Over-inflation protecting apparatus

A technology of protection devices and components, applied in valve devices, valve operation/release devices, packaging, etc., can solve problems such as inability to accurately control filling volume, poor conversion accuracy, poor sealing effect, etc., and achieve simple structure and extreme conversion The effect of accurate position and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Drawing No.:

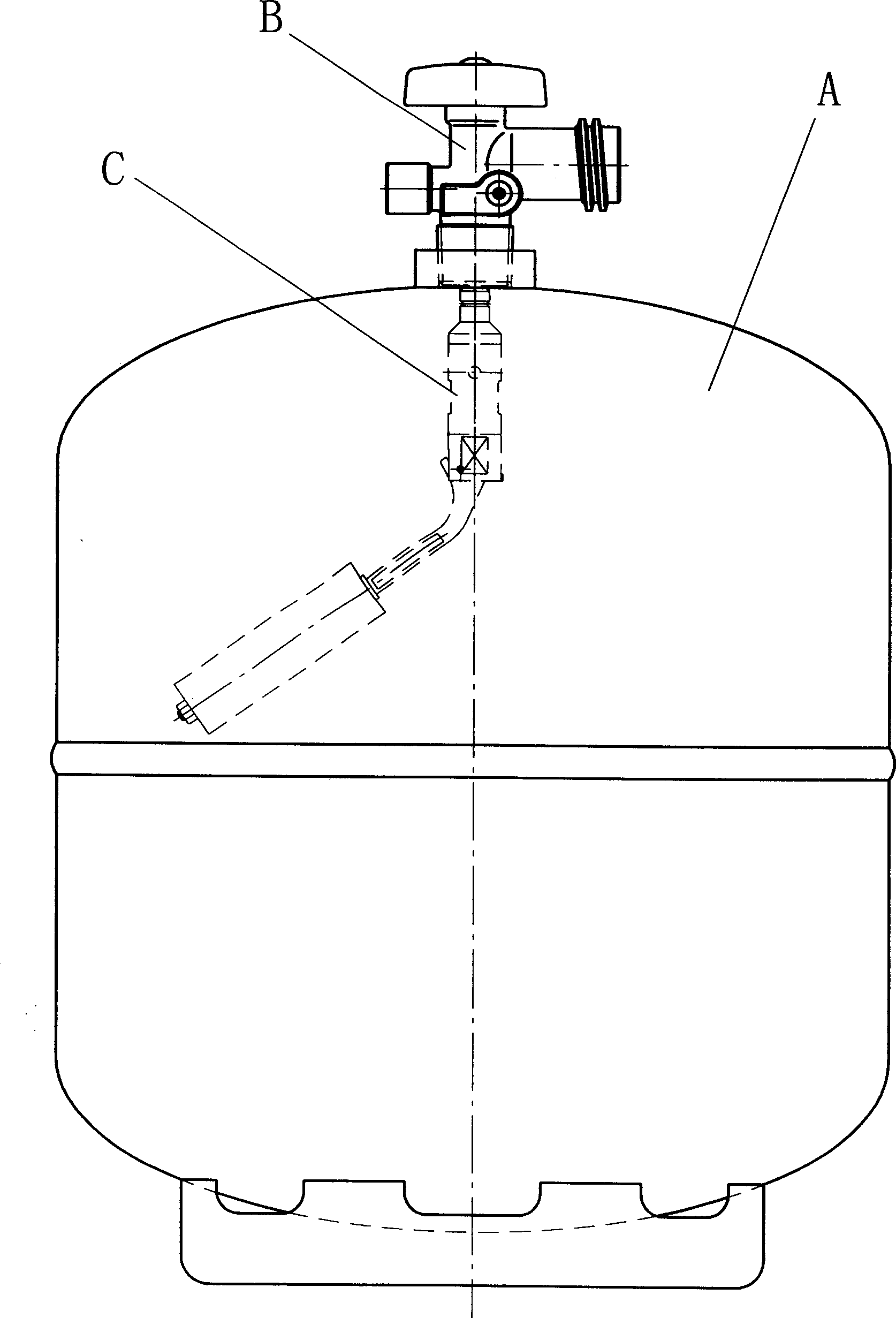

