Double-lumen tube connector, preparation thereof and using method

A technology for connection devices and lumen tubes, which is applied in the field of double-cavity tube connection devices, can solve the problems that pipe joints cannot be sealed by pipelines, and cannot meet the functions of sealing, fastening and sealing, and achieve simple structure and improved torsion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Superelastic double-lumen tube connection device and method for making and using the same

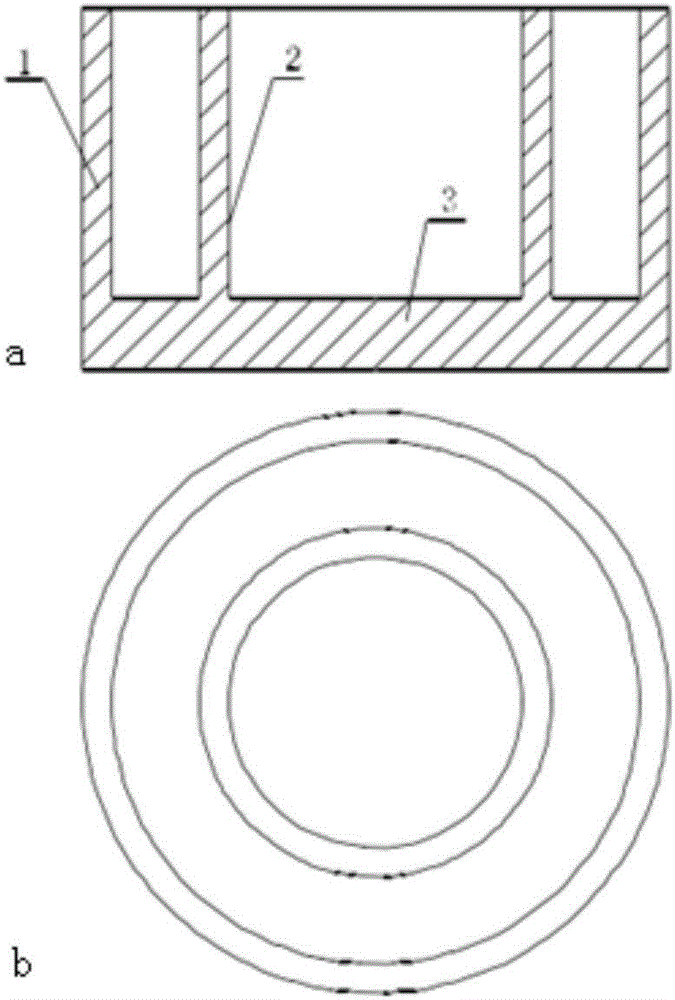

[0031] The structure of the memory alloy double-cavity tube connection device is mainly composed of an outer ring 1, an inner ring 2, and a bottom ring 3, which is an integral structure, see the attached figure 1 a-b; Internal unsupported rib structure. The outer ring 1 has memory performance, can produce diameter shrinkage, and produces ring fastening to the connected pipe 7, and the inner ring 2 has superelasticity, and relies on the elastic support contact of the inner ring 2 pipe wall to realize the fastening contact connection and realize Pipeline connection and blockage to improve airtightness.

[0032] The memory alloy of the double-cavity tube connection device adopts NiTi alloy, and the outer ring 1 of the double-cavity tube connection device is expanded from a diameter of 20mm to 10% in advance in a martensitic state, and the plastic deformation will increase the marte...

