Magnetic powder detection method for large cast valve

A magnetic particle detection and valve technology, which is applied in the direction of material magnetic variable, can solve problems such as valve body leakage, achieve the effects of prolonging service life, ensuring sensitivity, and enhancing contrast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

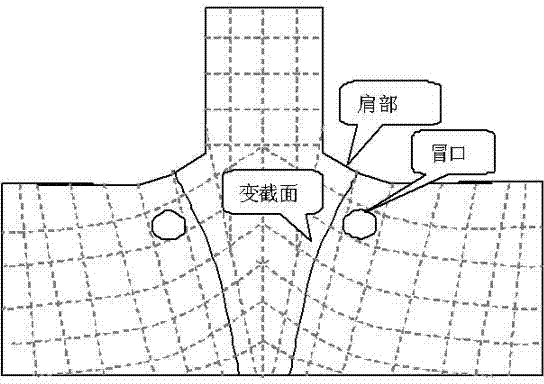

Image

Examples

Embodiment Construction

[0046] The following is the process of a specific embodiment of the present invention:

[0047] 1. Treat the surface of the valve body. Within the scope of magnetic particle testing, all rust, splashes and oxide skins that affect the detection should be removed to expose the metallic luster on the surface.

[0048] 2. Spray the contrast enhancer evenly on the surface of the valve body. Use the field contrast enhancer heating box to heat the contrast enhancer to the set temperature before spraying.

[0049] 3. Verify that the device is within the validity period of the calibration.

[0050] 4. Configure the magnetic suspension, the concentration of the magnetic suspension is in the range of 10-25g / L.

[0051] 5. Will A 1 The -30 / 100 sensitivity test piece is fixed at the detected place by a standard test piece fixing device, and the comprehensive performance of the detection system is evaluated to confirm that there are magnetic marks gathered on the back of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com