Elongation automatic testing apparatus and testing method of stretcher

An automatic test device, elongation technology, applied in the direction of measuring device, using stable tension/pressure to test the strength of materials, instruments, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

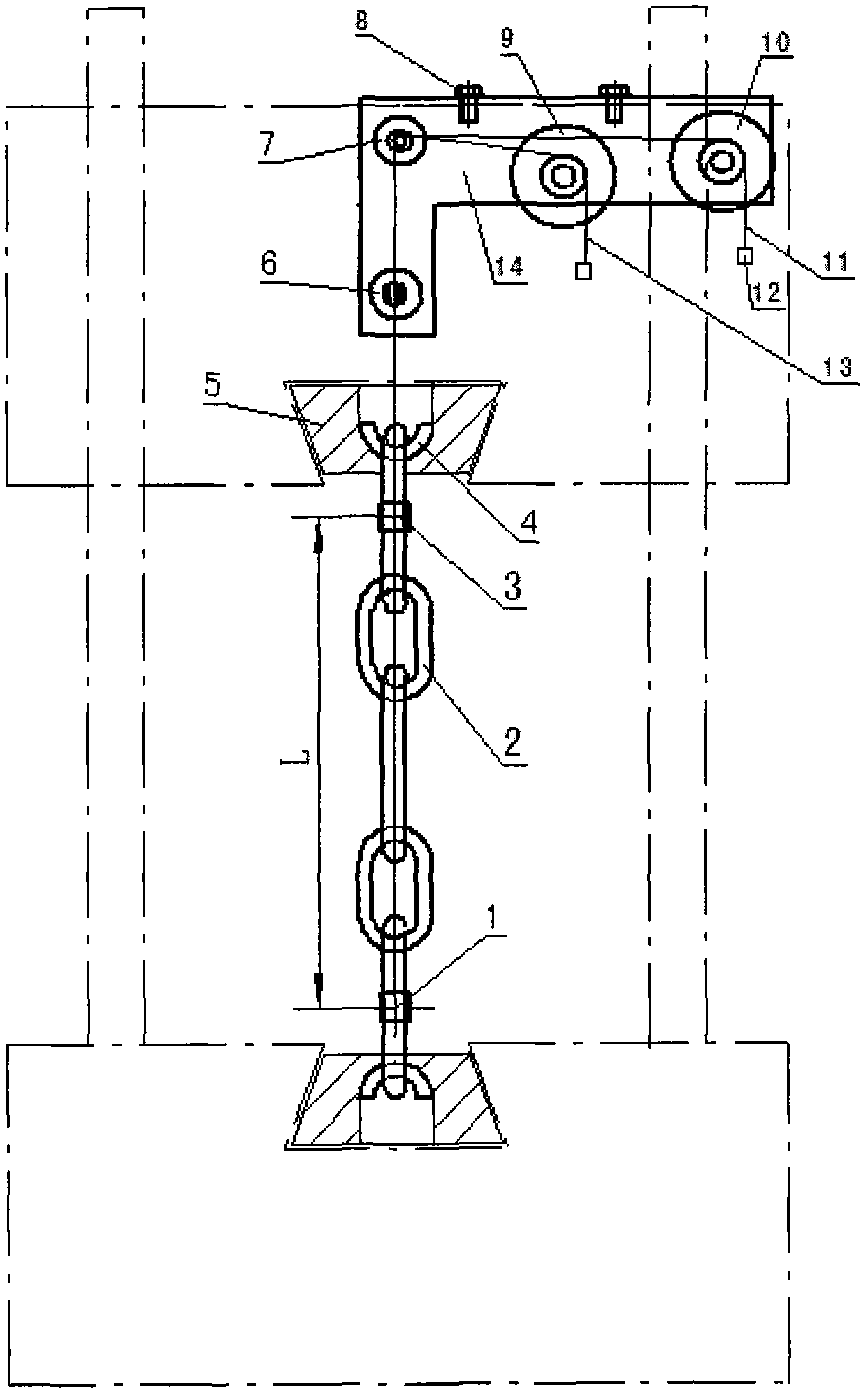

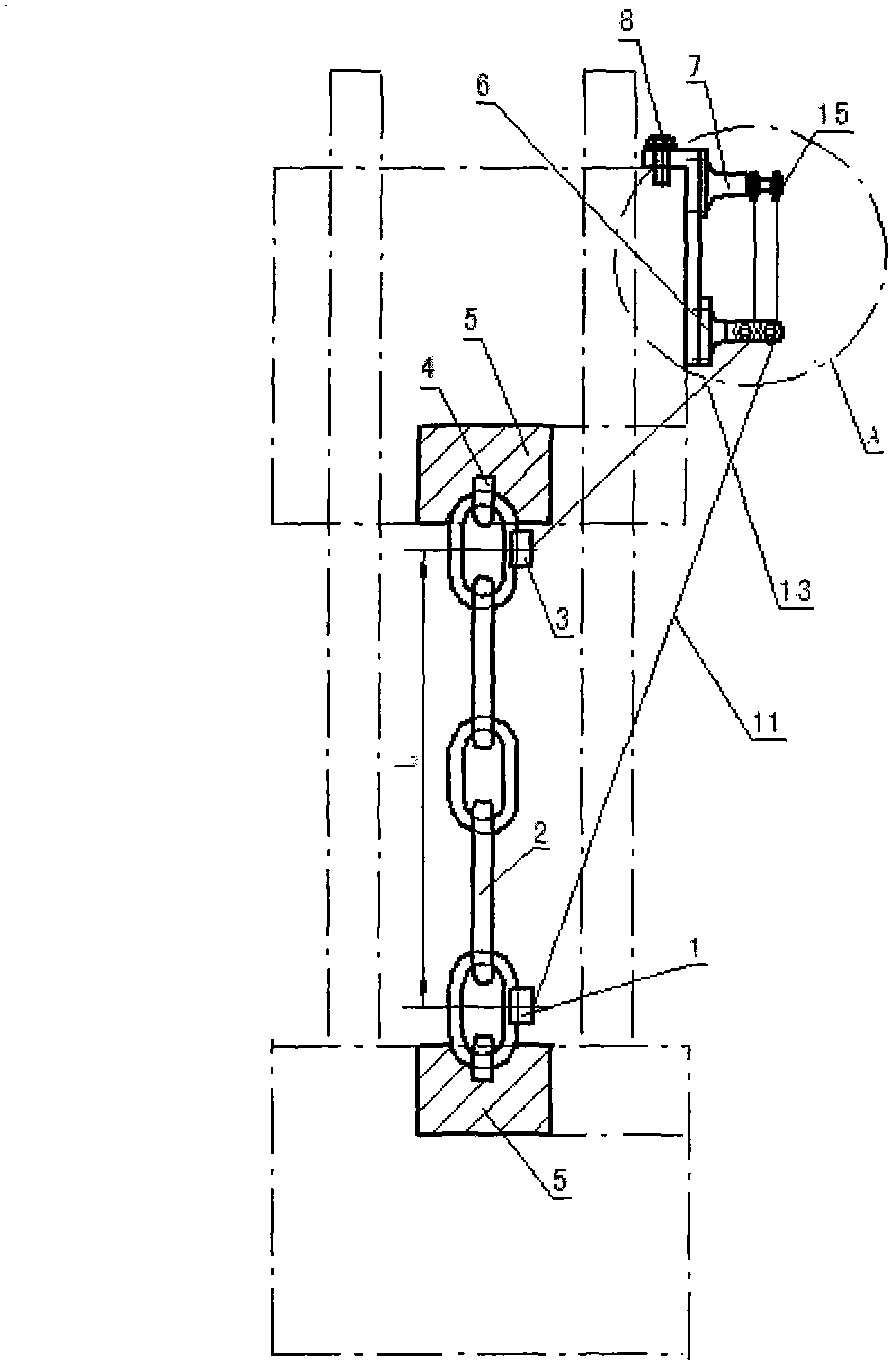

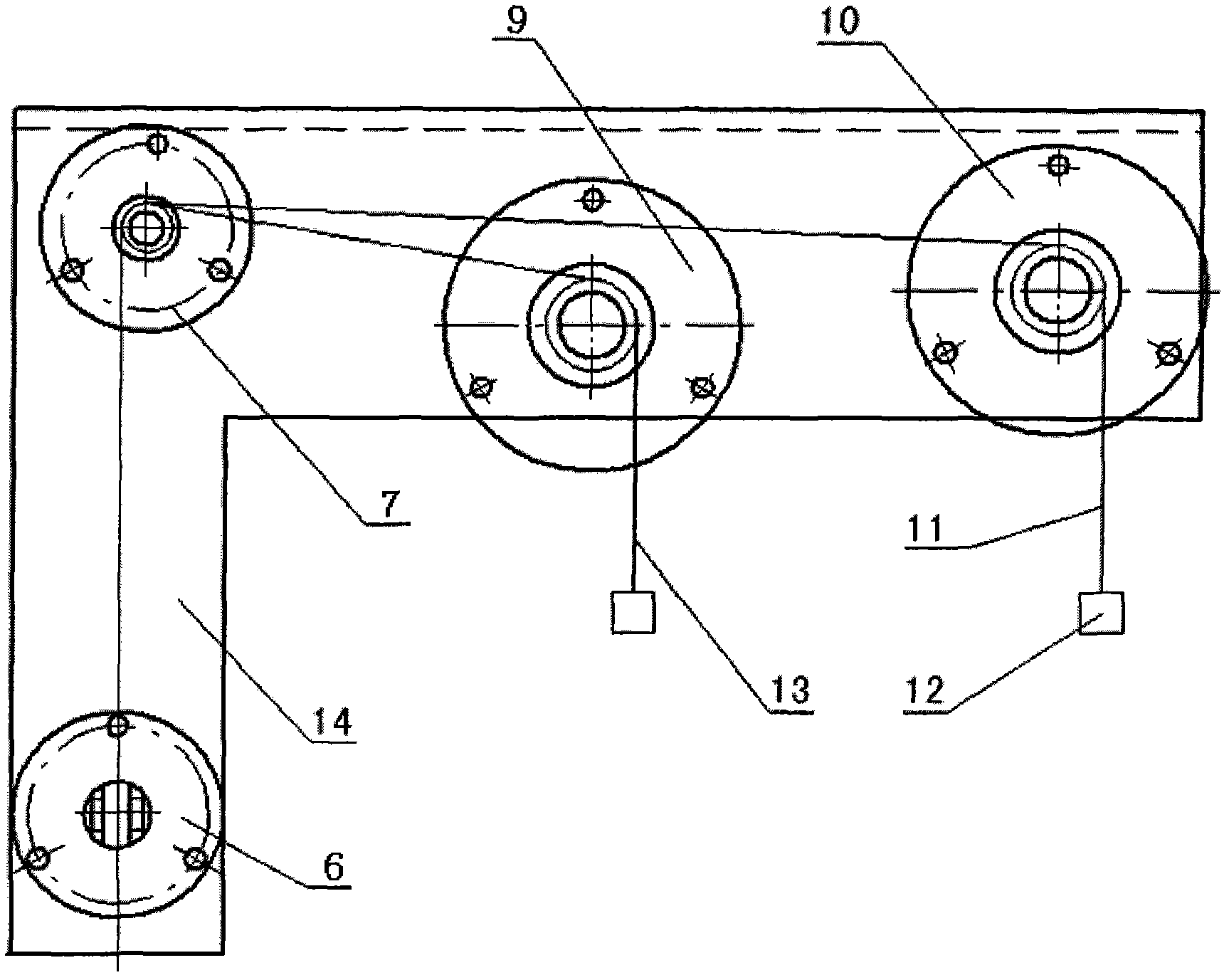

[0023] Depend on Figure 1-6 It can be seen that the automatic test device for elongation of the stretching machine consists of strong magnet suction seats A and B, test sample 2, semicircular pin 4, trapezoidal block 5, guide wheel bracket 6, steering wheel bracket 7, bolt 8, displacement sensors A and B , stay cord A and B, weight 12, right angle frame 14 and nylon wheel A15, nylon wheel B15, nylon wheel C15, nylon wheel D15 constitute.

[0024] The test sample 2 is loaded into the trapezoidal groove of the tensile testing machine with the trapezoidal block 5 and the semicircular pin 4, and the centers of the strong magnet suction seats A and B are placed at two points above and below the test gauge length L of the test sample 2.

[0025] The bottom of guide wheel support 6 is fixed on the lower end position of right angle frame 14 vertical frames with screw, and the upper end of guide wheel support 6 has through groove, is provided with two holes side by side with through g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com