Patents

Literature

179results about How to "Prevent secondary combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

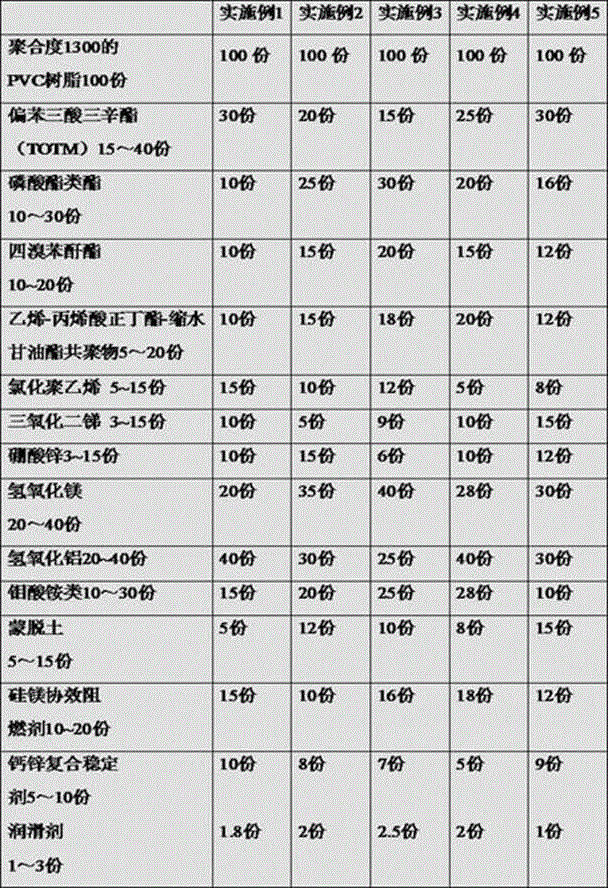

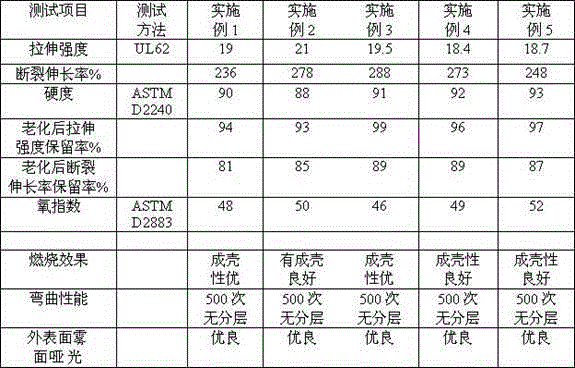

High-flame-retardation low-smoke composite cable material for boosting communication light cables, and preparation technology thereof

The invention relates to a high-flame-retardation low-smoke PVC composite material for boosting communication light cables, and a preparation technology thereof. The high-flame-retardation low-smoke PVC composite material for boosting communication light cables comprises, by weight, 100 parts of PVC resin with the polymerization degree of 1300, 15-40 parts of tricapryl trimellitate, 10-30 parts of phosphate ester, 10-20 parts of tetrabromophthalate, 10-30 parts of an ethylene-n-butyl acrylate-glycidyl ester copolymer, 5-15 parts of chlorinated polyethylene, 3-15 parts of diantimony trioxide, 3-15 parts of zinc stannate, 20-40 parts of magnesium hydroxide, 20-40 parts of aluminum hydroxide, 10-30 parts of ammonium molybdate, 5-15 parts of montmorillonite, 10-20 parts of a silicon-magnesium synergistic flame retardant, 5-10 parts of a calcium-zinc composite stabilizer, 1-3 parts of a lubricant, 0.2-1 part of an antioxidant, 2-4 parts of an acrylate polymer, and 1-3 parts of a linear polymer of alpha-methyl styrene. The high-flame-retardation low-smoke PVC composite material has the advantages of high flame retardation, good fire resistance, low smoke during combustion, unlikely propagation of flames, low heat release amount, and low release amount of toxic gases.

Owner:中广核三角洲(江苏)塑化有限公司

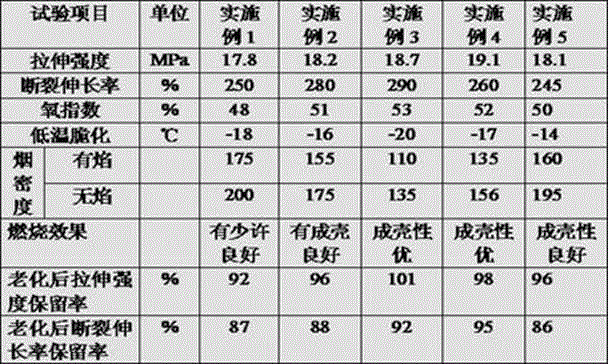

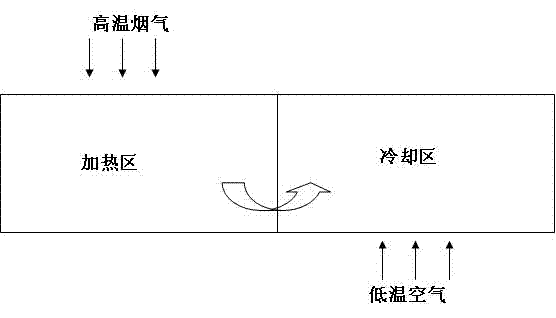

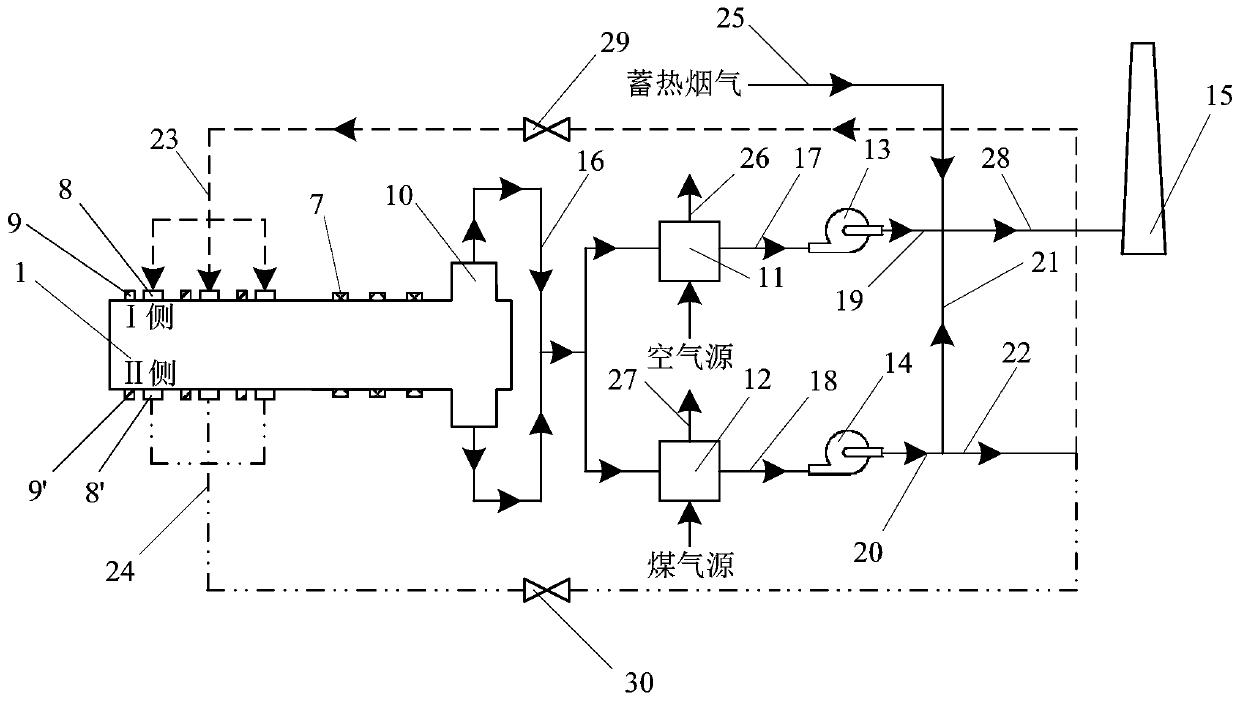

Smoke circulating combusting system for waste palm boiler

InactiveCN104896482ASolve combustion instability and cokingInhibit the combustion processAir supply regulationIndirect carbon-dioxide mitigationFlueEngineering

The invention provides a smoke circulating combusting system for a waste palm boiler. The system is that a fire grate comprises a drying section reciprocating fire grate and a combustion section reciprocating fire grate which are connected through continuously-inclined staggering disconnecting layers; inclination angles of the drying section reciprocating fire grate and the combustion section reciprocating fire grate are 20 to 30 degrees; a plurality of primary air branch tubes and a plurality of smoke circulating branch tubes are arranged in the drying section reciprocating fire grate and the combustion section reciprocating fire grate, wherein the primary air branch tubes and the smoke circulating branch tubes are respectively communicated with an air preheater and a tail smoke channel through primary air head tubes and smoke circulating head tubes; the tail smoke channel, the smoke circulating head tubes, the smoke circulating branch tubes, the smoke circulating branch tubes, a hearth and a smoke outlet are sequentially communicated by a circulating manner; the air preheater, the primary air head tubes, the primary air branch tubes and the hearth are sequentially communicated by circulating. The system can solve the problems of unstable combustion of the hearth and coking, and achieves efficient, energy-saving and safe operation of the waste palm steam boiler.

