Patents

Literature

87results about How to "Constrained deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

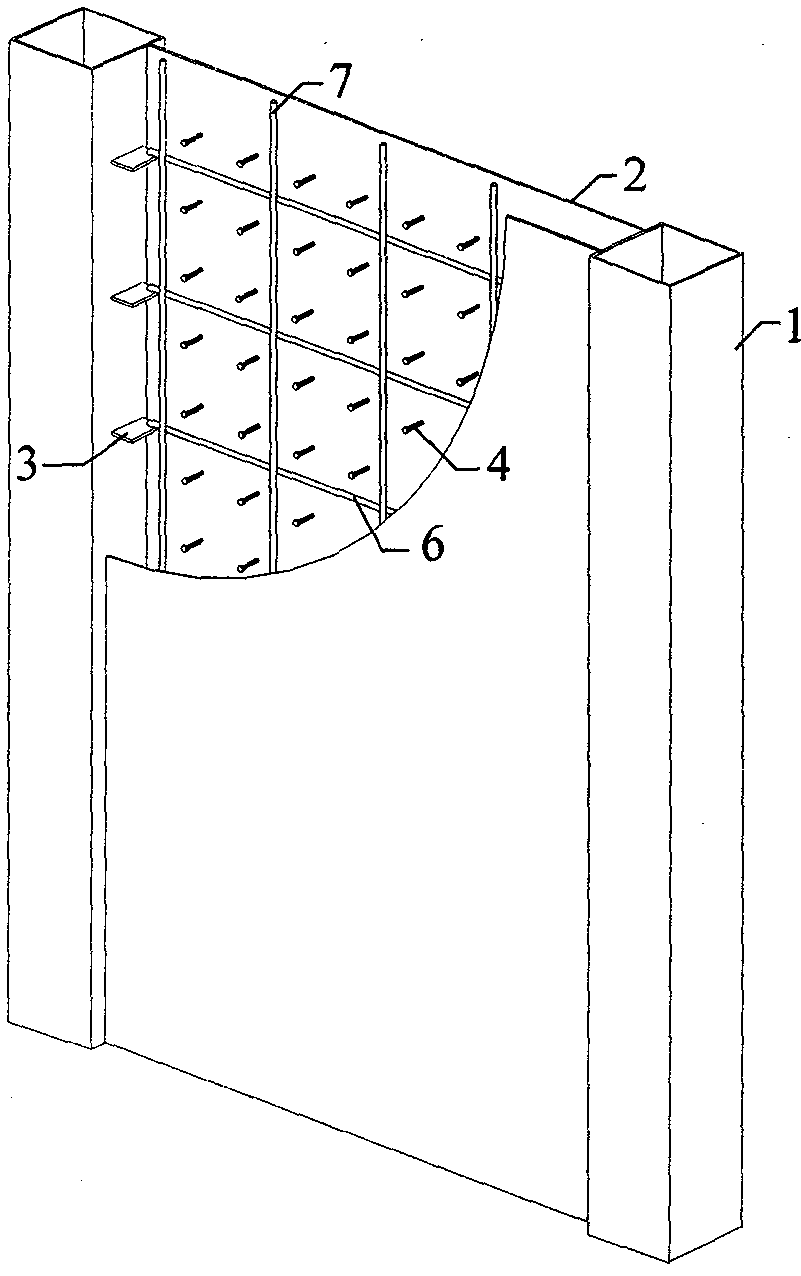

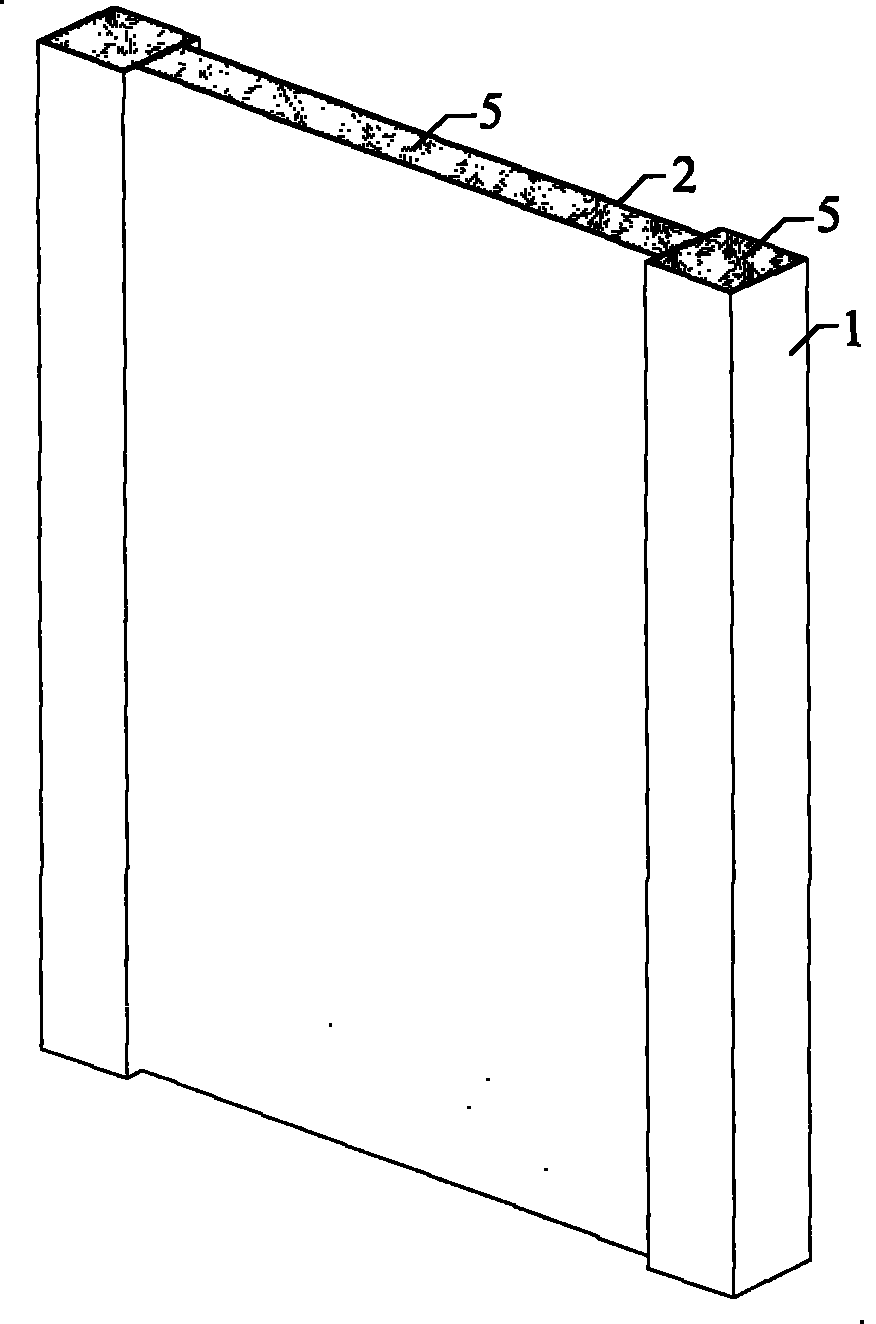

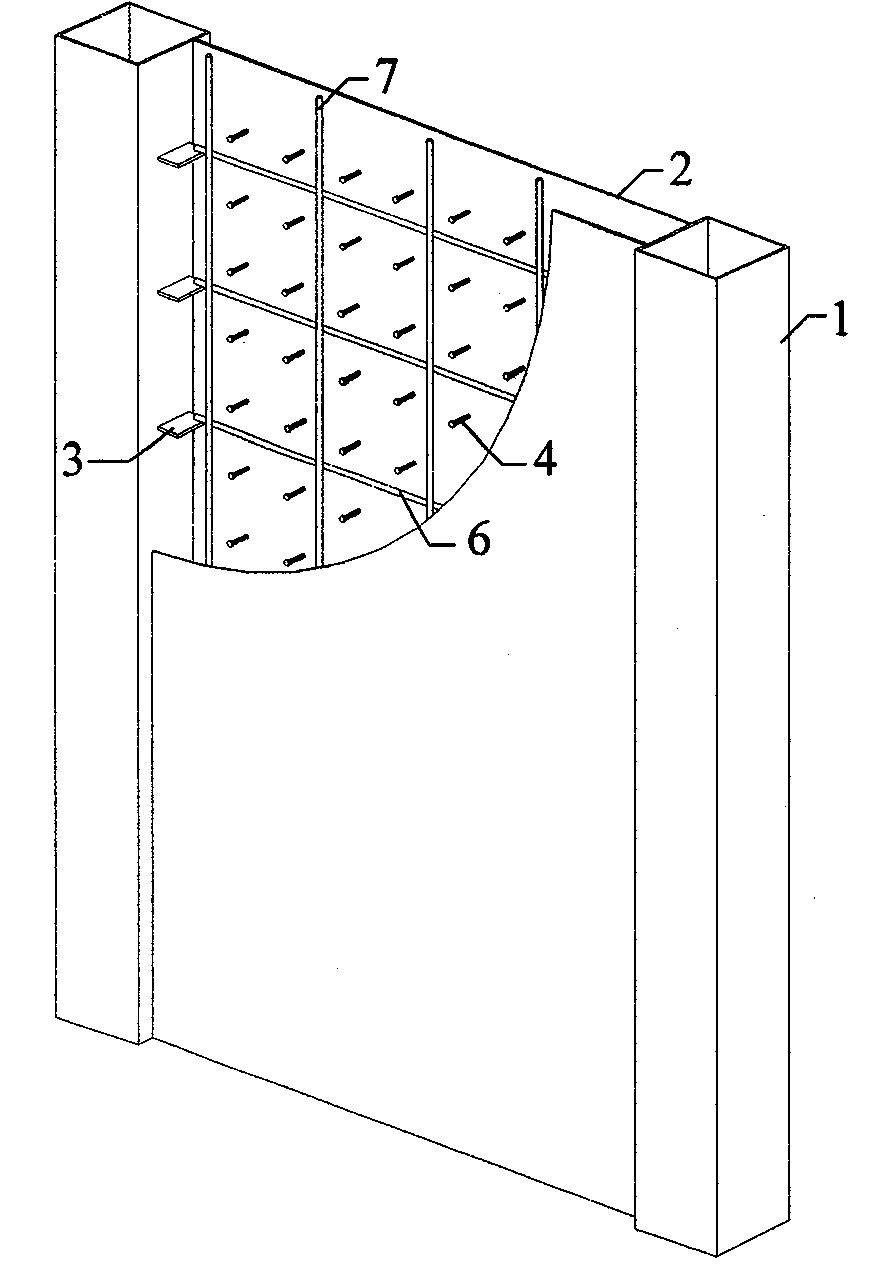

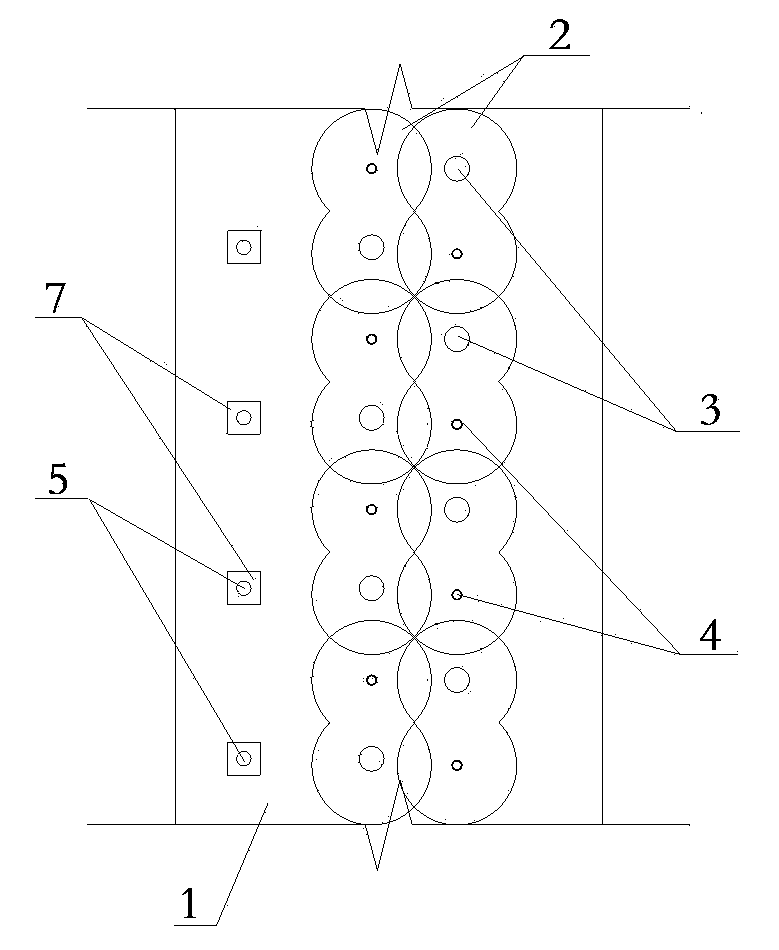

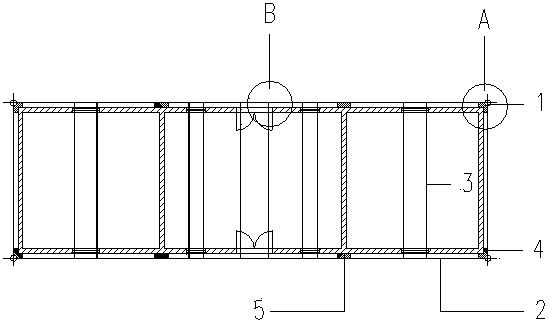

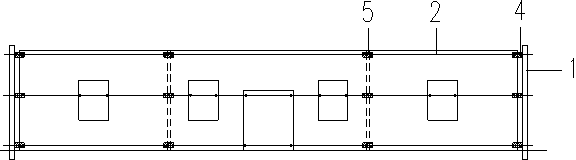

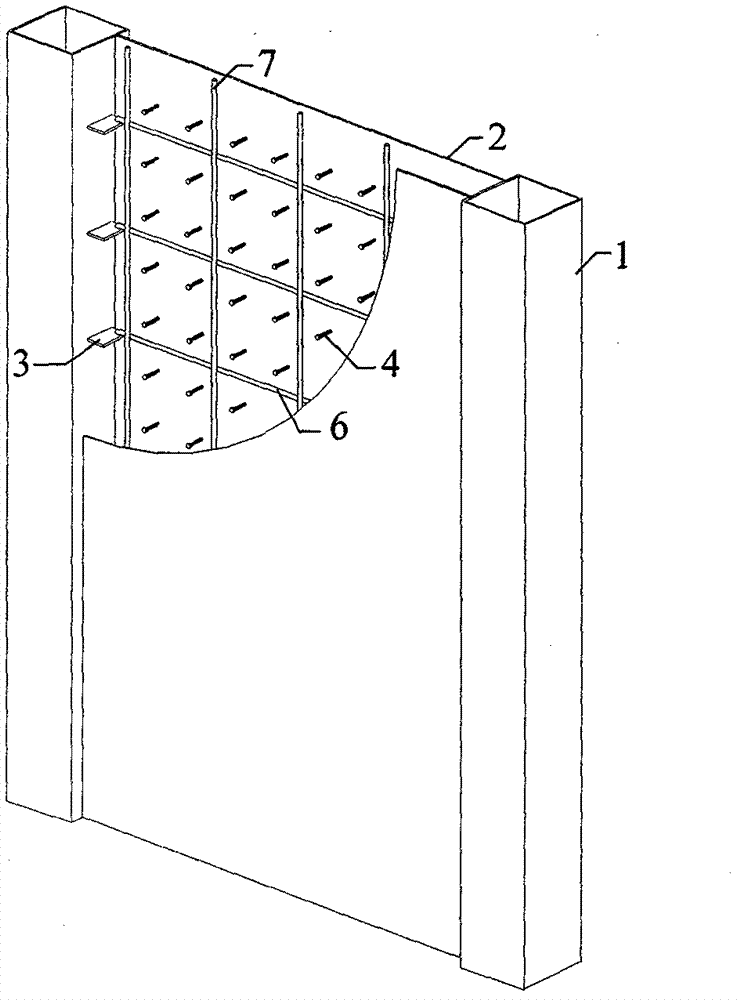

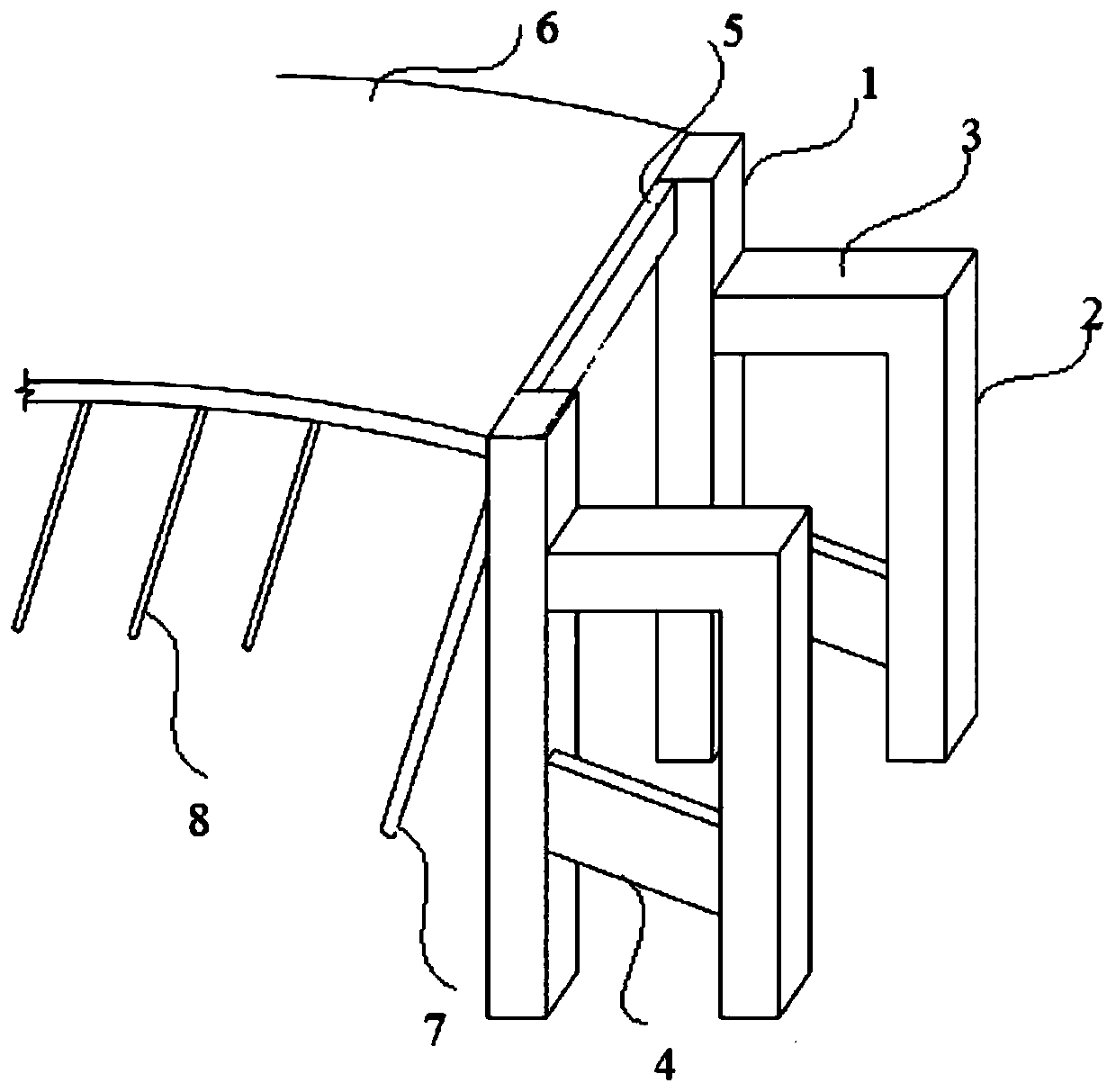

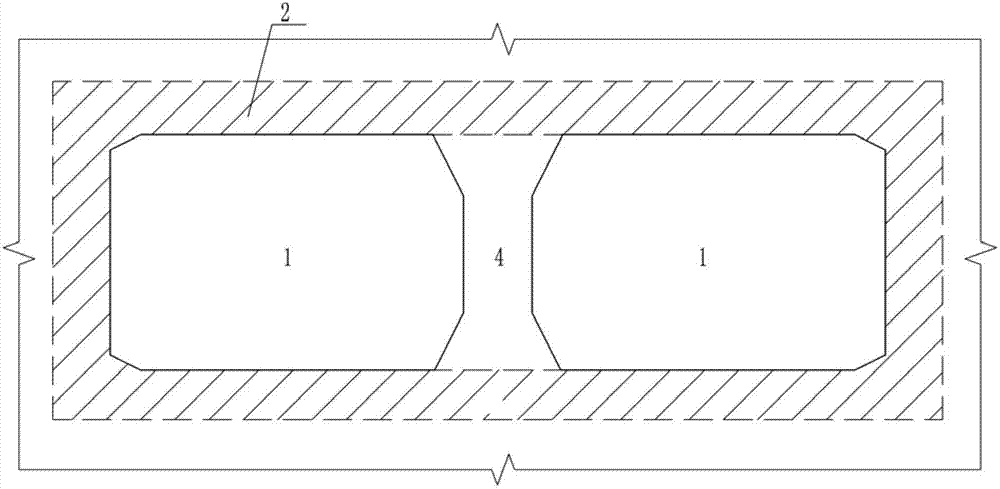

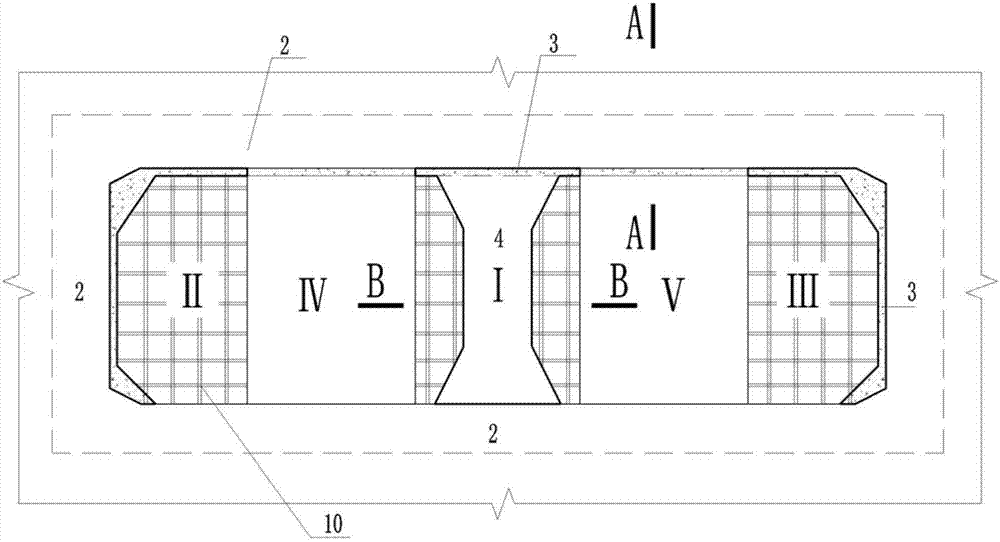

Steel tube concrete column-double-layer steel plate combined shear wall and construction method thereof

ActiveCN102127941AIncreased bearing capacity and ductilityImprove seismic performanceWallsRebarSteel plates

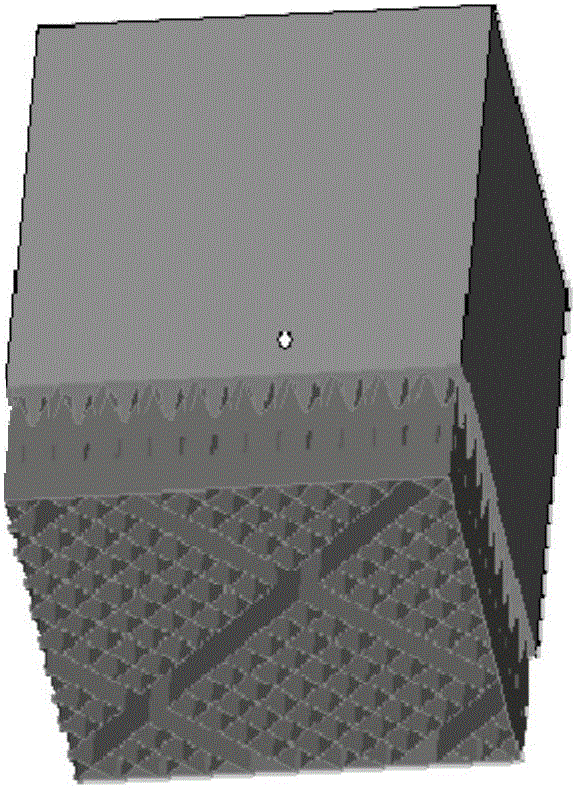

The invention relates to a steel tube concrete column-double-layer steel plate combined shear wall belonging to the technical field of constructional engineering and combination structures. The steel tube concrete column-double-layer steel plate combined shear wall comprises two steel tubes, two steel plates, distributed reinforcing steel bars, connecting keys, male pins and concrete, wherein the connecting keys are vertically and alternately arranged at the opposite sides of the two steel tubes; both ends of each of transversally distributed reinforcing steel bars in the distributed reinforcing steel bars are respectively connected with the connecting keys in corresponding positions on the two steel tubes; the male pins are welded on the opposite sides of the two steel plates; two lateral ends of the two steel plates are connected with the steel tubes; and concrete is cast in the two steel tubes and in a planar closed space encircled by the two steel plates and the two steel tubes. The shear wall of the invention can restrict the concrete from deforming, improve the bearing capacity and the tensility of the shear wall and enhance the whole quake-proof performance of the structure. Moreover, the shear wall has favorable stress performance and improved quake-proof performance, is favorable to engineering of building space arrangement, decreasing self weight and reducing template engineering and is suitable for being used as a shear wall in a high-rise or ultra-high-rise building.

