A detection method for the air leakage rate of the flue gas heat exchanger in the desulfurization unit of the thermal power plant

A technology of flue gas heat exchanger and desulfurization device, which can solve the problems of large measurement deviation and high humidity of flue gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

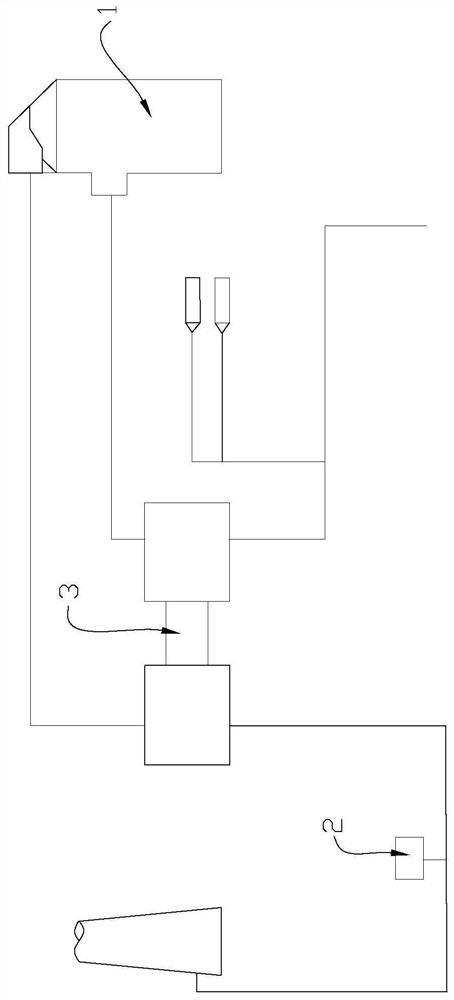

[0012] refer to figure 1 , the invention is a detection method for the air leakage rate of the flue gas heat exchanger of the desulfurization device of the thermal power plant, through the method of indirect measurement, the SO in the net flue gas 2 Equal to SO at the outlet of the absorption tower 2 The total amount plus the SO leaked from the raw flue gas into the clean flue gas 2 total amount. Among them, the original flue gas flow A 1 , net flue gas flow A 2 , SO at the outlet of the absorption tower 2 Concentration a, net flue gas SO 2 Concentration b, raw flue gas SO 2 Concentration c, air leakage rate x, A 2 ×a+A 1 ×x×c=A 2 ×b, get x=A 2 (b-a) / cA 1 , so in order to calculate the air leakage rate x, the key is to accurately measure the SO at the outlet of the absorption tower 2 Concentration a, and other parameters can be directly read through the smoke automatic online monitoring system 2.

[0013] Measurement of SO at the outlet of the absorption tower 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com