Smoke circulating combusting system for waste palm boiler

A boiler flue gas, circulating combustion technology, applied in the boiler field, can solve the problems of damage to the incineration boiler, easy bridge blockage, corrosion of the heating surface at the tail, etc., to achieve the effects of inhibiting the combustion process, improving temperature distribution, and solving combustion instability and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

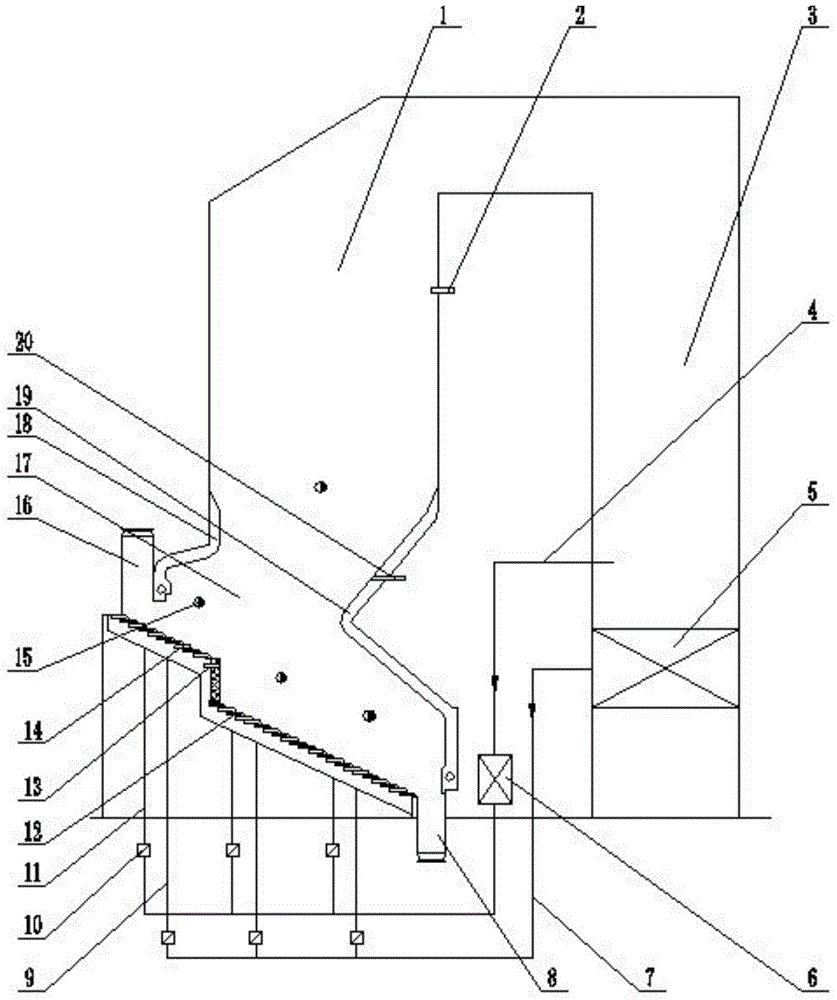

[0024] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

[0025] A palm waste boiler flue gas circulation combustion system, the palm waste boiler includes a hopper 16, a furnace 17, a front arch 18, a rear arch 19, a fire grate, an ash hopper 8, a smoke outlet 1, a tail flue 3, and an air preheater 5. The furnace wall in the furnace is provided with a front arch and a rear arch, and a smoke outlet is formed above the front arch and the rear arch. The smoke outlet is connected to the tail flue, and an air preheater is installed in the tail flue; A fire g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com