Owner:TSINGHUA UNIV

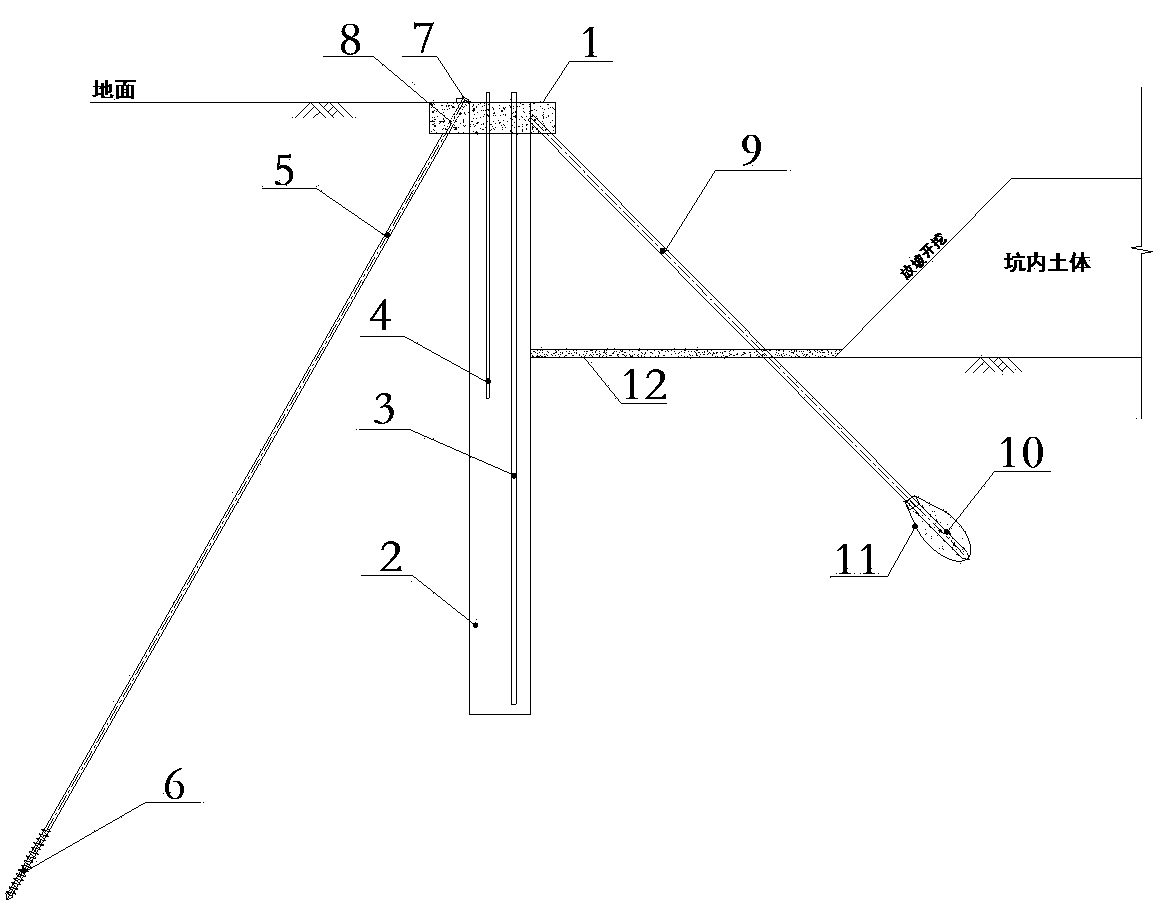

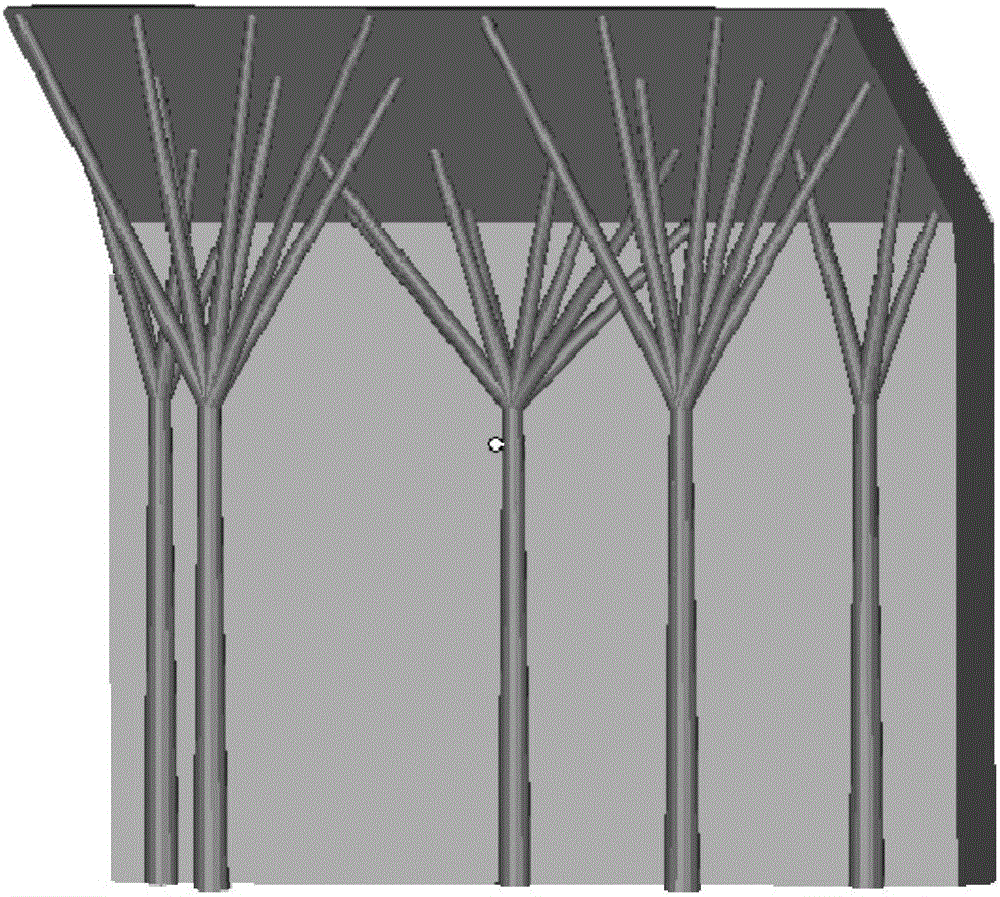

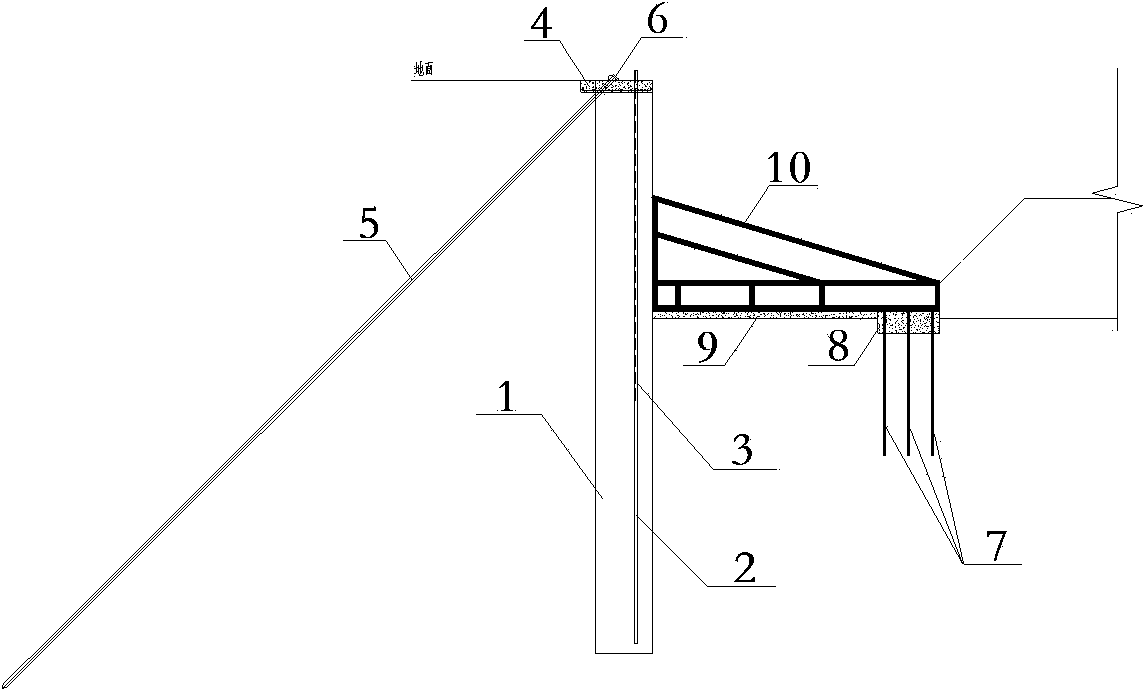

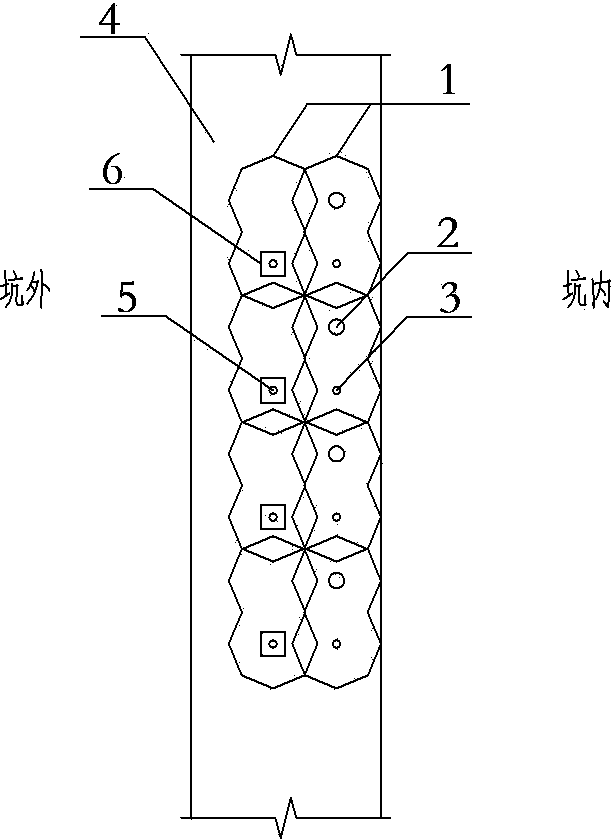

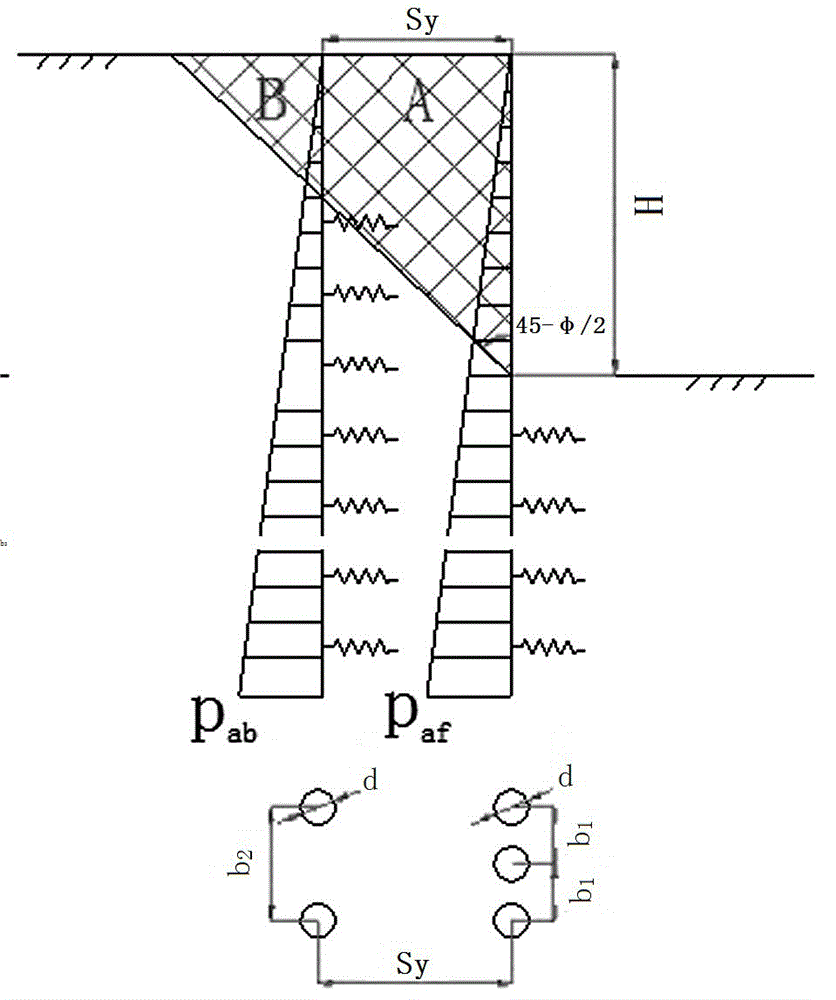

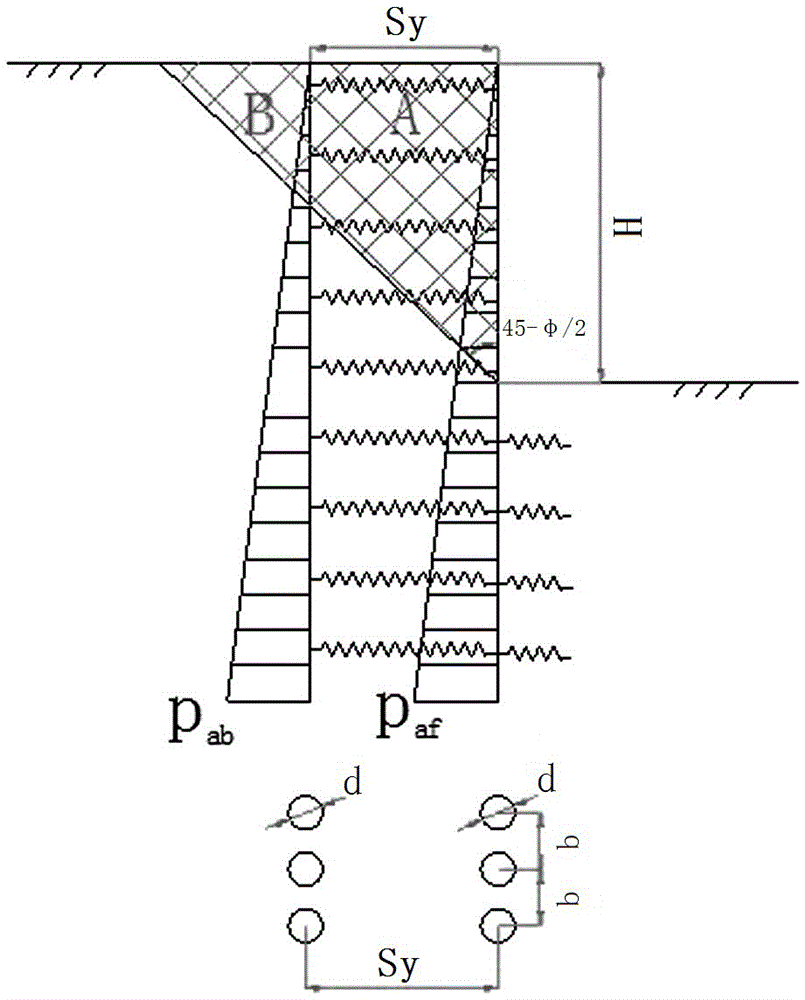

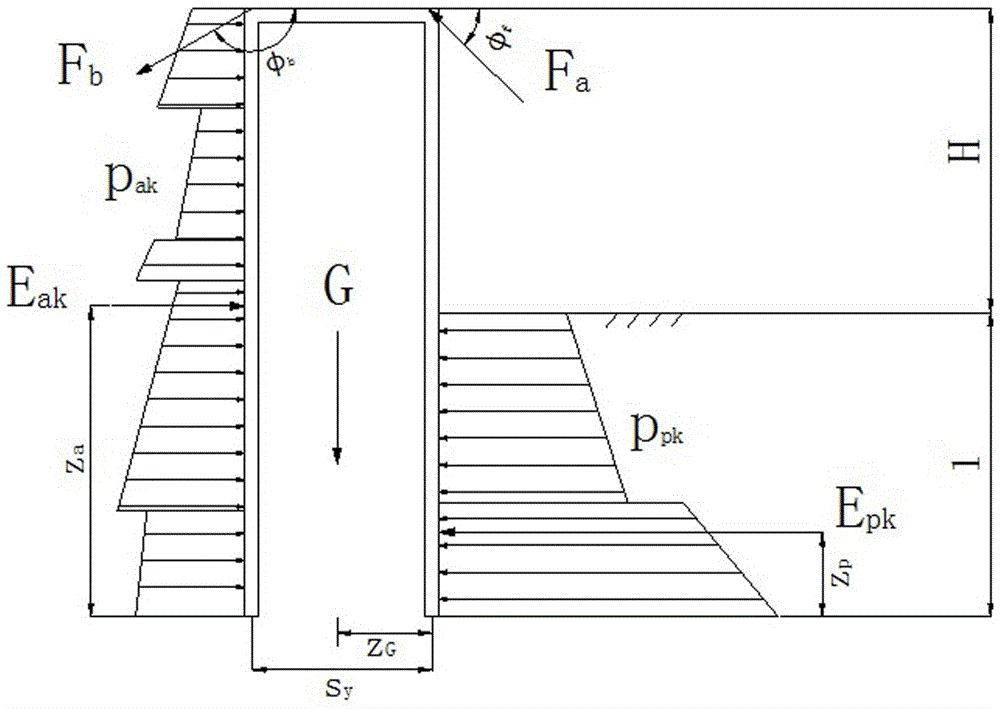

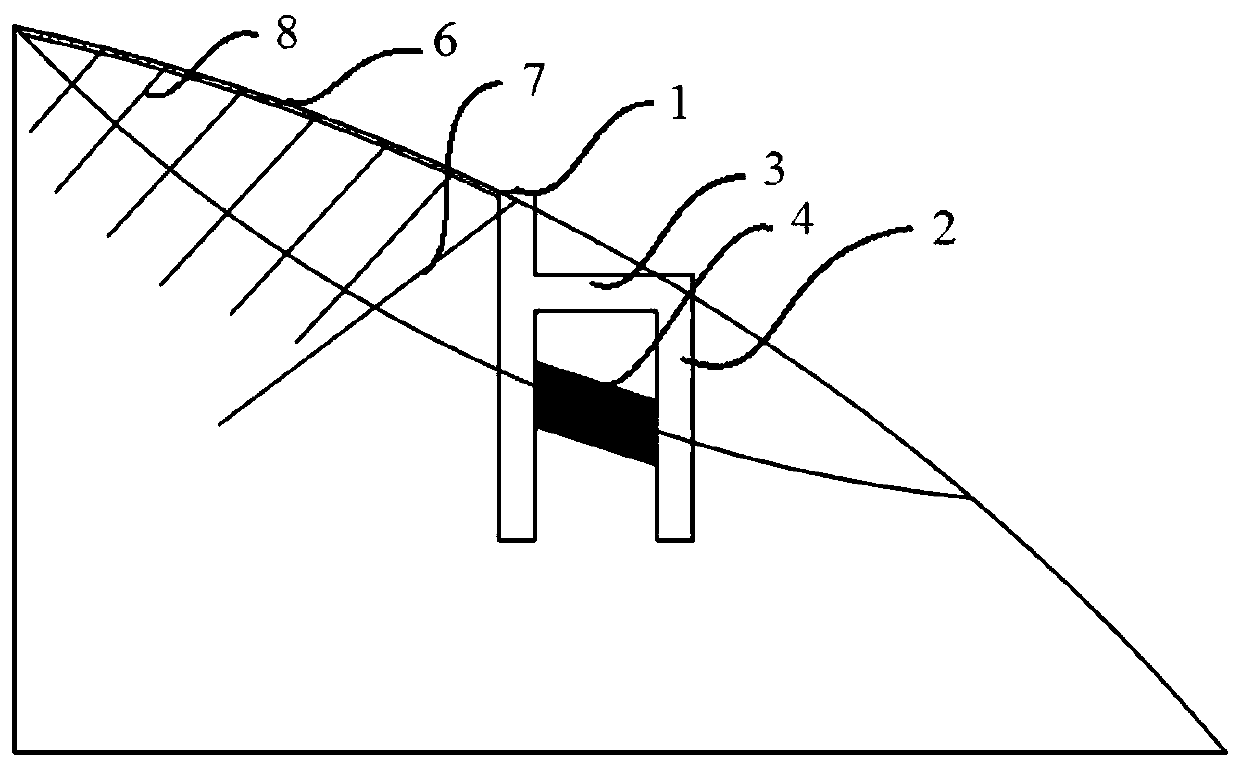

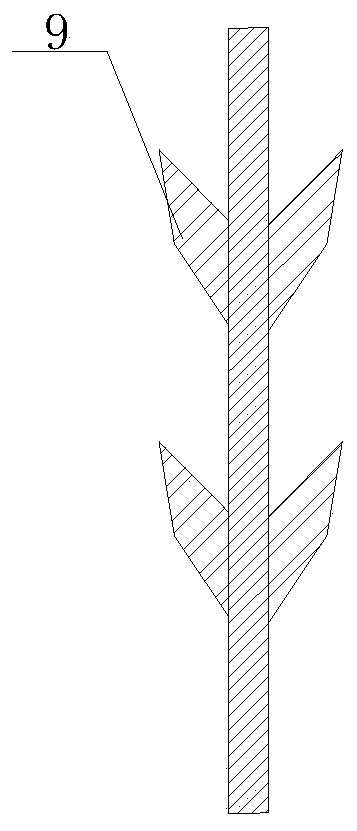

Recyclable vertical steel tube front supporting envelop enclosure and applying method thereof