Owner:天津机电进出口有限公司

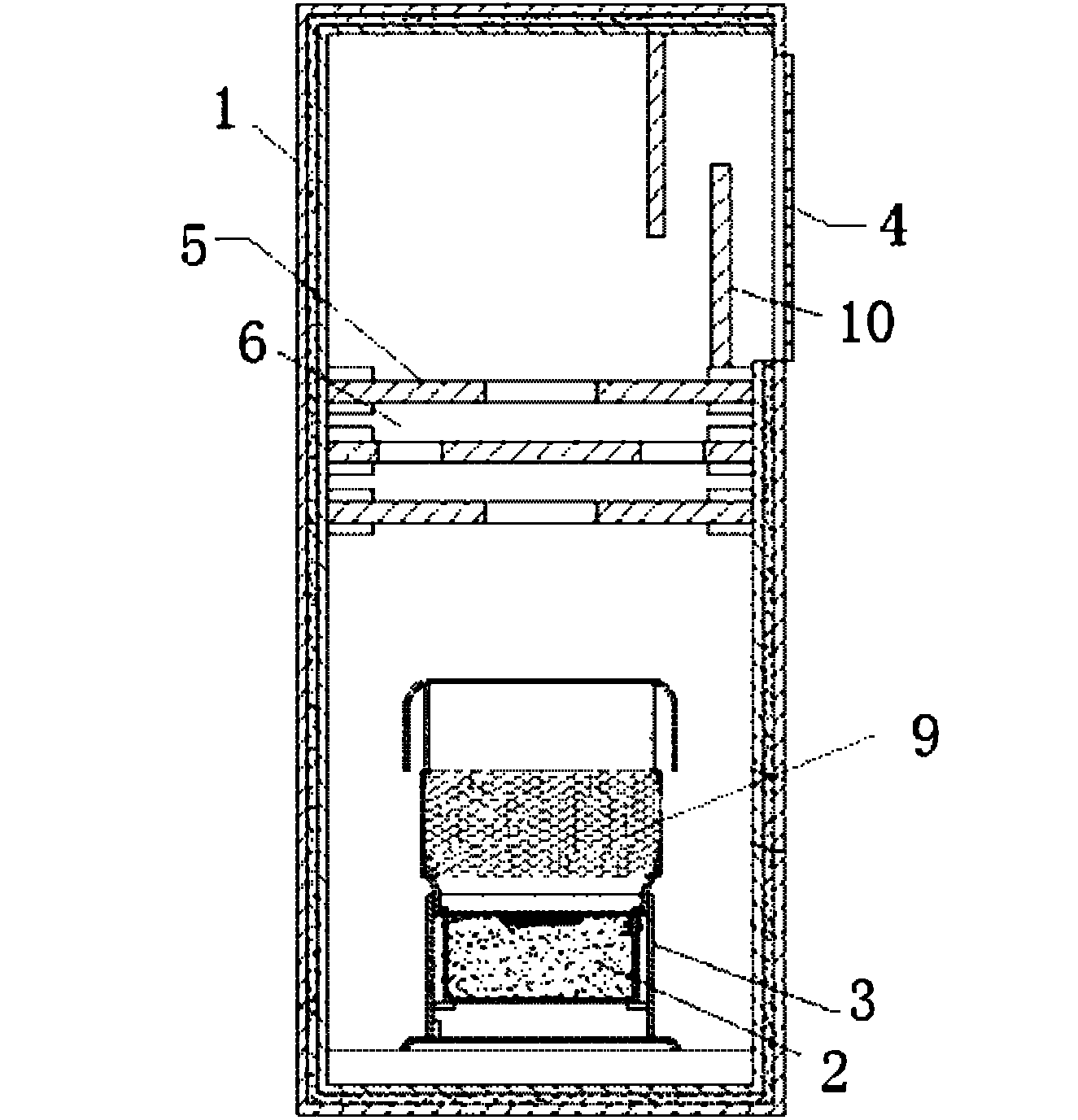

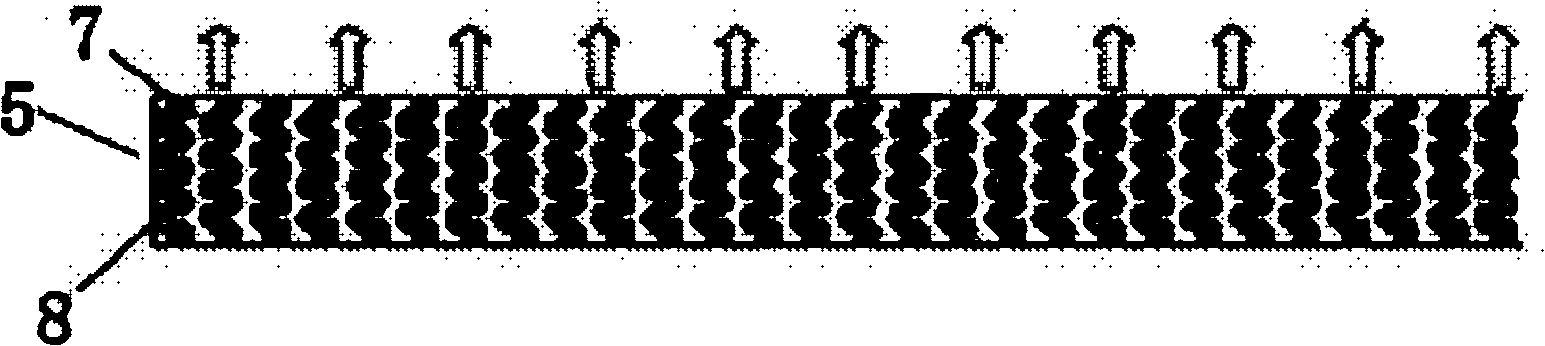

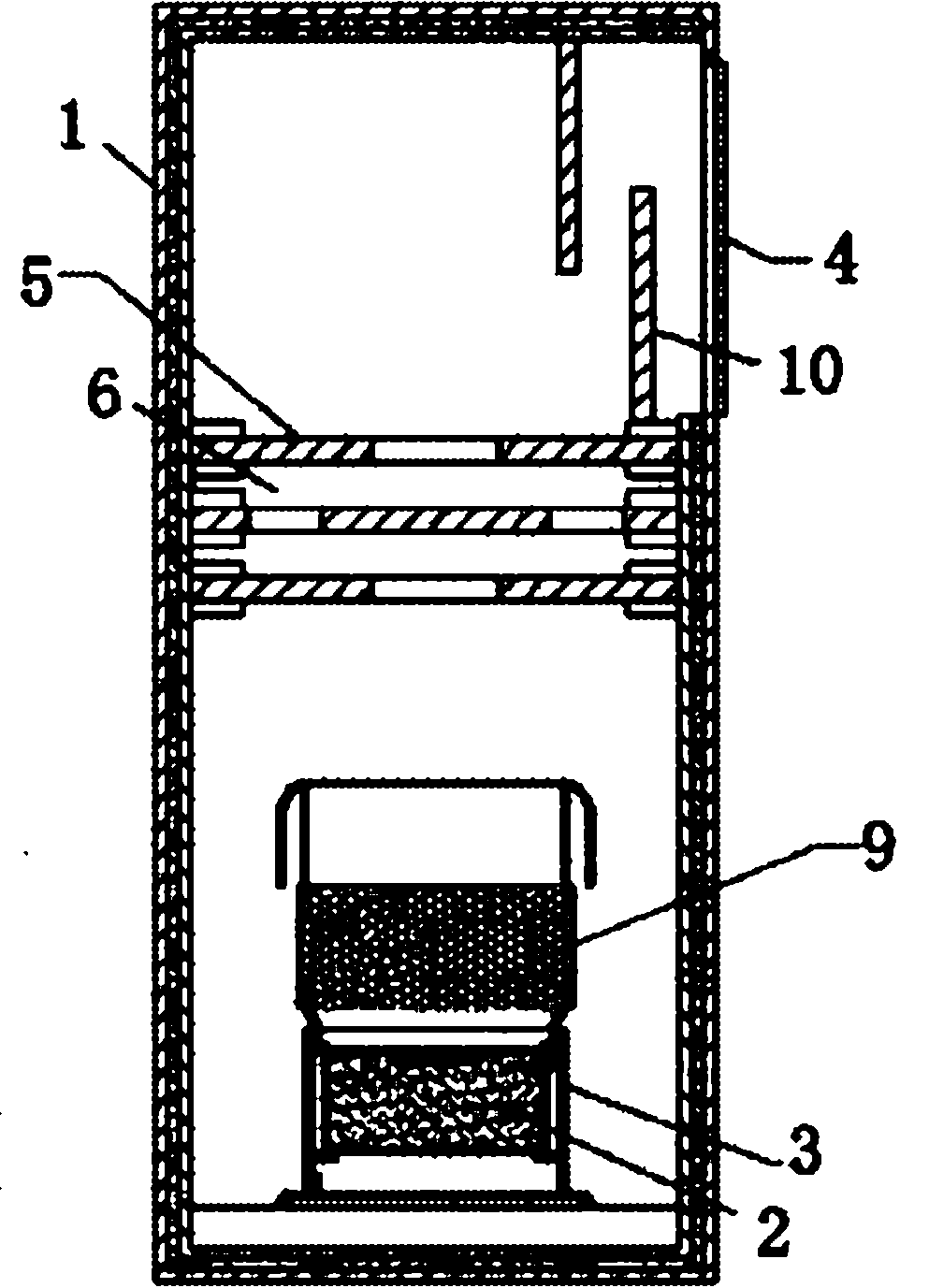

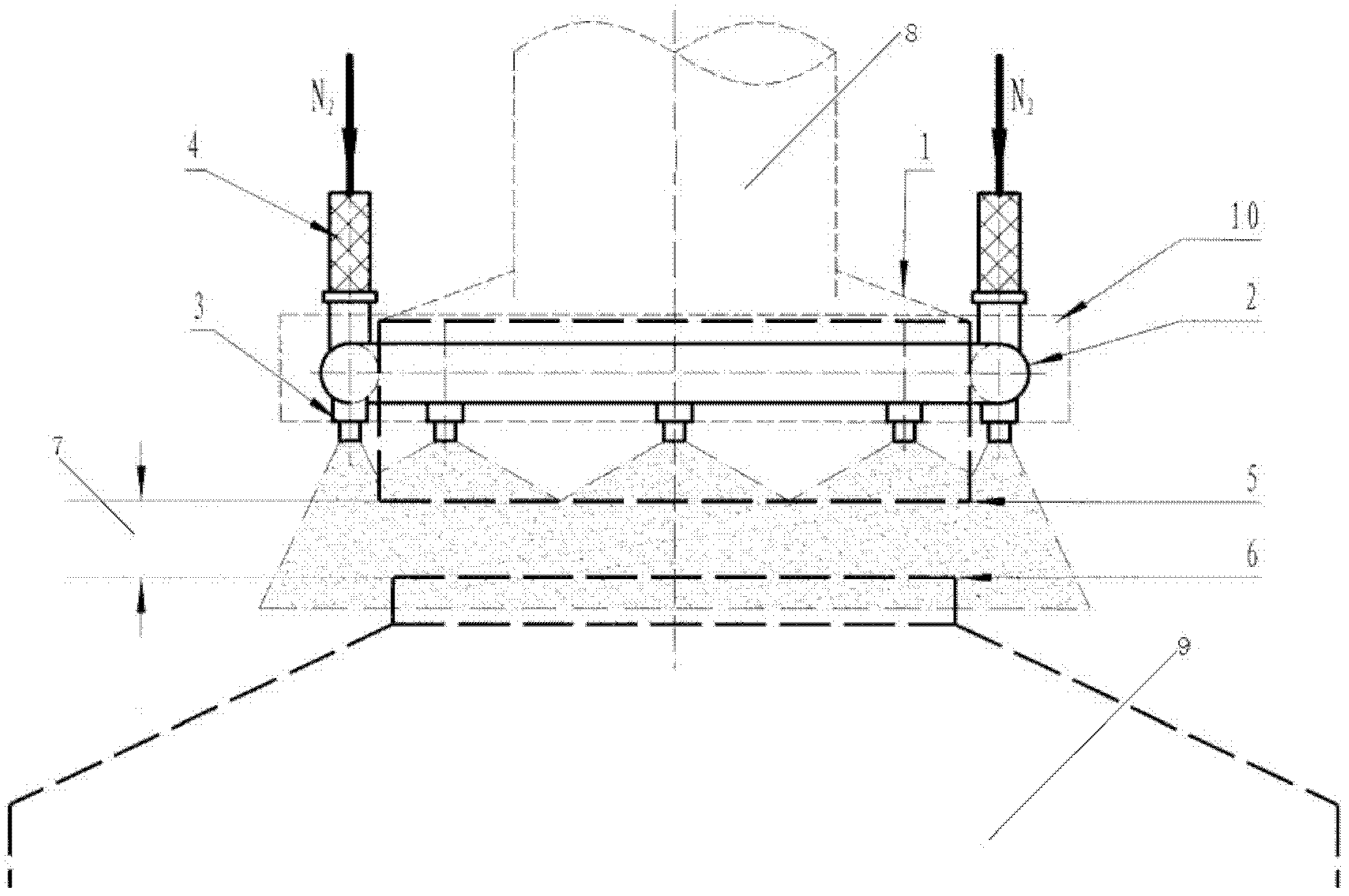

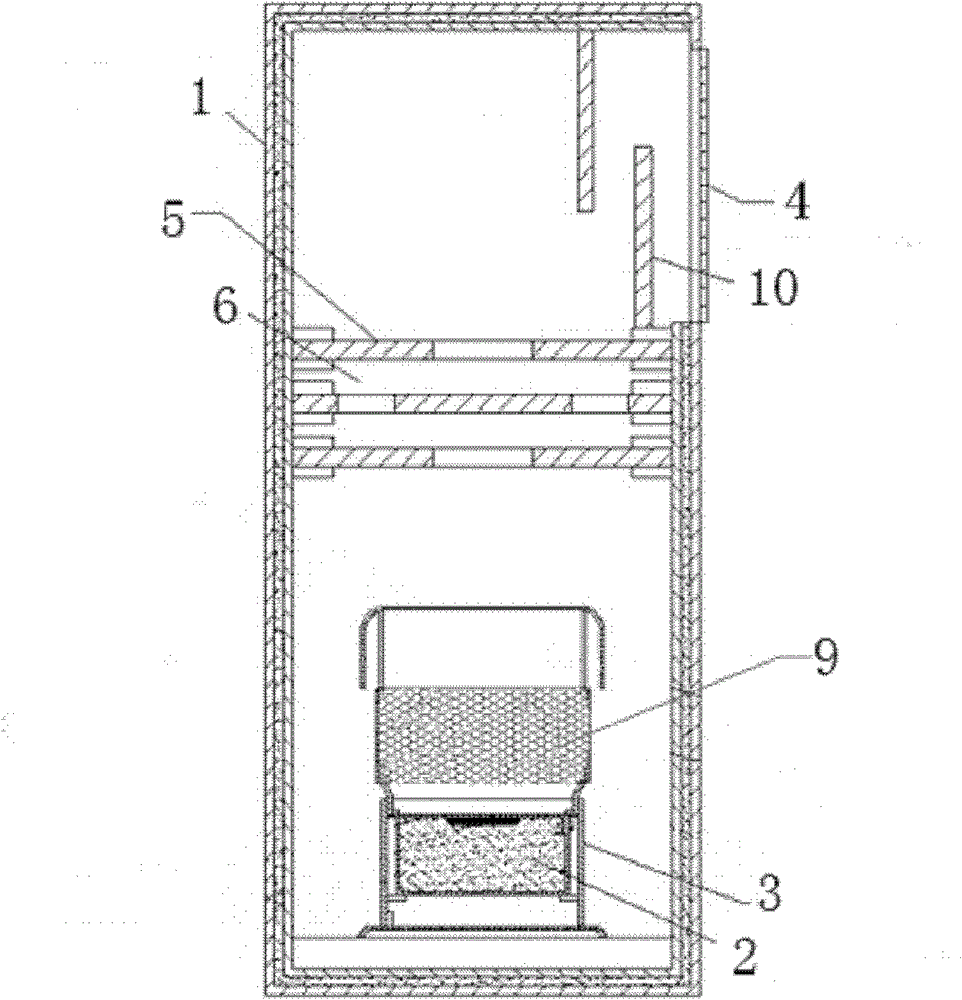

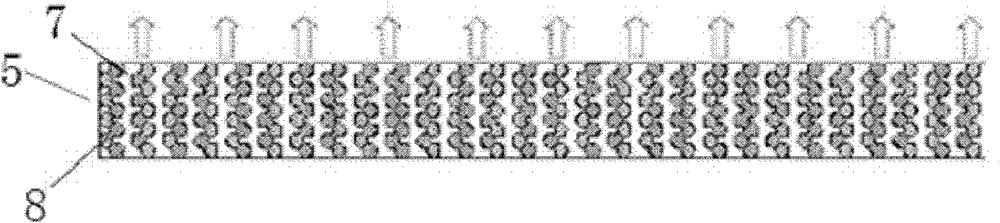

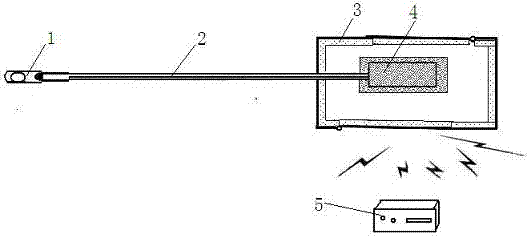

Cooling method for hot gas dispersoid fire-extinguishing device

ActiveCN102179018AGood cooling efficiencyPrevent secondary combustionFire rescueFire extinguisherProduct gasCooling methods

The invention discloses a cooling method for a hot gas dispersoid fire-extinguishing device. The method is applied to the hot gas dispersoid fire-extinguishing device. The hot gas dispersoid fire-extinguishing device comprises a box body (1); a reaction barrel (3) filled with a hot gas dispersoid generating medicament (2) is arranged in the box body (1); and one side of the box body (1) is provided with a gas outlet (4). The method comprises the following steps of: improving the structure of the hot gas dispersoid fire-extinguishing device to realize physical cooling; and improving componentsand ratio of a chemical agent to realize chemical cooling. By improving the structure of the hot gas dispersoid fire-extinguishing device and the formula of the cooling agent, the temperature of a gas dispersoid passing through a nozzle is effectively reduced and the cooling effect is ideal; moreover, the cooling method is nontoxic and harmless, and has excellent safety and social benefit.

Owner:浙江华神消防科技有限公司

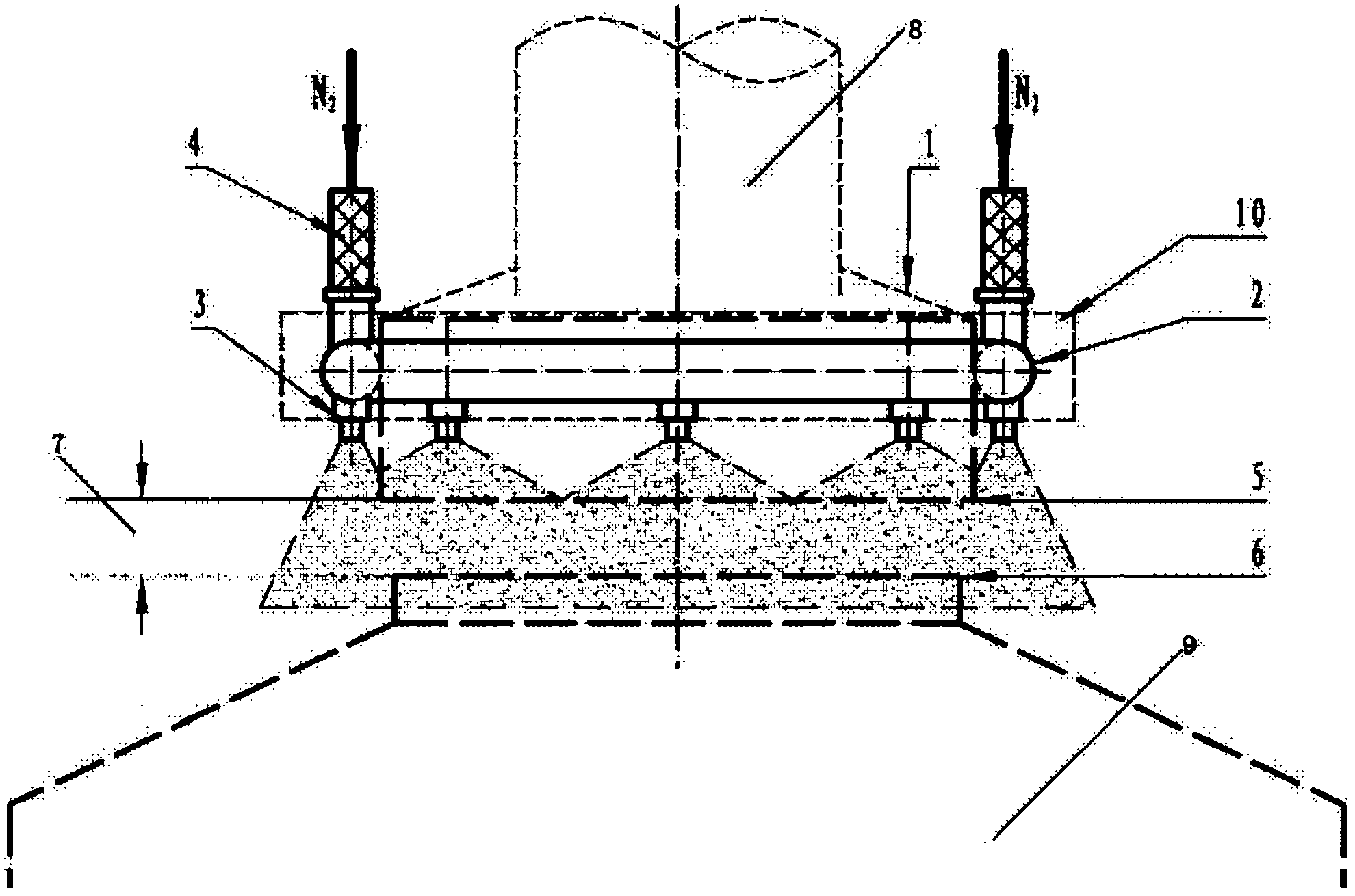

Soft sealing device for converter mouth and fume hood

InactiveCN102605136AAvoid Explosion HazardsGuaranteed shrink volumeManufacturing convertersSteelmakingElectricity

The invention relates to a steelmaking process control device for a steel making factory, in particular to a soft sealing device for an LD (linz-donawitz) converter mouth and fume hood. The periphery of the inlet of the fume hood is provided with a ring pipe; the ring pipe is provided with a nitrogen inlet pipe; and a plurality of nitrogen spraying nozzles are annularly distributed on the ring pipe at intervals. During each period of production of a converter, a nitrogen sealing curtain is formed between the inside fume and the outside air of the fume hood, and the fume is separated from the outside air without contacting. Because the fume is separated from the outside air without contacting, the secondary combustion of a system is avoided, the hidden danger of explosion of a dedusting system is avoided, the calorific value of gas is improved, the rear dedusting fume is reduced, the purity and the yield of gas are improved, and water and electricity are saved. The soft sealing device for the LD converter mouth and fume hood can be used safely and reliably, and radically solves the problem on the sealing of the converter mouth and fume hood.

Owner:北京五一环保科技股份有限公司

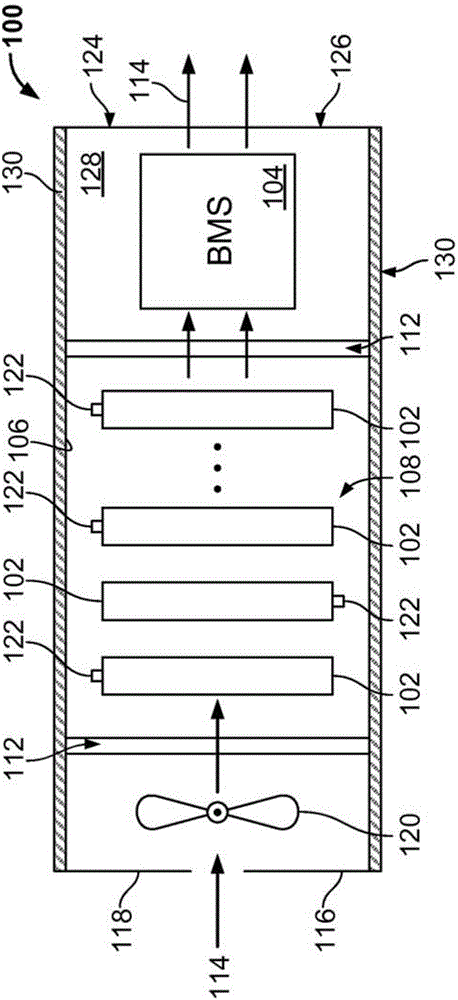

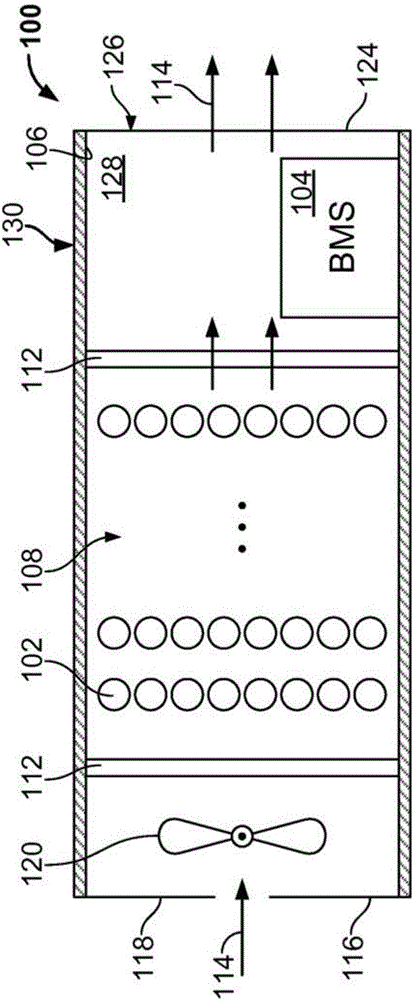

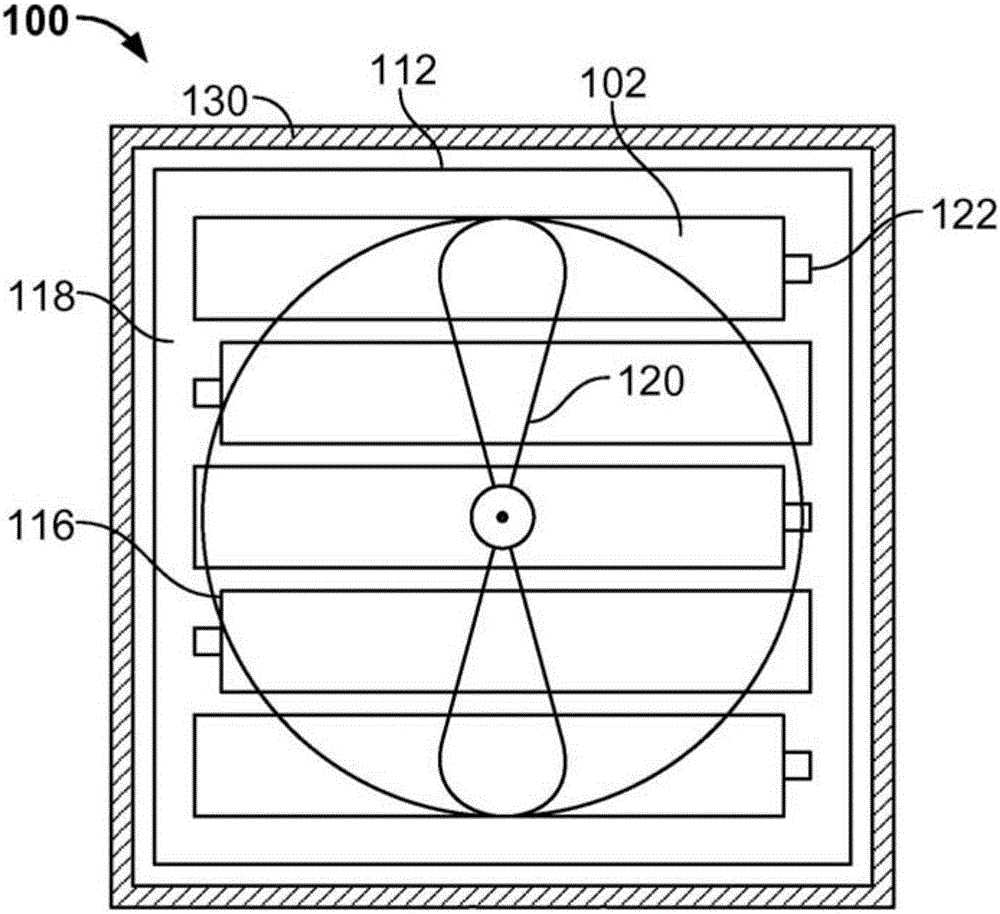

Battery module

ActiveCN106663766APrevent proliferationAvoid damageSecondary cellsCell component detailsEngineeringElectric power

A battery module includes a housing that defines an inner volume and includes an airflow path from an aperture formed in a first end member of the housing, through the inner volume, and to an aperture formed in a second end member of the housing; a plurality of power cells mounted in the inner volume of the housing, each of the power cells including a vent member at an end of the power cell; and a flame arrestor mounted across the airflow path and between the plurality of power cells and the aperture formed in the second end member of the housing. The flame arrestor includes a screen that includes a plurality of fluid pathways sized to allow an airflow from the airflow path through the fluid pathways and sized to impede a combusted fluid to pass therethrough.

