Cooling method for hot gas dispersoid fire-extinguishing device

A technology of fire extinguishing device and cooling method, applied in fire protection equipment, fire rescue and other directions, can solve problems such as unreasonable chemical coolant formulation and secondary fire, achieve ideal cooling efficiency, avoid secondary combustion, and superior social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

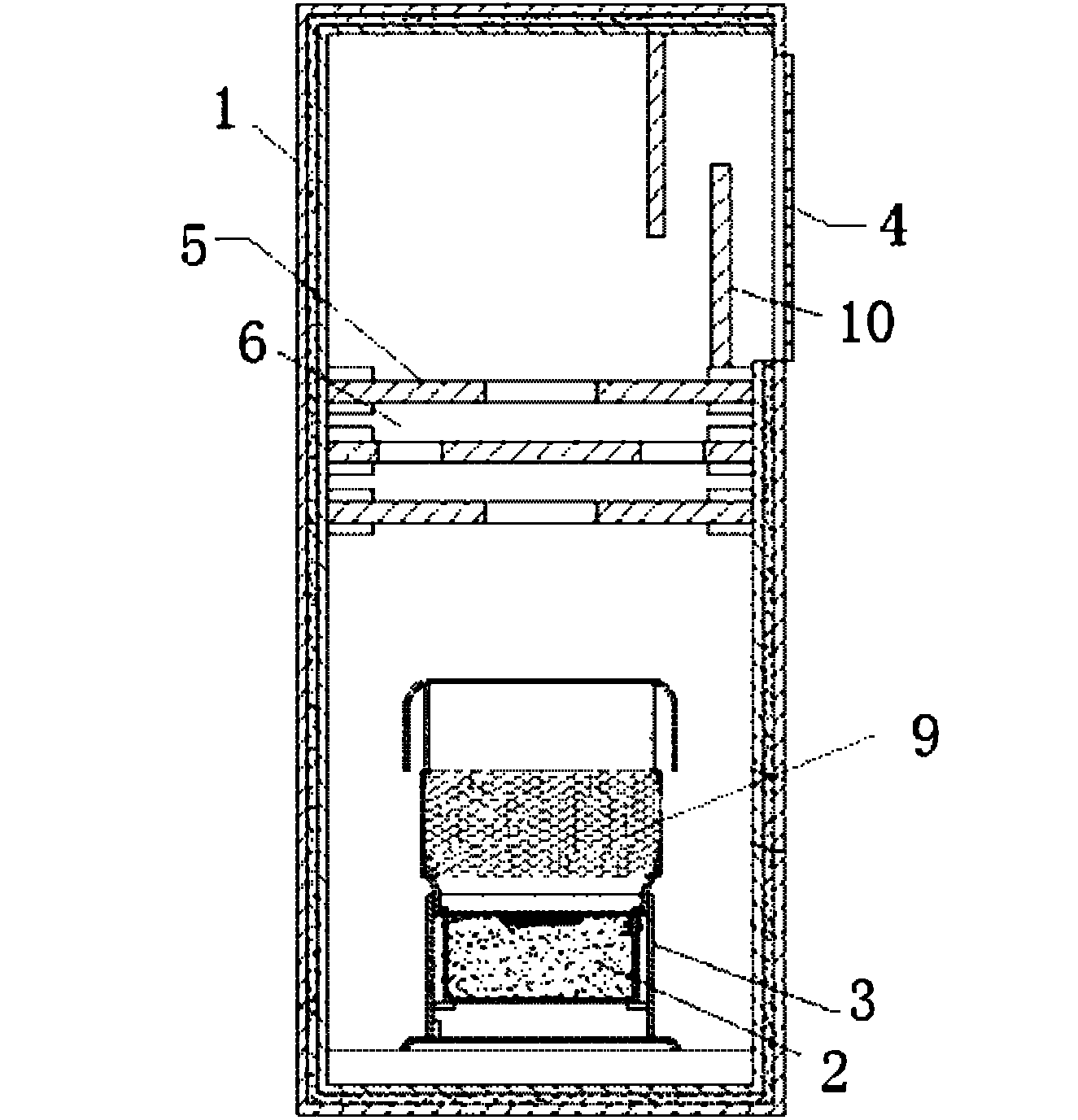

[0023] Embodiment 1: the cooling method that hot aerosol fire extinguishing device is used, this method is applied to hot aerosol fire extinguishing device, and hot aerosol fire extinguishing device comprises box body 1, and the reaction tube 3 that hot aerosol generating agent 2 is housed in box body 1, box body One side of 1 is provided with a gas outlet 4; the method includes a physical cooling method and a chemical cooling method;

