Screw conveyor provided with material blocking and cleaning device

A screw conveyor and material cleaning technology, applied in the field of screw conveyors, can solve the problems of personal safety accidents, equipment safety accidents, damage to the bearing seat sealing ring, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

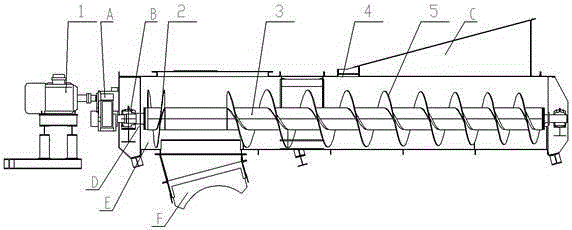

[0012] Referring to the accompanying drawings, a screw conveyor with a material blocking and cleaning device includes a main screw drive 1, a reverse spiral blade 2 for blocking and cleaning materials, a screw shaft 3, a material tank body 4, and a screw blade 5. The reverse spiral blade 2 and spiral blade 5 for feeding and cleaning are welded on the screw shaft 3. After welding, they are loaded into the material tank 4, and the main screw drive 1 is connected to the screw shaft 3 through the reducer A and the bearing seat B. Seal with O-ring D.

[0013] The working principle of the screw conveyor with a blocking and cleaning device is that, using the principle of screw conveying, a reverse spiral blade 2 for blocking and cleaning is added at the accumulated material to convey materials in the opposite direction. , play the role of cleaning the accumulation of materials; on the same screw shaft 3, on the non-discharge side of the discharge port F, that is, the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com