Non phase separation type traction power supply equipment for railway locomotive

A technology for traction power supply and railway locomotives, applied in power lines, vehicle components, transportation and packaging, etc., can solve the problem of large negative sequence current value and grid harmonic content, small distance between traction substations, and impossible three-phase balance Power supply and other issues, to achieve the effect of less harmonic content, improve utilization efficiency, and improve power supply quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

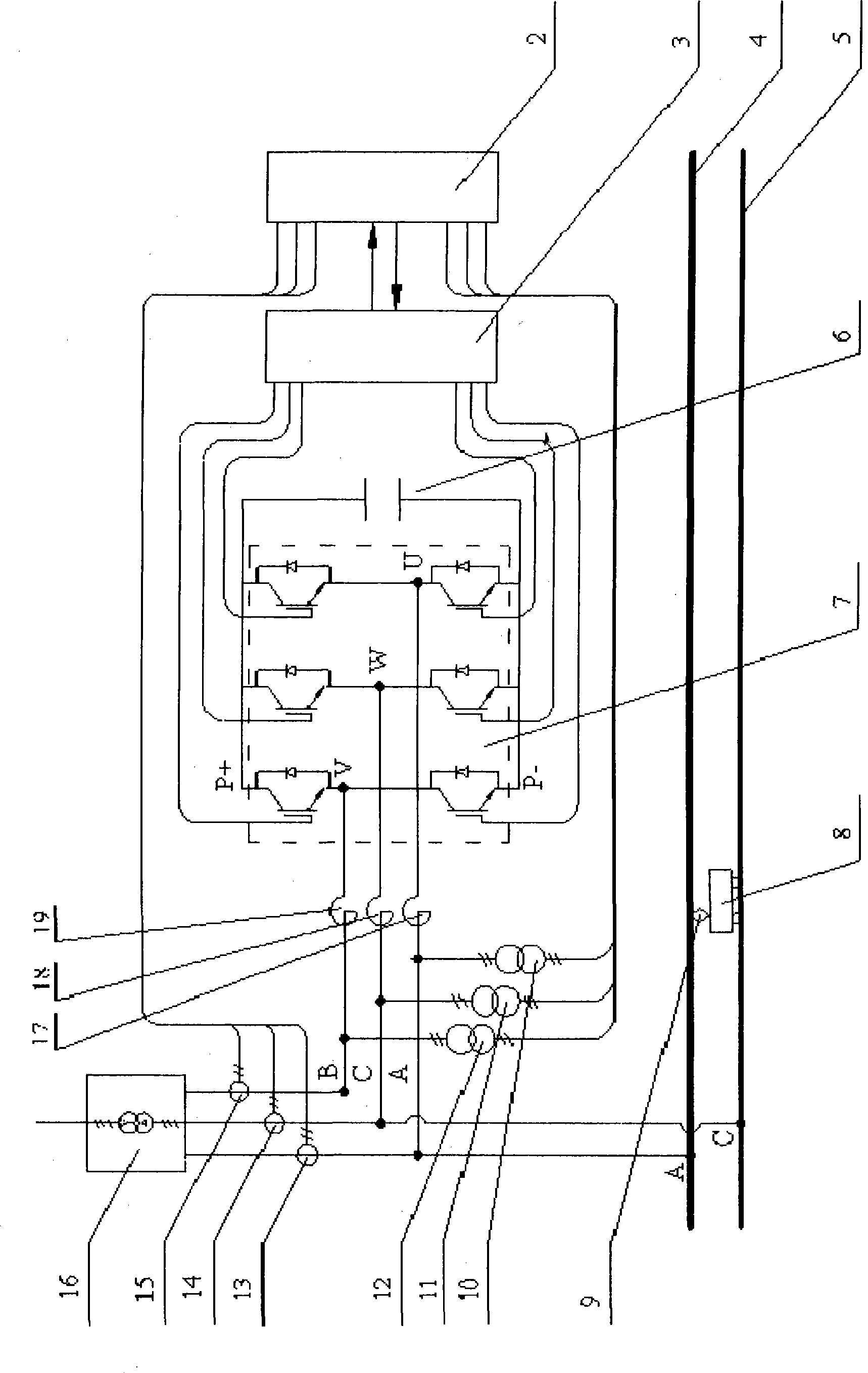

[0008] Attached below figure 1 The present invention is described in detail.

[0009] see figure 1 , the non-phase-splitting traction power supply device for the railway locomotive is composed of a traction transformer and an energy distribution regulator, the A phase of the output end of the traction transformer 16 is connected to the traction catenary 4, the C phase is connected to the rail 5, and the B phase is connected to the energy distribution Regulator, the energy distribution regulator consists of a main controller 2, a driver 3, three current sensors 13, 14, 15, three voltage sensors 10, 11, 12, three reactors 17, 18, 19, power The electronic switch bridge arm 7 and the supporting capacitor arm 6 are composed, wherein the power electronic switch bridge arm 7 is connected in parallel with the supporting capacitor arm 6, and the driver 3 is connected between the control terminal of the power electronic switch bridge arm 7 and the main Between the controllers 2, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com