Method for producing high purity nano-level bismuth oxide micro-powder

A production method and technology of bismuth oxide, applied in chemical instruments and methods, nanotechnology, nanotechnology and other directions, can solve the problems of easy wear and tear of liquid metal bismuth, increase production cost, affect production efficiency, etc., and meet the requirements of equipment is not high, Easy-to-control, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

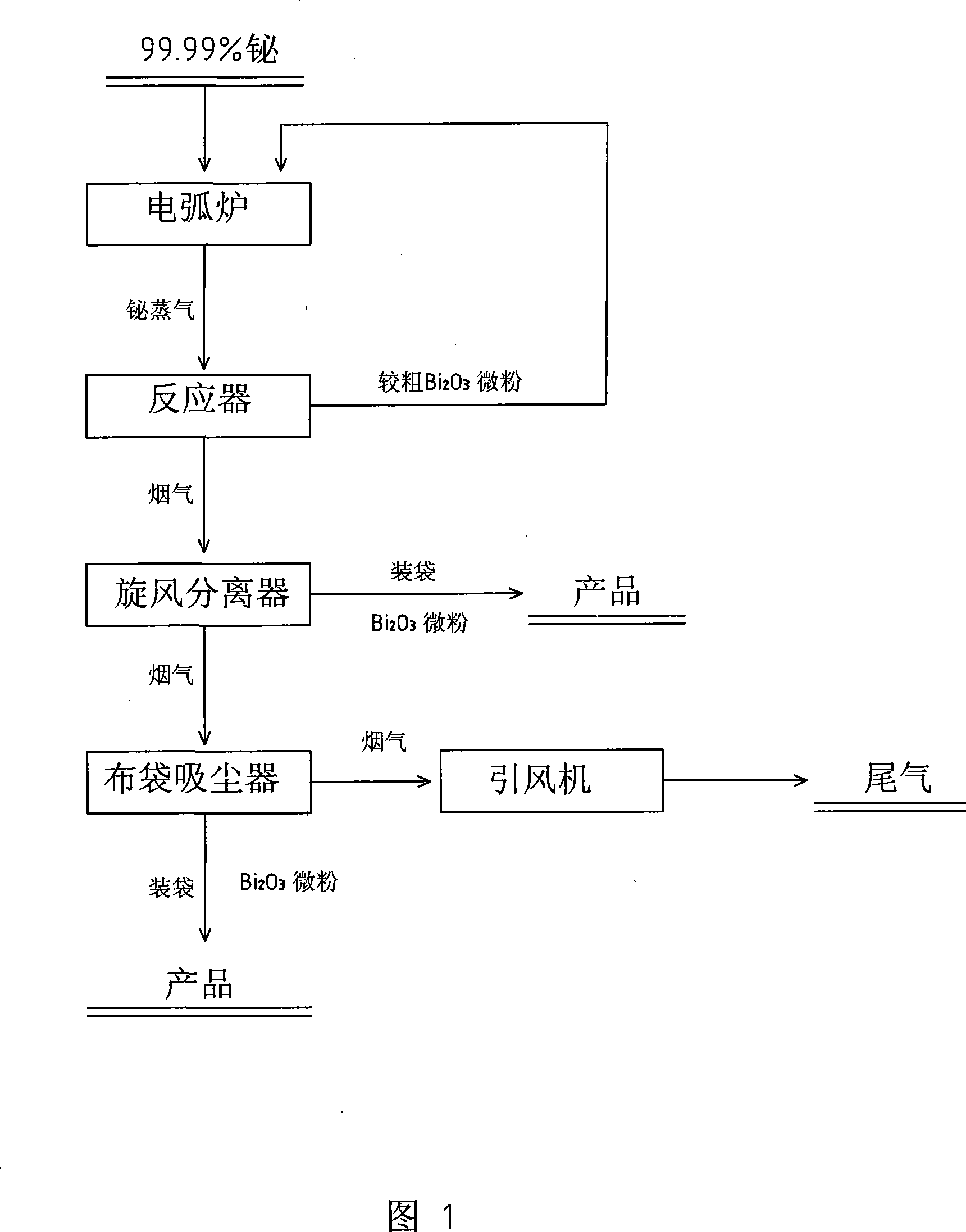

[0022] Now describe the present invention with specific embodiment in conjunction with accompanying drawing.

[0023] A production method of high-purity nano-scale bismuth oxide micropowder, the process steps are as follows:

[0024] a. Add bismuth ingots with a content of 99.99% into an electric arc furnace made of 316L stainless steel, heat and melt the bismuth ingots, and produce bismuth vapor through evaporation under the conditions of a temperature of 1000-1500°C and a pressure of 0.6-0.95 atmospheres;

[0025] b. After the bismuth vapor is sent into the reactor, it merges with the air sent into the reactor, and the high-temperature bismuth vapor is oxidized to form nano-scale solid bismuth oxide particles. At the same time, after the reactor inhales cold air, the flue gas temperature drops to about 170°C , after cooling by water circulation, part of the coarse bismuth oxide powder accumulates at the bottom of the reactor and is discharged back to the electric arc furnace...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com