High-toughness flexible power cable for communication base station

A communication base station and flexible cable technology, which is applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems that the degree of softness cannot meet the expected requirements, the labor intensity of construction personnel is high, and the manufacturing cost of flexible cables is high. Effect of thermal stability, improvement of reliability and service life, effect of high carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

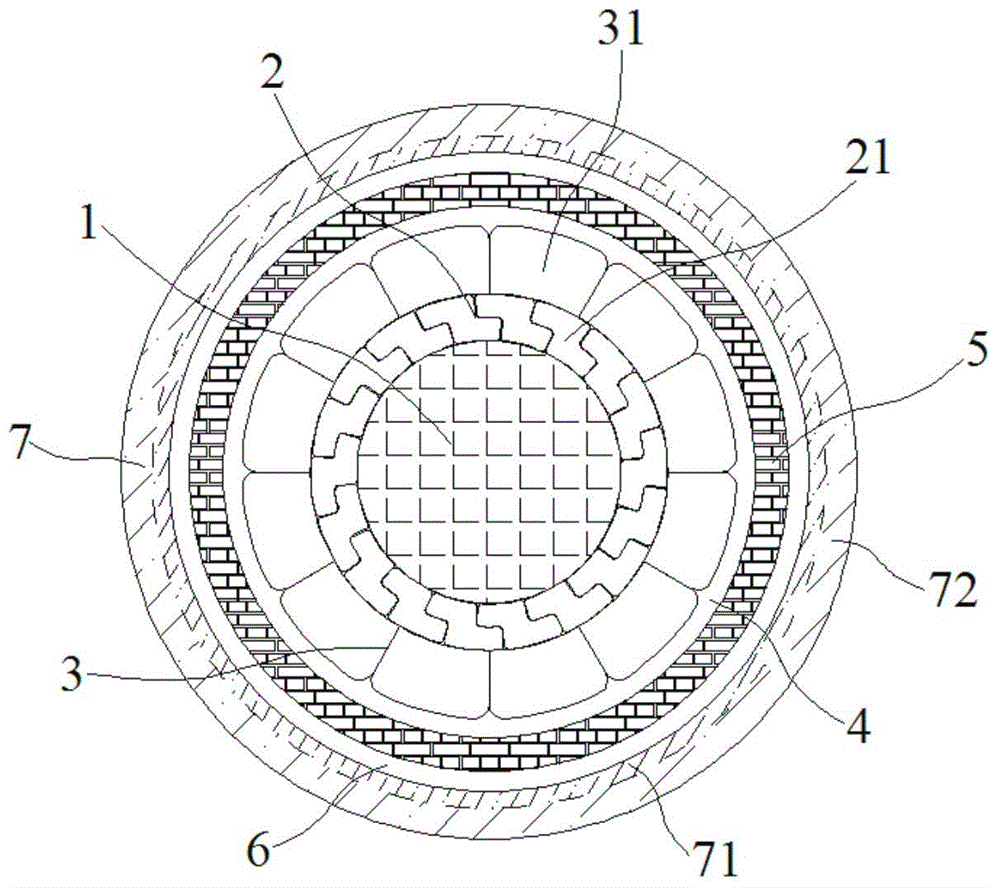

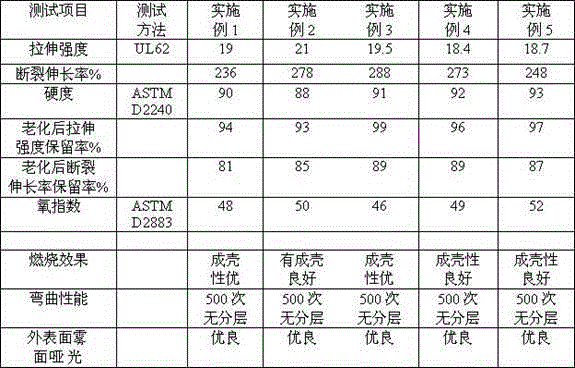

[0050] Embodiments 1 to 5: A flexible power cable with high toughness for communication base stations, including a circular aramid fiber core 1, the outer surface of the circular aramid fiber core 1 is twisted with several "Z"-shaped conductors 21, and several The "Z" shaped conductor 21 forms an inner conductive layer 2, and the outer surface of the inner conductive layer 2 is stranded with several trapezoidal conductors 31, and several trapezoidal conductors 31 form an outer conductive layer 3, a polyethylene insulating tape 4 wrapped around the outer surface of the outer conductive layer 3;

