High-strength expandable polystyrene filled resin and preparation method thereof

A technology of expandable polystyrene and filled resin, which can be used in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., and can solve problems such as low mechanical properties and flammability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

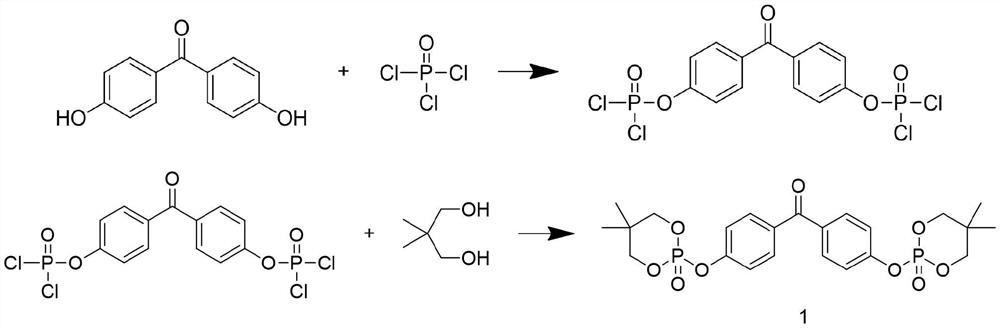

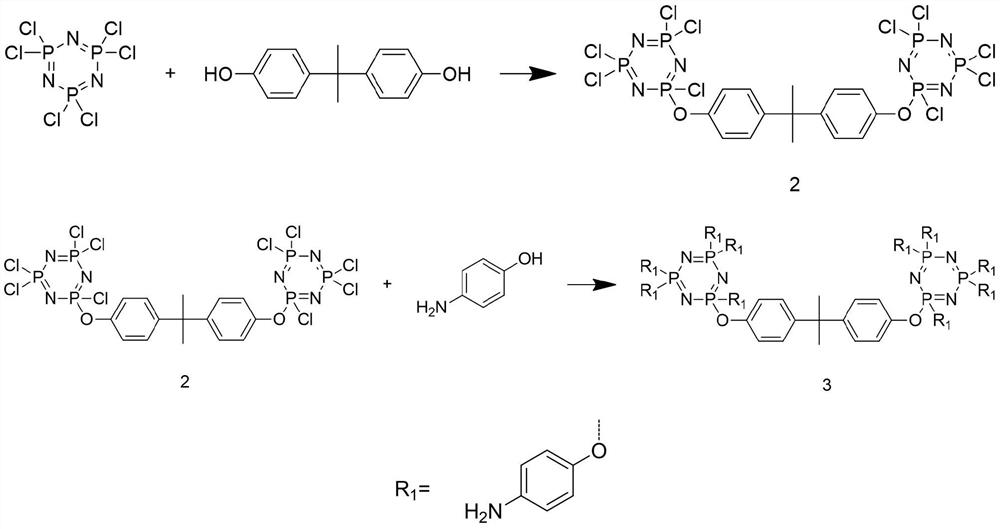

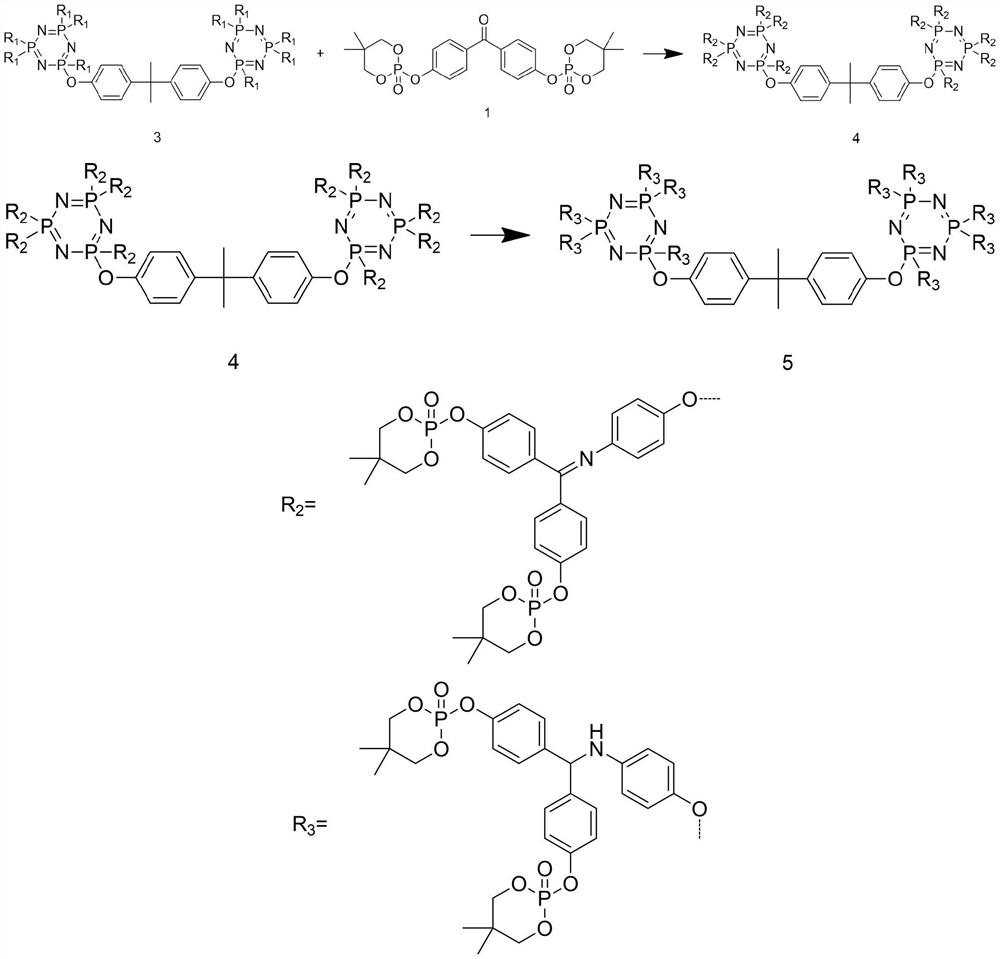

Method used

Image

Examples

Embodiment 1

[0039] A high-strength expandable polystyrene filled resin, comprising the following raw materials in parts by weight: 100 parts of modified polystyrene, 5 parts of flame retardant, 5 parts of calcium carbonate, 1 part of dibutyltin dilaurate, stearic acid Calcium 0.1 part;

[0040] The expandable polystyrene filled resin is made by the following steps:

[0041] The above-mentioned raw materials were weighed, mixed evenly, and foamed at a temperature of 120° C. and a pressure of 0.3 MPa to obtain an expandable polystyrene filled resin by molding.

[0042] Modified polystyrene is made by the following steps:

[0043] Step A1: Add concentrated sulfuric acid into the reaction kettle, stir at a speed of 150r / min and a temperature of 1°C, add graphite and sodium nitrate, stir for 30min, add potassium permanganate, continue stirring for 2h, and heat up to The temperature is 30°C, continue to stir for 30 minutes, add deionized water, raise the temperature to 95°C, stir for 15 minut...

Embodiment 2

[0052] A high-strength expandable polystyrene filled resin, comprising the following raw materials in parts by weight: 110 parts of modified polystyrene, 10 parts of flame retardant, 6 parts of magnesium carbonate, 1.3 parts of dibutyltin dimaleate, 0.2 parts of paraffin wax share;