The invention belongs to the technical field of foundation pit engineering and particularly relates to recyclable vertical steel tube front supporting envelop enclosure and an applying method thereof. The recyclable vertical steel tube front supporting envelop enclosure is characterized by comprising a coping ring beam, a cemented soil mixing wall and at least three groups of steel tubes. The cemented soil mixing wall is positioned in the middle and perpendicular to the coping ring beam, and end portions of the three groups of steel tubes are connected and fixed with the coping ring beam. The middle group of steel tubes in the middle of the three groups of the steel tubes are perpendicular to the coping ring beam and positioned in the cemented soil mixing wall, the other two groups of steel tubes are positioned on the inner side and the outer side of the middle group of steel tubes, and angles are formed between the other two groups of steel tubes and the middle group of steel tubes. The recyclable vertical steel tube front supporting envelop enclosure has the advantages of being easy to install and dismantle, convenient to construct, recyclable, friendly to the environment, low in manufacture cost and convenient to popularize, and having reinforced sliding preventing, soil blocking and water retaining functions. By means of the recyclable vertical steel tube front supporting envelop enclosure, anti-sliding capacity and deformation resistance capability of a soil body within an enveloping range are remarkably improved.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST +1

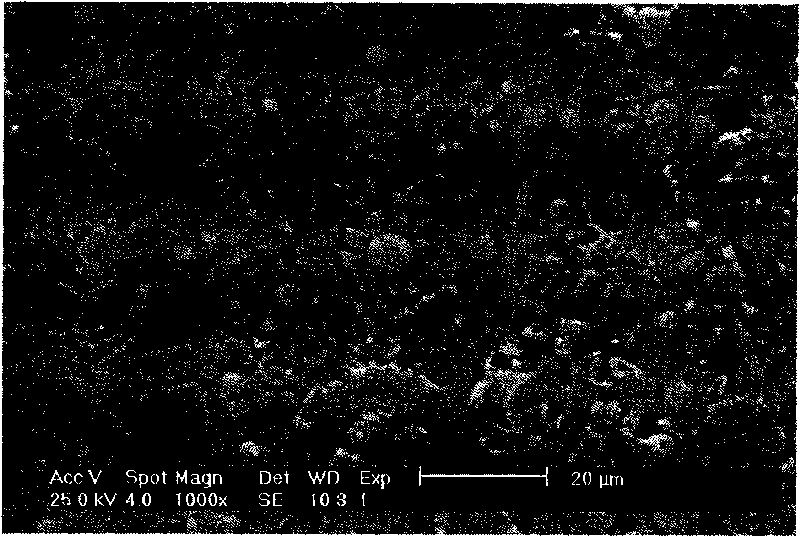

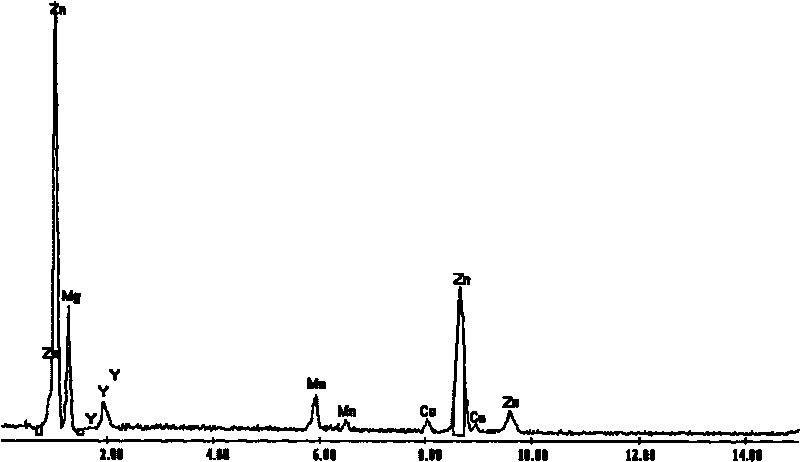

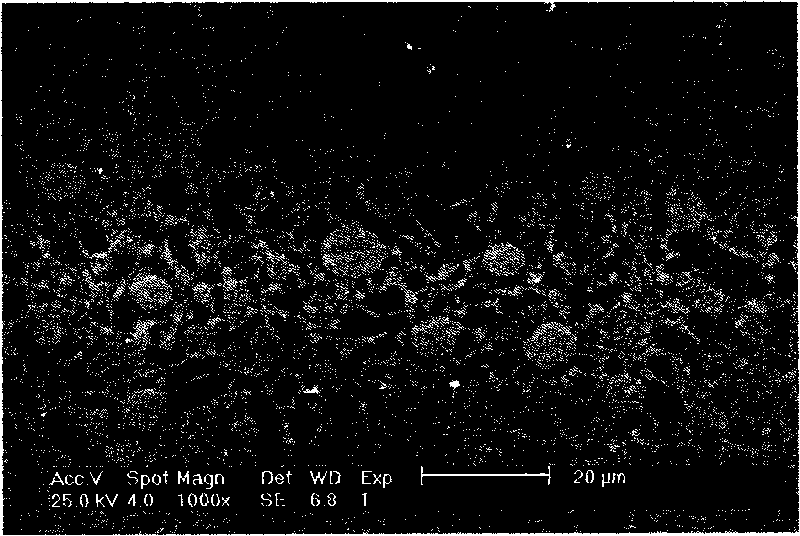

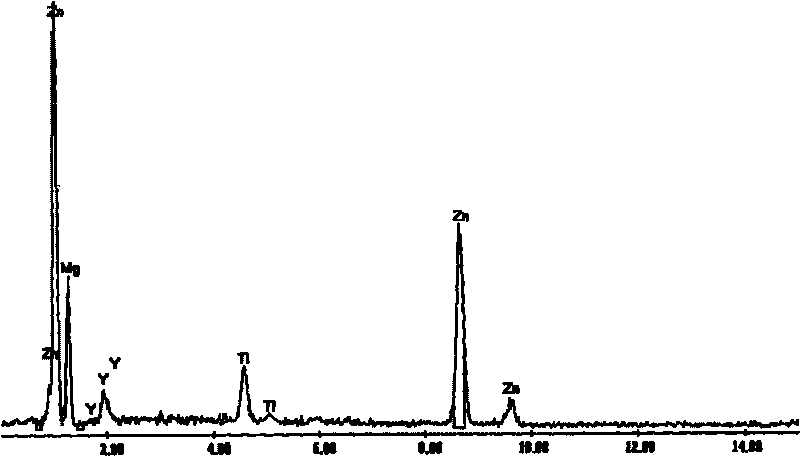

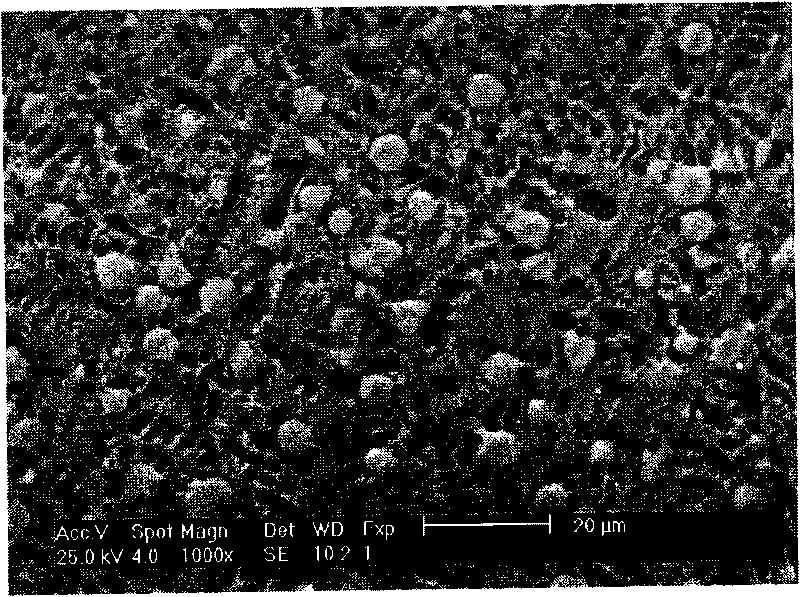

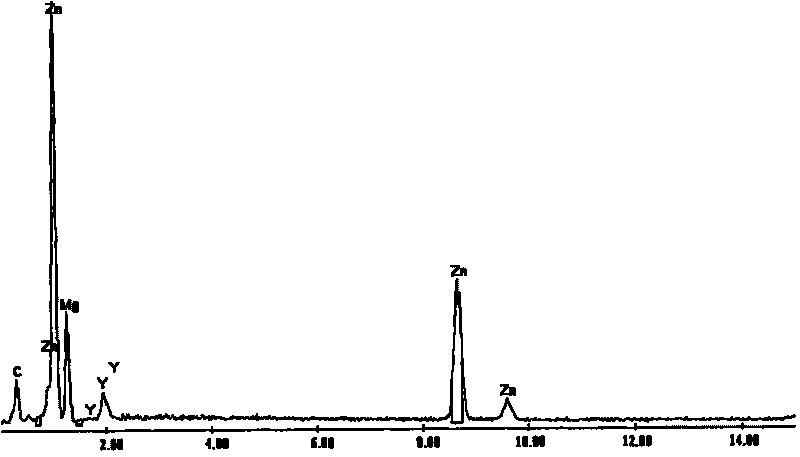

Magnesium base spherical quasicrystal master alloy and preparation method thereof

The invention provides a magnesium base spherical quasicrystal master alloy and a preparation method thereof, relating to magnesium base alloys with zinc as a submaster component. The alloy is Mg-Zn-Y-Mn-Cu quinary magnesium base icosahedral spherical quasicrystal master alloy, comprising the following chemical components: 55.0-65.0% of Mg, 30.0-40.0% of Zn, 2.5-5.5% of Y, 0.10-1.50% of Mn and 0.10-0.50% of Cu, wherein the diameter of the spherical quasicrystal is 2-7mu m and the mean diameter is 6mu m. The volume of the spherical quasicrystal is 35-45% of the total volume of the alloy. The preparation method is characterized by adopting control of the solidification rate, namely pouring the alloy melt into a casting mold capable of controlling the cooling rate, wherein the solidification rate is controlled between 72.2K / s and 88.6K / s. The product of the invention can better improve the mechanical property of the alloy materials while enhancing the magnesium alloy substrate, has simple process, low requirement on equipment and wide raw material sources, is convenient to realize industrialized production and saves resources.

Owner:HEBEI UNIV OF TECH

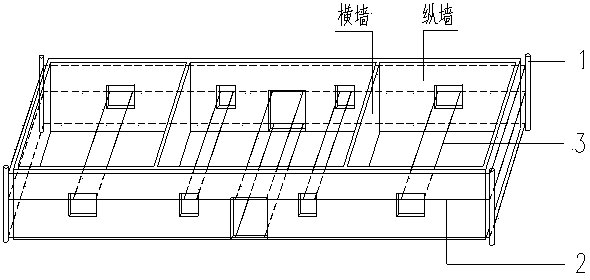

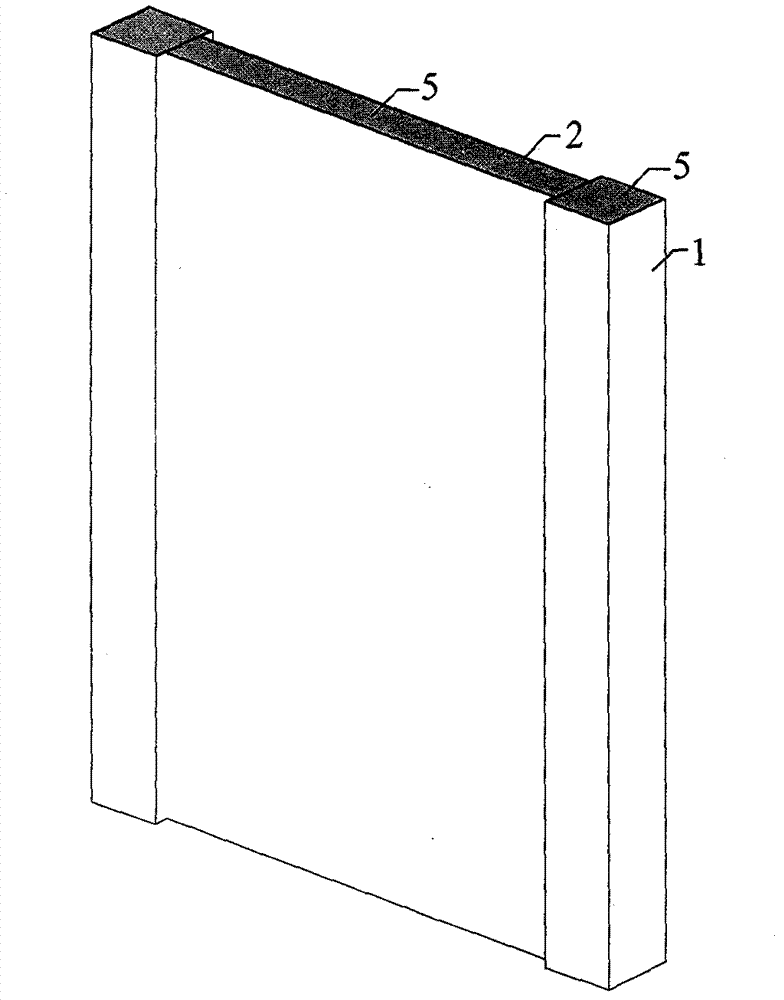

Wall reinforcing structure and method for improving integrality of historic buildings

InactiveCN103993751ARaise the natural frequencyPrevent instability and collapseBuilding repairsUrban regionBrick

The invention discloses a wall reinforcing structure and method for improving the integrality of historic buildings. According to the wall reinforcing structure and method, the characteristics that most historic buildings are of brick concrete structures, no ring beam is used, and dead loads are large are considered, walls are reinforced through the reinforcing scheme based on offsite component prefabricating and site assembling, and the historic buildings are prevented from being continuously collapsed by vibration. By means of the wall reinforcing structure and method, the structure integrality can be improved, when vibration loads are externally and suddenly exerted, deformation of the walls is effectively controlled, and continuous collapse caused by overall instability of the historic buildings is prevented. Meanwhile, the wall reinforcing structure and method have the advantages of being high in reversible degree, free of working with naked fire in a site, easy to operate, convenient to apply, free of damage to historic building bodies and the like, the effective protection effect can be achieved when the historic buildings and particularly key cultural relics distributed in urban areas with dense buildings are influenced by construction technologies, with vibration characteristics, of municipal administration dismantling projects, metro building blasting projects, metro building deep foundation pit excavation projects, metro building large-diameter pile foundation construction and the like, and the wall reinforcing structure and method have the wide application prospects in the aspect of preventing extreme damage conditions, such as continuous collapse, of the historic buildings.