Owner:GOOGLE LLC

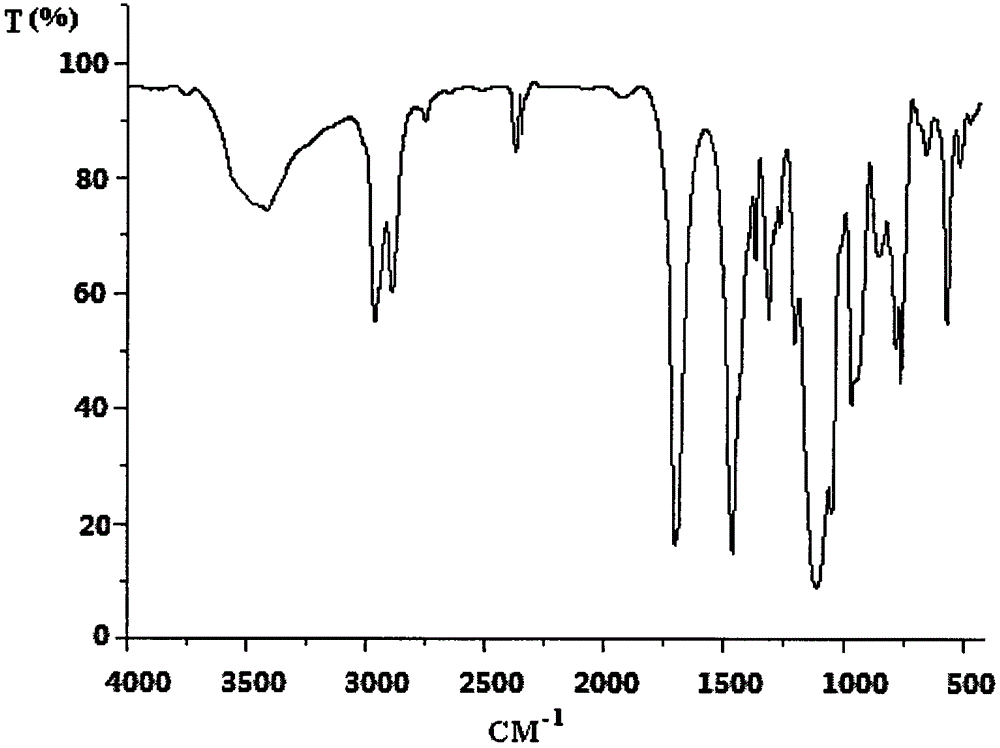

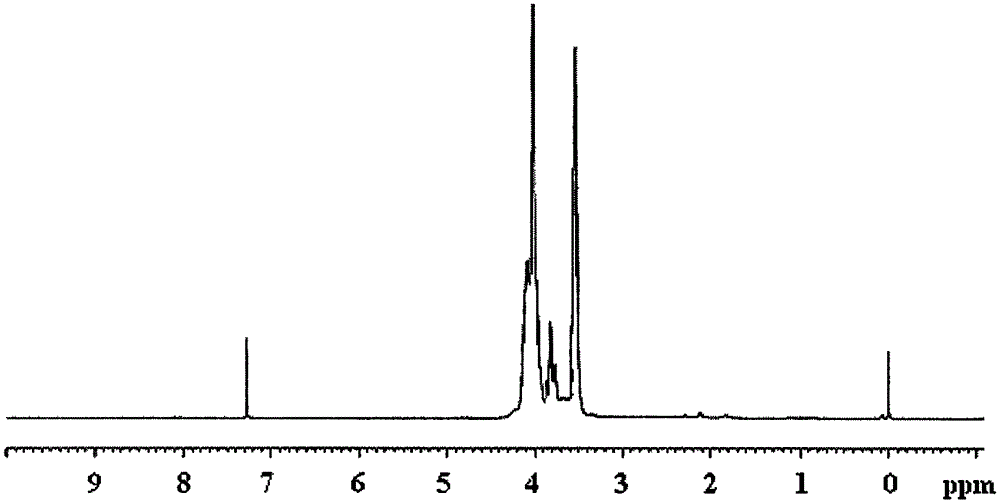

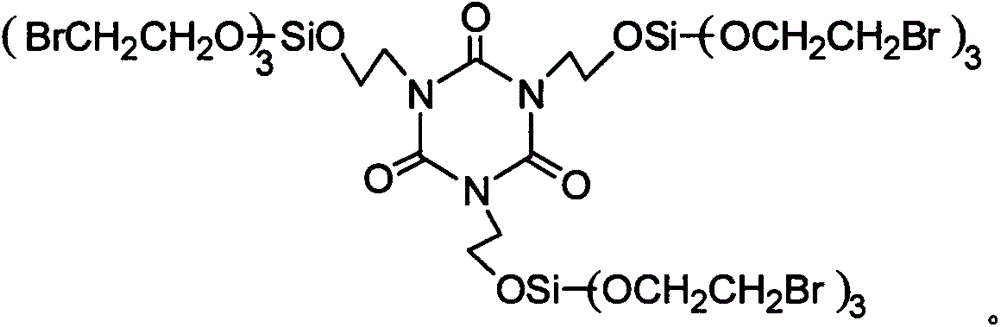

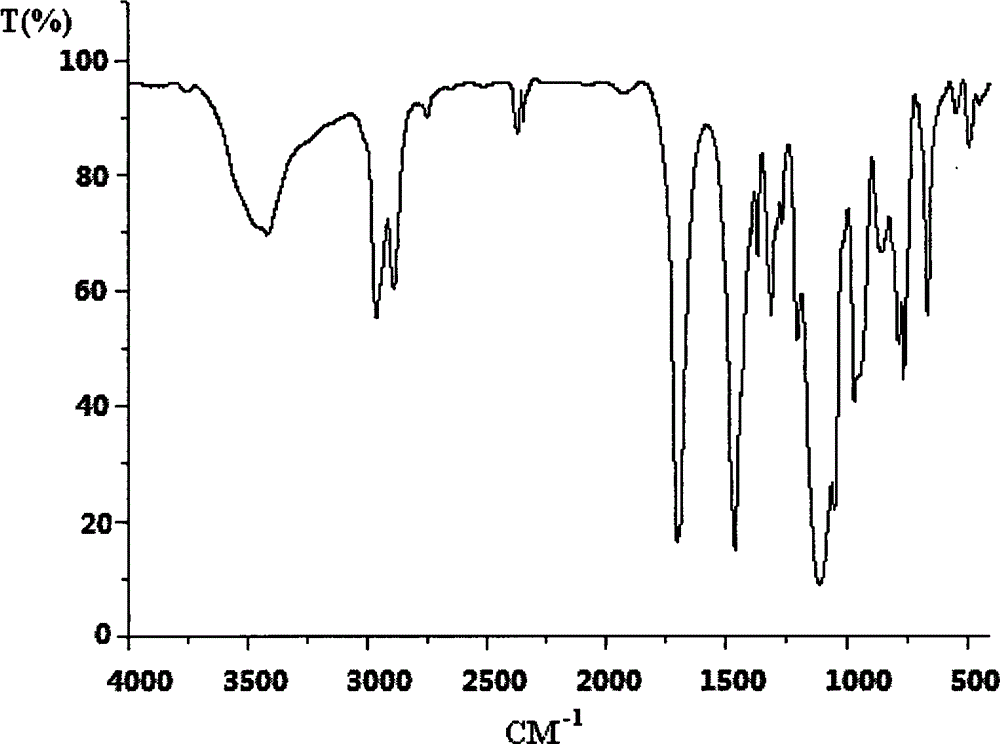

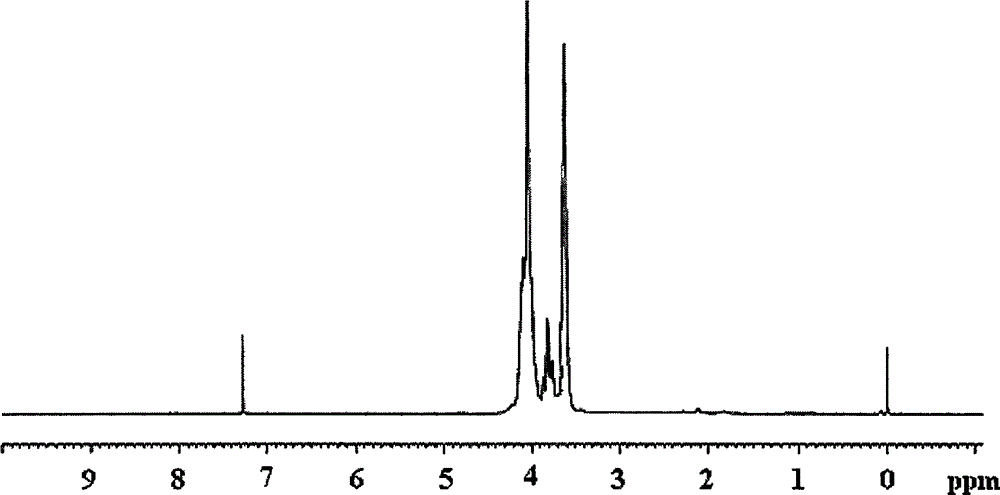

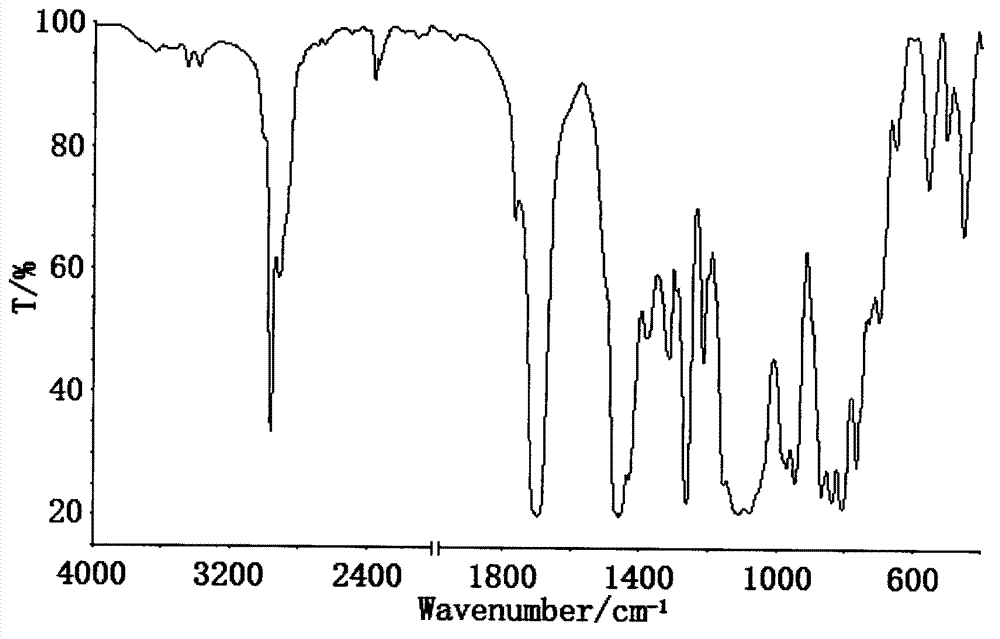

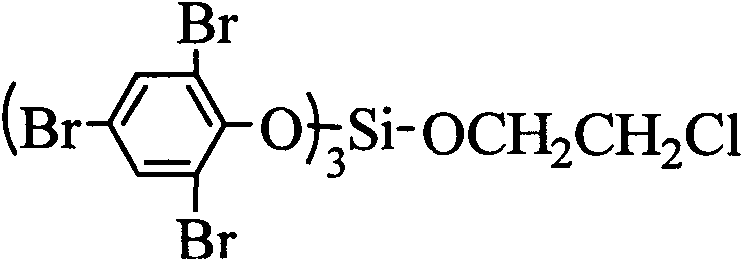

Flame retardant cyclo-bromoethyl trisilicate compound and preparation method thereof

ActiveCN103554148APrevent secondary combustionHigh synergistic flame retardant performanceSilicon organic compoundsEpoxyOrganic solvent

The invention relates to a flame retardant cyclo-bromoethyl trisilicate compound and a preparation method thereof. The structure of the compound is represented by a formula shown in a drawing. The preparation method comprises the steps of reacting silicon tetrachloride with bromoethanol of a mole which is equal to that of silicon tetrachloride in an organic solvent at the temperature below 20 DEG C, then, dropwise adding an organic solution of trishydroxyethyl isocyanurate of a mole which is 1 / 3 that of silicon tetrachloride, heating to the temperature of 75-85 DEG C after completing dripping, and reacting for 8-10 hours; then, dropwise adding bromoethanol of a mole which is 2-3 times that of silicon tetrachloride, and carrying out heat-preservation reaction for 7-9 hours at the temperature of 75-85 DEG C; then, adding an acid binding agent, and carrying out heat preservation for 1 hour while stirring; purifying, thereby obtaining the flame retardant cyclo-bromoethyl trisilicate. The compound disclosed by the invention has high flame retarding efficacy and is suitable for serving as a flame retardant for materials, such as polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like, and the preparation method is simple and is low in cost, so that the industrial production is easy to realize.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Multi-scale layered flame-retardant material and preparation method thereof

ActiveCN110421776AHigh flame retardant efficiencyReduce manufacturing costCoatingsSolventInjection molding machine

The invention provides a preparation method of a multi-scale layered flame-retardant material. The preparation method comprises the following steps that S1, the layered flame retardant is prepared, specifically, a certain amount of graphene oxide is dispersed in a solvent, then a certain amount of intumescent flame retardant is added into the solvent dissolved with graphene oxide, dispersing continues carrying out, finally a water absorbent is added, and the layered flame retardant is obtained after stirring and reacting; and S2, the multi-scale layered flame-retardant material is prepared, specifically, a certain amount of the layered flame retardant prepared in the step 1, a certain amount of intumescent flame retardant and a certain amount of polymer matrix are mixed, and the multi-scale layered flame-retardant material is prepared in an injection molding machine under a specified injection molding process. The invention further provides the multi-scale layered flame-retardant material prepared by the preparation method of the multi-scale layered flame-retardant material. The flame-retardant material prepared by the preparation method has the advantages of being good in flame-retardant effect, good in mechanical property, low in production cost, environmentally friendly, safe and the like.

Owner:XIHUA UNIV

Cooling method for hot gas dispersoid fire-extinguishing device

ActiveCN102179018BReduce the temperatureImprove cooling efficiencyFire rescueFire extinguisherSocial benefitsCooling effect

The invention discloses a cooling method for a hot gas dispersoid fire-extinguishing device. The method is applied to the hot gas dispersoid fire-extinguishing device. The hot gas dispersoid fire-extinguishing device comprises a box body (1); a reaction barrel (3) filled with a hot gas dispersoid generating medicament (2) is arranged in the box body (1); and one side of the box body (1) is provided with a gas outlet (4). The method comprises the following steps of: improving the structure of the hot gas dispersoid fire-extinguishing device to realize physical cooling; and improving components and ratio of a chemical agent to realize chemical cooling. By improving the structure of the hot gas dispersoid fire-extinguishing device and the formula of the cooling agent, the temperature of a gas dispersoid passing through a nozzle is effectively reduced and the cooling effect is ideal; moreover, the cooling method is nontoxic and harmless, and has excellent safety and social benefit.

Owner:浙江华神消防科技有限公司

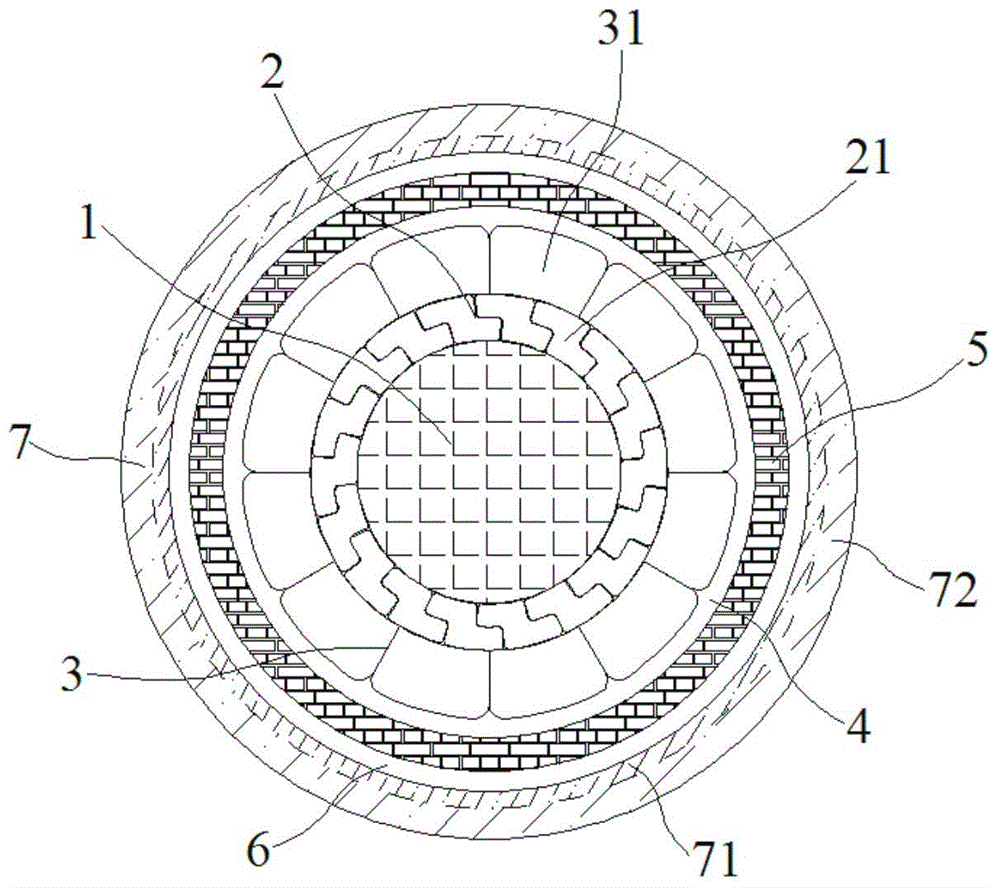

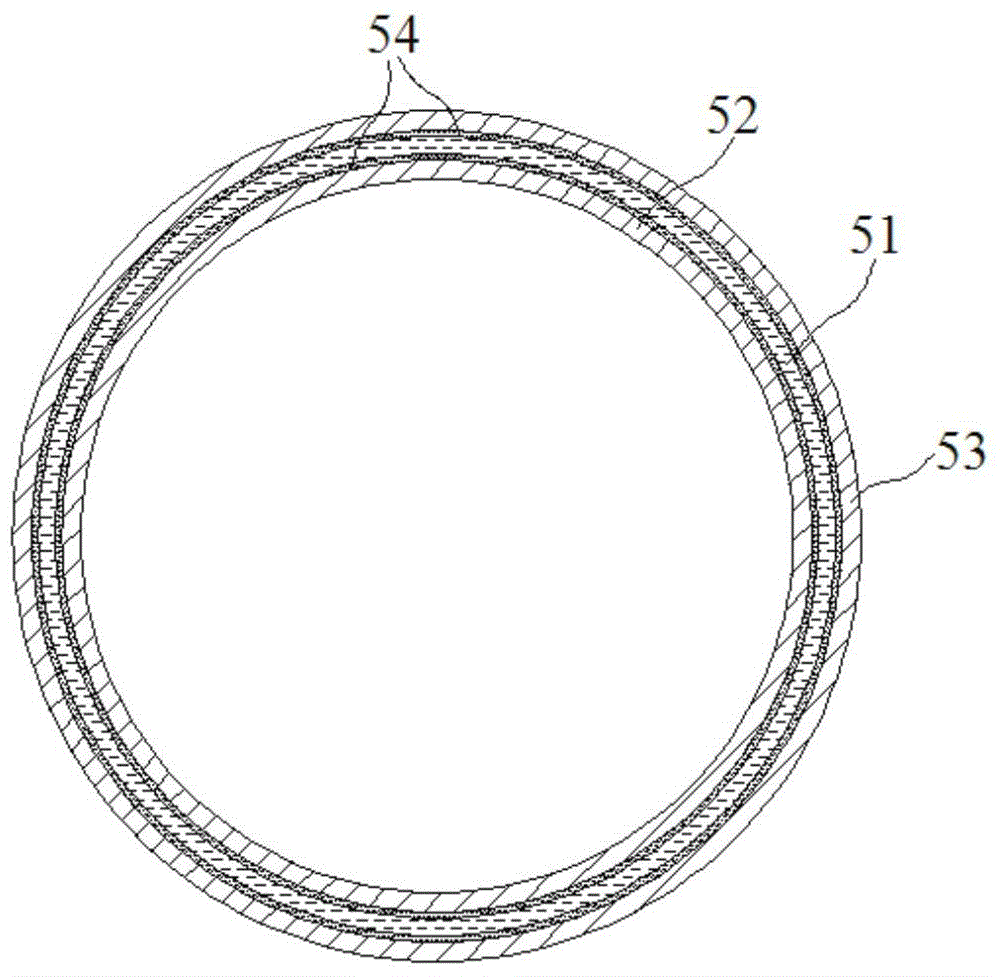

High-toughness flexible power cable for communication base station

ActiveCN104616747AImprove thermal stabilityImproved radiation resistance propertiesFlexible cablesFlexible conductorsLow-density polyethyleneElectrical conductor

The invention discloses a high-toughness flexible power cable for a communication base station. The high-toughness flexible power cable comprises a circular aramid fiber core and an inner conductive layer; a plurality of trapezoidal conductors are stranded on the outer surface of the inner conductive layer; a fireproof flame-retardant layer wraps the outer surface of the polyethylene insulating belt, comprising mica paper, a first glass fabric and a second glass fabric; the mica paper is adhered to the first glass fabric and the second glass fabric through adhesive layers; a glass tape wraps the outer surface of the fireproof flame-retardant layer; a protecting sleeve layer comprises an inner polyvinyl chloride protecting layer at the inner side and an outer protecting layer at the outside; the outer protecting layer is prepared from a thermoplastic polyurethane phenol elastomer, low-density polyethylene, ethylene acrylic ester, an ethylene-butylene copolymer, silica, a nitrile compound, chlorinated polyethylene and zinc stannate. The cable is non-combustible, high in heat resistance, tight and difficultly to breath; in addition, the layering phenomenon due to relatively large material difference can be avoided; the contact surface compatibility and adhering firmness can be improved, and the product performances are increased.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

Metal wall temperature measurement system for rotary air preheater

InactiveCN102243109AKeep abreast of the operating status at any timeMaster the operating statusThermometer detailsThermometers using electric/magnetic elementsAir preheaterAcid corrosion

The invention relates to a temperature measurement system, particular to a metal wall temperature measurement system for a rotary air preheater. The metal wall temperature measurement system for a rotary air preheater comprises an online continuous temperature measurement device and a receiver, wherein the online continuous temperature measurement device is arranged at the lower part of a metal heat accumulation body of the rotary air preheater and rotates with the metal heat accumulation body and consists of a temperature measuring probe, a compensation lead wire, a wireless temperature sensor and an incubator; a chip thermocouple is communicated with the wireless temperature sensor through the compensation lead wire; the wireless temperature sensor is placed in the incubator, is kept ina use temperature range, and is connected with the receiver through a wireless signal; and the receiver is arranged in a transmission distance of the wireless temperature sensor. By using the device,operators of a power plant can know the running state of the air preheater at any time, low-temperature acid corrosion, ash blockage, secondary combustion and the like can be avoided, and safe operation can be guaranteed. Meanwhile, according to measurement data, the running parameters of a steam air heater and smoke exhaust temperature can be controlled, and economical operation is realized.