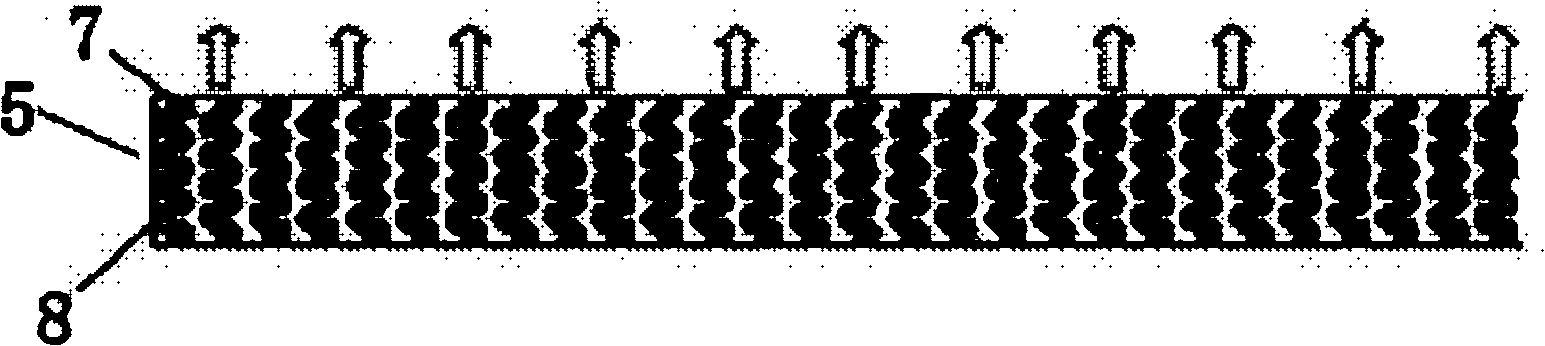

[0024] The physical cooling method is provided with more than 2 heat shields 5 above the reaction cylinder 3, and the heat shields are provided with ventilation holes 6, and the ventilation holes 6 are alternately arranged; as attached figure 2 As shown, the heat shield 5 is also provided with a grid-shaped diversion hole 7, and the diversion hole 7 is coated with nanoparticles 8 to form an S-shaped curved channel to realize the cooling of the hot aerosol;

[0025] Described chemical cooling method is by arranging coolant 9 in reaction cylinde...