Owner:SOUTHEAST UNIV

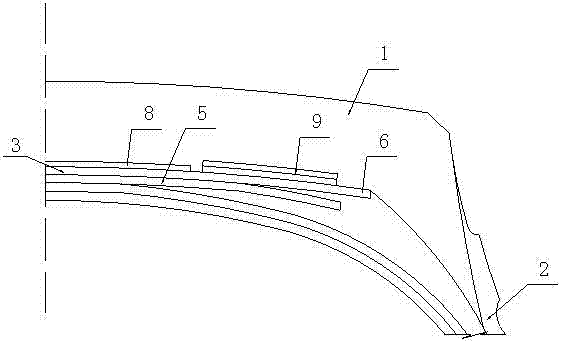

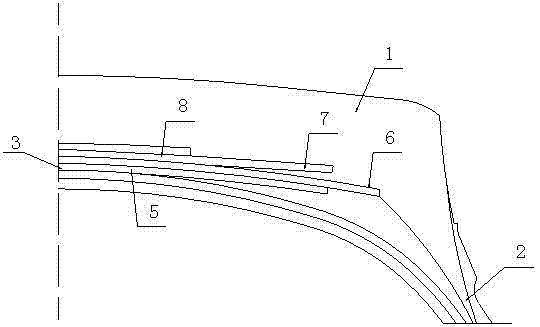

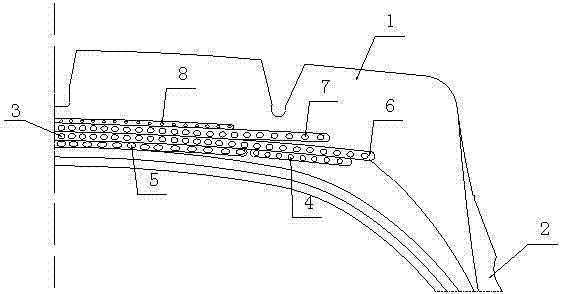

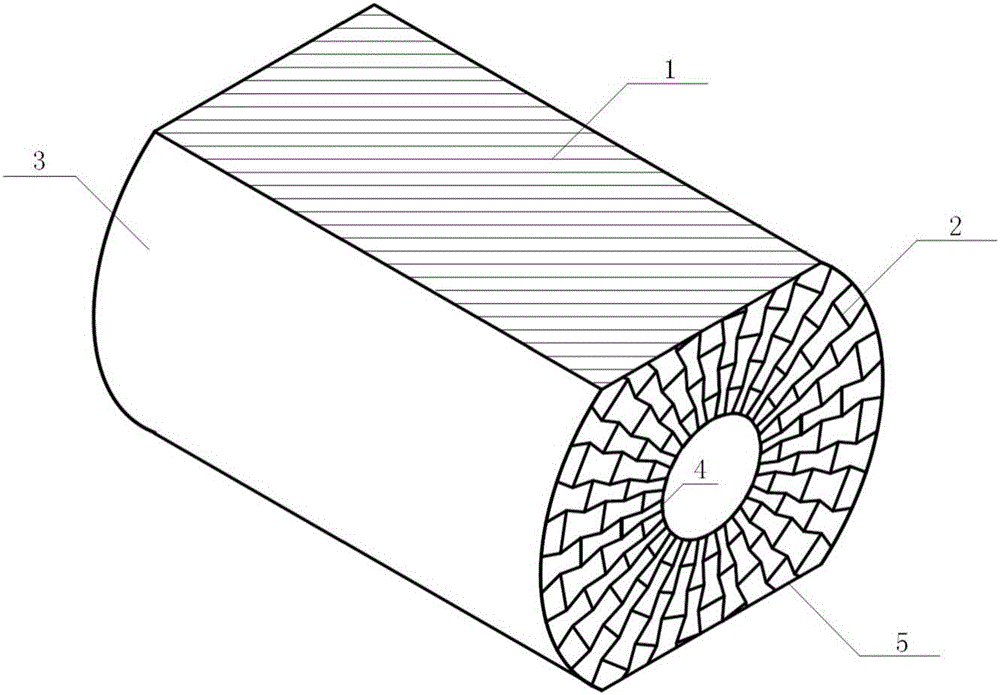

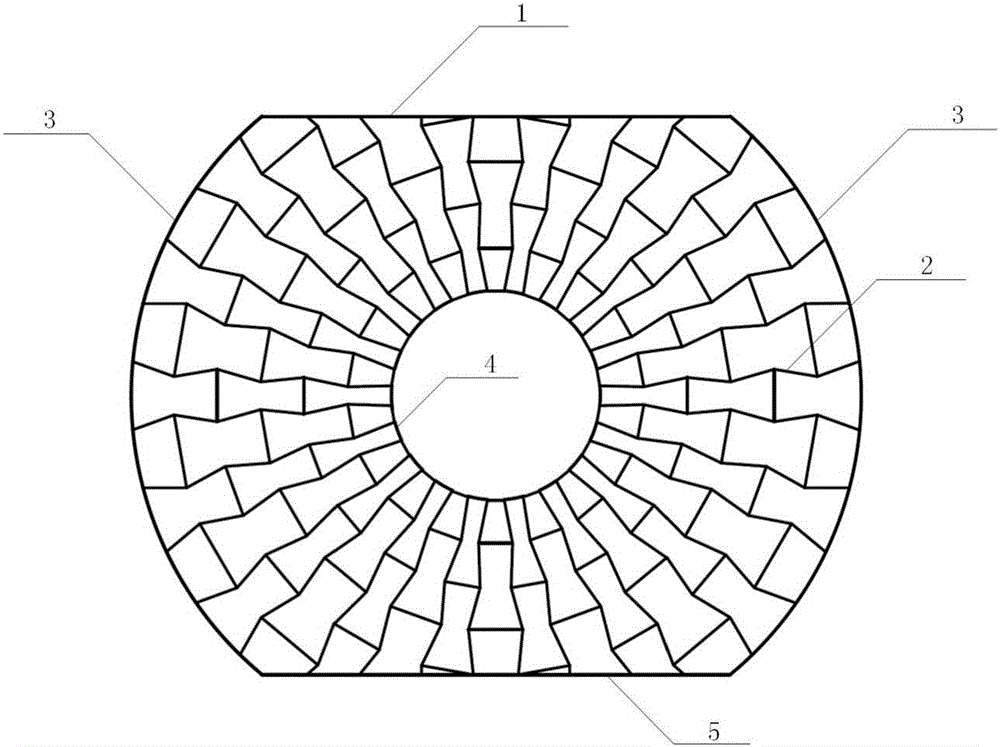

Radial tire with twining type steel wire belted layer and manufacturing method thereof

ActiveCN102358110AIncrease stressEliminate negative effectsTyresPneumatic tyre reinforcementsCapacitanceEngineering

The invention relates to the field of radial tire manufacture, in particular to a radial tire with a twining type steel wire belted layer and a manufacturing method thereof. The radial tire comprises a tire surface, a belted layer and a tire side. The belted layer consists of a 1# belted layer, a 2# belted layer, a 3# belted layer, a 4# belted layer and a 0# belted layer, wherein the 1# belted layer is arranged at the bottom and serves as a transition layer, the 2# belted layer and the 3# belted layer are sequentially arranged above the 1# belted layer, the 4# belted layer is arranged above the 3# belted layer, the width of two ends of the 2# belted layer is larger than that of the 1# belted layer, the 0# belted layer is twining type wirecord fabric which is identical with the circumferential direction of the tire, and the 0# belted layer is symmetrically attached to two sides of the 1# belted layer and under the 2# belted layer through a twining method. The radial tire with the twining type steel wire belted layer can effectively avoid deformation of shoulders of tires, optimize stress of the belted layers and pressure distribution of ground connection of the tire surface, improve durability, wear-resisting property and loading capacitance and reduce oil consumption.

Owner:ZHONGCE RUBBER GRP CO LTD

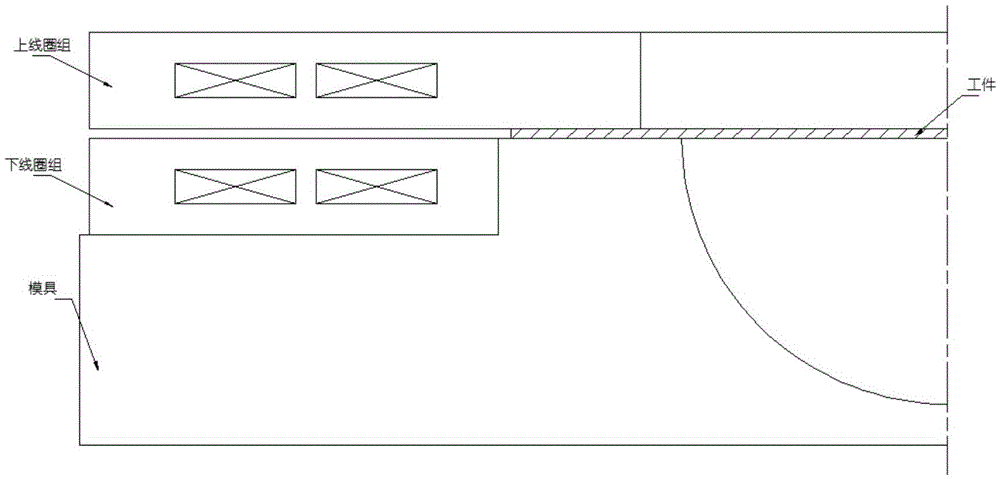

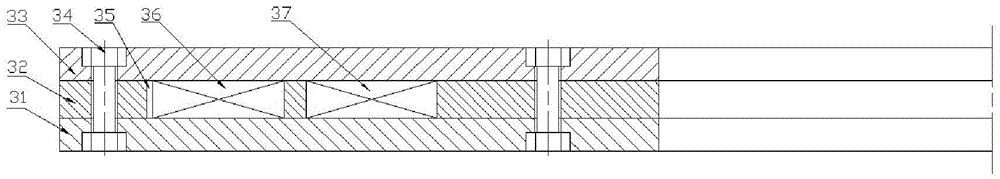

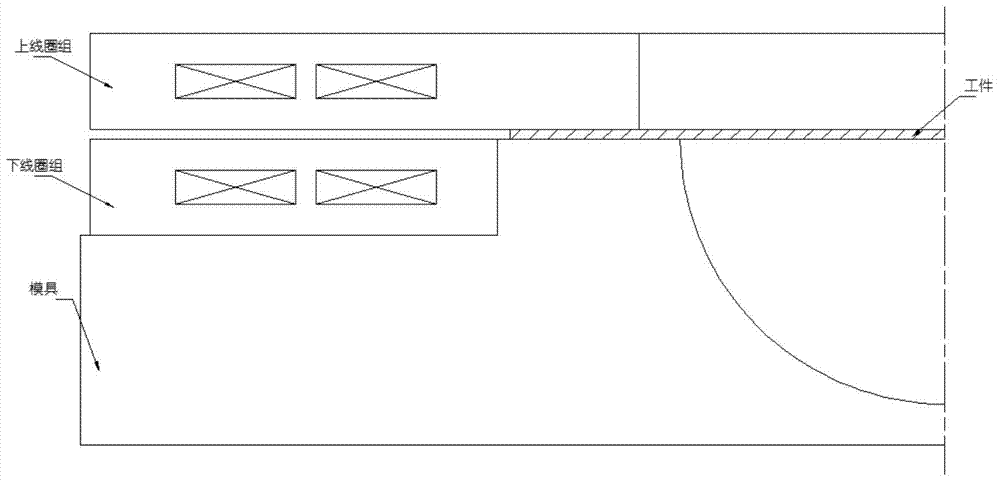

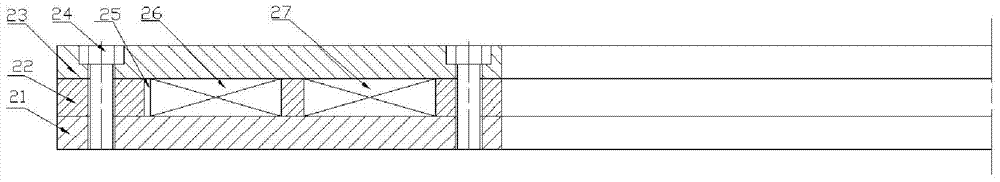

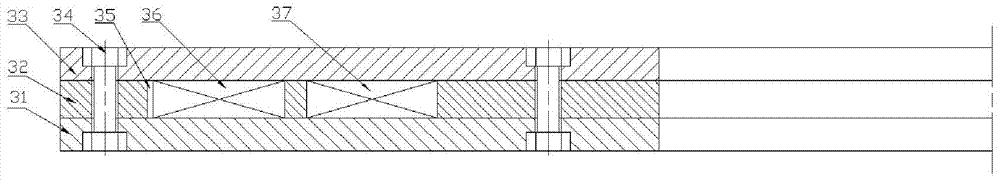

Electromagnetic blank holder method suitable for high-speed forming

The invention discloses an electromagnetic blank holder method suitable for high-speed forming. The method includes the steps that (1) blank holder coil assemblies are placed on end faces of a blank holder portion of a metal sheet part, can be only placed on the upper end face or the lower end face of the blank holder portion of the metal sheet part and can also be placed on the upper end face and the lower end face of the blank holder portion of the metal sheet part at the same time, the blank holder coil assembly placed on the lower end face of the blank holder portion of the metal sheet part is supported by means of a female die, the blank holder coil assembly placed on the upper end face of the blank holder part of the metal sheet part restrains blank holder coils to move through a pressing machine or a bolt fastening structure, and pressure can be applied to the blank holder coil assemblies when moving of the blank coils is restrained; (2) in the high-speed forming process, pulse currents are fed into the blank holder coil assemblies, vortexes are sensed on the blank holder portion of the metal sheet part, and therefore electromagnetic pressure is generated on the blank holder portion of the metal sheet part. The method eliminates the contradiction that in a traditional forming process, blank holder force cannot prevent the metal sheet part from wrinkling, is high and causes high frictional resistance to block shaping flowing of the metal sheet part.

