Full-automatic gas ultralimit preventing device

A fully automatic, gas-fired technology, applied in drilling equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems of non-reusable, unclamped drill pipe, long construction period, etc., and achieve simple and reliable structure, The effect of improving overall efficiency and saving cost input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

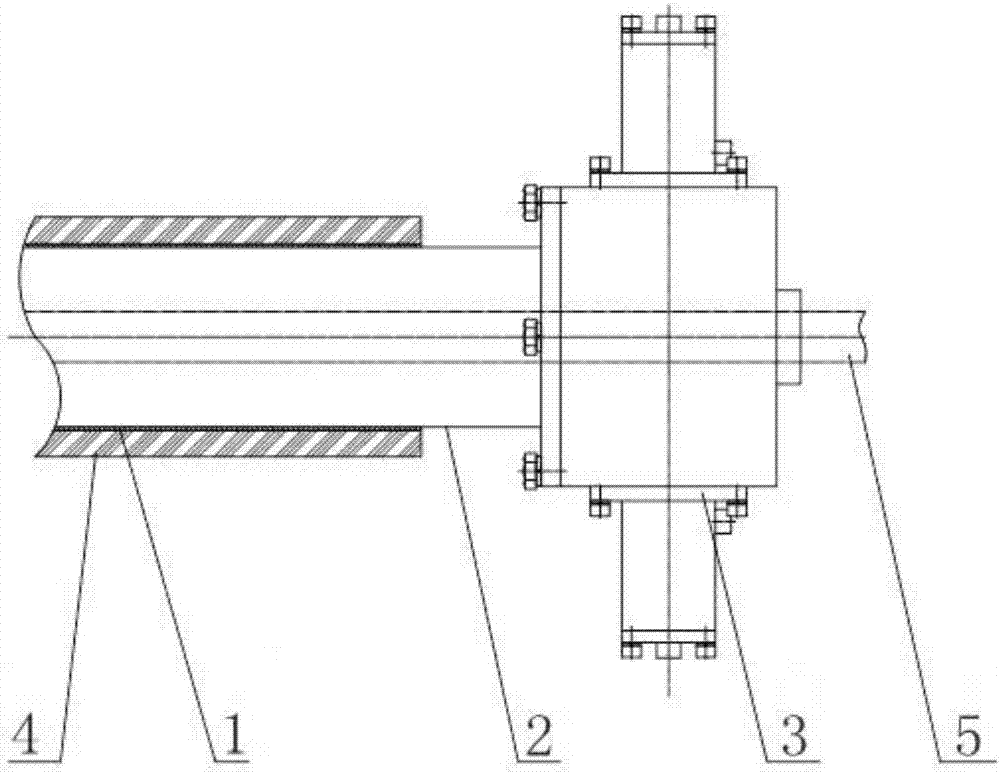

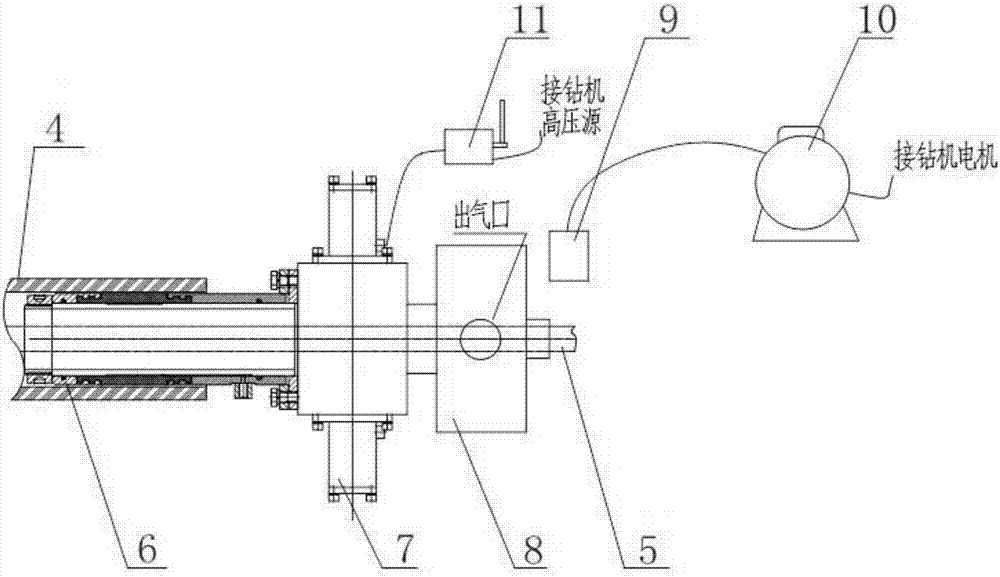

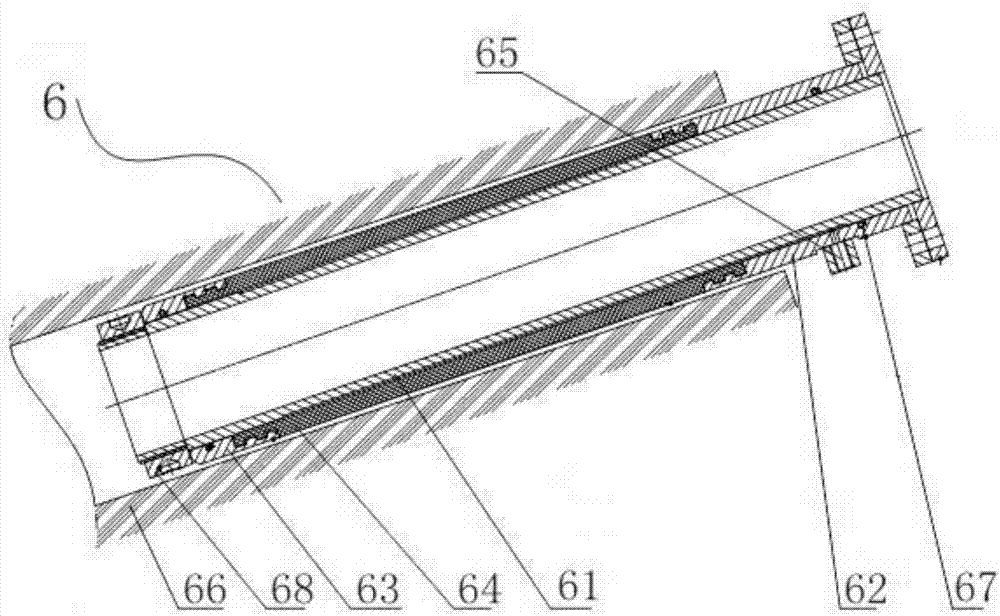

[0029] Such as Figure 2-5 As shown, the fully automatic gas overrun prevention device in the present invention includes a high-pressure capsule hole-fixing device 6, an automatic reset hole-sealing device 7 and a buffer box 8 connected in sequence. The high-pressure capsule hole-fixing device 6 is mainly composed of an inner tube 61 , a front sealing tube 62, a rear sealing tube 63 and a capsule 64, the front sealing tube 62 and the rear sealing tube 63 are arranged at both ends of the inner tube 61, the capsule 64 is set outside the inner tube 61 and the two ends are respectively connected to the front The sealing tube 62 and the rear sealing tube 63 are connected, and the front sealing tube, the capsule, the rear sealing tube and the inner tube together form a filling cavity, and the front sealing tube is provided with an interface 65 co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com