[0053] The expandable polystyrene filled resin is made by the following steps:

[0054] The above raw materials were weighed, mixed evenly, and foamed at a temperature of 130° C. and a pressure of 0.4 MPa to obtain an expandable polystyrene filled resin by molding.

[0055] Modified polystyrene is made by the following steps:

[0056] Step A1: Add concentrated sulfuric acid into the reaction kettle, stir at a speed of 180r / min and a temperature of 2°C, add graphite and sodium nitrate, stir for 35min, add potassium permanganate, continue stirring for 2.5h, and heat up Continue stirring for 35 minutes until the temperature is 35°C, add deionized water, raise the temperature to 96°C, stir for 18 mi...

Embodiment 3

[0065] A high-strength expandable polystyrene filled resin, comprising the following raw materials in parts by weight: 120 parts of modified polystyrene, 15 parts of flame retardant, 8 parts of sodium bicarbonate, 1.5 parts of zinc stearate, stearic acid 0.3 part of glyceride;

[0066] The expandable polystyrene filled resin is made by the following steps:

[0067]The above-mentioned raw materials were weighed, mixed evenly, and foamed at a temperature of 140° C. and a pressure of 0.5 MPa to obtain an expandable polystyrene filled resin by molding.

[0068] Modified polystyrene is made by the following steps:

[0069] Step A1: Add concentrated sulfuric acid into the reaction kettle, stir at a speed of 200r / min and a temperature of 4°C, add graphite and sodium nitrate, stir for 40min, add potassium permanganate, continue stirring for 3h, and heat up to The temperature is 40°C, continue to stir for 40 minutes, add deionized water, raise the temperature to 98°C, stir for 20 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com