Multi-scale layered flame-retardant material and preparation method thereof

A flame retardant material, multi-scale technology, applied in the direction of coating, can solve the problems of damage to the mechanical properties of the matrix, reduce the flame retardant effect, and high production costs, and achieve the goal of overcoming poor compatibility, improving flame retardant properties, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

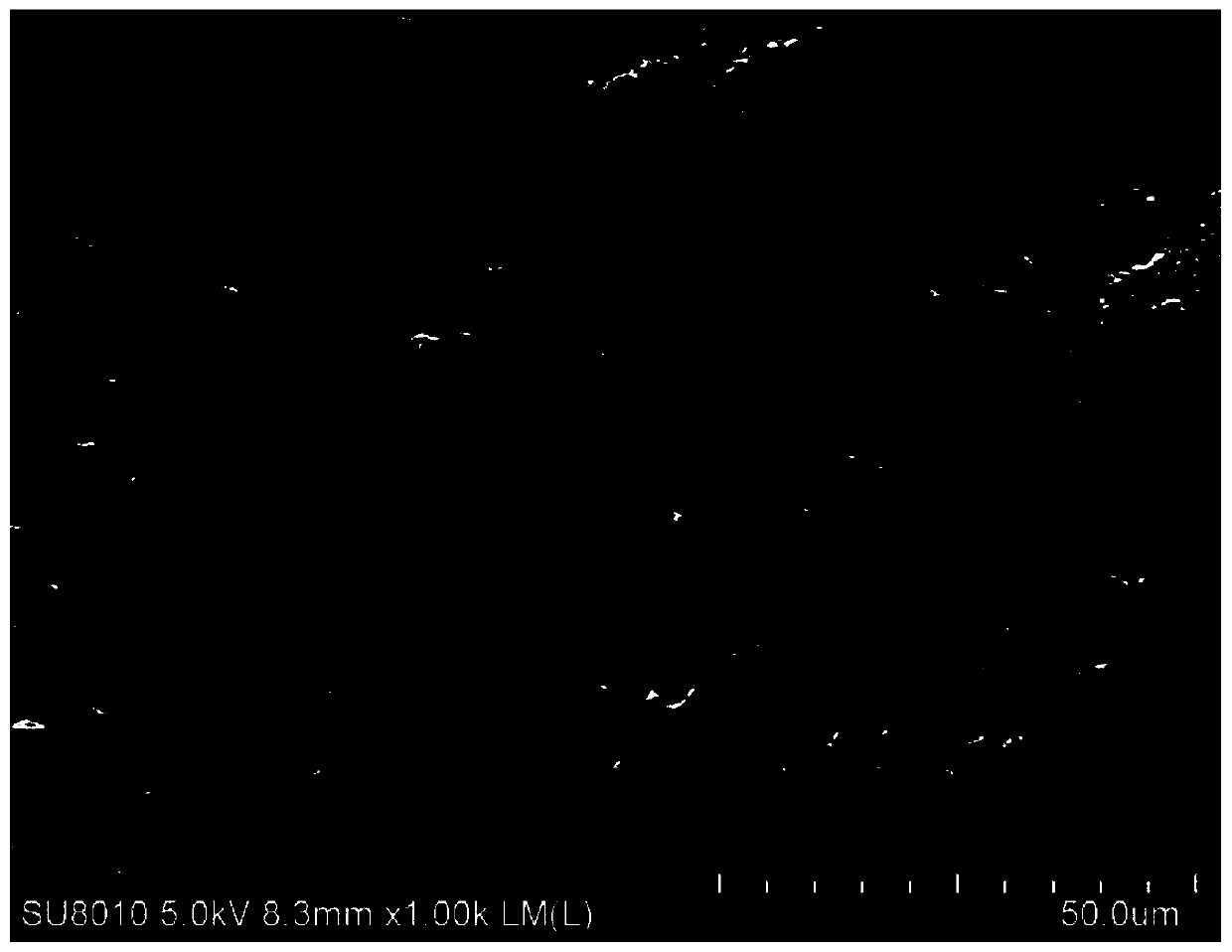

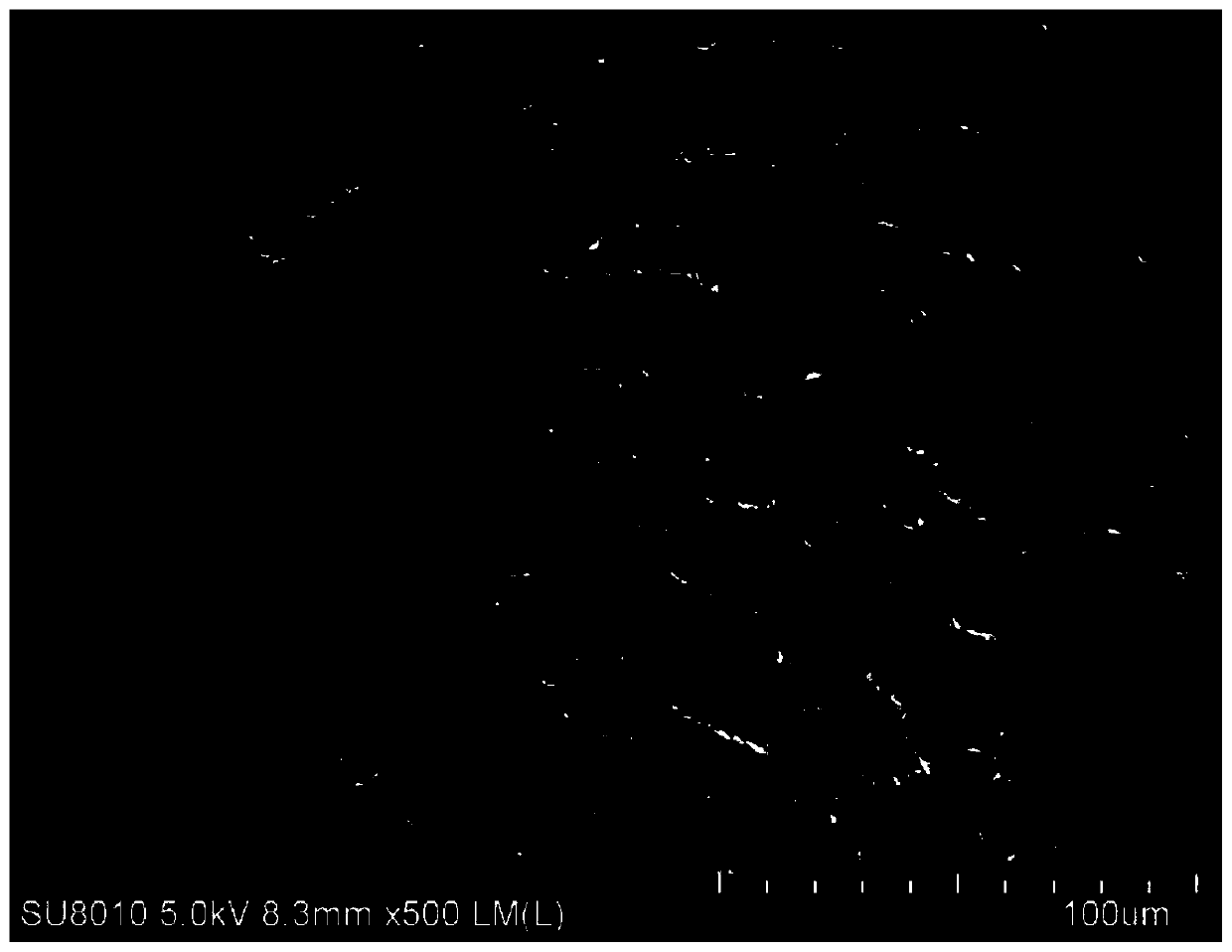

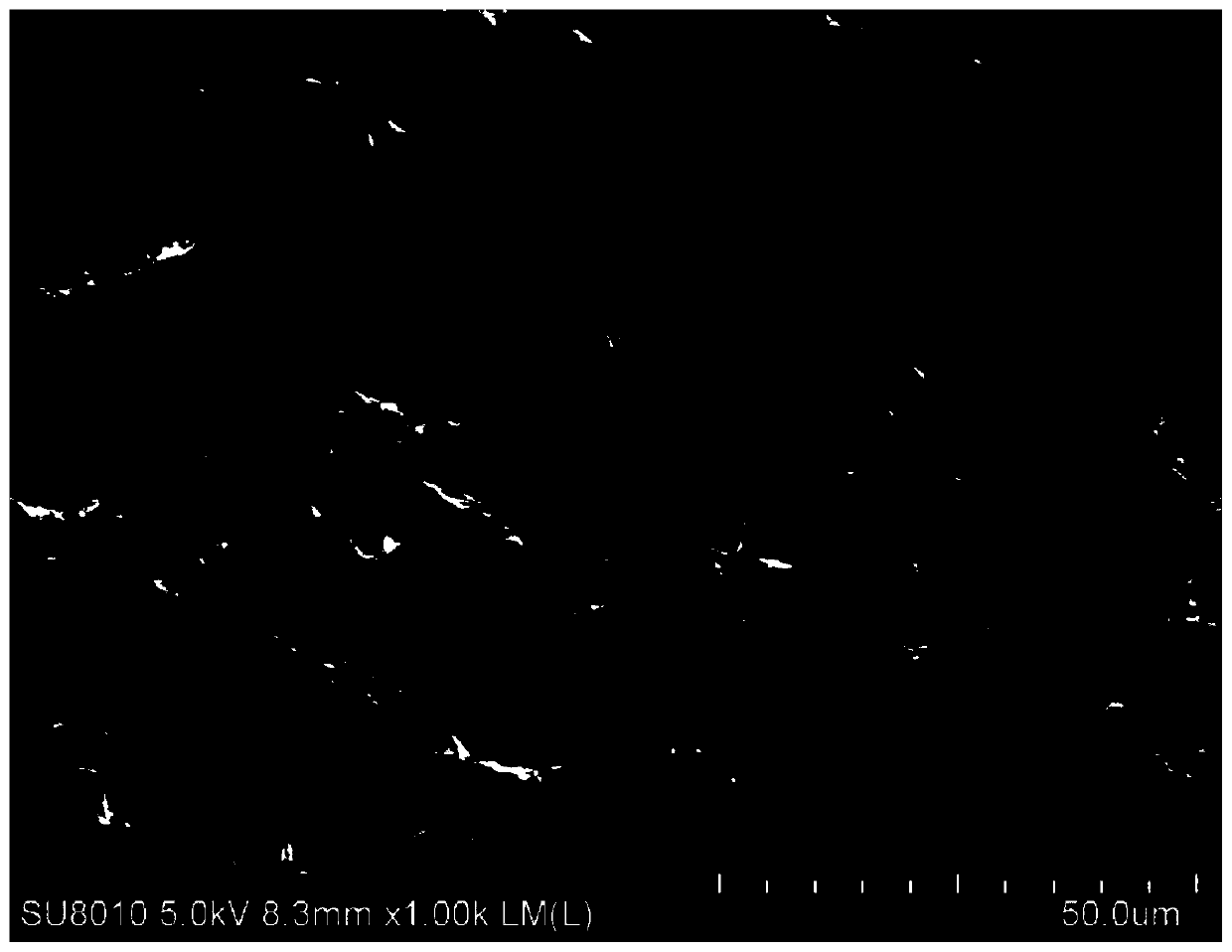

[0026] The invention provides a method for preparing a multi-scale layered flame retardant material, comprising the following steps: S1, preparing a layered flame retardant: ultrasonically dispersing a certain amount of graphene oxide in a solvent, and then adding graphene oxide dissolved thereto Add a certain amount of intumescent flame retardant to the solvent, continue ultrasonic dispersion, finally add water absorbent, stir and react to obtain