Owner:HUAZHONG UNIV OF SCI & TECH

Manufacturing method for shape follow-up supporting model for selective laser melting metal additive manufacturing

InactiveCN106623933AConstrained deformationReduce temperature gradientAdditive manufacturingIncreasing energy efficiencySelective laser meltingMetal

The invention relates to a manufacturing method for a shape follow-up supporting model for selective laser melting metal additive manufacturing. The manufacturing method comprises the following steps of: a, establishing a model of a three-dimensional part by utilizing a three-dimensional drawing software; b, determining the position of a shape follow-up support; c, manufacturing an original shape follow-up supporting model according to the position determined in the step b; d, putting the original shape follow-up supporting model on the position determined in the step b; e, removing a part, superposed with the part, in the original shape follow-up supporting model through Boolean operation to obtain a middle shape follow-up supporting model; and f, pruning away the excessive part of the middle shape follow-up supporting model through a pruning function to obtain a final shape follow-up supporting model.

Owner:北京航信增材科技有限公司

Magnesium base spherical quasicrystal master alloy and preparation method thereof

The invention provides a magnesium base spherical quasicrystal master alloy and a preparation method thereof, relating to magnesium base alloys with zinc as a submaster component. The alloy is Mg-Zn-Y-Ti quaternary magnesium base icosahedral spherical quasicrystal master alloy, comprising the following chemical components: 55.0-65.0% of Mg, 30.0-40.0% of Zn, 2.5-5.5% of Y and 0.1-0.5% of Ti, wherein the diameter of the spherical quasicrystal is 6-10mu m and the mean diameter is 8 mu m. The volume of the spherical quasicrystal is 30-40% of the total volume of the alloy. The preparation method is characterized by adopting control of the solidification rate, namely pouring the alloy melt into a casting mold capable of controlling the cooling rate, wherein the solidification rate is controlled between 52.6K / s and 68.4K / s. The product of the invention can better improve the mechanical property of the alloy materials while enhancing the magnesium alloy substrate, has simple process, low requirement on equipment and wide raw material sources, is convenient to realize industrialized production and saves resources.

Owner:HEBEI UNIV OF TECH

Steel tube concrete column-double-layer steel plate combined shear wall and construction method thereof

The invention relates to a steel tube concrete column-double-layer steel plate combined shear wall belonging to the technical field of constructional engineering and combination structures. The steel tube concrete column-double-layer steel plate combined shear wall comprises two steel tubes, two steel plates, distributed reinforcing steel bars, connecting keys, male pins and concrete, wherein theconnecting keys are vertically and alternately arranged at the opposite sides of the two steel tubes; both ends of each of transversally distributed reinforcing steel bars in the distributed reinforcing steel bars are respectively connected with the connecting keys in corresponding positions on the two steel tubes; the male pins are welded on the opposite sides of the two steel plates; two lateral ends of the two steel plates are connected with the steel tubes; and concrete is cast in the two steel tubes and in a planar closed space encircled by the two steel plates and the two steel tubes. The shear wall of the invention can restrict the concrete from deforming, improve the bearing capacity and the tensility of the shear wall and enhance the whole quake-proof performance of the structure. Moreover, the shear wall has favorable stress performance and improved quake-proof performance, is favorable to engineering of building space arrangement, decreasing self weight and reducing template engineering and is suitable for being used as a shear wall in a high-rise or ultra-high-rise building.

Owner:TSINGHUA UNIV

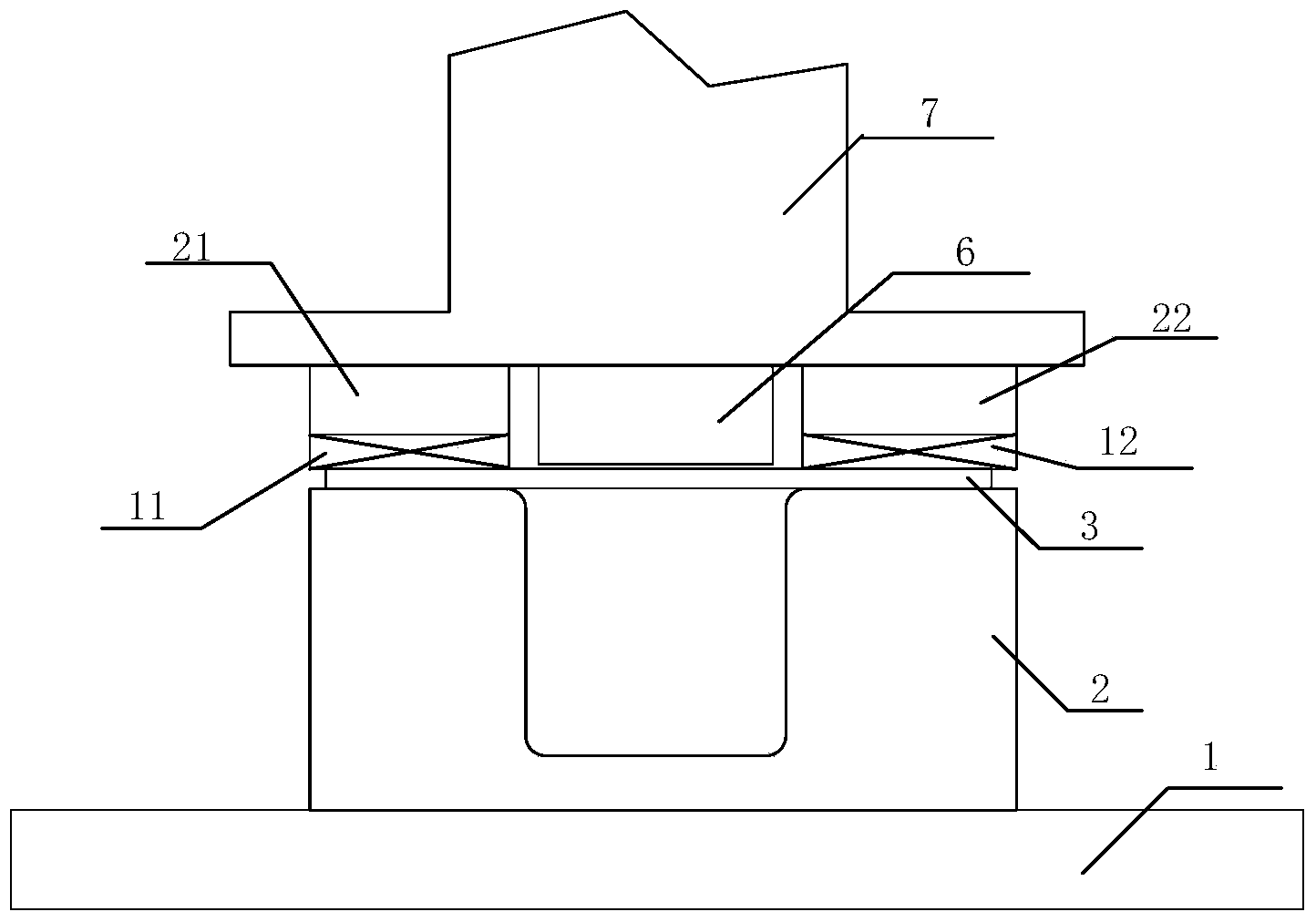

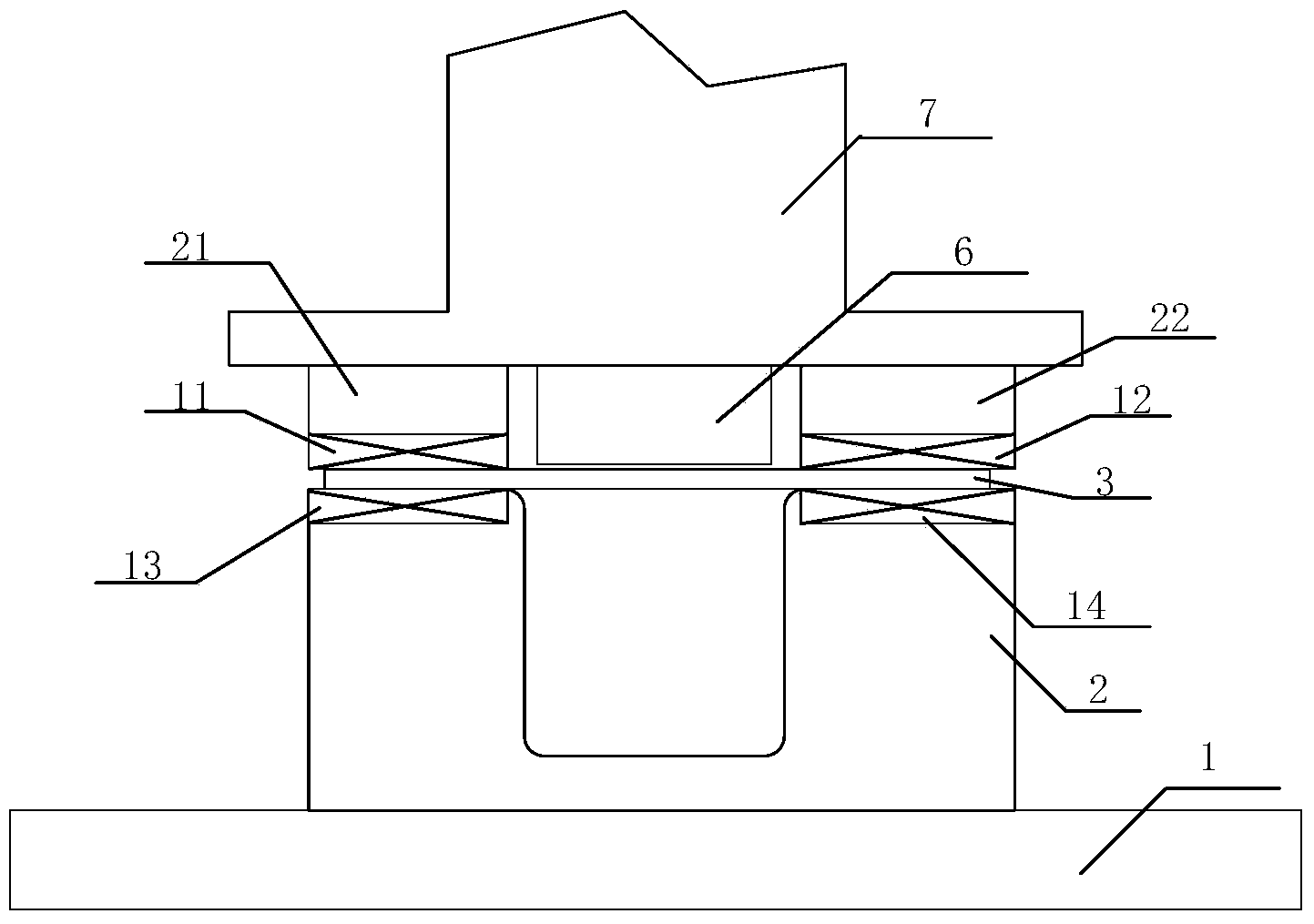

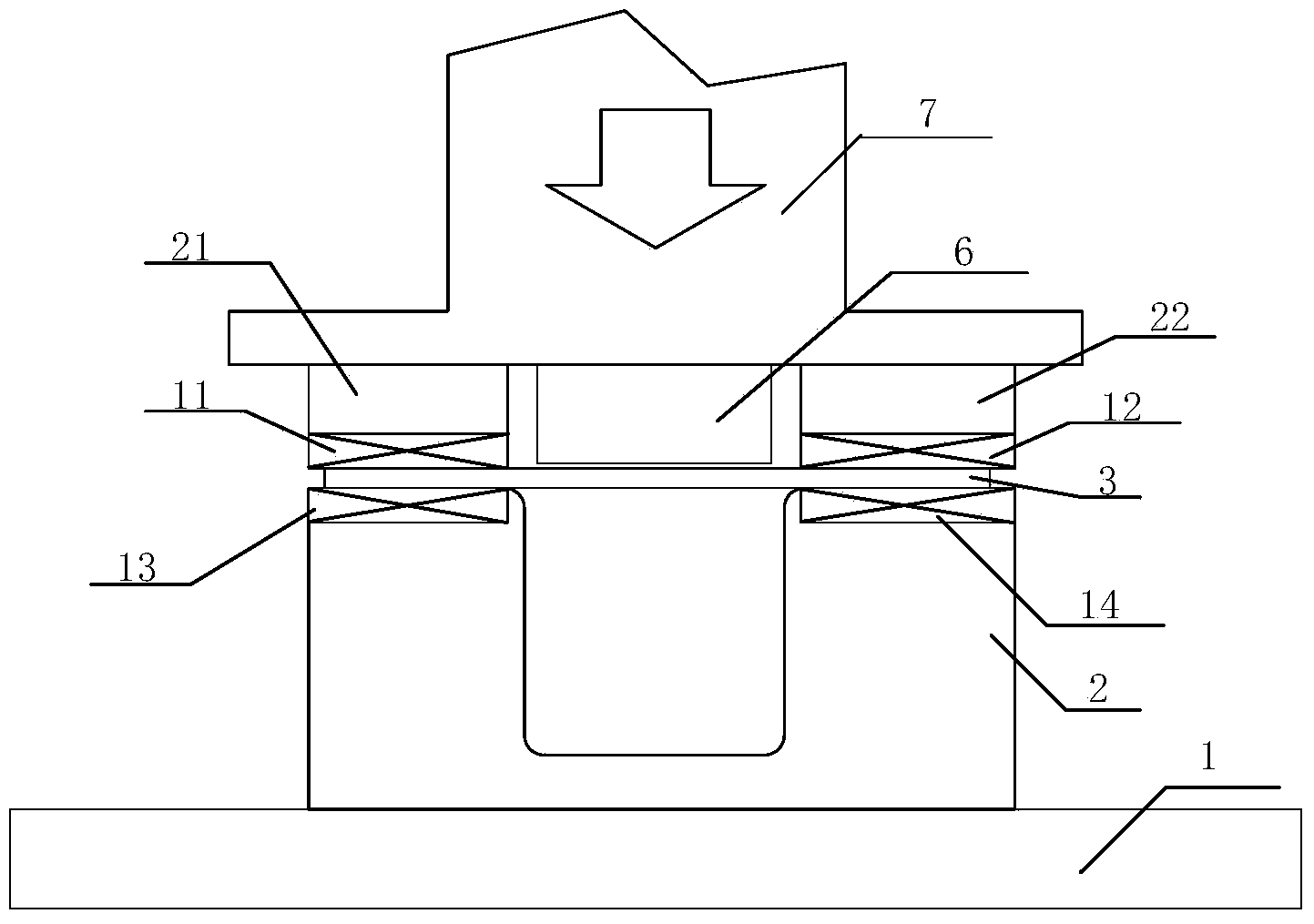

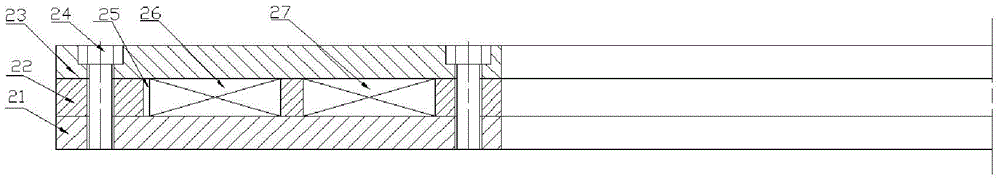

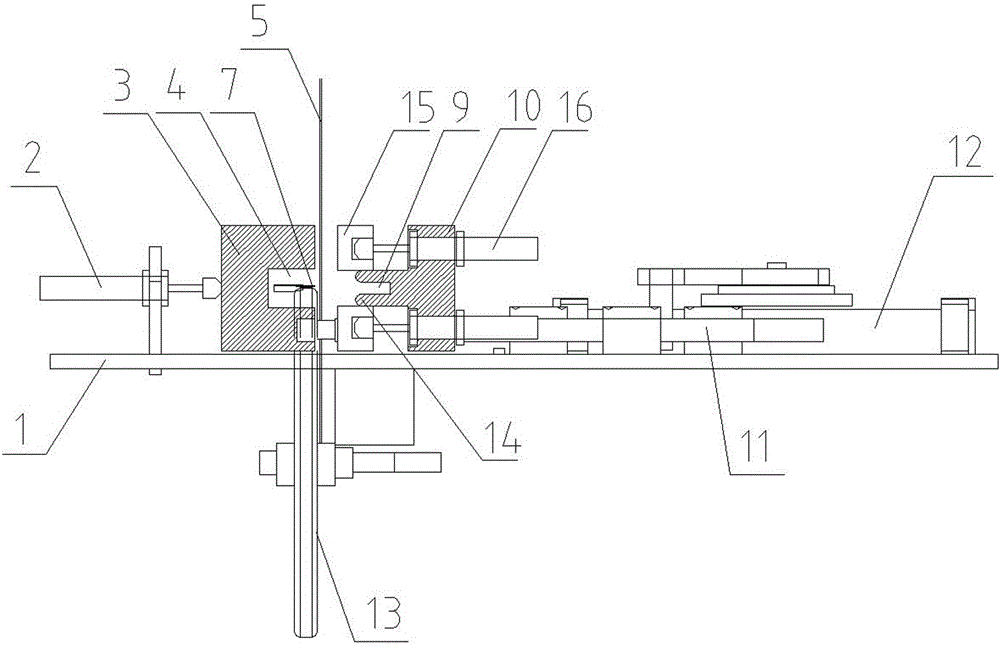

Electromagnetic blank pressing method and device applicable to high-speed forming