Owner:高明逊 +1

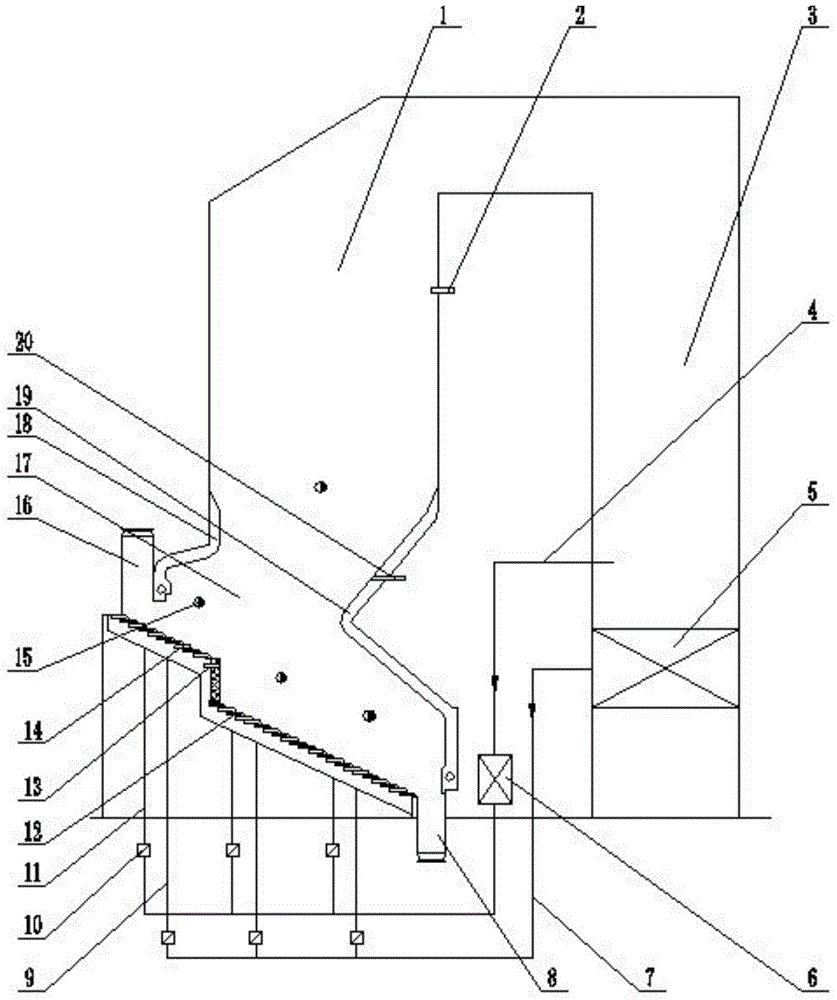

Flame retardant tris(hydroxyethyl) isocyanurate trisilicate ethyl chloride compound and preparation method thereof

ActiveCN103554155APrevent secondary combustionHigh synergistic flame retardant performanceSilicon organic compoundsEpoxyEthylene oxide

The invention relates to a flame retardant tris(hydroxyethyl) isocyanurate trisilicate ethyl chloride compound and a preparation method thereof. The compound has a structure shown in the specification. The preparation method comprises the following steps: introducing ethylene oxide into an organic solution of the silicon tetrachloride at a temperature being below 0 DEG C and reacting for 1 hour at 30 DEG C, wherein the molar mass of the ethylene oxide is 2 times that of the silicon tetrachloride; dropwise adding an organic solution of tris(hydroxyethyl) isocyanurate and reacting for 7-10 hours at 70-85 DEG C, wherein the molar mass of the organic solution of tris(hydroxyethyl) isocyanurate is 1 / 3 that of the silicon tetrachloride; cooling to the temperature being below 30 DEG C, introducing the ethylene oxide and reacting for 3-6 hours at 35-50 DEG C, wherein the molar mass of the ethylene oxide is 1-1.5 times that of the silicon tetrachloride; performing purification to obtain the tris(hydroxyethyl) isocyanurate trisilicate ethyl chloride. The compound disclosed by the invention is suitable to be used as flame retardants of the materials such as polyvinyl chloride, polyurethane, epoxy resin and unsaturated resin, is high in synergistic flame retardant performance, simple in preparation process and low in cost, and can be put into industrial production easily.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Toughened halogen-free flame-retardant polylactic acid blending material

The invention discloses a toughened halogen-free flame-retardant polylactic acid blending material which is prepared by melting and blending the following components in percentage by weight: 40-93 percent of polylactic acid, 1-40 percent of toughener, 5-30 percent of flame retardant, 0-30 percent of auxiliary flame retardant and 0.5-1 percent of antioxidant. Because the toughener is also introduced into the polylactic acid blending material on the basis of adding a halogen-free flame retardant, the material has excellent flame retardant performance and also markedly improves the toughness of the polylactic acid simultaneously, thereby not only enlarging the use range of the material, but also solving the two great problems of easy combustion and poor toughness of the polylactic acid simultaneously.

Owner:SICHUAN UNIV

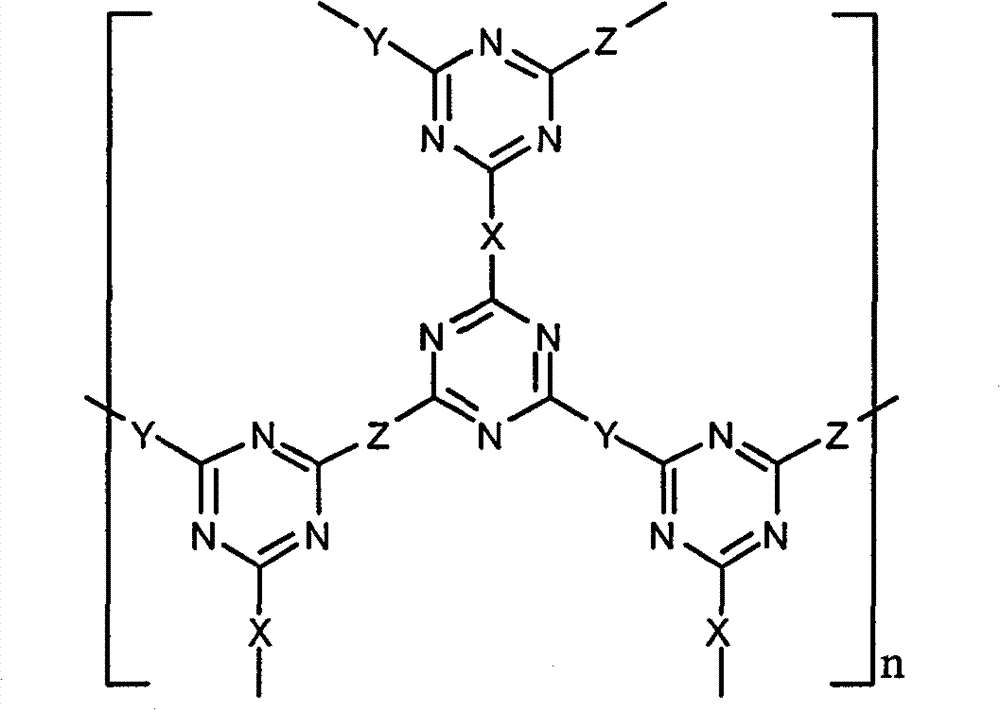

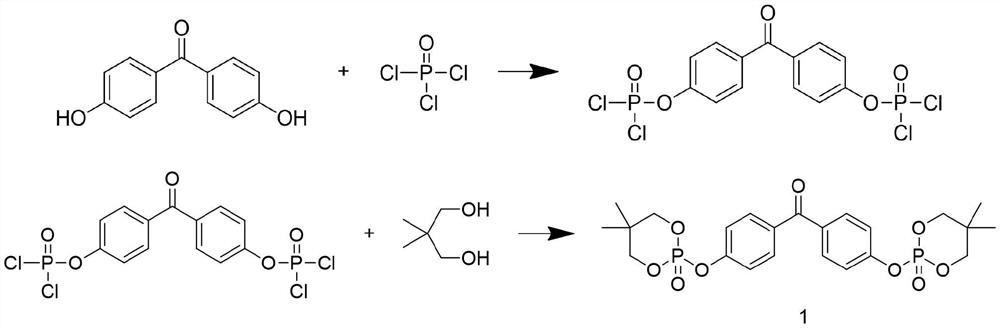

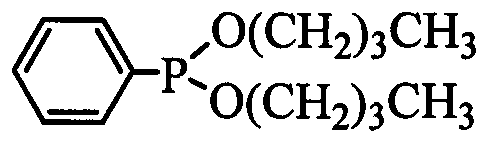

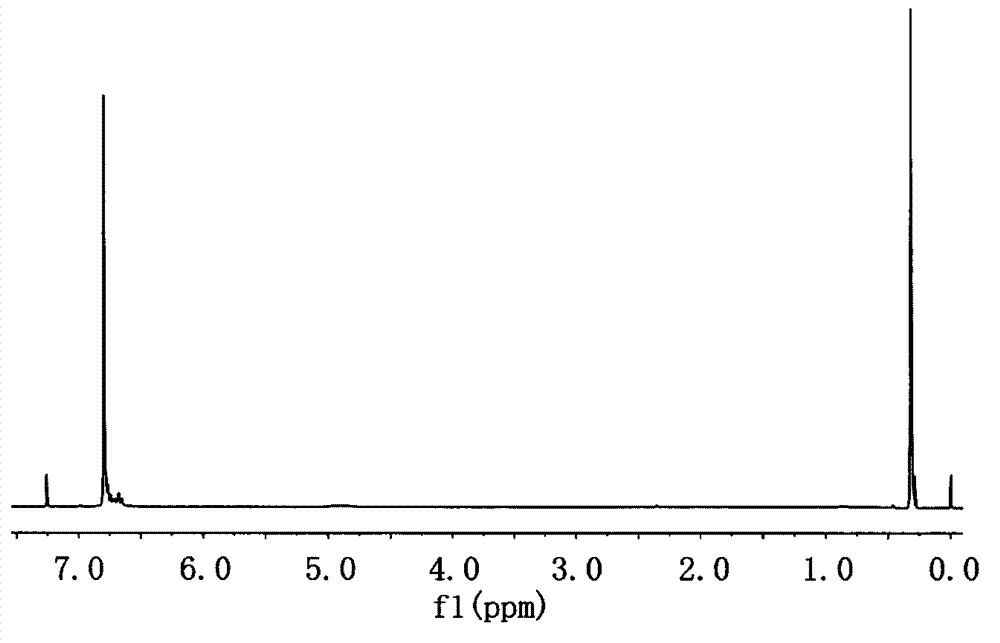

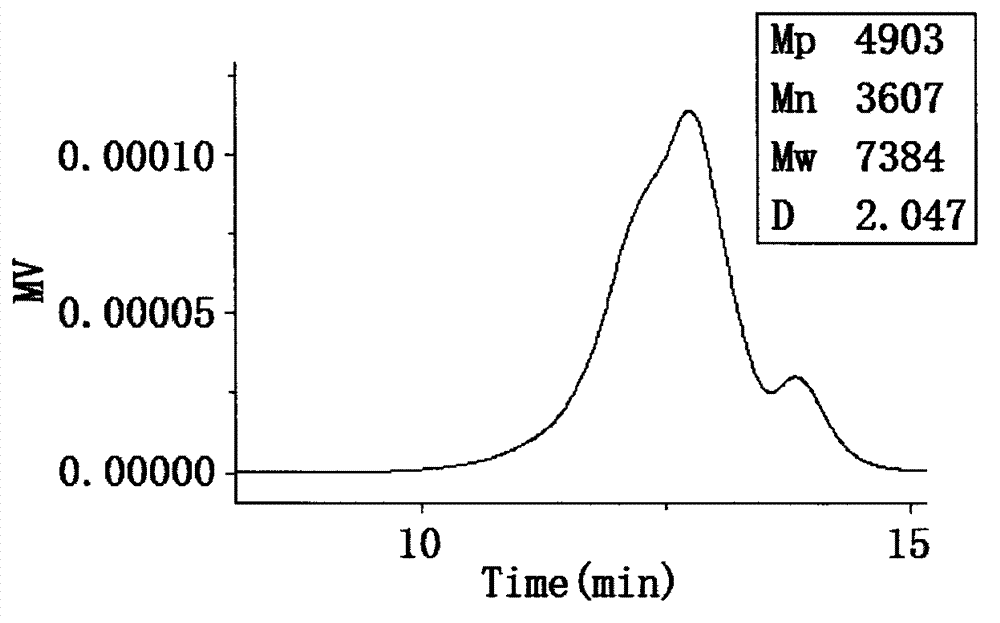

Fire retardant alkyl silicic acid trithio phosphonia trioxa bicyclo[2.2.2]octyl methyl ester compound and preparation method thereof

InactiveCN106496273APrevent secondary combustionChange decomposition processGroup 5/15 element organic compoundsPolyesterEpoxy

The invention relates to a fire retardant alkyl silicic acid trithio phosphonia trioxa bicyclo[2.2.2]octyl methyl ester compound and a preparation method thereof. A structural formula of the compound is as shown in the specification, wherein R refers to CH3, CH3CH2 or CH3CH2CH2. The preparation method includes: performing reaction of alkyl trimethoxy silane or alkyltrichlorosilane with 1-thiophosphonia-4-hydroxymethyl-2,6,7-trioxa bicyclo[2.2.2]octane, and purifying to obtain alkyl silicic acid tri-1-thiophosphonia-2,6,7-trioxa bicyclo[2.2.2]octyl-4-methyl ester. The fire retardant is high in fire retardation efficiency, great in charring effect and suitable for serving as a fire-retardant charring agent for polyesters, polyurethanes, epoxy resin, unsaturated polyester resin and the like, and technical simplicity in production, low cost and easiness for industrial production are realized.