[0055] A. Steel cylinder B. Cylinder valve C. Overfill protection device

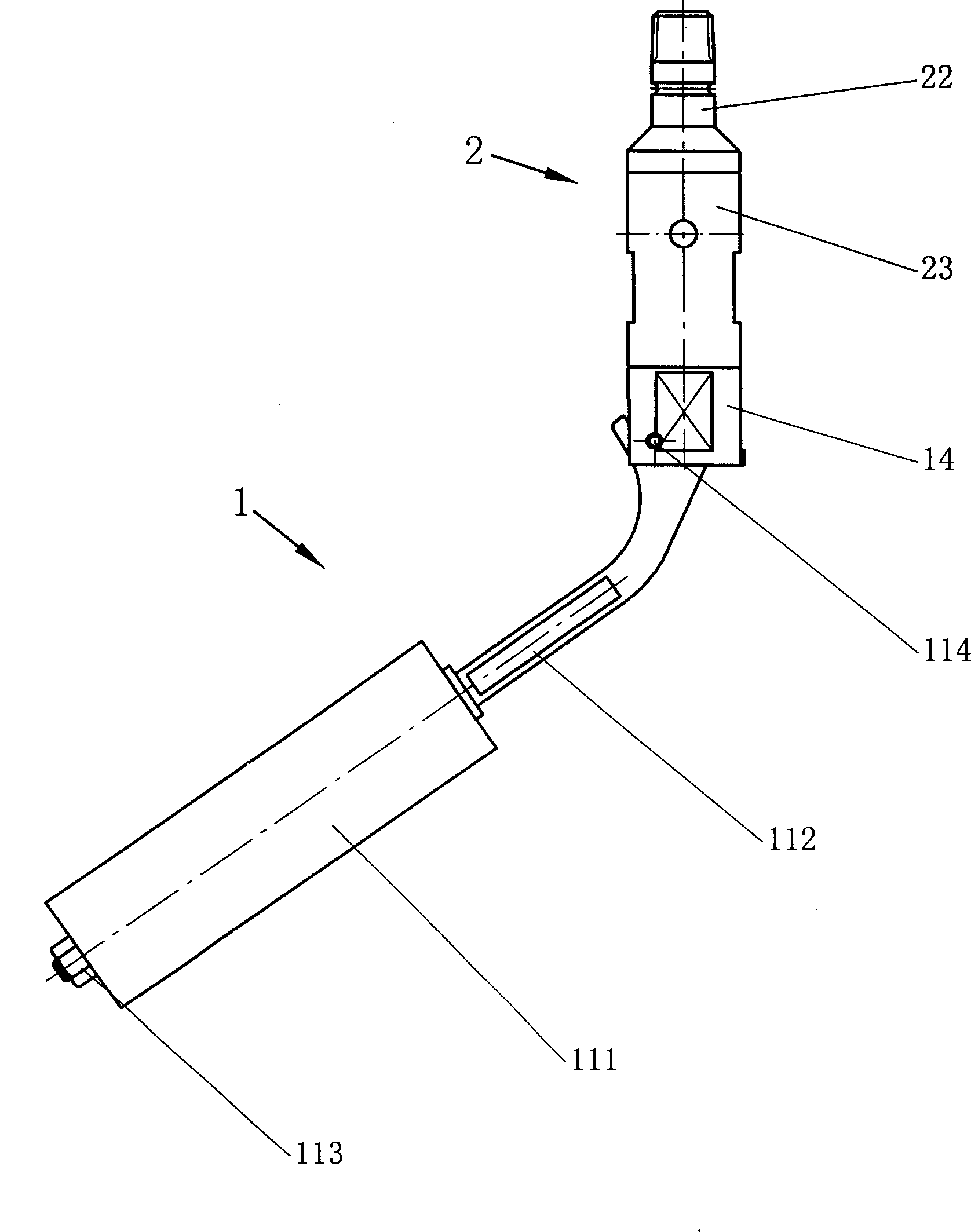

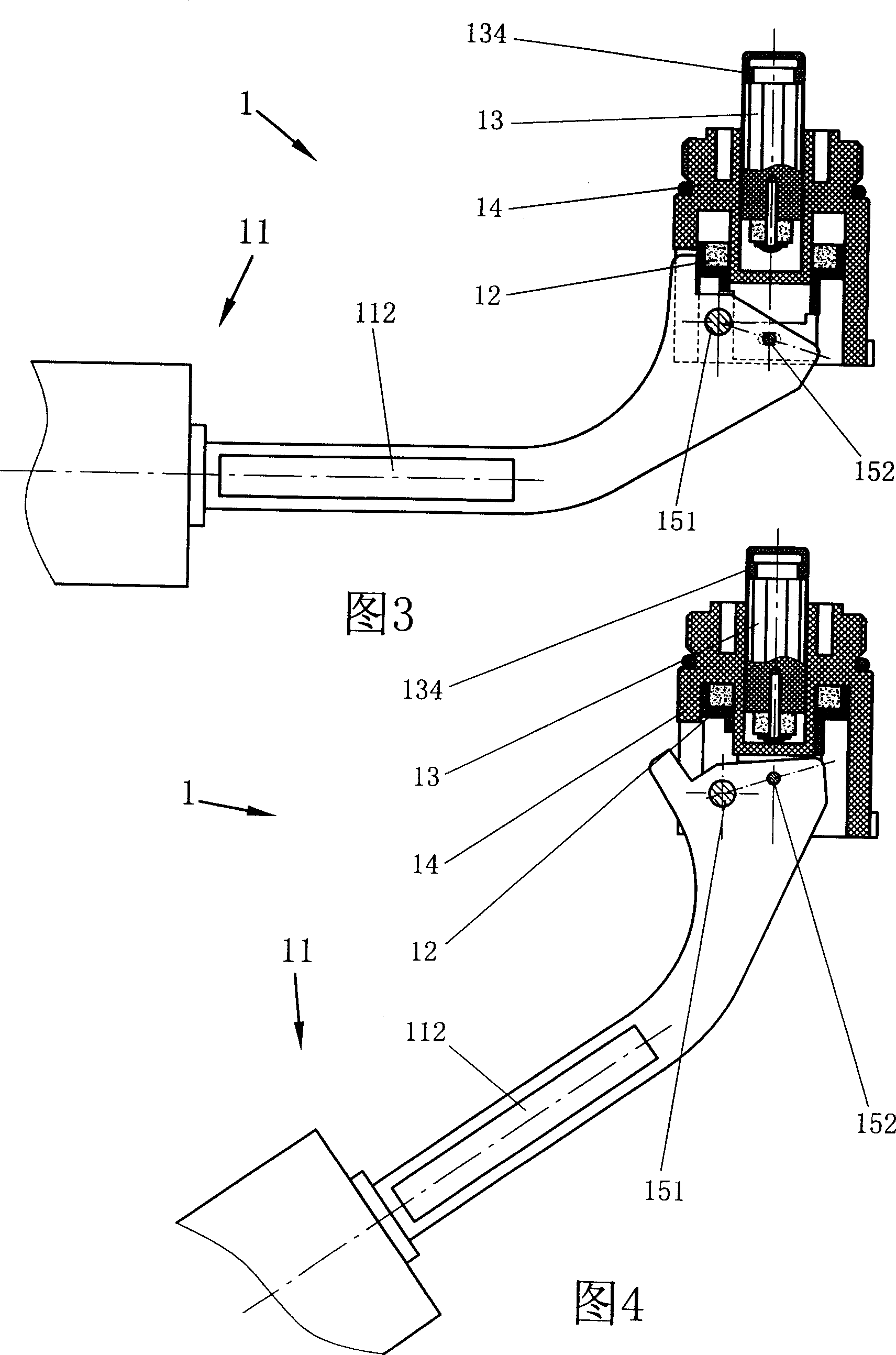

[0056] 1. State component

[0057] 11. Float parts

[0058] 111. Float 112. Connecting rod 113. Nut

[0059] 114. Large hole 115. Small hole

[0060] 116. Block

[0061] 12. Magnetic ring sleeve (component)

[0062] 121. Magnetic ring 122. Magnetic ring seat

[0063] 13. Spool (component)

[0064] 131. Screw 132. Magnetic 133. Spool stem

[0065] 134. Spool pad

[0066] 14. Lower part

[0067] 141. Lower end cover 142. O-ring 143. Round hole with bottom

[0068] 144. Ring groove

[0069] 151. Shaft 152. Pin shaft

[0070] 2. Opening and closing components

[0071] 21. Piston (component)

[0072] 211. Piston body 212. (Bowl-shaped) piston gasket 213. Y-shaped sealing ring

[0073] d1. Valve port hole

[0074] d2. Radial hole

[0075] 22. Upper end cap D1. Inlet hole

[0076] 23. Barrel

[0077] D2. Axial hole (inflow hole)

[0078] D3. (with top) valve hole (chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com