Four-head mouth-bonding unit for film-lined pouches

A technology of lining film and bonding device, which is applied in the direction of device and coating for coating liquid on the surface, which can solve the problems of inability to control the needle head, the adhesion of the bag mouth, and affecting the filling operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

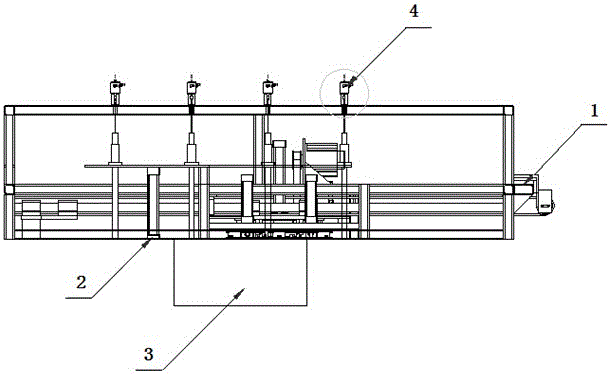

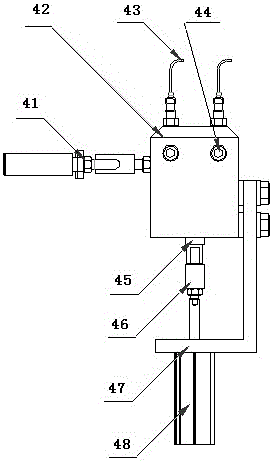

[0016] A four-nozzle mouth bonding device for a film-lined packaging bag, including a lateral movement mechanism 1, a longitudinal movement mechanism 2, a hot-melt glue sprayer 3 and a nozzle mechanism 4, such as figure 1 , the lateral movement mechanism 1 includes a servo motor, a synchronous belt pulley group, and a frame bracket. The frame body bracket is provided with a nozzle mechanism 4. The servo motor drives the frame body bracket through the synchronous pulley group, and the lateral movement mechanism 1 drives the nozzle mechanism 4 to move laterally. The distance is the length of the glue path required by the mouth of the bag; the longitudinal movement mechanism 2 includes a longitudinal cylinder, the base of the longitudinal cylinder is connected to the frame support, and the longitudinal movement mechanism 2 is stretched and stretched by the longitudinal cylinder to complete the nozzle mechanism 4 longitudinally extending into the mouth of the bag or exiting Pocket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com