Owner:SUZHOU UNIV OF SCI & TECH

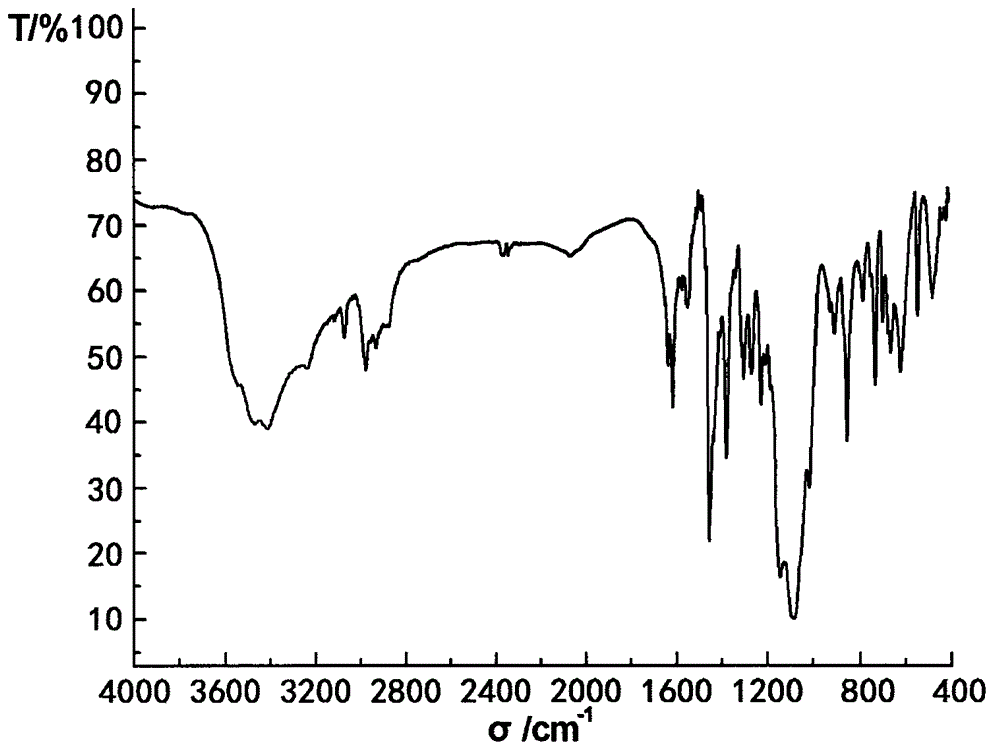

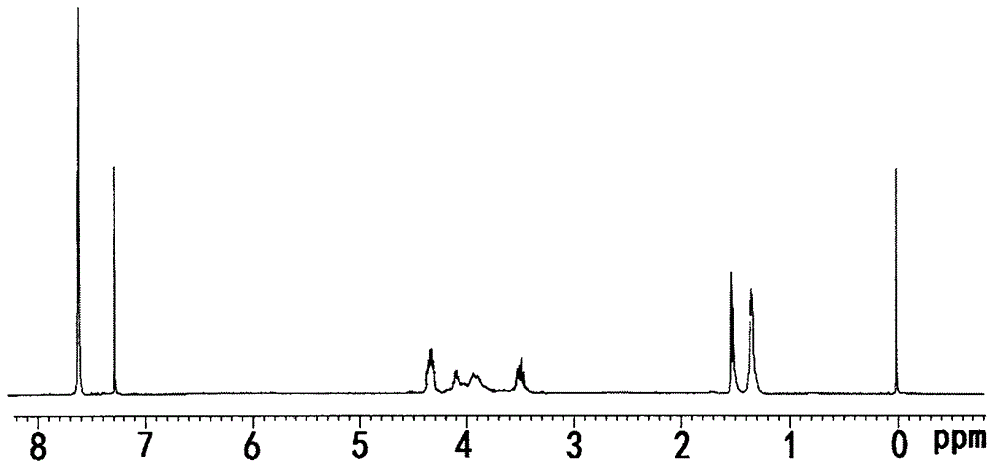

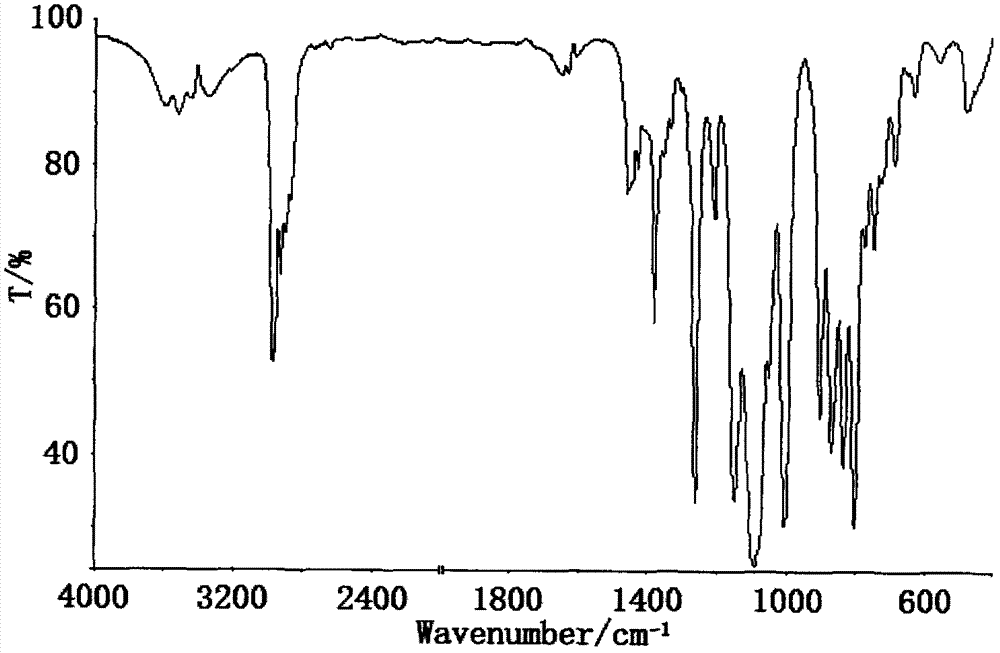

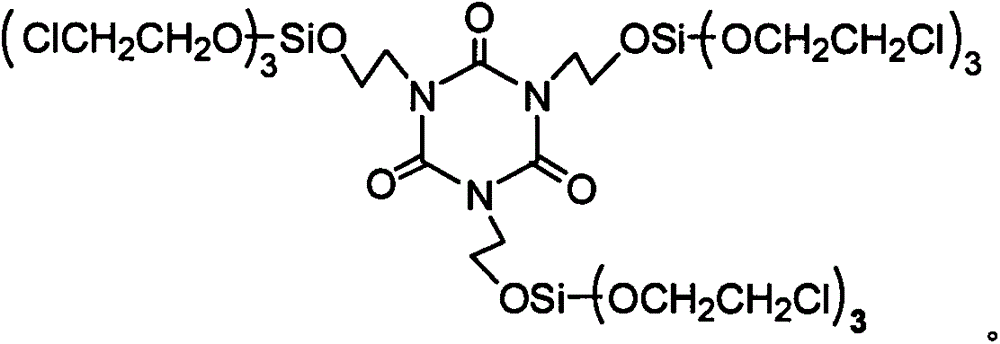

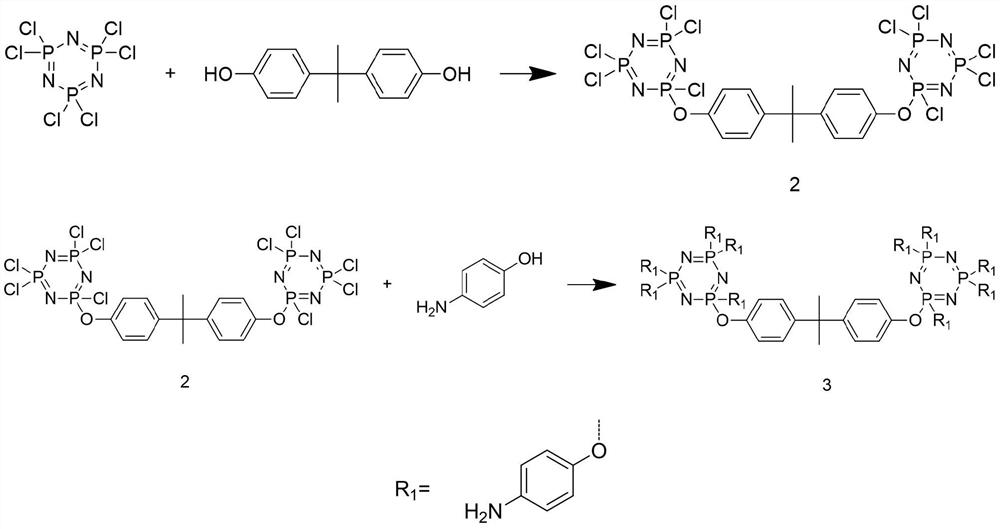

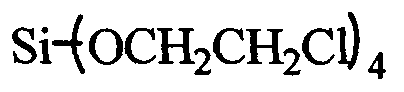

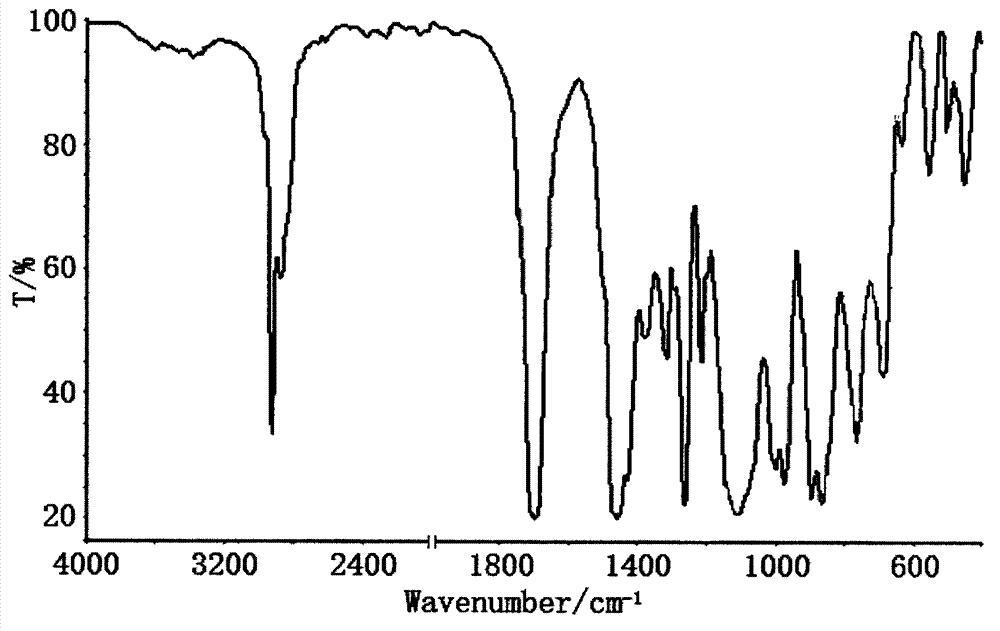

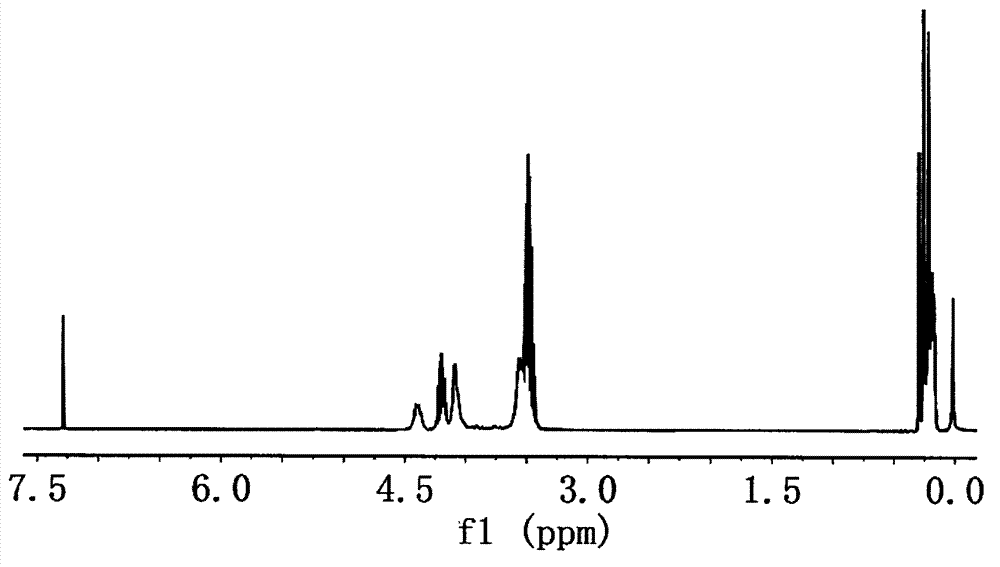

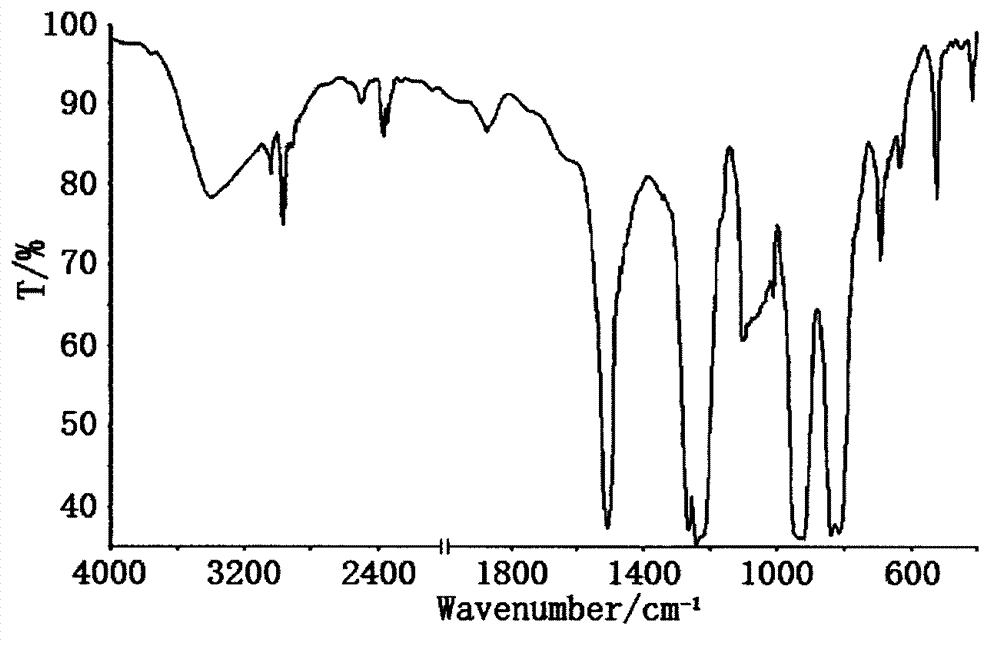

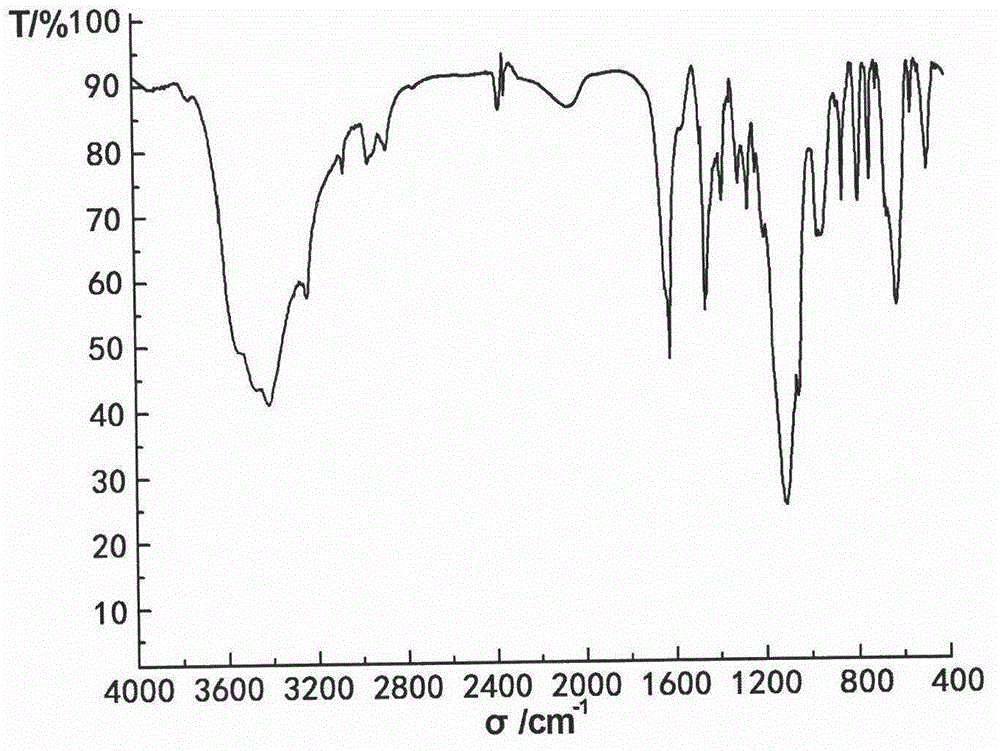

Method for preparing flame retardant tris[2-tri(chloroethoxy)silicon-acyloxy-ethyl]isocyanurate

The invention relates to a method for preparing a flame retardant tris[2-tri(chloroethoxy)silicon-acyloxy-ethyl]isocyanurate. The structure of the compound is represented by a formula shown in a drawing. The preparation method comprises the steps of reacting silicon tetrachloride with chloroethanol of a mole which is equal to that of silicon tetrachloride in an organic solvent at the temperature below 20 DEG C, then, dropwise adding an organic solution of trishydroxyethyl isocyanurate of a mole which is 1 / 3 that of silicon tetrachloride, heating to the temperature of 75-85 DEG C after completing dripping, and reacting for 7-10 hours; then, dropwise adding chloroethanol of a mole which is 2-3 times that of silicon tetrachloride, and carrying out heat-preservation reaction for 6-8 hours at the temperature of 75-85 DEG C; then, adding an acid binding agent, and carrying out heat preservation for 1 hour while stirring; purifying, thereby obtaining the flame retardant tris[2-tri(chloroethoxy)silicon-acyloxy-ethyl]isocyanurate. The compound disclosed by the invention has high flame retarding efficacy and is suitable for serving as a flame retardant for materials, such as polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like, and the preparation method is simple and is low in cost, so that the industrial production is easy to realize.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

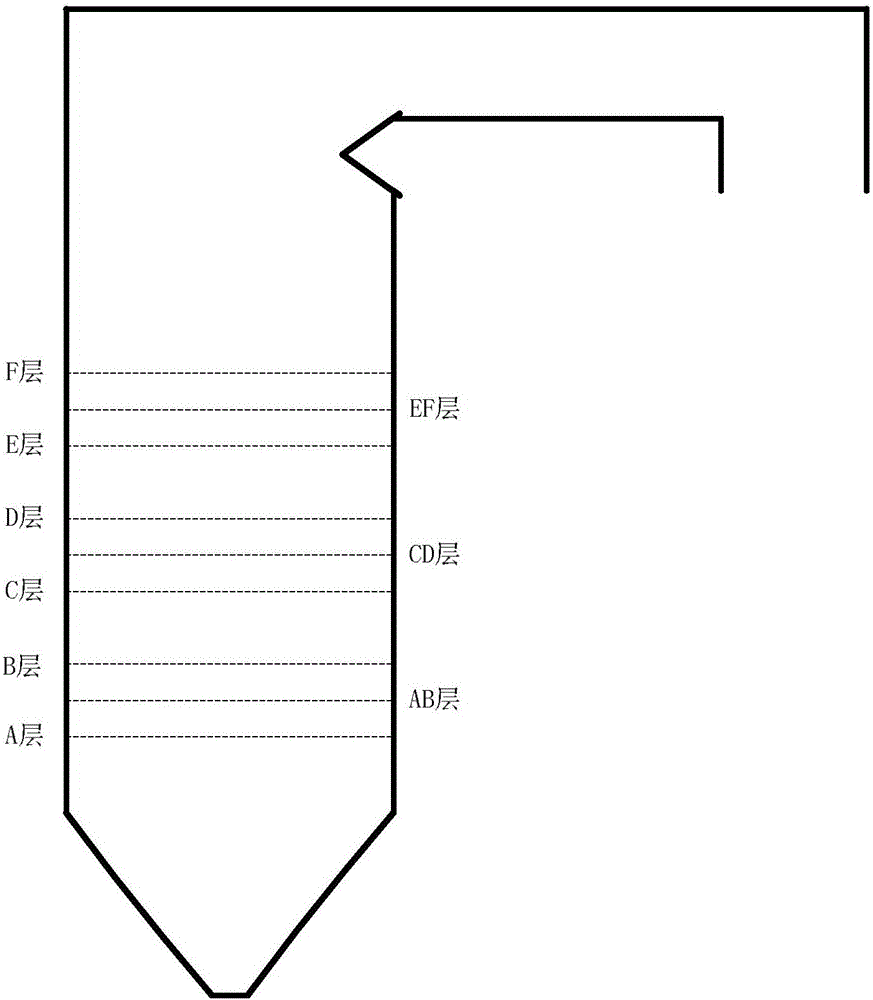

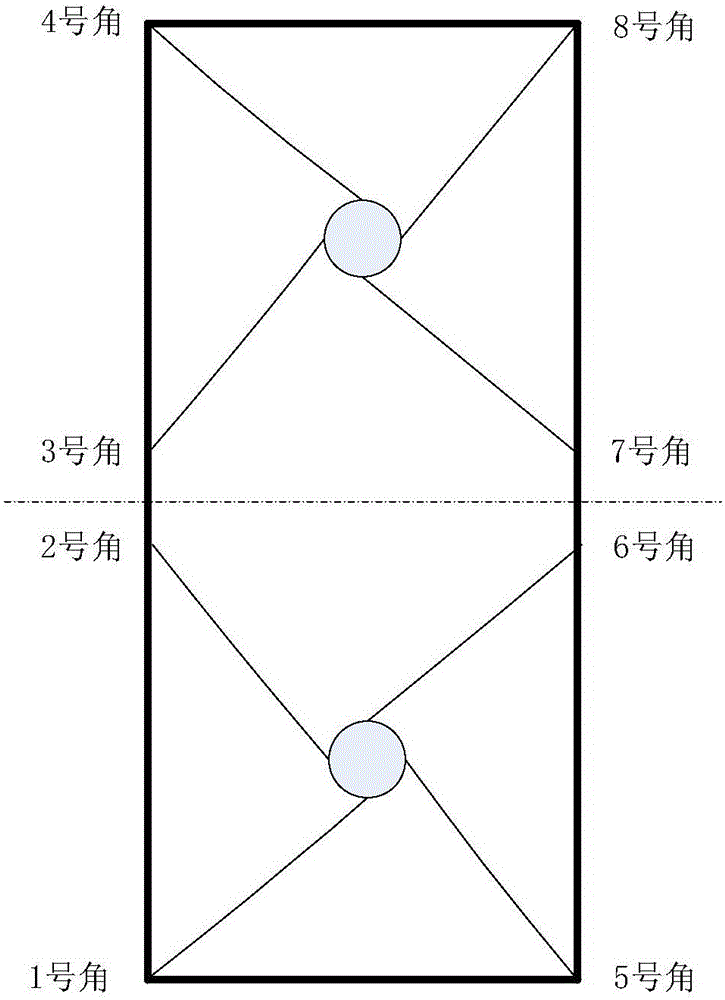

Boiler starting method for preventing oxide skin generation of 1,000 MW octagonal tangent circle boiler and secondary combustion accident of tail flue

The invention discloses a boiler starting method for preventing oxide skin generation of a 1,000 MW octagonal tangent circle boiler and a secondary combustion accident of a tail flue. Boiler warming is carried out before a combustor is put into operation, then, the combustor is put into operation, and the operation of the combustor is adopted according to the following operation principles that all large oil guns in an AB layer and part of large oil guns in a CD layer are put one by one, and when the outlet pressure of a boiler steam-water separator reaches 0.3 MPa, all micro oil guns in an A layer are put, and then a powder manufacturing system of the A layer is put into operation; and at the thermal state flushing and temperature rising and boosting stage, part of or all large oil guns quit one by one according to the pulverized coal combustion situation, and at the load rising stage, powder manufacturing systems are put into operation layer by layer according to the load situation. According to the method, the temperature rising rate of a heating surface of the boiler in the starting process can be controlled, and the good combustion effect of the pulverized coal in a hearth can be guaranteed; and generation of pipe oxide kin of the heating surface of the boiler is effectively prevented, and the purposes of preventing secondary combustion of the tail flue and the detonation accident of the hearth can be achieved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

