Metal wall temperature measurement system for rotary air preheater

A technology of air preheater and measurement system, which is applied in the direction of measuring device, heat measurement, thermometer with electric/magnetic element directly sensitive to heat, etc., to avoid low-temperature acid corrosion and ensure safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings, but the present invention is not limited to specific embodiments.

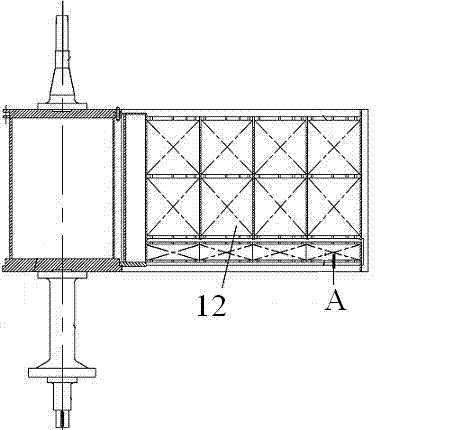

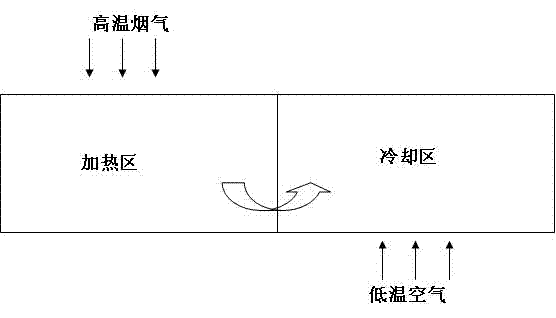

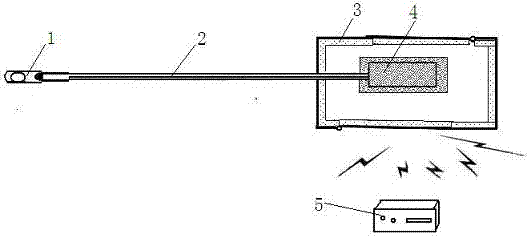

[0024] like image 3 The metal wall temperature measurement system of the rotary air preheater shown is composed of an online continuous temperature measurement device and a receiver. Plate position heat storage fin ( figure 1 middle point A), and rotates with the metal heat storage body, the online continuous temperature measurement device is composed of a patch thermocouple 1, a compensation wire 2, a wireless temperature sensor 4 and a constant temperature box 3, and the patch thermocouple 1 is connected to a wireless sensor through a compensation wire 2 The temperature sensor 4 and the wireless temperature sensor 4 are placed in the incubator 3 to keep the wireless temperature sensor within the operating temperature range. The wireless temperature sensor is connected to the receiver 5 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com