The invention discloses an electromagnetic blank pressing method and device applicable to high-speed forming. The electromagnetic blank pressing method comprises the steps that (1) in the forming process of a metal plate, an upper blank pressing coil set and a lower blank pressing coil set are arranged on the end surface of an blank pressing part; each blank pressing coil set comprises two different-direction current coils, each blank pressing coil set is embedded in a framework made of high-strength materials, and the frameworks are encapsulated with epoxy resin and then connected into a whole through a high-strength bolt; a lead end of each coil is guided out of the corresponding framework through a copper bar; and (2) in the high-speed forming process, pulse current is led into the blank pressing coil sets, and the two coil sets generate big mutual attraction force; the attraction force is transmitted to the metal plate through the frameworks to carry out blank pressing, or transmitted to a blank holder through the frameworks to carry out blank pressing. By means of the electromagnetic blank pressing method and device applicable to high-speed forming, the problems that a traditional electromagnetic forming process needs a press or a mechanical tool, and existing workpiece forming is limited by the size of a table surface of press equipment are solved, and the electromagnetic blank pressing method and device applicable to high-speed forming particularly meet the needs of large tonnage and a large table surface in a large-workpiece forming process.

Owner:HUAZHONG UNIV OF SCI & TECH

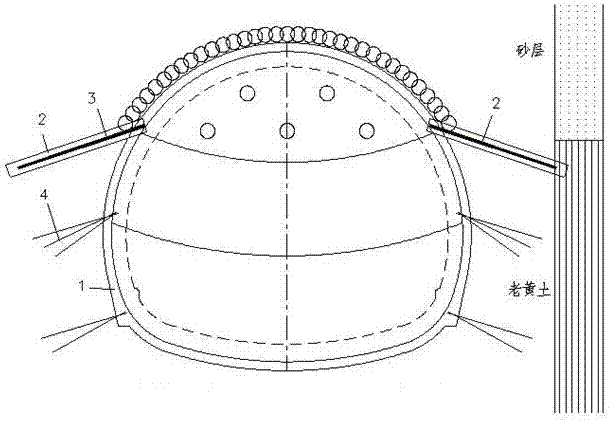

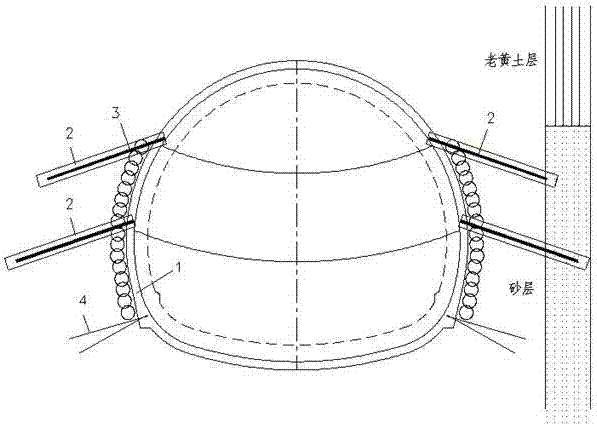

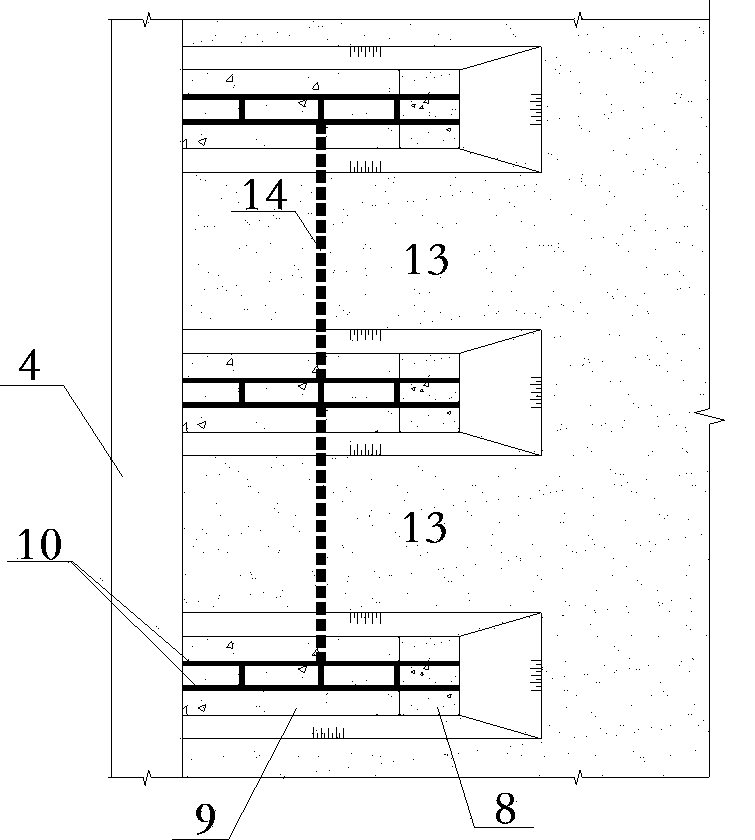

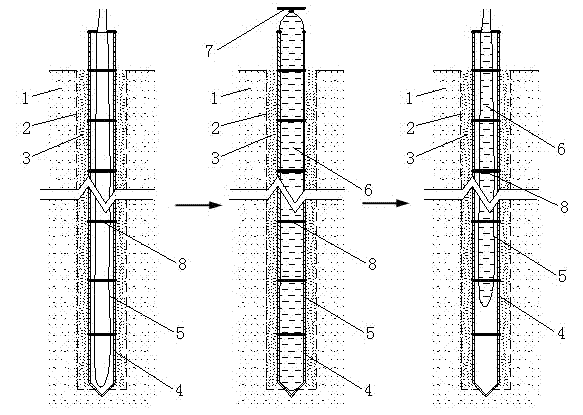

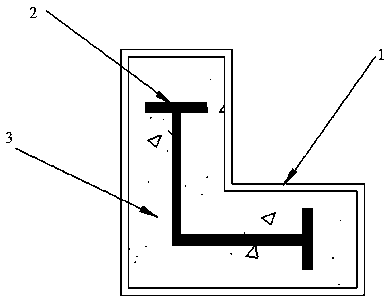

Lock foot pile support structure for controlling tunnel initial support settlement convergence

PendingCN106979027ASimple processLess impact from process changeoverUnderground chambersTunnel liningArchitectural engineeringSteel frame

The invention discloses a lock foot pile support structure for controlling tunnel initial support settlement convergence. The structure comprises an initial support in the tunnel grotto. A tilted lock foot pile is arranged at the outer wall of the initial support; the lock foot pile comprises a rotary jetting pile body, and the rotary jetting pile body is connected to an L-shaped steel core material. The other end of the L-shaped steel core material is connected with a connecting steel bar. The connecting steel bar is connected to an I beam steel frame of the initial support. The lock foot pile support structure for controlling the tunnel initial support settlement convergence has the advantages that the technical process is simple; the effected interference to the process conversion is less, the operation is convenient; the work efficiency is improved; the problems that the excavations of middle and lower steps cause the arch foot to be vacant, the side wall of the tunnel is unstable or the slippage and the grouting and anchorage effect of lock foot are poor are overcome; the stability of the palm surface, the deformation and settlement of the control cavern and the mechanized construction are achieved.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

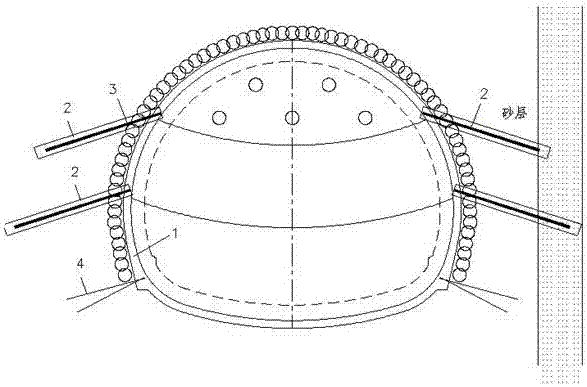

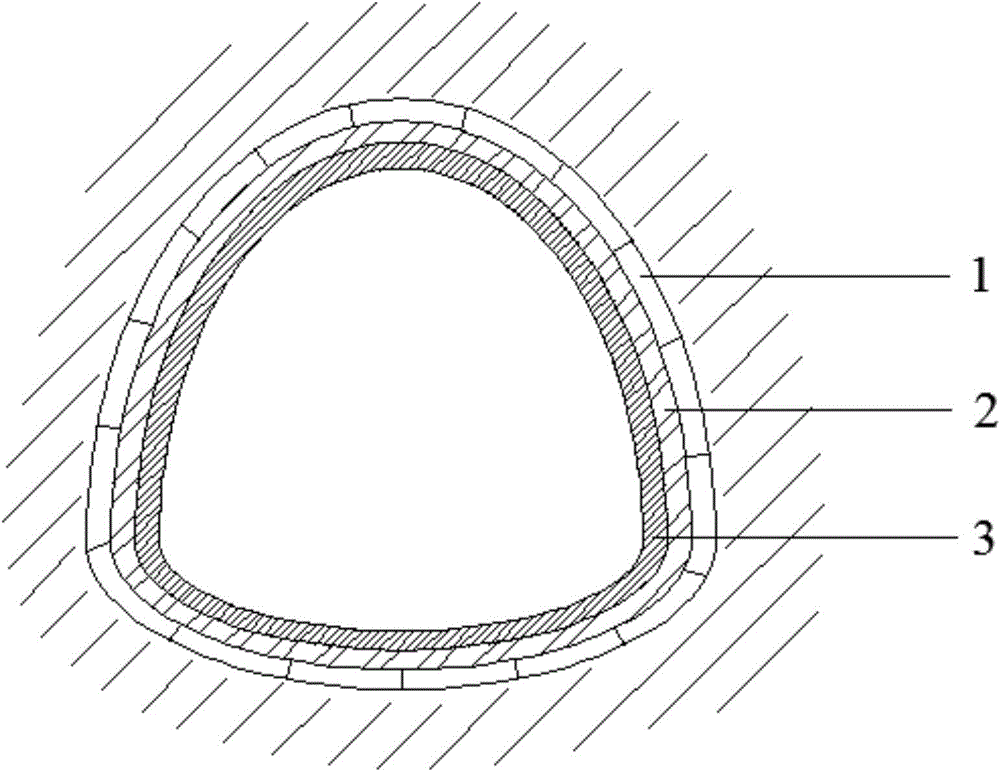

Supporting device and method for loess tunnel

InactiveCN104612708AEasy constructionImprove support strengthUnderground chambersTunnel liningReinforced concreteRebar

The invention discloses a supporting device and method for a loess tunnel. The method includes the steps that first wood boards are arranged on the outmost layer of the supporting device, are tightly attached to the wall of the tunnel and surround the tunnel by one circle, so that a load-bearing arch is formed; a plurality of steel arch frames are arranged on the inner layers of the first wood boards at intervals, and the steel arch frames are tightly attached to the first wood boards; the space between every two adjacent steel arch frames is filled with a second wood board, and the second wood boards are flush with the surfaces of the steel arch frames; prefabricated steel reinforced concrete pipe pieces are tightly attached to the inner layers of the steel arch frames and the inner layers of the second wood boards and arranged on the innermost layer of the supporting device. The supporting device and method have the advantages that construction is convenient, supporting strength is high, safety and reliability are achieved, no water is needed in the whole process, the number and spacing of the steel arch frames can be adjusted according to on-site practical situations, the prefabricated steel reinforced concrete pipe pieces are adopted as a secondary lining so that construction quality can be better guaranteed compared with conventional anchor sprayed concrete, and the prefabricated steel reinforced concrete pipe pieces also make the tunnel more attractive.

