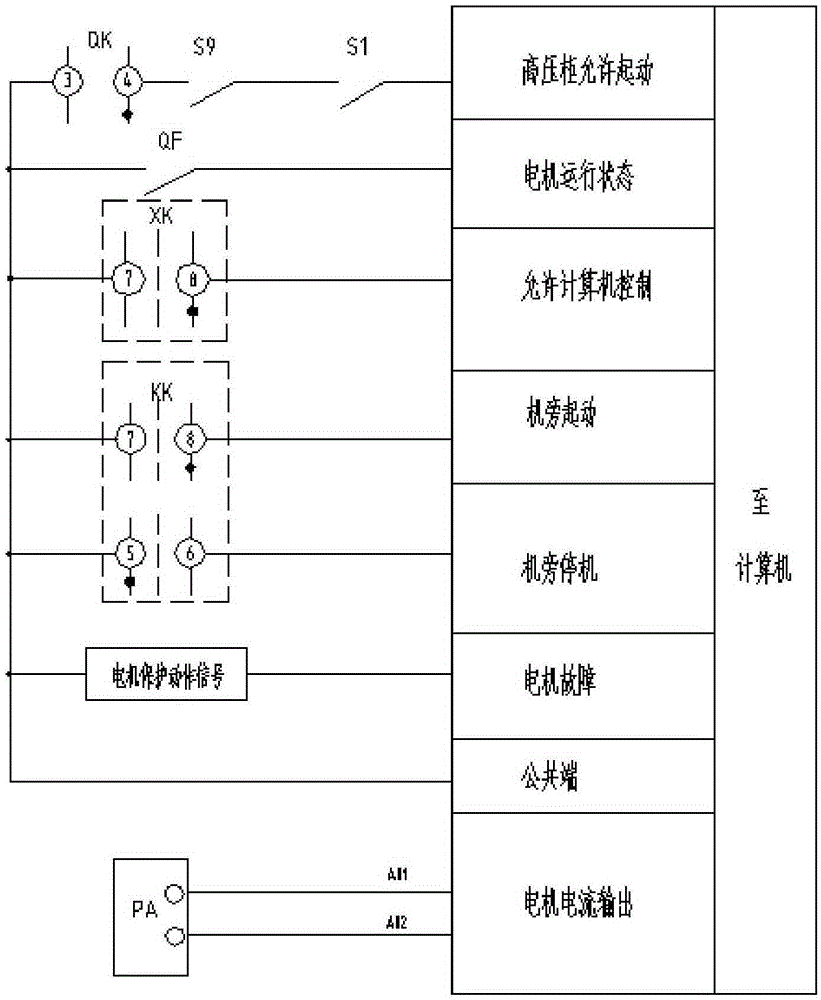

[0104] combine Figure 1-4 , a 10kV motor switch control circuit, the method of operation is the same as that of embodiment 1, and the structure is as follows: it includes an automatic air switch ZK, a microcomputer comprehensive protection device 1n, a circuit breaker QF, a control switch KK, a selection switch XK, intermediate relays ZJT and ZJH, The signal lamps YD, HR, HG, switch QK and emergency stop button JA, the positive and negative terminals of the automatic air switch ZK are respectively connected to the positive and negative poles of the DC 220V working power supply; the motor start indicator YD, the selection switch XK, The control switch KK, emergency stop button JA, motor running signal light HR and motor stop signal light HG are all located in the operation box next to the machine; the switch QK is "prohibited operation / allowing remote control", and the selection switch XK is "beside the machine / computer", The control switch KK is "start / stop".

[0105] The mi...

Embodiment 3

[0133] A shaft furnace in a steel mill is equipped with a combustion-supporting fan with a rated working voltage of 10kV and a rated power of 280kW. According to the factory operation position setting, the high-voltage switchgear of the motor is managed and maintained by the substation, and the substation adopts regular inspections, and there is no one on duty at ordinary times, and the fans are controlled by the production line operator.

[0134] According to the production requirements, the fan needs to be controlled by the operation box next to the machine and the computer in the central control room. The start-up conditions of the fan are that the inlet valve is closed, the relief valve is opened, the winding temperature is normal, the lubricating oil pressure and oil level are normal, and the electric control design will be the outlet and inlet. The valve signal is sent to the computer, and the oil pressure, oil level signal and winding temperature signal of the lubricatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com