High-pressure capsule hole-fixing device

A capsule and hole-fixing technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as too long drilling, long construction hours, and excessive consumables, and achieve high bearing capacity, Cost saving and rapid hole fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

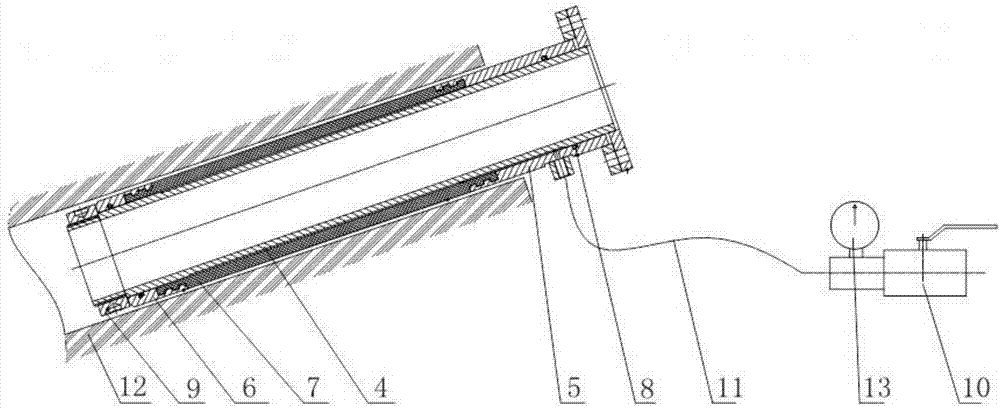

[0016] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

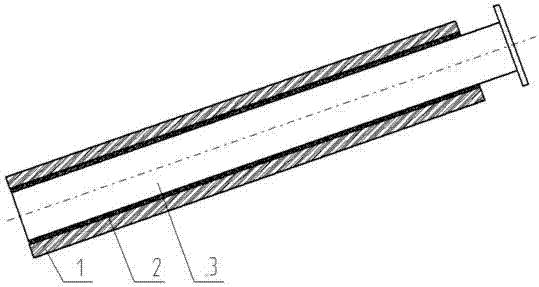

[0017] Such as figure 2 As shown, the high-pressure capsule hole-fixing device in the present invention includes an inner tube 4, a front sealing tube 5 and a rear sealing tube 6 arranged at both ends of the inner tube 4, and a capsule 7, which is set outside the inner tube 4 And the two ends are respectively connected with the front sealing tube 5 and the rear sealing tube 6, and the front sealing tube 5, the capsule 7, the rear sealing tube 6 and the inner tube 4 together form a filling cavity, and the front sealing tube 5 is provided with a filling cavity The connected interface is used to connect to an external high voltage source.

[0018] In this embodiment, the front sealing tube 5 and the rear sealing tube 6 are provided with O-rings 8 correspondingly to ensure the tightness; the inner tube 4 is provided with a limit nut 9, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com