Large separable combined jaw crusher frame

A jaw crusher, combined technology, applied in the field of mechanical equipment manufacturing, can solve problems such as weak structure, large safety accidents, easy to be swelled, etc., to achieve the effect of solid and reliable frame, convenient maintenance, and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

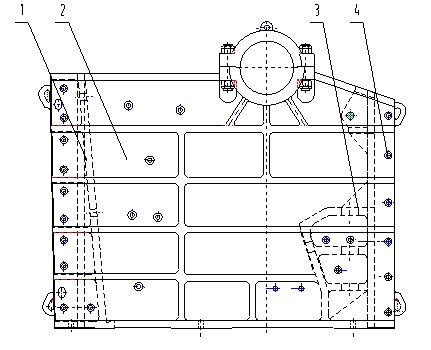

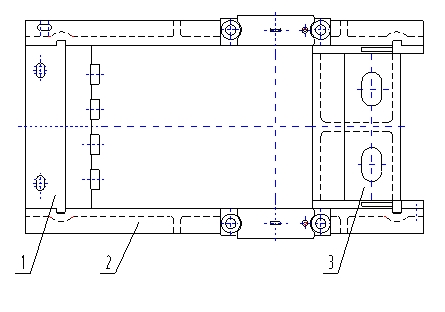

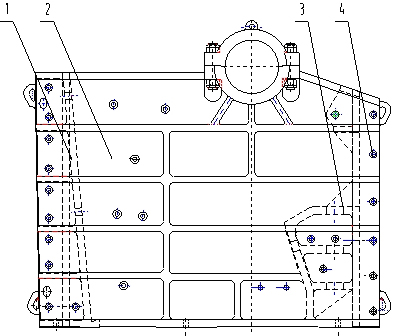

[0009] like figure 1 , figure 2 As shown, the present invention comprises front box body 1, frame side plate 2, rear box body 3, high-strength hinged hole bolt 4, and described frame side plate 2 inner side all is provided with wide groove front and rear, front box body, back box Bosses are arranged on both sides of the body, and the bosses correspond to the shape of the wide groove; the bosses are installed in the wide grooves of the side plate 2 of the frame; 1. The frame side plate 2 and the rear box body 3 are joined together by the high-strength reaming bolt 4. With such a structure, the front and rear positioning cannot be moved, and the whole frame is combined into a solid whole.

[0010] In order to achieve better technical effect, the cross-section of the wide groove is rectangular, and the shape of the boss is also rectangular; the cross-section of the wide groove can also be dovetail-shaped, and the shape of the boss is correspondingly dovetail-shaped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com