a layered flame retardant; S2, prepare a multi-scale layered flame retardant material: the layer prepared in step S1 The multi-scale layered flame retardant material is prepared by mixing the shape flame retardant, a certain amount of intumescent flame retardant and a certain amount of polymer matrix in the injection molding machine under the specified injection molding process. The present invention utilizes the sheet structure of graphene oxide to disperse IFR between the sheets of graphene oxide with a certain concentration gradien...

Embodiment 1

[0037] This embodiment provides a method for preparing a multi-scale layered flame retardant material, which includes the following steps:

[0038] S1, preparation of layered flame retardant: Weigh 0.6g of graphene oxide and dissolve it in 0.3L of DMF solution, and disperse it ultrasonically for 30min at a temperature of 40°C; then add 1.156gIFR to the solution containing graphene oxide, and then ultrasonically Disperse for 30 minutes, and the ultrasonic temperature is still 40°C; after the mixing is completed, add 4.464g of DCC and react for 20 hours under magnetic stirrer stirring, then centrifuge, dry and grind to obtain a powdery layered flame retardant;

[0039] S2, preparation of multi-scale layered flame retardant materials: dry the polymer matrix and IFR in an electric constant temperature blast drying oven for 8h to 12h before weighing; then weigh 800g of polymer matrix and 200g of IFR and mix well in the bag , and add 3g of antioxidant, a little liquid paraffin and a...

Embodiment 2-5

[0046] The difference between the preparation method of Examples 2-5 and the preparation method of Example 1 is that the injection molding time of the injection molding process is different, and the injection molding times of Examples 2-5 are 3S, 5S, 10S, and 15S respectively.

[0047] Embodiments 2-5 also provide a multi-scale layered flame-retardant material, which is prepared by the preparation methods of Embodiments 2-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com