Drilling and protecting integrated method for directional long drill hole

A long drilling and hole protection technology, which is applied in directional drilling, drilling tools, earthwork drilling, etc., can solve the problems of small drainage range, poor drainage effect, long drilling length, etc., and achieve a large range of hole protection, Guarantee the effect of pumping and reduce the effect of supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

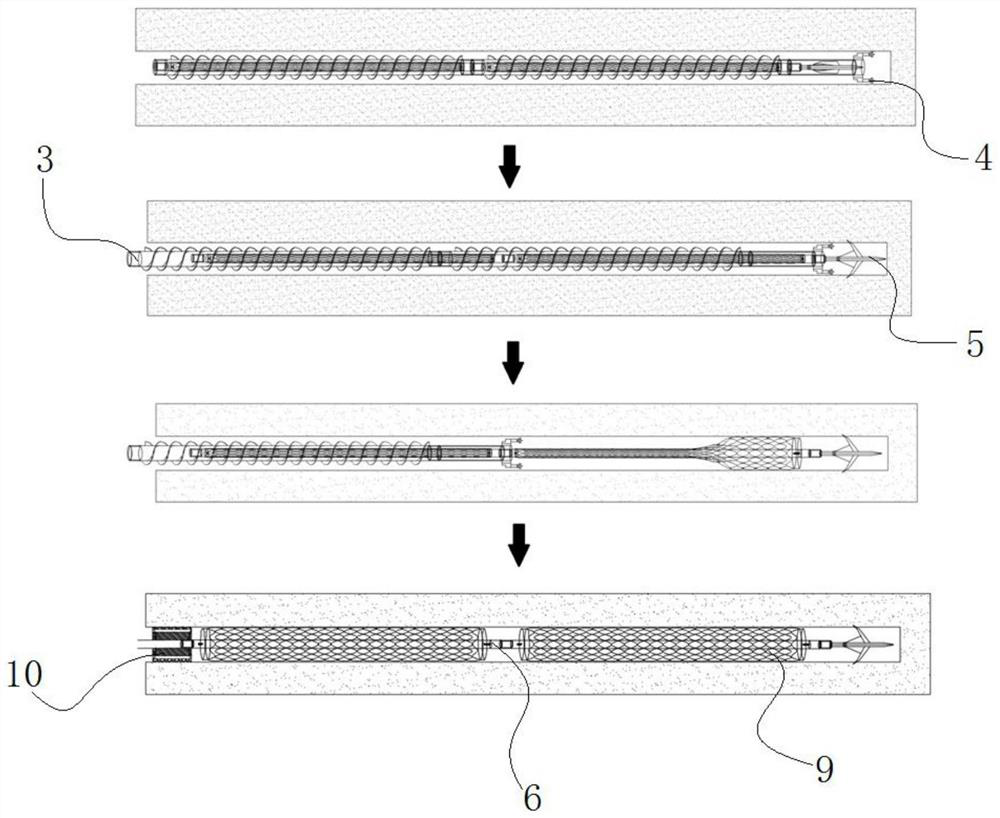

[0033] see figure 1 , the present embodiment provides a drilling-protection integrated method for directional long drilling, which is characterized in that it includes the following steps:

[0034] 1) Arrange the drilling site in the groove of the pre-mined working face.

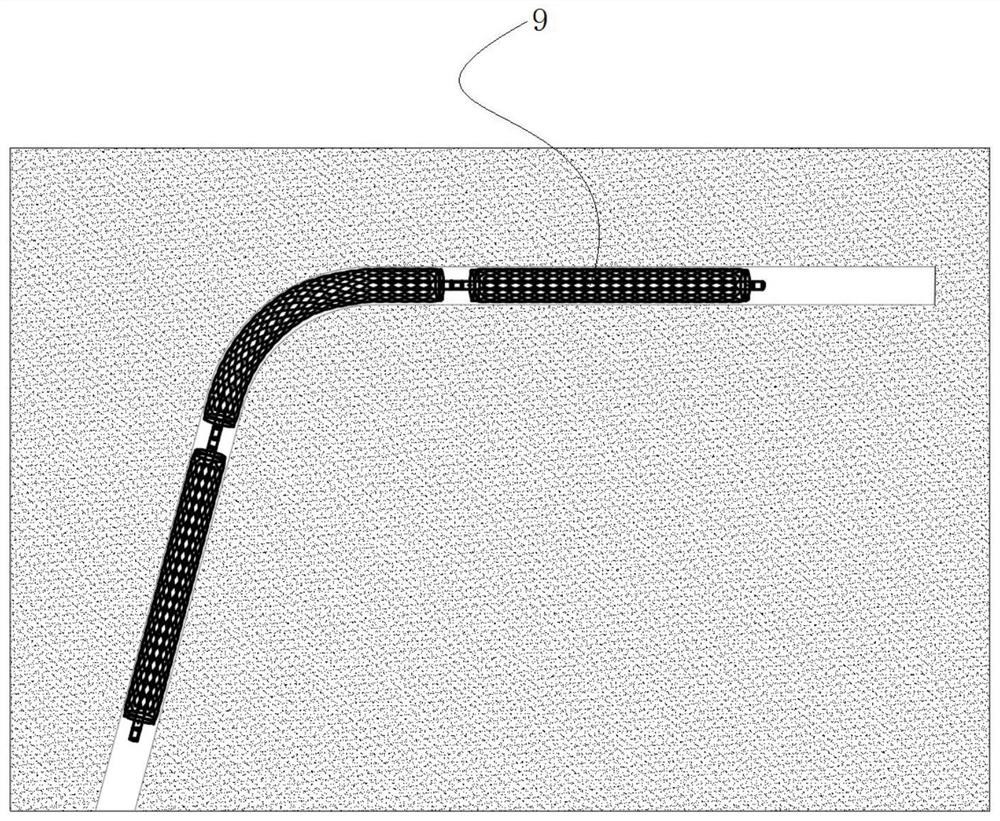

[0035] 2) According to the outburst prevention design of the working face, construct directional long drilling holes in the drilling field along the reverse mining direction of the working face. Wherein, the directional long borehole includes a sealing hole section, a layer penetration hole section and a drainage hole section. The hole sealing section is communicated from the working face coal seam drilling field to the lower end of the layer penetration hole section. The layer-penetrating hole section is located between the coal seam of the working face and the crack zone of the roof. The trajectory of the through-layer hole segment is a curve. The extraction hole section is located in the crack zone of...

Embodiment 2

[0045] The main steps of this embodiment are the same as those of Embodiment 1, wherein the directional long drilling holes are multiple. The spacing between the directional long boreholes shall not be greater than 1.4 times the gas drainage radius.

Embodiment 3

[0047] The main steps of this embodiment are the same as those of Embodiment 1, wherein the flexible water injection support pipe 6 is made by splicing several sections of support pipes. A flexible hole protecting bracket 9 is correspondingly arranged on each section of the support tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com