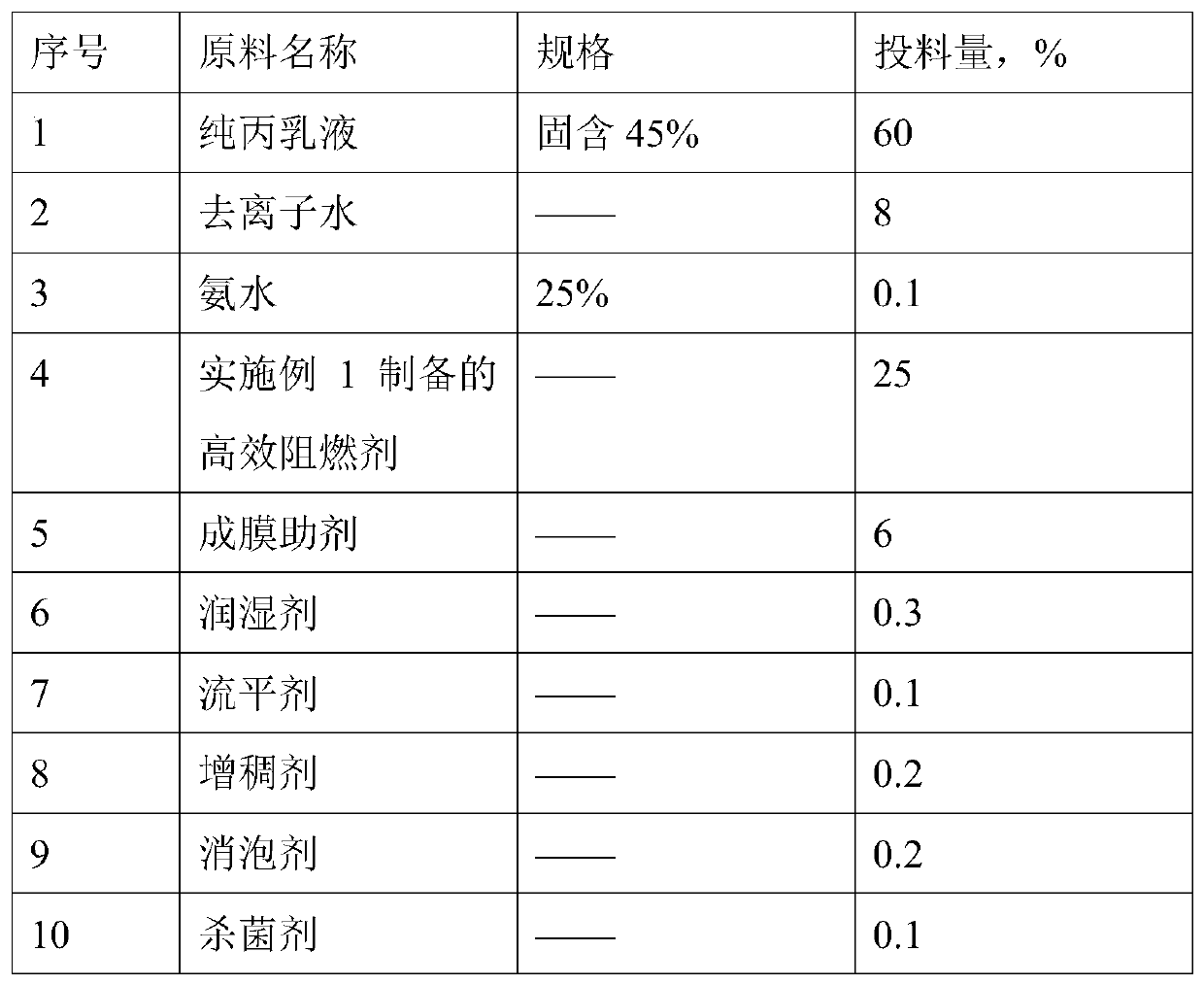

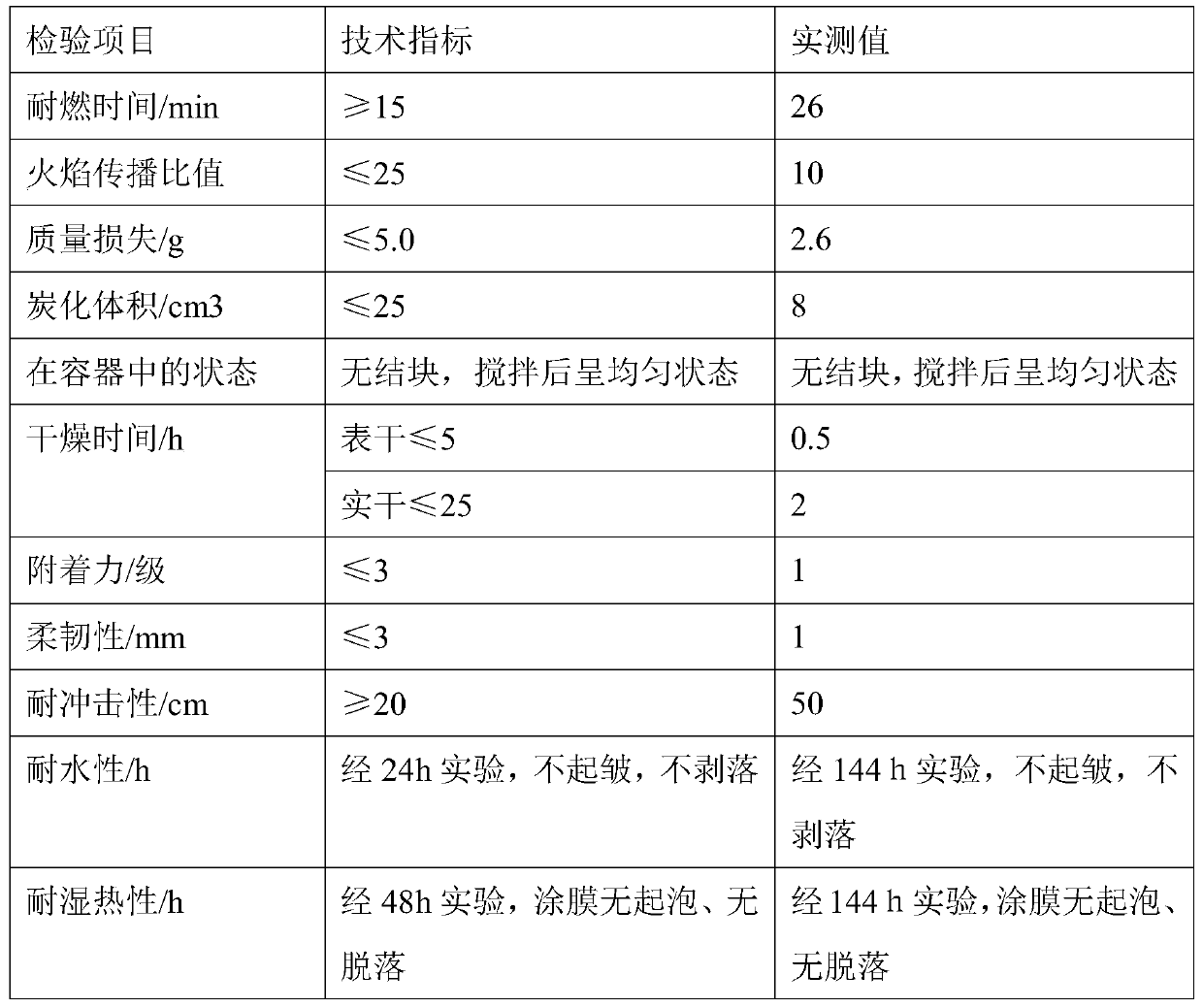

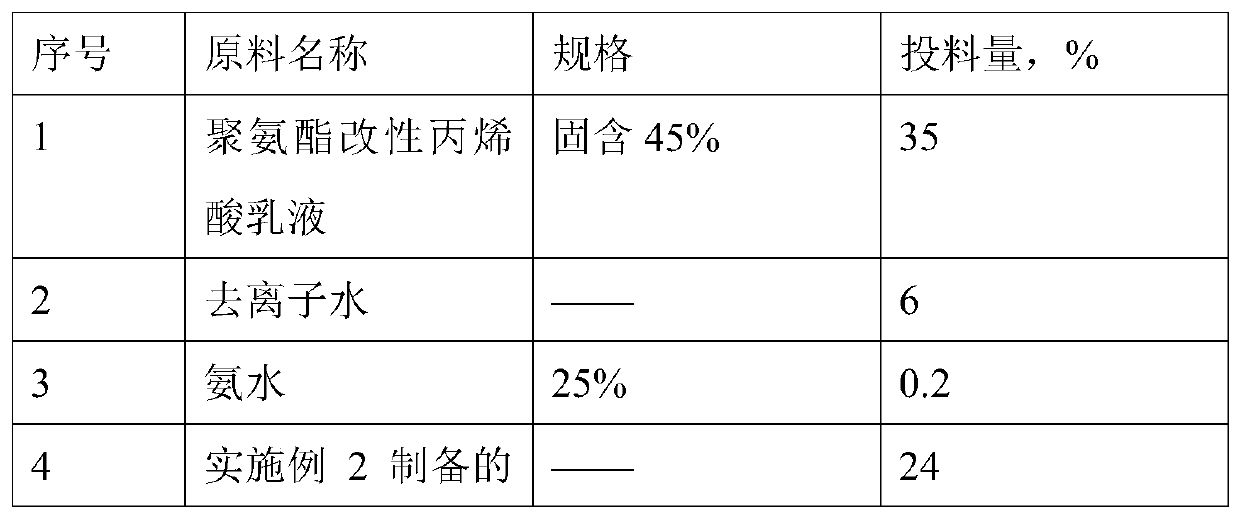

Silicon, nitrogen and phosphorus efficient halogen-free flame retardant for fireproof flame-retardant coating, preparation method of flame retardant and application of flame retardant

ActiveCN109735157AEmission-free productionImprove flame retardant performanceFireproof paintsRubber derivative coatingsCarbon layerEpoxy

The invention relates to a silicon, nitrogen and phosphorus efficient halogen-free flame retardant, a preparation method thereof and an application of the flame retardant, and further discloses a fireproof flame-retardant coating and a preparation method thereof. The preparation method includes the steps: adding epoxy siloxane, triglycidyl isocyanurate and aminoimidazole into a reaction container,and uniformly mixing raw materials; slowly dripping phosphoric acid, and heating mixture to reach the temperature of 60-70 DEG C to perform reaction for 3-5 hours to prepare the silicon, nitrogen andphosphorus efficient halogen-free flame retardant. The self-made flame retardant is applied to preparation of the fireproof flame-retardant coating. A structure of a design molecule of the efficientflame retardant integrates an acid source, a carbon source and an air source, formation of carbon can be facilitated in combustion, a compact silicon carbon layer is formed, secondary combustion caused by melt dripping of high-molecular materials in combustion is prevented, better flame resistance is provided for the high-molecular materials, water resistance and weather resistance of the coatingcannot be affected, high flame retardant efficiency can be formed in combustion, and the environments cannot be polluted as the flame retardant is free from halogen.

Owner:SOUTHEAST UNIV

Method for preparing natural fiber/polylactic acid composite material with anti-flaming function

InactiveCN101260228BImprove flame retardant performanceReduce generationMolecular materialsNatural fiber

The invention belongs to the high molecular material modification technical field, and in particular relates to a preparation method of natural fiber / poly lactic acid composite material with fire-retarding performance. The preparation method comprises the following steps: the surface modification and the fire-retarding modification of natural fiber are completed to improve the interface combination degree and the fire-retarding performance between the natural fiber and a poly lactic acid matrix; and then, the modified natural fiber is combined with poly lactic acid and fire retardant, therebyobtaining natural fiber-reinforced poly lactic acid composite material with excellent fire-retarding performance, mechanical property and full biodegradation. The poly lactic acid composite material,which can pass the fire-retarding testing in accordance with the standards of Federal Aviation Administration (FAA) and UL94V-O grade testing, can be used in fields such as airplane, automobile and electronic industry, which have strict requirements on material fire-retarding performance and mechanical property.

Owner:TONGJI UNIV

High-strength expandable polystyrene filled resin and preparation method thereof

InactiveCN114106503AHigh mechanical strengthGuaranteed persistenceGroup 5/15 element organic compoundsPolymer scienceFoaming agent

The invention discloses high-strength expandable polystyrene filled resin and a preparation method thereof. The expandable polystyrene filled resin comprises the following raw materials in parts by weight: 100-120 parts of modified polystyrene, 5-15 parts of a flame retardant, 5-8 parts of a foaming agent, 1-1.5 parts of a stabilizer and 0.1-0.3 part of a lubricant. The relative molecular weight of the flame retardant is large, the flame retardant cannot be separated out in the using process of the expandable polystyrene filling resin, the durability of the flame retardant effect of the expandable polystyrene filling resin is guaranteed, meanwhile, when the expandable polystyrene filling resin is combusted, oxygen-containing acid of phosphorus in the flame retardant catalyzes a hydroxyl-containing compound to be dehydrated into carbon, and therefore the flame retardant effect of the expandable polystyrene filling resin is improved. Furthermore, a coke layer is generated on the surface of the material, the coke layer can insulate oxygen and heat to extinguish flame, dripping is prevented, and secondary combustion is avoided.

Owner:安徽乾泰新材料股份有限公司

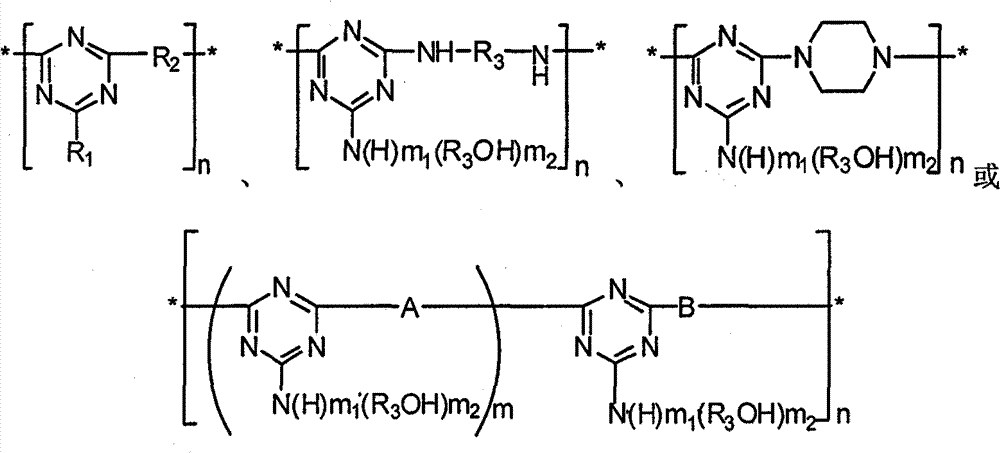

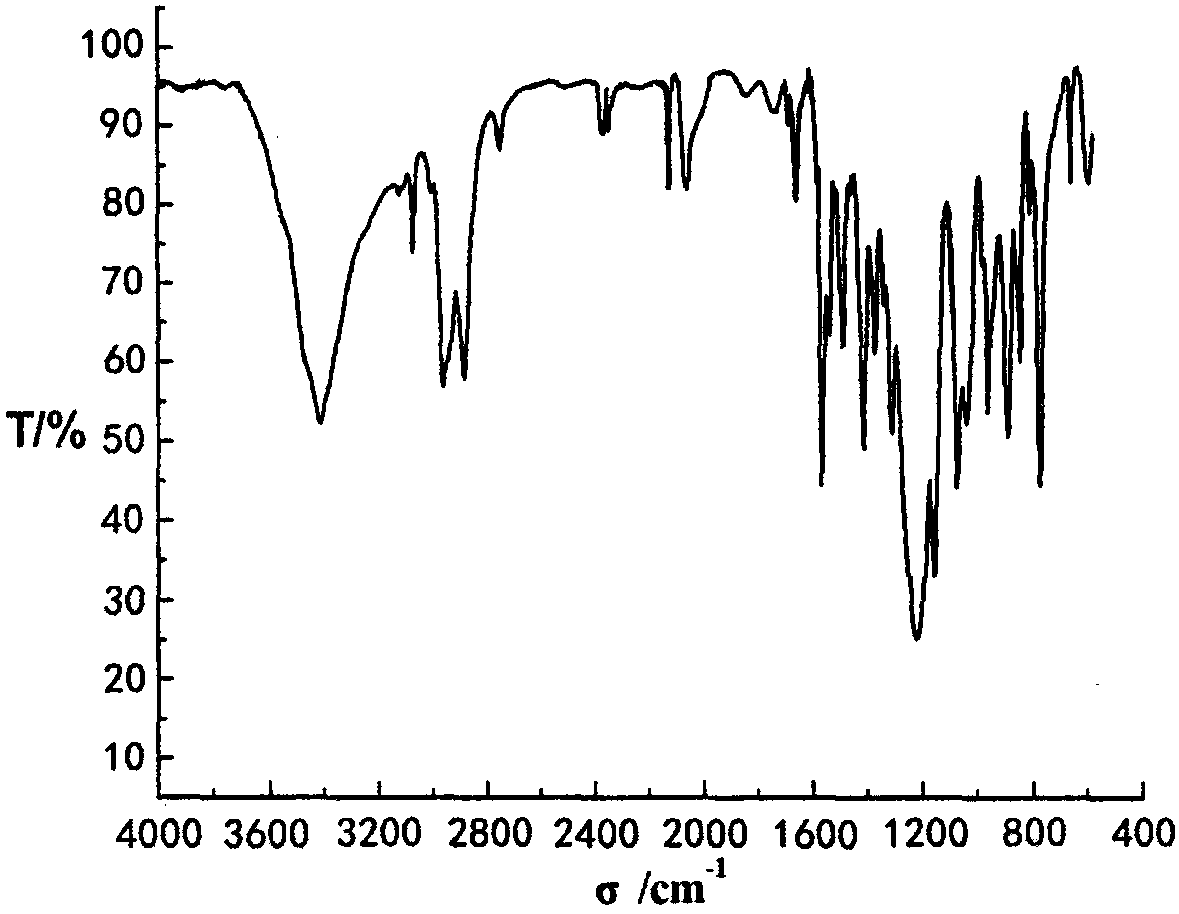

A kind of triazine macromolecule halogen-free flame retardant char-forming agent compound and preparation method thereof

ActiveCN106009037BGood compatibilityAdapt to high temperature processingOrganic chemistryFiltrationSolvent

The invention relates to a triazine macromolecular halogen-free flame-retardant char-forming agent compound and a preparation method thereof. The structure of the compound is as shown in the description, wherein n is larger than 1, X is alcohol amine, and Y is dialkylamine. The preparation method comprises the steps that under the stirring condition, an equimolar amount of alcohol amine is added into a solution of triglycidyl isocyanurate, the temperature is increased to a certain value, and heat preservation reaction is conducted for a period of time to enable the pH of the solution to range from 7 to 8; a certain molar of dialkylamine is added, the temperature is increased to a certain value, and heat preservation reaction is conducted for a period of time to enable the pH of the solution to range from 7 to 8; cooling is conducted, suction filtration (recycling of solvent), water washing, drying and smashing are conducted, and the triazine macromolecular flame-retardant char-forming agent product is obtained. The triazine macromolecular halogen-free flame-retardant char-forming agent is an excellent flame-retardant char-forming agent, has a char-forming anti-dropping effect, is good in compatibility with high molecular materials and excellent in processability and can be used as the flame-retardant char-forming agent of materials such as polyethylene (PE), polypropylene (PP) and silicone rubber; the raw materials of the char-forming agent are low in price and easy to obtain, the production cost is low, the equipment investment is low, the production technology is simple, and scale production is easy.

