Self-pressurization coal body fracturing permeability-increasing enhanced gas extraction method based on ultrasonic waves

A gas drainage and ultrasonic technology, applied in the direction of gas discharge, mining fluid, mining equipment, etc., can solve the problems of large consumption, large energy, and inability to achieve continuous increase in permeability of coal seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below.

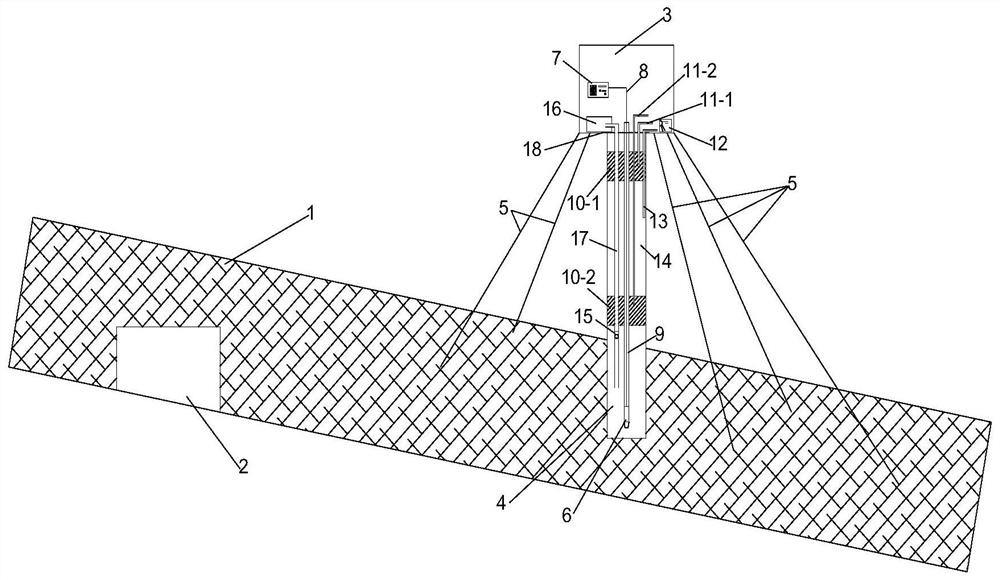

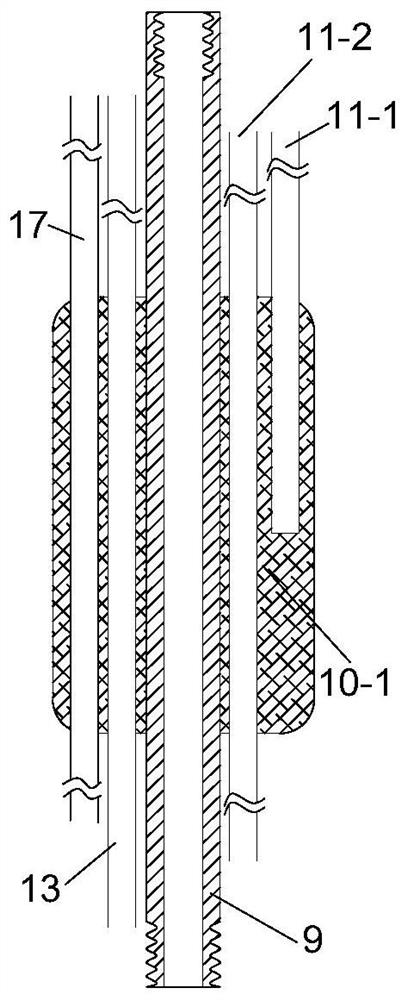

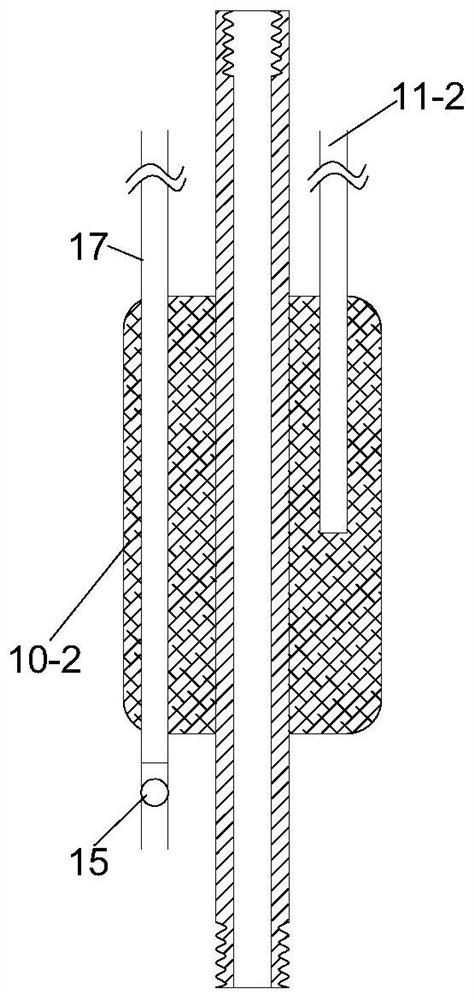

[0022] Such as Figure 1 to Figure 4 Shown, concrete steps of the present invention are:

[0023] A. Select a position in the high-level drainage roadway 3 above the coal seam 1 to drill down the anti-reflection borehole 4, and the deepest part of the anti-reflection borehole 4 penetrates the rock layer and extends into the coal seam 1 without passing through the coal seam 1;

[0024] B. According to the depth of the anti-reflection drilling 4, select the required number of PVC pipes 9 to connect end to end to form a transmission line protection tube. One end of the transmission line protection tube is fixed with an ultrasonic vibrator 6, and this end of the transmission line protection tube is extended into the anti-reflection drilling 4 The other end of the transmission line protection tube is fixed at the opening of the anti-reflection drilling 4 through steel bars; the transmission line protection tube is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com