Embodiment 2

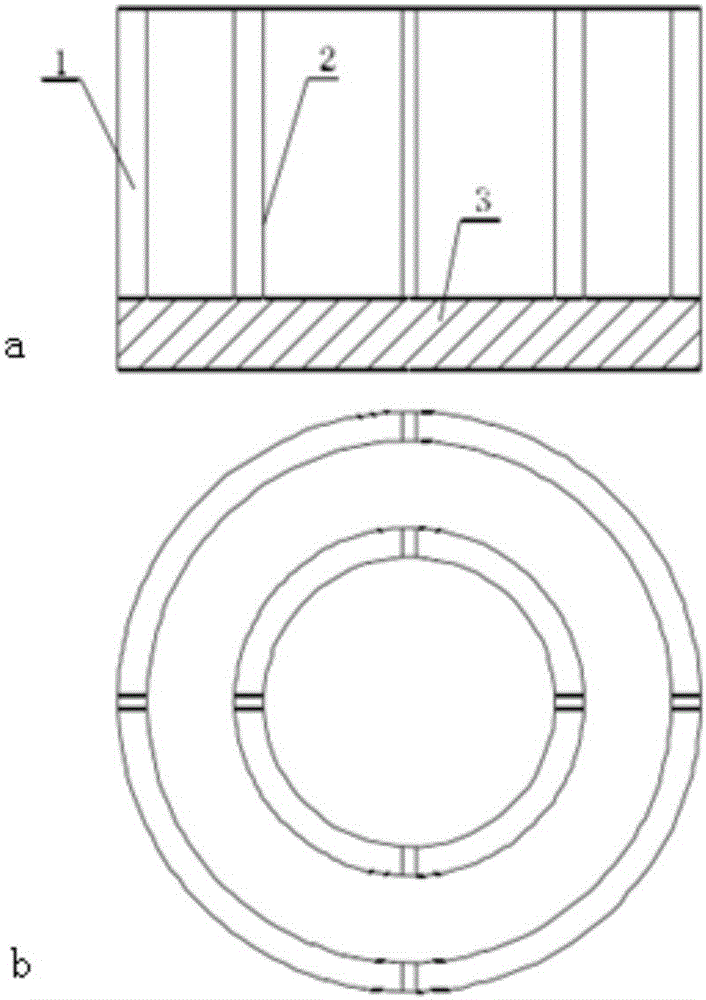

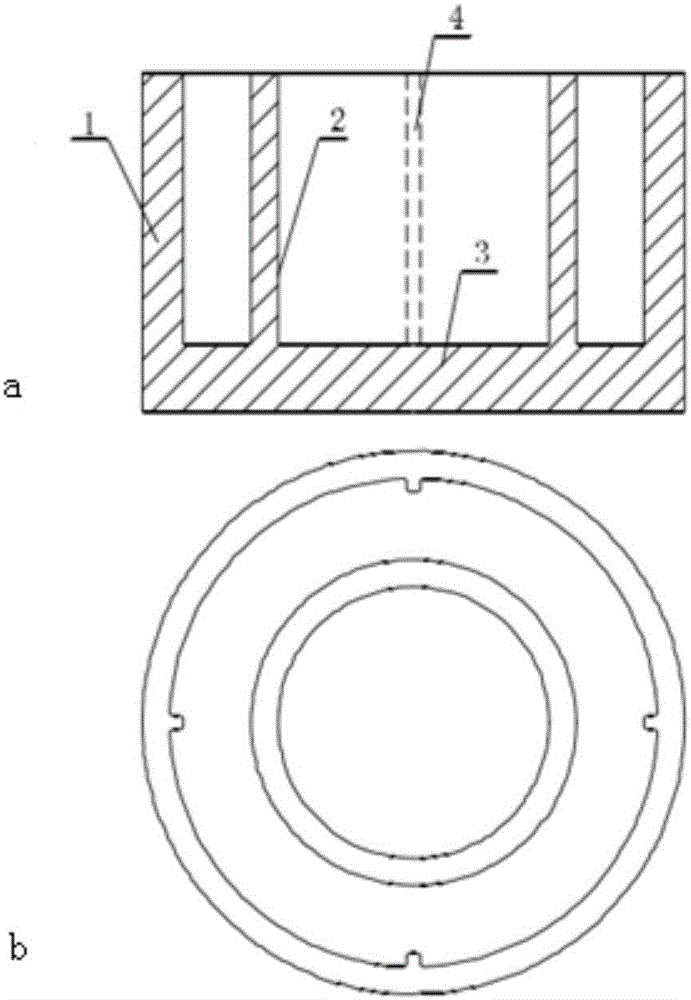

[0036] Superelastic double-lumen tube connection device with support ribs and its preparation and use method

[0037] On the basis of the integral structure of the NiTi alloy double-lumen tube connection device in Example 1, there is an axial support rib 4 inside the outer ring 1 of the double-lumen tube connection device, image 3 It is a schematic diagram of the axial support rib structure of a double-lumen tube connection device. Or there is a circumferential support rib 5 on the inner side of the outer ring 1 of the double-lumen tube connection device, Figure 4 It is a schematic diagram of the structure of a double-lumen tube connection device in the circumferential support rib. The structural design with axial support rib 4 can further improve the impact resistance and sealing performance, and the choice of the structure with circumferential support rib 5 can further improve the sealing performance and pull-off resistance.

Embodiment 3

[0039] Bilateral double-lumen tube connection device and its preparation and use method

[0040] In order to achieve the purpose of double-sided fastening connection, choose Figure 5 The double-lumen tubing connection device with double-sided connection structure is shown.

[0041]The memory alloy material of the double-sided double-lumen tube connecting device is NiTi alloy, and the inner diameter of the outer ring 1 of the double-lumen tube connecting device on one side is expanded by 8% from a diameter of 15 mm in advance in a martensitic state, and then the other The inner diameter of the outer ring 1 of the side double-lumen tube connection device is expanded by 8% from a diameter of 15mm, and the phase transition temperature after the expansion is 80°C; while the inner ring 2 is expanded with a supporting core rod to maintain the original inner diameter.

[0042] The outer ring 1 has an inner diameter of 16.2 mm and has memory properties. When heated to 120° C., exceed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com