Owner:ZHEJIANG XUSEN NON HALOGEN SMOKE FLAME RETARDANT CO LTD

Process for preparing polyvinyl chloride cable material

InactiveCN106398018AImprove flame retardant performanceGood char formationInsulated cablesInsulated conductorsPolymer scienceAluminium hydroxide

Owner:中广核三角洲(江苏)塑化有限公司

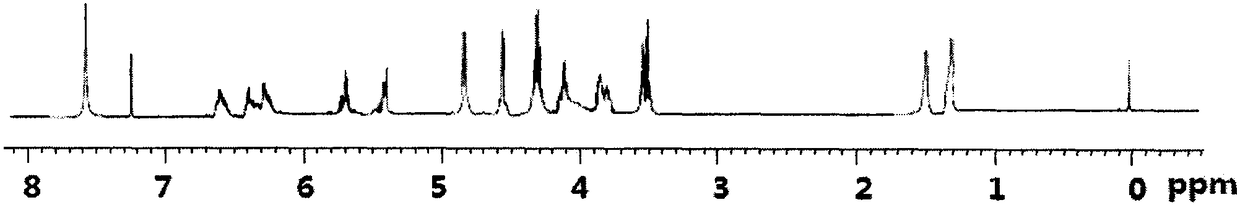

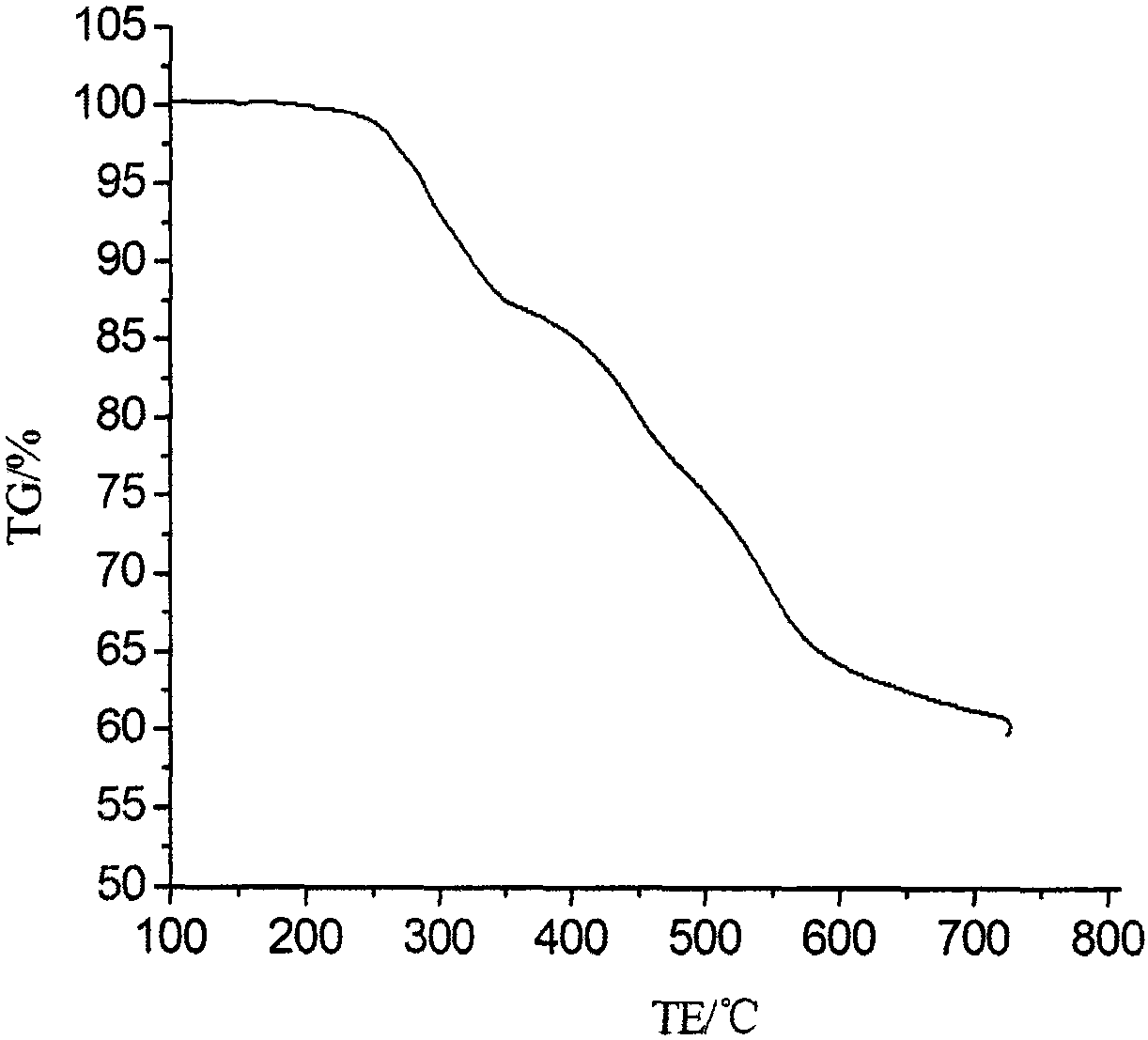

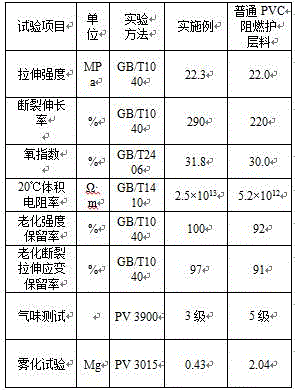

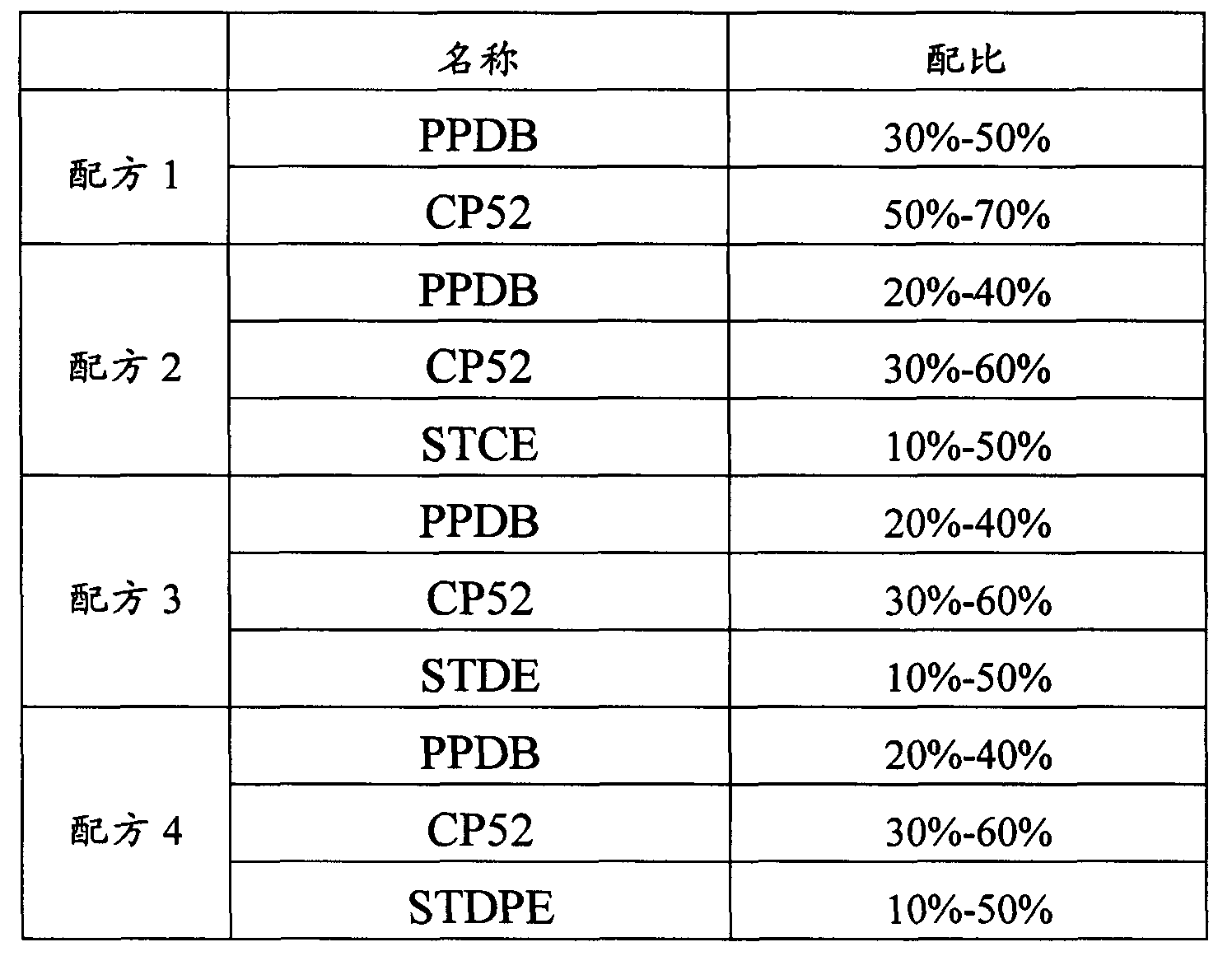

Dibutyl phenylphosphinate (PPDB) flame retardant composition and application method thereof

The invention relates to a dibutyl phenylphosphinate (PPDB) flame retardant composition and an application method thereof. The flame retardant composition is prepared by the steps of compounding one or two of PPDB, chlorinated paraffin-52 (short for CP52), tetrachloroethyl silicate (short for STCE), tetradichloropropyl silicate (short for STDE) or tridichloropropyl phenyl silicate (short for STDPE) according to any ratio, and then, uniformly mixing, wherein the weight parts of both PPDB and CP52 are larger than zero. The flame retardant composition provided by the invention has the advantages of synergistic effect among various elements, good compatibility with materials, high flame-retardant efficiency, low cost and the like, and can be used as a flame retardant for materials such as polyvinyl chloride, polyurethane, unsaturated resin, epoxy resin and the like so as to have favorable application prospects.

Owner:RES INST OF XIANGCHENG SUZHOU UNIV OF SCI & TECH

Method for preparing silicon, nitrogen and halogen multielement synergistic fire retardant compound

ActiveCN104744504AHigh synergistic flame retardant performanceGood stabilityGroup 4/14 element organic compoundsPlasticizerFire retardant

The invention relates to a method for preparing a silicon, nitrogen and halogen multielement synergistic fire retardant compound. The structure of the compound is shown in a formula which can be seen in the specification; in the formula, when m is 1, n is 0; when m is 0, n is 1; X is Cl or Br; Y is Cl or Br; OC3H5Y2 is OCH(CH2Br)2, OCH2CHBrCH2Br, OCH(CH2Cl)2 or OCH2CHClCH2Cl. The preparation method comprises the following steps: in an organic solvent, reacting triglycidyl isocyanurate with dimethyl dihalogenosilane for 5-8h at the temperature of 70-100 DEG C, dropwise adding dihalogen propyl alcohol, reacting for 5-8h at the temperature of 70-110 DEG C, and purifying to obtain t isocyanuric acid tri(dimethyl dihalogen propoxy silicane acyloxy propyl halide)ester. The fire retardant provided by the invention is high in fire retarding efficiency, good in char forming effect and is suitable for being used as a fire retardant plasticizer for polyvinyl chloride, polyurethane, epoxy resin and unsaturated resin; in addition, the production process is simple, the cost is low and the industrial production can be easily realized.

Owner:HUZHOU RUIGAO NEW MATERIALS CO LTD

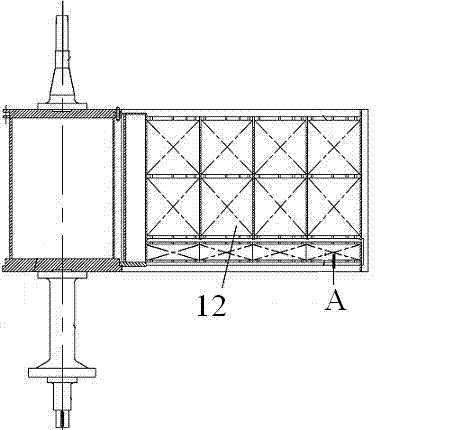

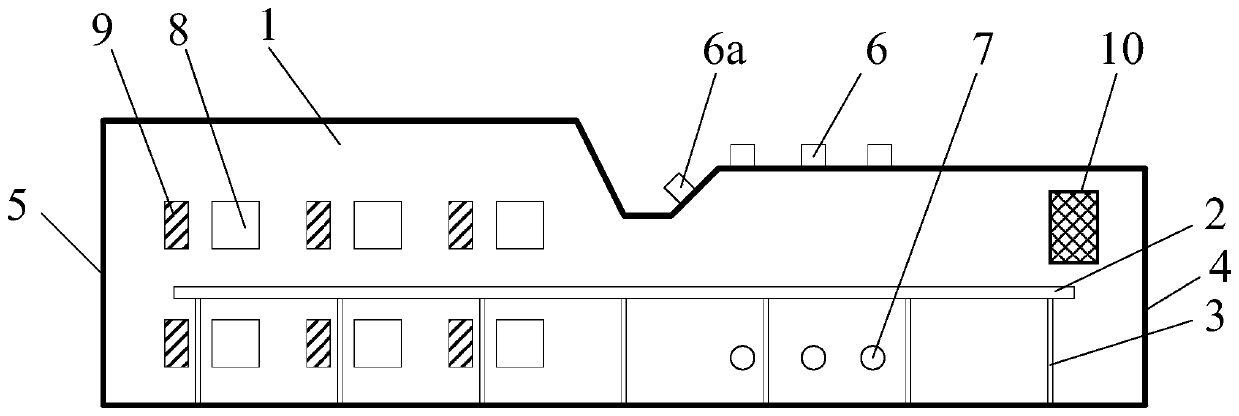

Heat storage and heat exchange linked heating furnace and operation method thereof

InactiveCN111521005ASuppress mutual interferenceImprove pressure fluctuationsFurnace typesWaste heat treatmentThermodynamicsCombustion

The invention discloses a heat storage and heat exchange linked heating furnace and an operation method thereof. The heat storage and heat exchange linked heating furnace comprises a hearth, a steel tapping furnace door, a steel input furnace door, a flue ad a stepping beam mounted in the hearth. The hearth is divided into a first heating section, a second heating section and a third heating section along the side from the steel input furnace door to the steel tapping furnace door, a first flat flame burner is mounted at the position, on the first heating section, of the top of the hearth, andflame adjusting burners are mounted on the two sides of the position, on the first heating section, of the hearth. Heat storage type burners are mounted on the two sides of the position, on the thirdheating section, of the hearth. The horizontal height of the top of the position, of the first heating section, of the hearth is lower than that of the position, of the third heating section, of thehearth. The top of the position, on the second heating section, of the hearth is concaved downwards to form a U shape from the position, on the first heating section, of the top of the hearth to the position, on the third heating section, of the top of the hearth. According to the heat storage and heat exchange linked heating furnace and the operation method thereof, the problem of large heat storage type furnace pressure and secondary combustion in a coal gas burner is effectively relieved.

Owner:ZHANGJIAGANG HONGCHANG STEEL PLATE CO LTD +2

Polydimethyl silicate terephthalic diester polymer as flame-retardant charring agent and preparation method thereof

The invention relates to a polydimethyl silicate terephthalic diester polymer as a flame-retardant charring agent and a preparation method thereof. The structural formula of the polymer is shown in the description, and in the structural formula, n is equal to 20-50. The preparation method comprises the following steps: in the presence of triethylamine, enabling hydroquinone to react with equimolar dimethyl dihalide silane in an organic solvent, or enabling hydroquinone sodium to react with equimolar dimethyl dihalide silane in an organic solvent, and performing purification so as to obtain polydimethyl silicon acid terephthalic diester. The polydimethyl silicate terephthalic diester disclosed by the invention is high in molecular weight, is good in material compatibility, is not easy to separate out, is good in charring performance, and is suitable for being used as a flame-retardant charring agent of polyolefine, polyester, polyamide, an epoxy resin, an unsaturated resin and the like. The production technology is simple, the cost is low, and the industrialized production is easy to realize.

Owner:HUZHOU RUIGAO NEW MATERIALS CO LTD

Silicic acid-3-(3-bromophenyl)-chloropropyl ethyl ester compound used as fire retardant and preparation method thereof

ActiveCN103333194APhysicochemically stableHigh decomposition temperatureSilicon organic compoundsEpoxyPolymer science

The invention relates to a silicic acid-3-(3-bromophenyl)-chloropropyl ethyl ester compound used as a fire retardant and the preparation method thereof. The structural formula of the compound is shown in the specification. The preparation method comprises the following steps: filling ethylene oxide of which the mole is same as that of silicon tetrachloride in silicon tetrachloride organic solution at the temperature of below 20 DEG C, adding tribromophenol of which is three times the mole of silicon tetrachloride, carrying out the thermal reaction for 6-10 hours at the temperature of 100-120 DEG C, and reducing pressure and distilling to remove solvent and a small amount of low boiling point substances to obtain the silicic acid-3-(3-bromophenyl)-chloropropyl ethyl ester compound. The silicic acid-3-(3-bromophenyl)-chloropropyl ethyl ester compound is an excellent fire retardant plasticizer, has carbon-forming and anti-dripping functions and good compatibility with high polymer material, can be used as fire retardants made of polyvinyl chloride, unsaturated polyester, polyurethane, epoxy resin and the like, and is easy to access in raw material, low in production cost, small in equipment investment, simple in production technology, and easy for large-scale production.

Owner:张家港市乐余科创园投资发展有限公司

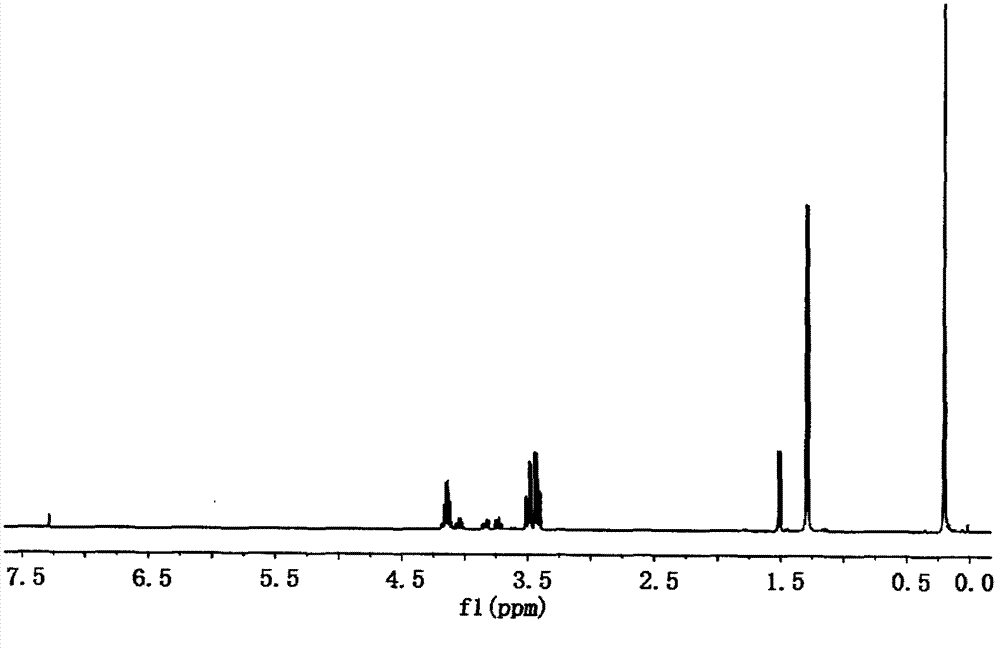

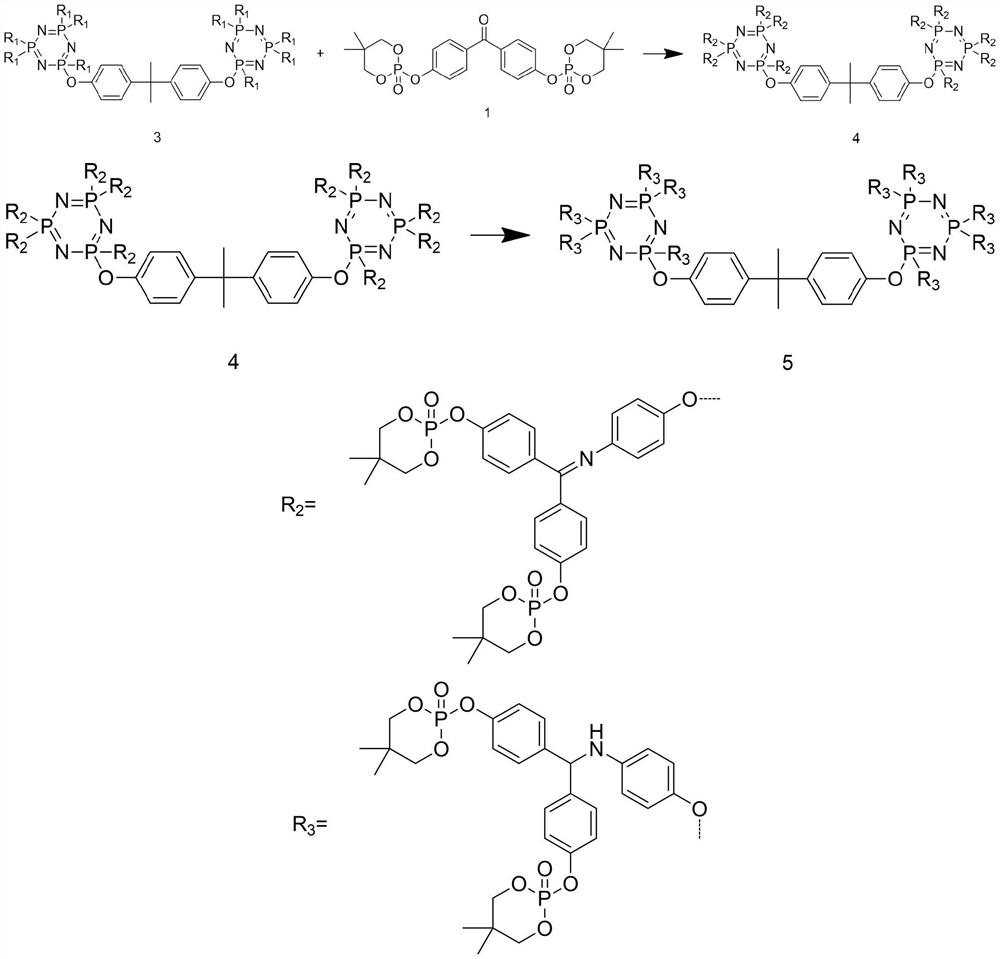

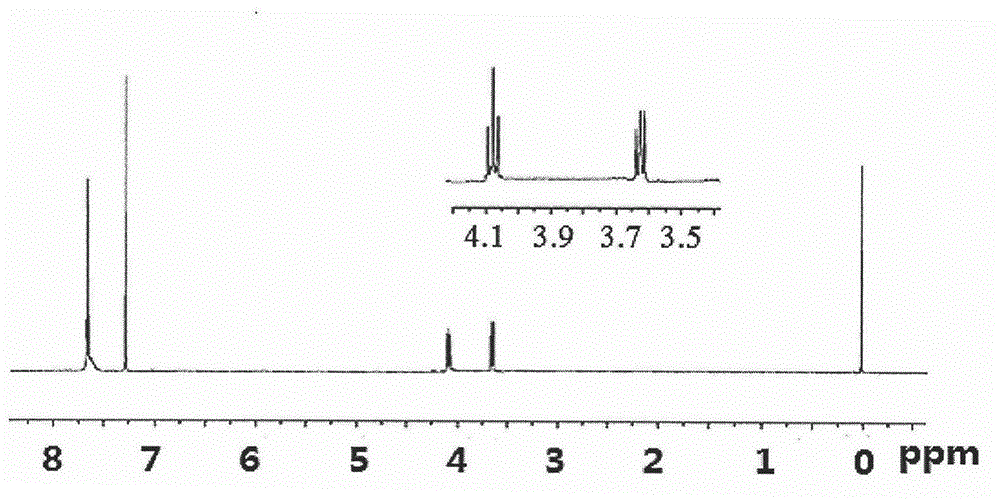

Tris [2-(dimethylthiopepaoxysilyloxy) ethyl] isocyanurate compound and preparation method thereof

ActiveCN104650146BWith expansion and heat insulation effectPrevent secondary combustionGroup 5/15 element organic compoundsEpoxyPolyester

The invention relates to a tris[2-(dimethylthioPEPAoxysilyloxy)ethyl] isocyanurate compound and a preparation method thereof. The structure of the compound is shown in the following formula: the preparation method is: Dissolve tris(2-hydroxyethyl)isocyanurate in an organic solvent, add dimethyldihalosilane which is 3 times molar relative to tris(2-hydroxyethyl)isocyanurate, and heat up to 50°C ~70°C, keep warm for 5~9h; cool down to below 30°C, add a certain mole of SPEPA, heat up to 70°C~100°C, keep warm for 6~14h; after purification, tris[2‑(2 MethylthioPEPAoxysilyloxy)ethyl] ester. The flame retardant of the invention has high flame retardant efficiency and good char formation performance, is suitable for use as a flame retardant for polyolefin, polyester, epoxy resin, unsaturated resin, etc., has simple production process, low cost, and is easy to realize industrialized production.

