Soft sealing device for converter mouth and fume hood

A converter mouth and soft sealing technology, applied in the manufacture of converters, etc., can solve the problems of difficult application effects, instrument ablation, and difficult sealing, so as to ensure the safety of people and equipment, prevent secondary combustion, and be easy to remove Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

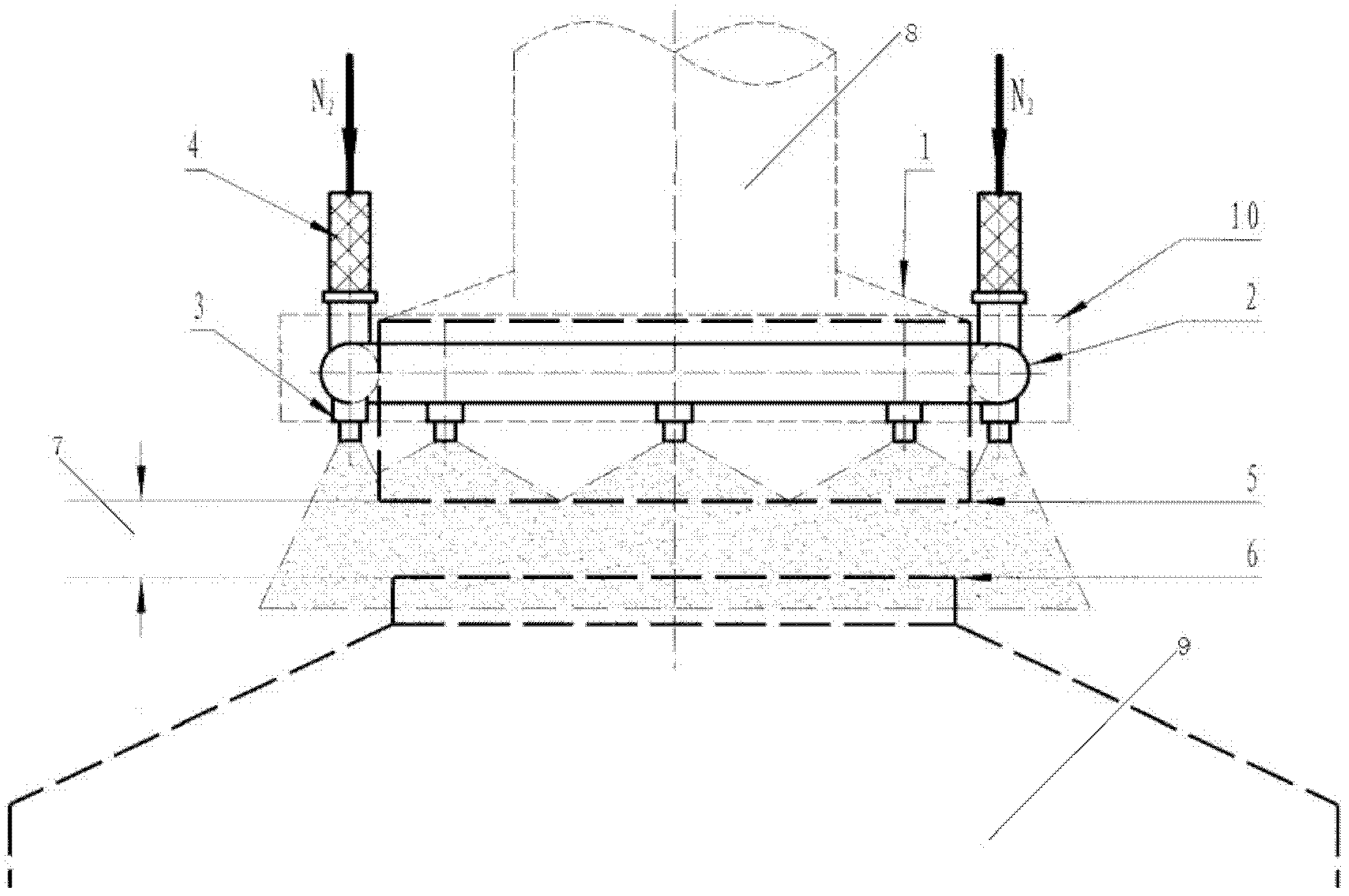

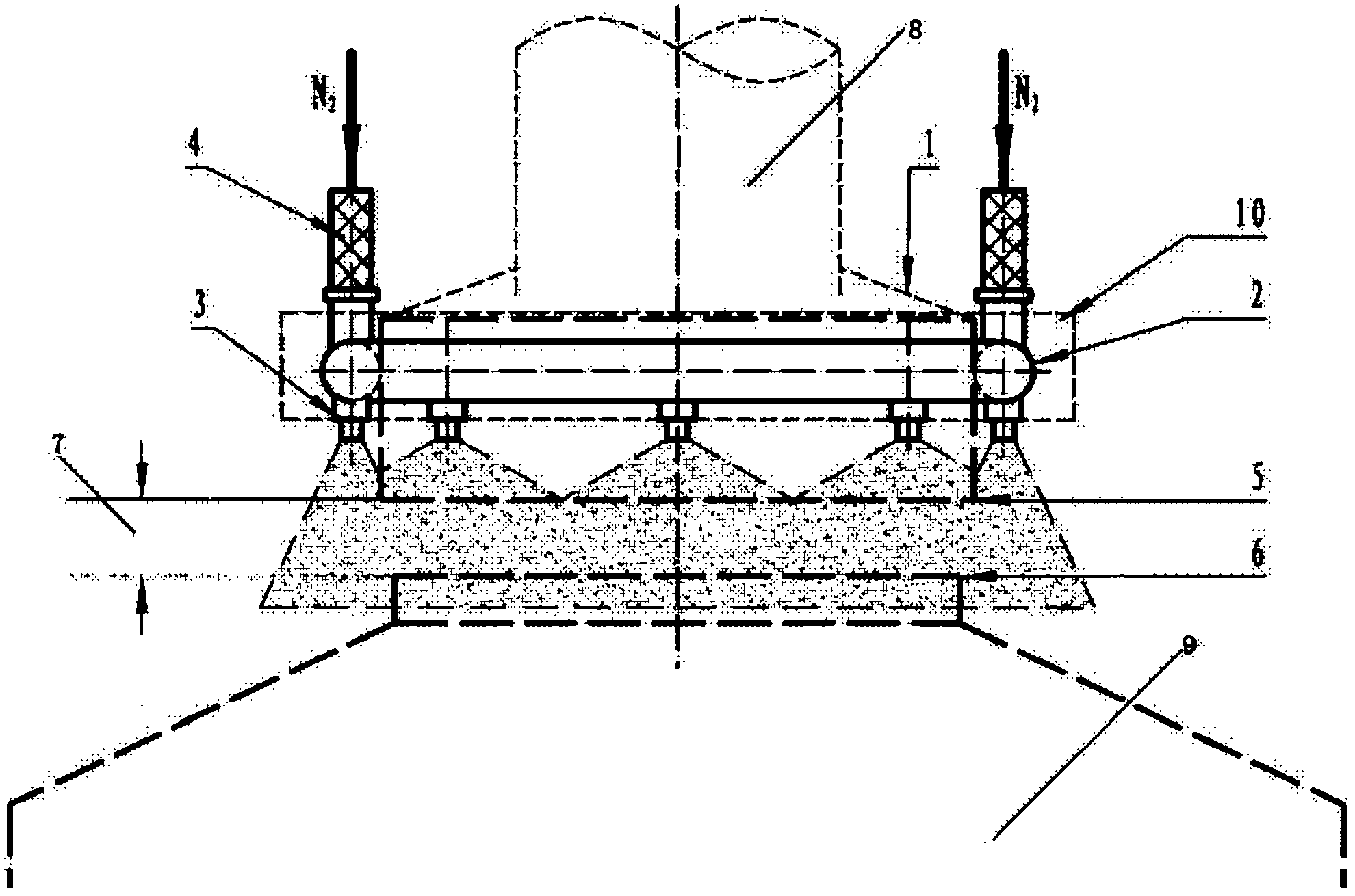

[0009] Referring to the accompanying drawings, the converter mouth and the smoke hood soft sealing device are installed with a circular ring pipe 2 along the surroundings at the upper entrance of the water-cooled fume hood 1 at the lower end of the flue gas water-cooled flue 8, and the nitrogen gas inlet pipe 4 (metal flexible hose), and the ring pipe 2 is provided with 6 to 8 arc-shaped front spraying nitrogen nozzles 3 at intervals along the circumference, evenly distributed, and vertically. In each period of converter production, between the flue gas inside the fume hood 1 and the air outside the fume hood 1, it enters the ring pipe 2 through the inlet pipe 4 to equalize pressure, and then flows between the lower end 5 of the fume hood 1 and the upper end 6 of the furnace mouth of the furnace body 9. Nitrogen is sprayed in between to form a nitrogen sealing curtain 7 to isolate the contact of flue gas and wild wind. In order to protect the ring pipe 2 and the nozzle 3 , a w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com