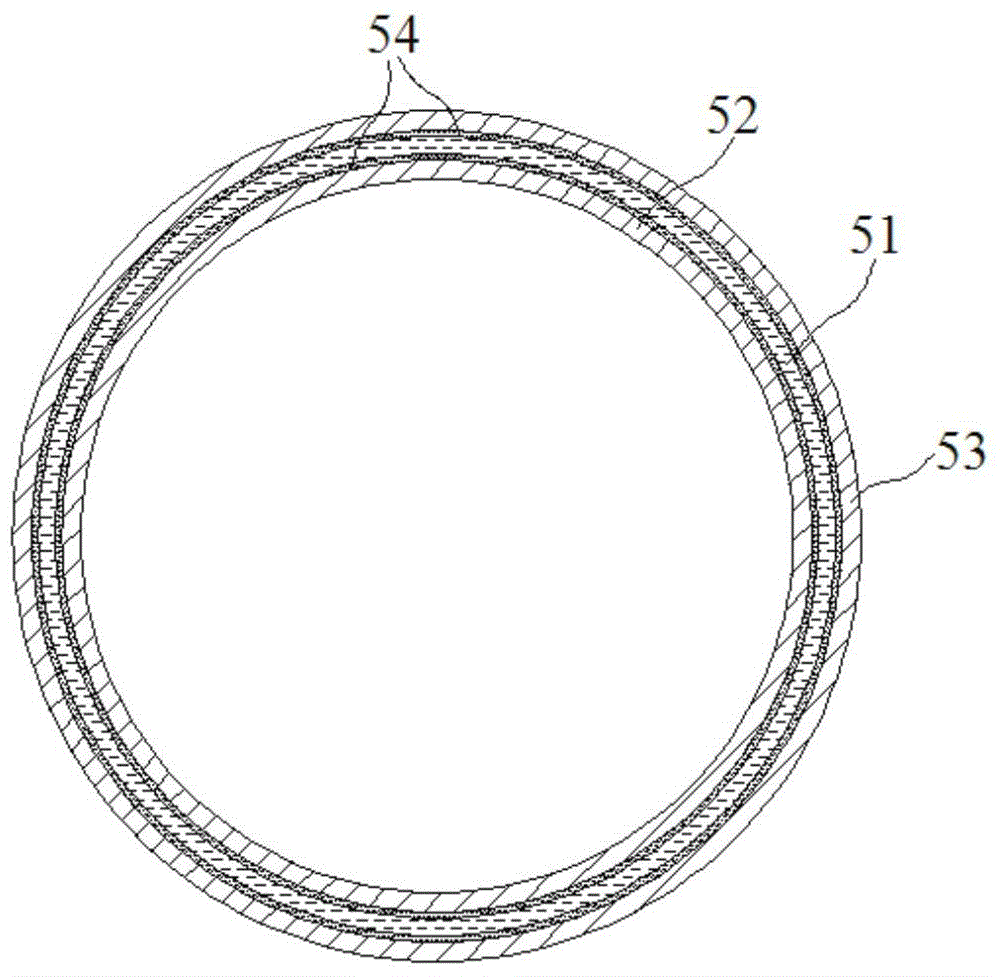

[0051] A fire-resistant and flame-retardant layer 5 is coated on the outer surface of the polyethylene insulating tape 4. The fire-resistant and flame-retardant layer 5 is composed of mica paper 51, a first glass fiber cloth 52 and a second glass fiber cloth 53. The mica paper 51 and the second glass fiber cloth The first glass fiber cloth 52 and the second glass fiber cloth 53 are bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com