Owner:HUZHOU RUIGAO NEW MATERIALS CO LTD

Fire-extinguishing agent for sodium fire

The invention belongs to the fire-fighting field, which particularly relates to an extinguishing agent for anti-sodium fire. The extinguishing agent contains the following materials with the contents: 98.9 to 99.9% of C, 0 to 0.03% of sulfur, 0.1 to 1% of moisture, 0 to 0.04% of nitrogen, chlorine c; the volume density of the extinguishing agent is among 0.120 to 0.820g / cm<3>, the grain diameter is 32 to 80 meshes, the oversize material is larger or equal to 80 percent, pH value is among 3 to 7, the fugitive constituent is smaller or equal to 10 percent, and the ash is smaller or equal to 10 percent. The extinguishing agent provides the extinguishing agent which has the sodium with fast anti-sodium fire speed, high inflation rate, and no-pollution consumption and can be filled into a special fire extinguisher, is easy to recycle and environmental friendly and can not generate harmful gases.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

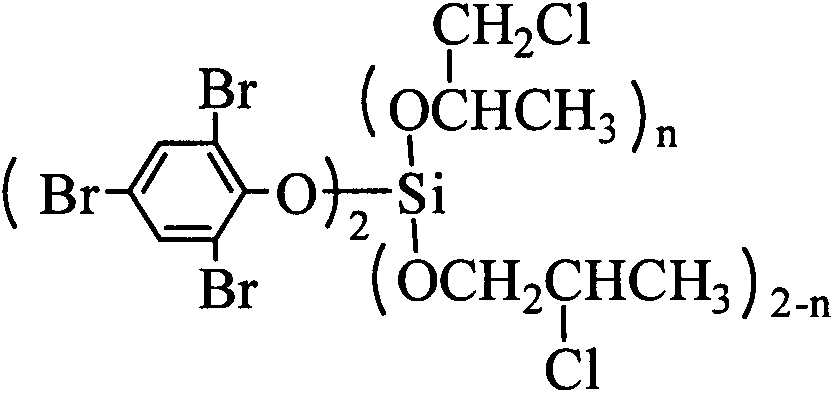

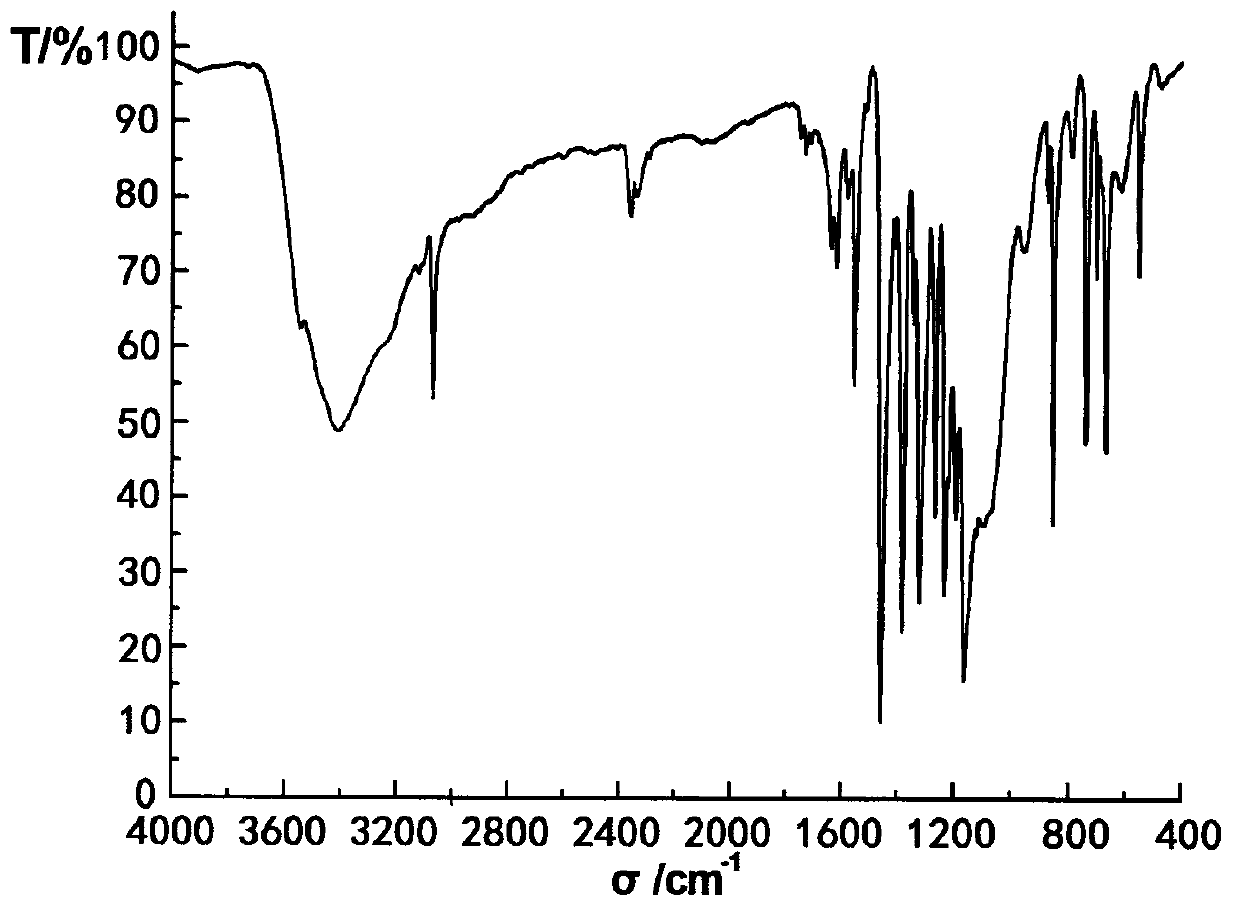

Flame retardant silicic acid di-(tribromophenyl) dichlorohydrin compound and preparation method thereof

ActiveCN103333193APhysicochemically stableHigh decomposition temperatureSilicon organic compoundsEpoxyPolymer science

The invention relates to a flame retardant silicic acid di-(tribromophenyl) dichlorohydrin compound and a preparation method thereof. A structural formula of the compound is shown in the specification, wherein n is an integer between 0 and 2. The preparation method comprises the steps that equimolar epoxy propane is dropwise added to an organic solution of silicon tetrachloride, and reacts at 30 DEG C for 30min; twice mole of tribromophenol is added, and reacts at 70-100 DEG C for 3-6h; epoxy propane at a certain mole ratio is dropwise added, and reacts at 60-85 DEG C for 4-6h; a solvent and a low-boiling-point object are removed by reduced pressure distillation; and silicic acid di-(tribromophenyl) dichlorohydrin is obtained. Silicic acid di-(tribromophenyl) dichlorohydrin is an excellent antiflaming plasticizer, has charring and dripping prevention functions, has good compatibility with a high polymer material, and can serve as a flame retardant of polyvinyl chloride, unsaturated polyester, polyurethane, epoxy resin and the like, raw materials of silicic acid di-(tribromophenyl) dichlorohydrin are low in cost and easy to obtain, the production cost is low, the equipment investment is low, a production technology is simple, and the scale production is facilitated.

Owner:张家港市乐余科创园投资发展有限公司

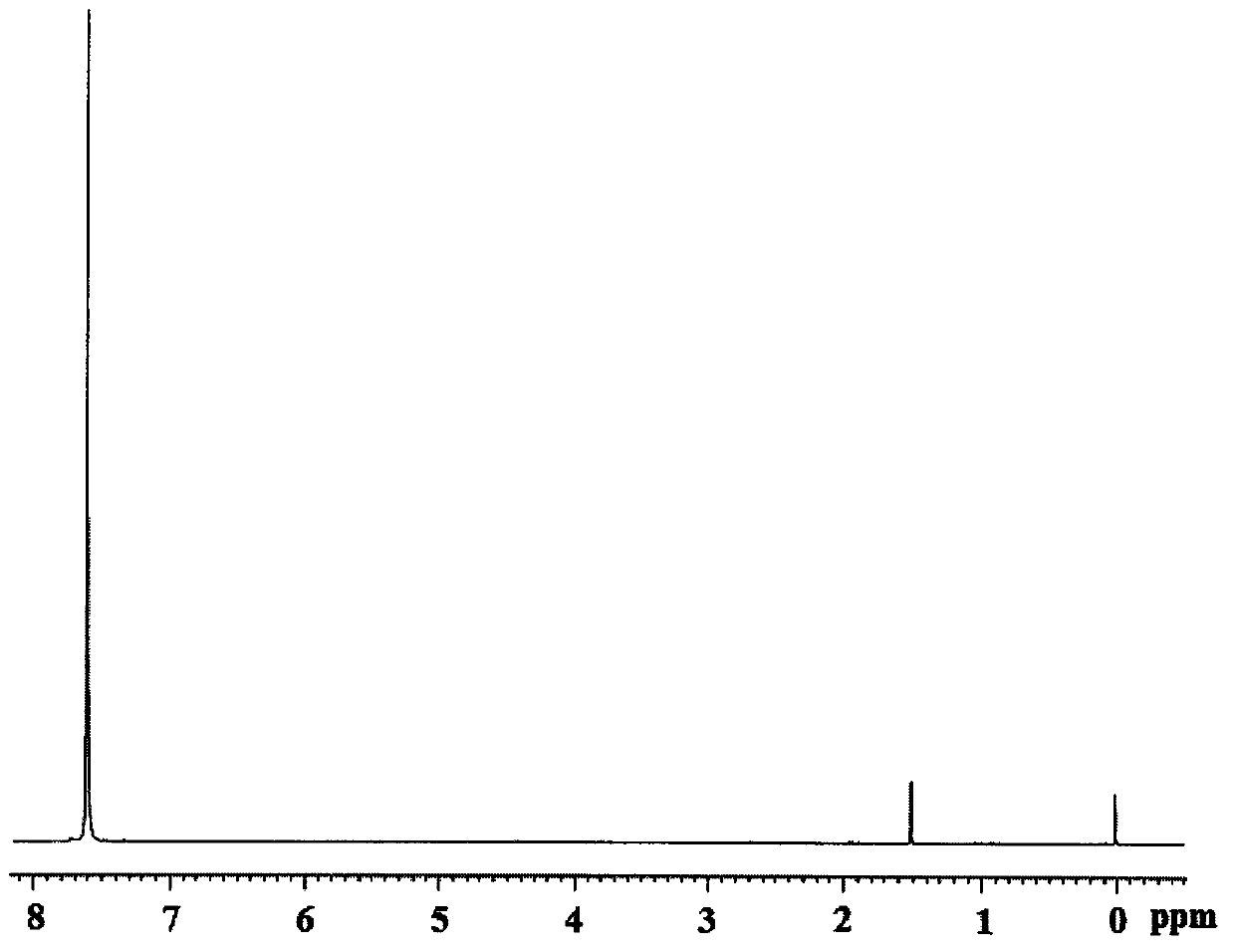

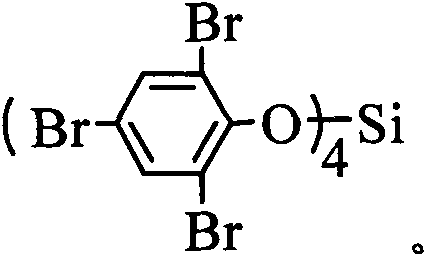

Flame retardant tetra(tribromophenyl) silicate esterification compound and preparation method thereof

ActiveCN103342714APhysicochemically stableHigh decomposition temperatureSilicon organic compoundsEpoxySilicic acid

The invention relates to a flame retardant tetra(tribromophenyl) silicate esterification compound and a preparation method thereof. The structure of the compound is shown in the specification. The preparation method comprises the following steps of: adding tribromophenol of quadruple molar weight into an organic solution of silicon tetrachloride at 30 DEG C; heating to 45 DEG C in one hour, and performing a thermal-insulation reaction for one hour; heating to 100-120 DEG C, and performing a thermal-insulation reaction for 8-12 hours; and performing reduced-pressure distillation to remove the solvent to obtain the product tetra(tribromophenyl) silicate. The tetra(tribromophenyl) silicate provided by the invention is an excellent flame-retardant plasticizer with a charring anti-drop effect and good compatibility with a high-molecular material, and can be used as a flame retardant for the materials such as polyvinyl chloride, unsaturated polyester, polyurethane, epoxy resin and the like; and moreover, the flame retardant has the advantages of cheap and easily-available raw materials, low equipment investment and simple production technology, and is easy to produce in a large scale.

Owner:张家港市乐余科创园投资发展有限公司

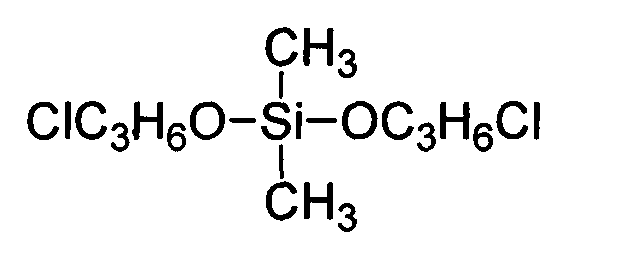

Preparation method of dimethyl silicic acid (chlorine acrylate) diester as flame resistant plastifier

InactiveCN104710465AHigh synergistic flame retardant performanceGood stabilityGroup 4/14 element organic compoundsNitrogen gasOrganic solvent

The invention relates to a preparation method of dimethyl silicic acid (chlorine acrylate) diester as a flame resistant plastifier. The structure of the compound is shown in the formula (refer to the Specification), wherein OC3H6Cl refers to OCH2CHClCH3 and OCH(CH2Cl)CH3. The preparation method comprises the following steps: under nitrogen protection, the molar ratio of dimethyl dichlorosilane or dimethyl dibromo-silane to chloropropyl alcohol is 1:2-3, under the temperature of 20-90 DEG C, and in an organic solvent, the reaction is performed for 5-9 hours; through purification, the dimethyl silicic acid (chlorine acrylate) diester is obtained. The dimethyl silicic acid (chlorine acrylate) diester as the flame resistant plastifier, disclosed by the invention, is high in flame resistant efficacy, is good in plasticity, is suitable for the flame resistant plastifier of polyvinyl chloride, polyurethane, epoxy resin, unsaturated resin and the like, is simple in production technology, and is low in cost, and industrialized production is easy to realize.

Owner:苏州阳桥新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Fire retardant alkyl silicic acid trithio phosphonia trioxa bicyclo[2.2.2]octyl methyl ester compound and preparation method thereof Fire retardant alkyl silicic acid trithio phosphonia trioxa bicyclo[2.2.2]octyl methyl ester compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/99f6ca2d-d368-4731-8f7d-16ad0c31912d/HSA0000134893770000011.png)

![Fire retardant alkyl silicic acid trithio phosphonia trioxa bicyclo[2.2.2]octyl methyl ester compound and preparation method thereof Fire retardant alkyl silicic acid trithio phosphonia trioxa bicyclo[2.2.2]octyl methyl ester compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/99f6ca2d-d368-4731-8f7d-16ad0c31912d/HSA0000134893770000012.png)

![Fire retardant alkyl silicic acid trithio phosphonia trioxa bicyclo[2.2.2]octyl methyl ester compound and preparation method thereof Fire retardant alkyl silicic acid trithio phosphonia trioxa bicyclo[2.2.2]octyl methyl ester compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/99f6ca2d-d368-4731-8f7d-16ad0c31912d/HSA0000134893770000013.png)

![Method for preparing flame retardant tris[2-tri(chloroethoxy)silicon-acyloxy-ethyl]isocyanurate Method for preparing flame retardant tris[2-tri(chloroethoxy)silicon-acyloxy-ethyl]isocyanurate](https://images-eureka.patsnap.com/patent_img/a22ccf7c-c591-43e6-89a4-5610626cc18d/HSA0000097406090000011.PNG)

![Method for preparing flame retardant tris[2-tri(chloroethoxy)silicon-acyloxy-ethyl]isocyanurate Method for preparing flame retardant tris[2-tri(chloroethoxy)silicon-acyloxy-ethyl]isocyanurate](https://images-eureka.patsnap.com/patent_img/a22ccf7c-c591-43e6-89a4-5610626cc18d/HSA0000097406090000012.PNG)

![Method for preparing flame retardant tris[2-tri(chloroethoxy)silicon-acyloxy-ethyl]isocyanurate Method for preparing flame retardant tris[2-tri(chloroethoxy)silicon-acyloxy-ethyl]isocyanurate](https://images-eureka.patsnap.com/patent_img/a22ccf7c-c591-43e6-89a4-5610626cc18d/BSA0000097406080000021.PNG)

![Tris [2-(dimethylthiopepaoxysilyloxy) ethyl] isocyanurate compound and preparation method thereof Tris [2-(dimethylthiopepaoxysilyloxy) ethyl] isocyanurate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/71c519be-386a-4ff0-982f-4965e9c7c044/HSA0000114515290000011.png)

![Tris [2-(dimethylthiopepaoxysilyloxy) ethyl] isocyanurate compound and preparation method thereof Tris [2-(dimethylthiopepaoxysilyloxy) ethyl] isocyanurate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/71c519be-386a-4ff0-982f-4965e9c7c044/HSA0000114515290000012.png)

![Tris [2-(dimethylthiopepaoxysilyloxy) ethyl] isocyanurate compound and preparation method thereof Tris [2-(dimethylthiopepaoxysilyloxy) ethyl] isocyanurate compound and preparation method thereof](https://images-eureka.patsnap.com/patent_img/71c519be-386a-4ff0-982f-4965e9c7c044/BSA0000114515280000021.png)