Embodiment 2

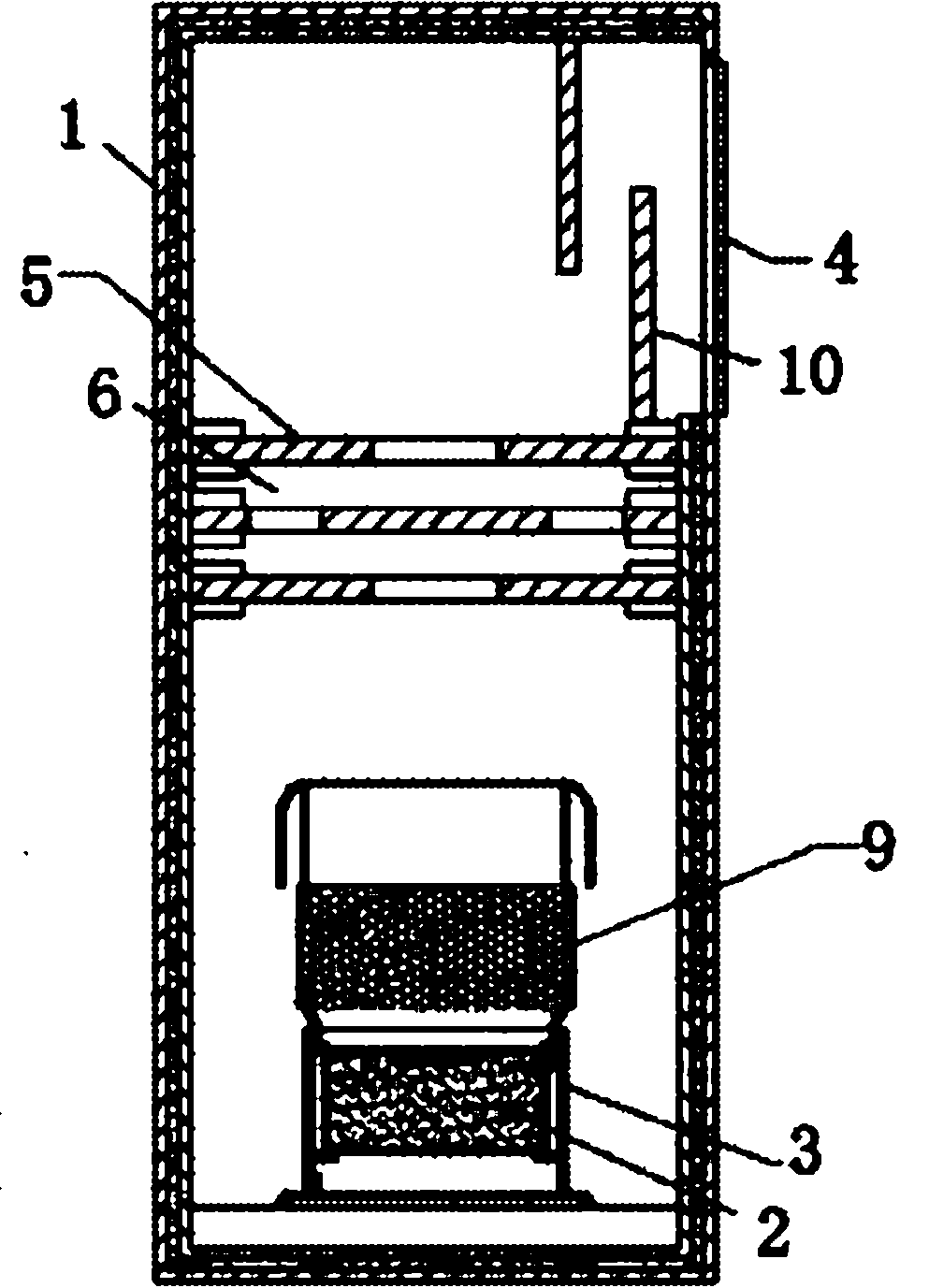

[0027] Embodiment 2: the cooling method that hot aerosol fire extinguishing device is used, this method is applied to hot aerosol fire extinguishing device, and hot aerosol fire extinguishing device comprises box body 1, and the reaction cylinder 3 that hot aerosol generating agent 2 is housed in box body 1, box body One side of 1 is provided with a gas outlet 4; the method includes a physical cooling method and a chemical cooling method;

[0028] In the physical cooling method, more than two heat shields 5 are arranged above the reaction cylinder 3, and vent holes 6 are provided on the heat shield, and the vent holes 6 are arranged alternately; the heat shield 5 is also provided with grid-shaped flow guide The holes 7 and the guide holes 7 are coated with nanoparticles 8 to form an S-shaped curved channel to realize the cooling of the hot aerosol; the physical cooling method also includes setting more than two heat baffles 10 at the gas outlet 4, and the heat baffles 10 and T...

Embodiment 3

[0030] Embodiment 3: the cooling method that hot aerosol fire extinguishing device is used, this method is applied to hot aerosol fire extinguishing device, and hot aerosol fire extinguishing device comprises box body 1, and the reaction cylinder 3 that hot aerosol generating agent 2 is housed in box body 1, box body One side of 1 is provided with a gas outlet 4; the method includes a physical cooling method and a chemical cooling method;

[0031] In the physical cooling method, more than two heat shields 5 are arranged above the reaction cylinder 3, and vent holes 6 are provided on the heat shield, and the vent holes 6 are arranged alternately; the heat shield 5 is also provided with grid-shaped flow guide The holes 7 and the guide holes 7 are coated with nanoparticles 8 to form an S-shaped curved channel to realize the cooling of the hot aerosol; the physical cooling method also includes setting more than two heat baffles 10 at the gas outlet 4, and the heat baffles 10 and T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com