Electrified spanning construction method for high-voltage line

A technology of high-voltage lines and construction methods, applied to overhead lines/cable equipment and other directions, can solve problems such as insufficient safety factor, complex mountain terrain, and indeterminate crossing time, so as to avoid conductors from falling, protect the lines being crossed, and ensure equipment and safety. The effect of construction safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] The construction method for live crossing of high-voltage lines of the present invention comprises the following steps:

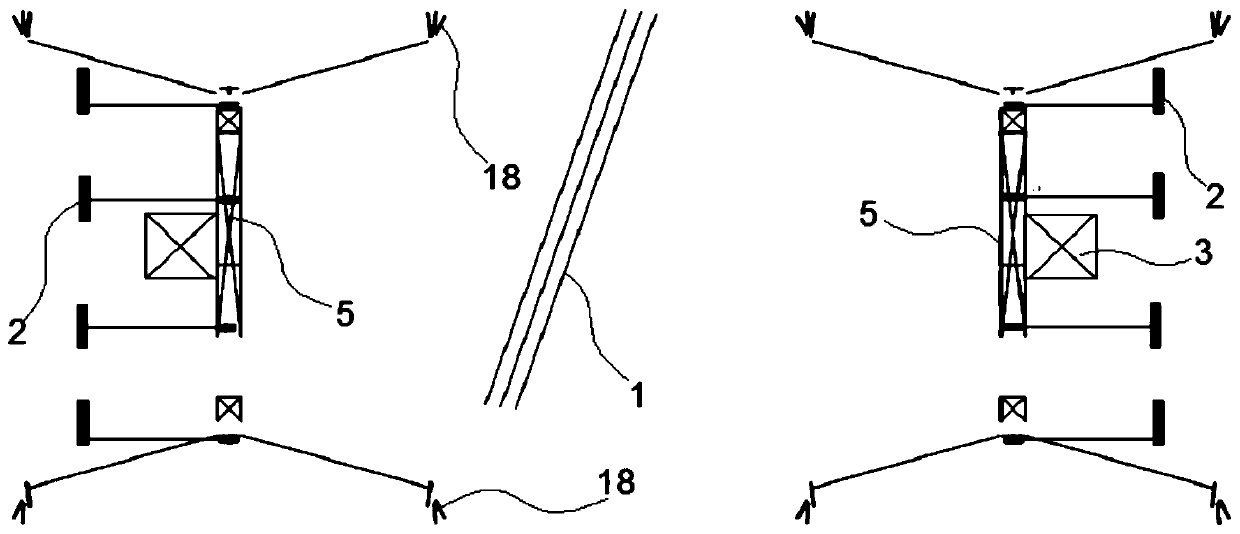

[0033] A. If figure 1 As shown, ground anchors 2 are buried on both sides of the spanned line 1. The depth of ground anchors 2 is 2.5m. When excavating, check whether there are underground pipelines and optical cable facilities nearby, and take effective avoidance measures.

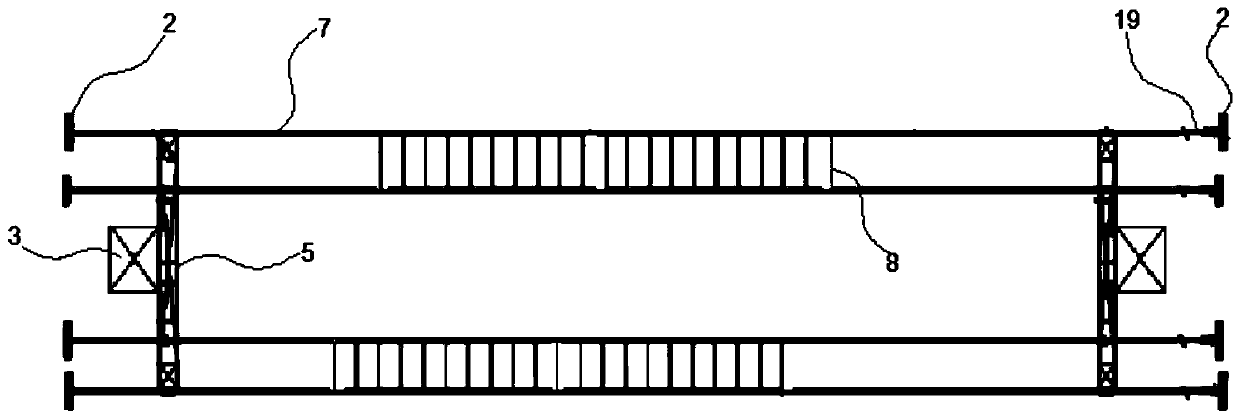

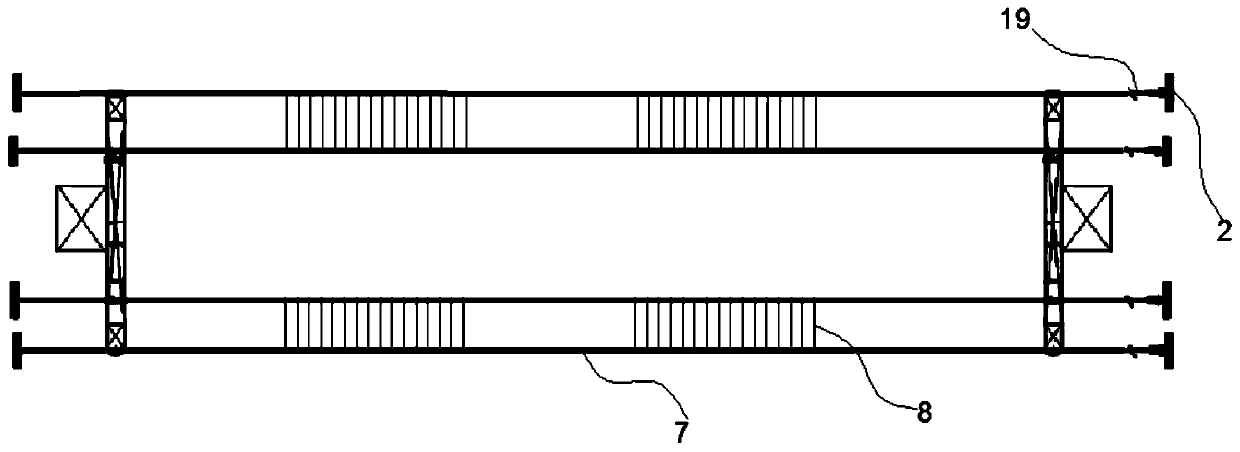

[0034] B. Using the iron tower 3 of the high-voltage line as a spanning frame, there is no need to build another spanning frame, which reduces the construction amount and saves construction costs. Below the wire cross arm 4 of the iron tower 3, a horizontal holding pole 5 is arranged, the length of the holding pole 5 is greater than the wire cross arm 4 of the iron tower 3, and the two ends of the holding pole 5 exceed the two ends of the wire cross arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com