Owner:SHANDONG UNIV +1

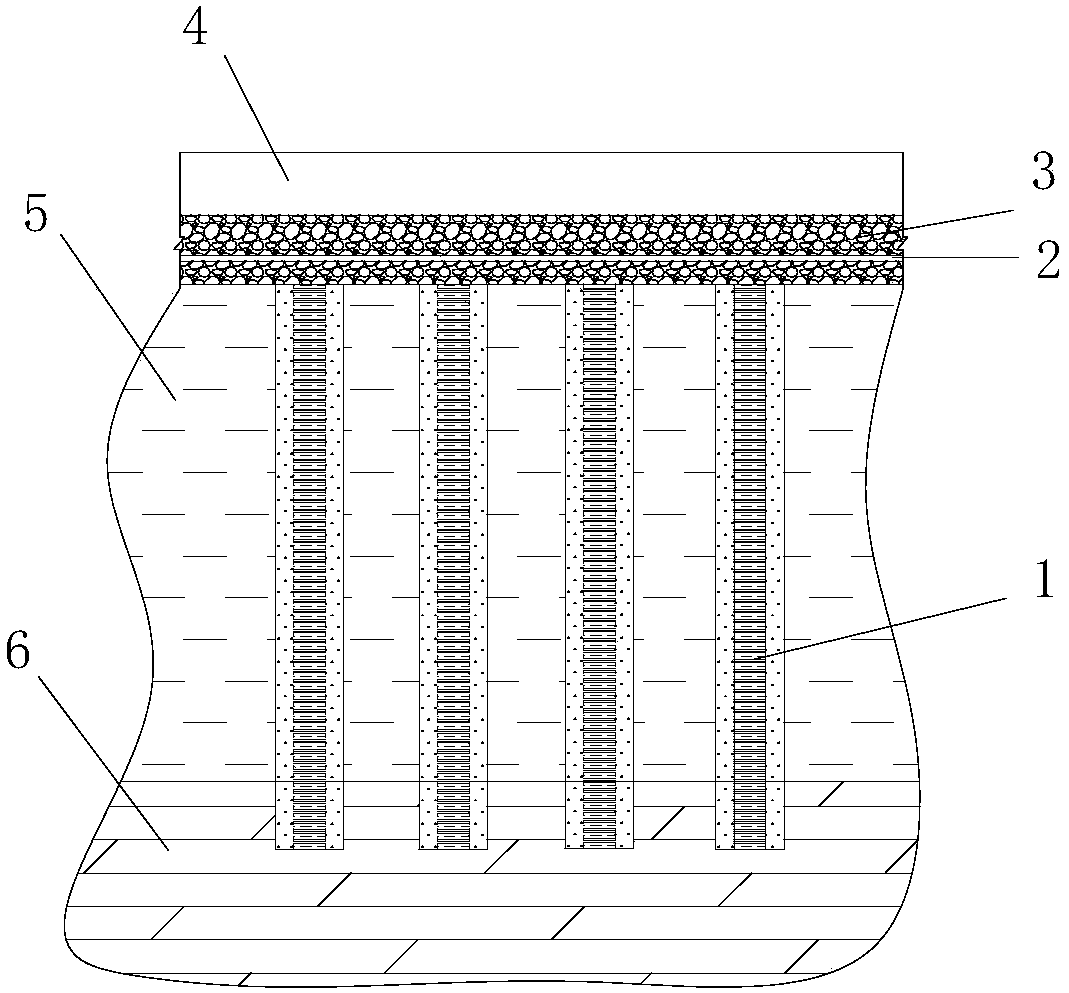

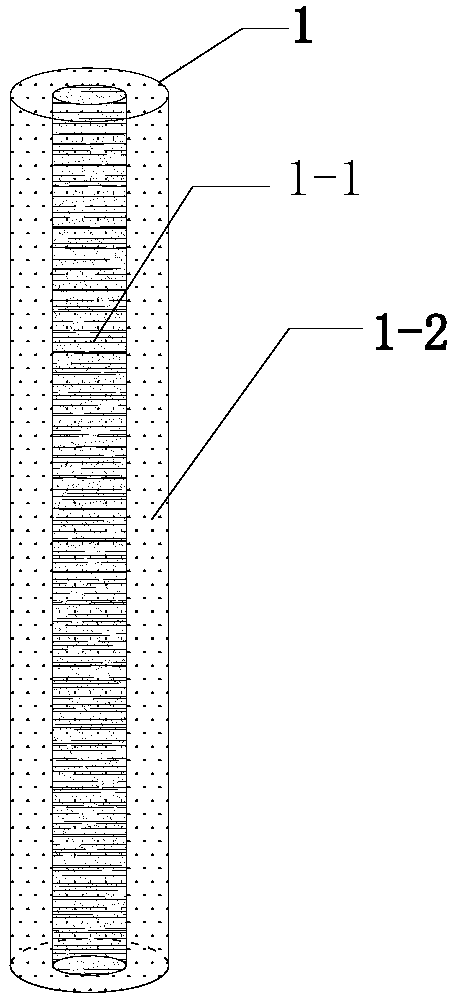

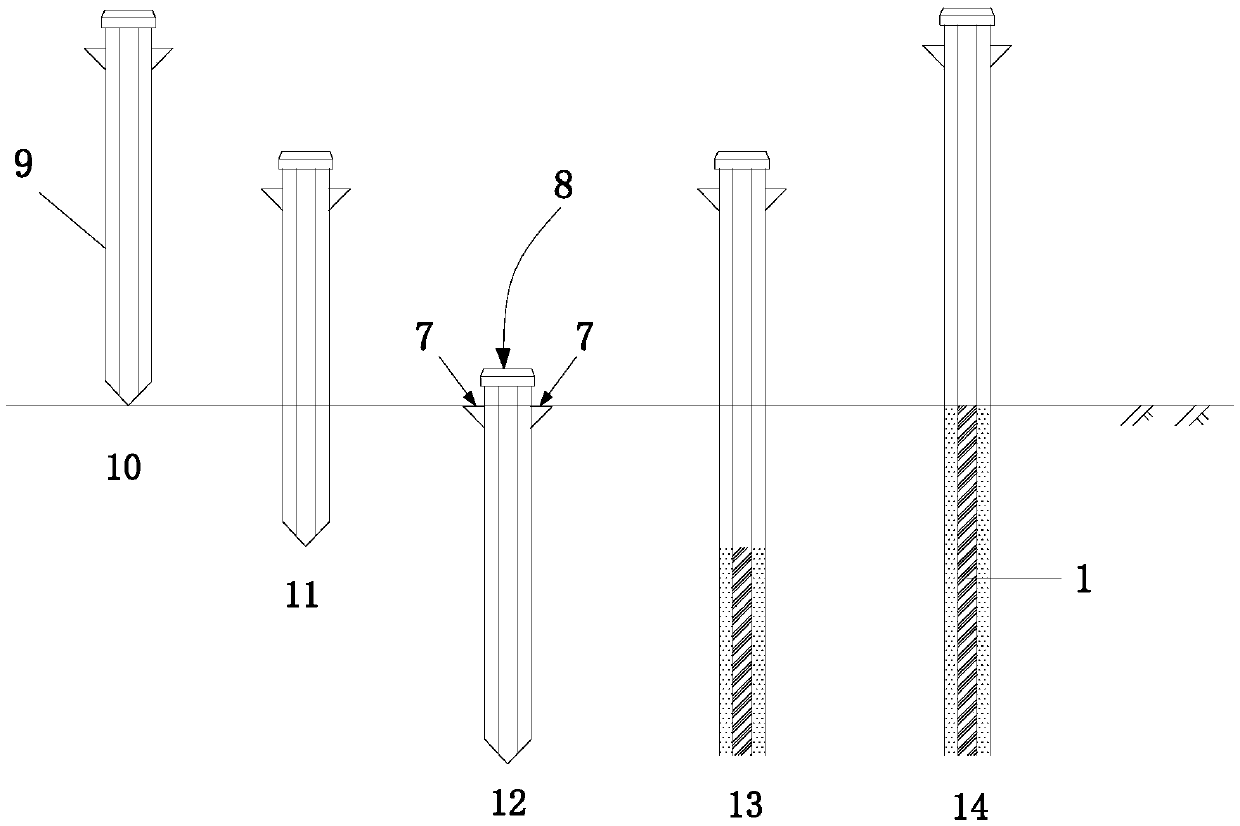

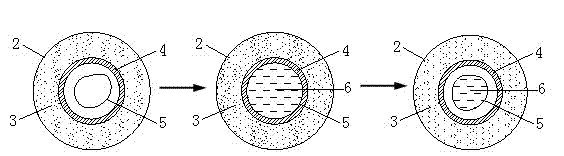

CFG core gravel composite pile, composite foundation formed by CFG core gravel composite pile and construction method

InactiveCN108677912AImprove stabilityShorten the construction periodSoil preservationSoil strengthIndustrial waste

The invention discloses a CFG core gravel composite pile, a composite foundation formed by the CFG core gravel composite pile and a construction method. The CFG core gravel composite pile comprises aCFG core and a gravel shell wrapping the CFG core, wherein the gravel shell is formed by sand and macadam according to the volume ratio being (1-2):1. The composite foundation formed by the CFG core gravel composite pile is characterized by comprising a soft soil foundation, the CFG core gravel composite pile driven into the soft soil foundation and a mattress layer filled into the position abovethe CFG core gravel composite pile and the soft soil foundation, and a geogrid is arranged on the mattress layer. The invention further discloses a construction method. The CFG core gravel composite pile, the composite foundation formed by the CFG core gravel composite pile and the construction method have the beneficial effects that the construction is easy and convenient, the pile forming speedis high, super-static pore water pressure in soil between piles in the construction period is quickly scattered, the soil strength is quickly restored, the working period is shortened, the post-construction settlement is small, and the industrial waste is used for reducing the building cost of projects; and the economic benefit and the social benefit are obvious.

Owner:JIANGSU UNIV OF SCI & TECH

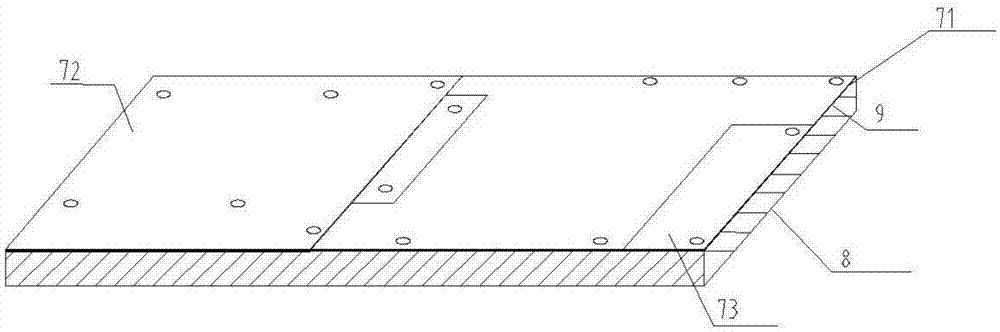

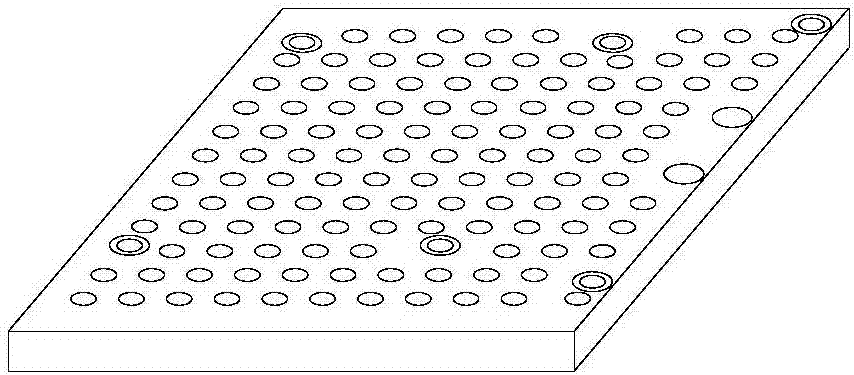

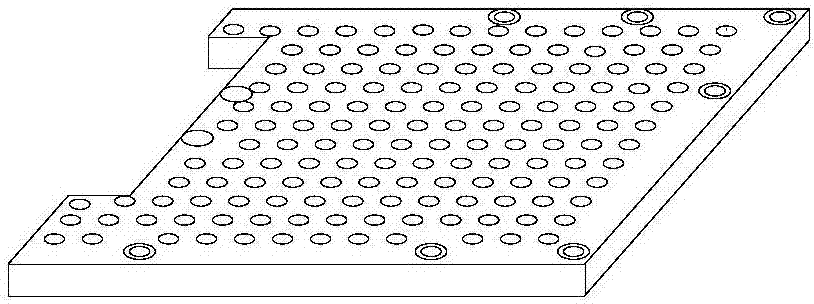

Metal substrate circuit board welding tool and application method thereof

ActiveCN107971602AConstrained deformationGood for volatilizationPrinted circuit assemblingSoldering auxillary devicesMetal substrateElectrical and Electronics engineering

A metal substrate circuit board welding tool comprises a backing board. The size of the backing board is consistent with that of a metal substrate. Fixed holes corresponding to threaded holes in the metal substrate are further formed in the backing board, and a spring screw is arranged on each fixed hole. The metal substrate circuit board welding tool further comprises a press plate, and springs are fixed to the bottom of the press plate. A hollowed portion is arranged at the middle position of the backing board, and stand columns used for locating the springs are put in the hollowed portion.

Owner:BEIJING BBEF SCI & TECH

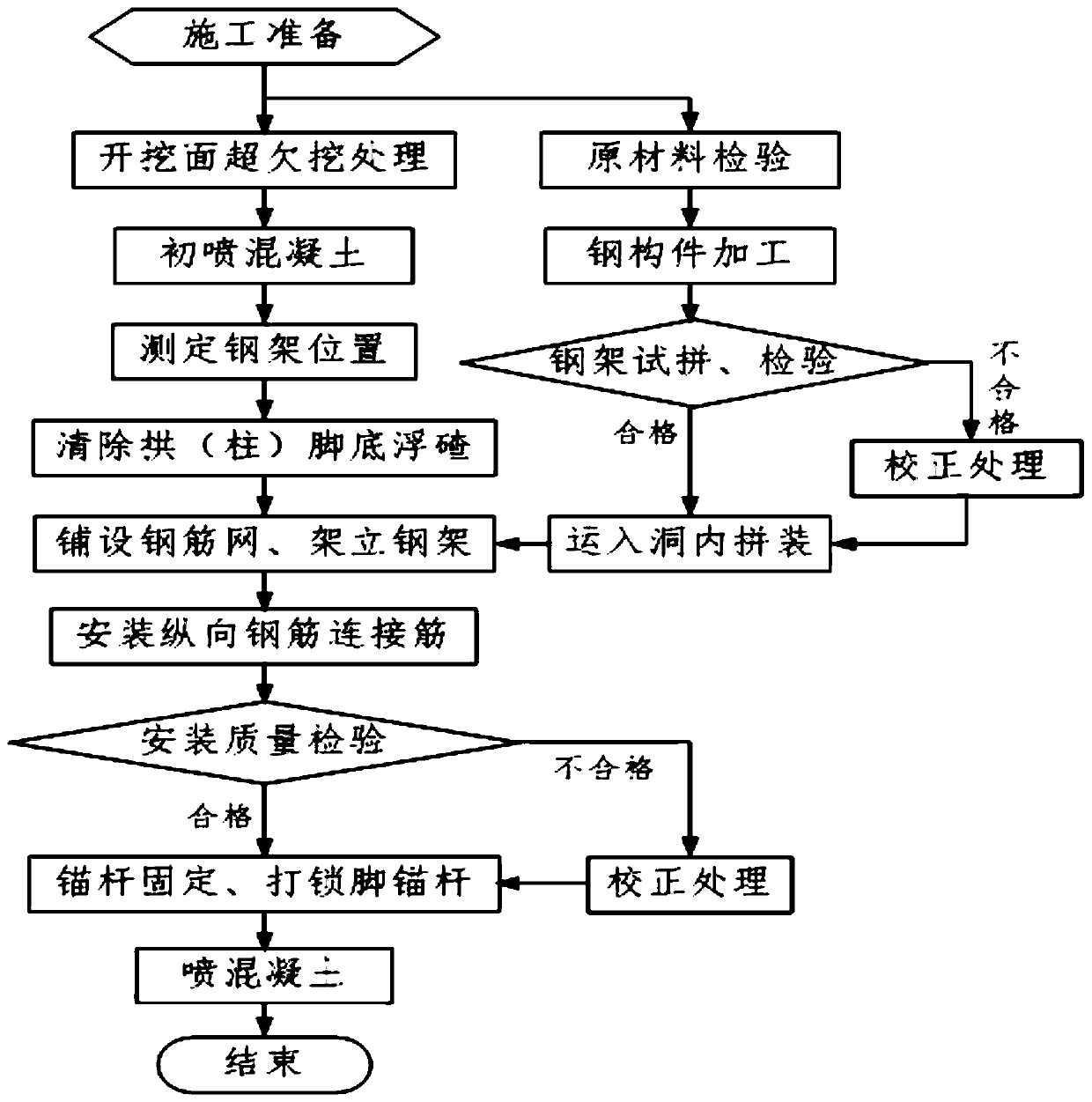

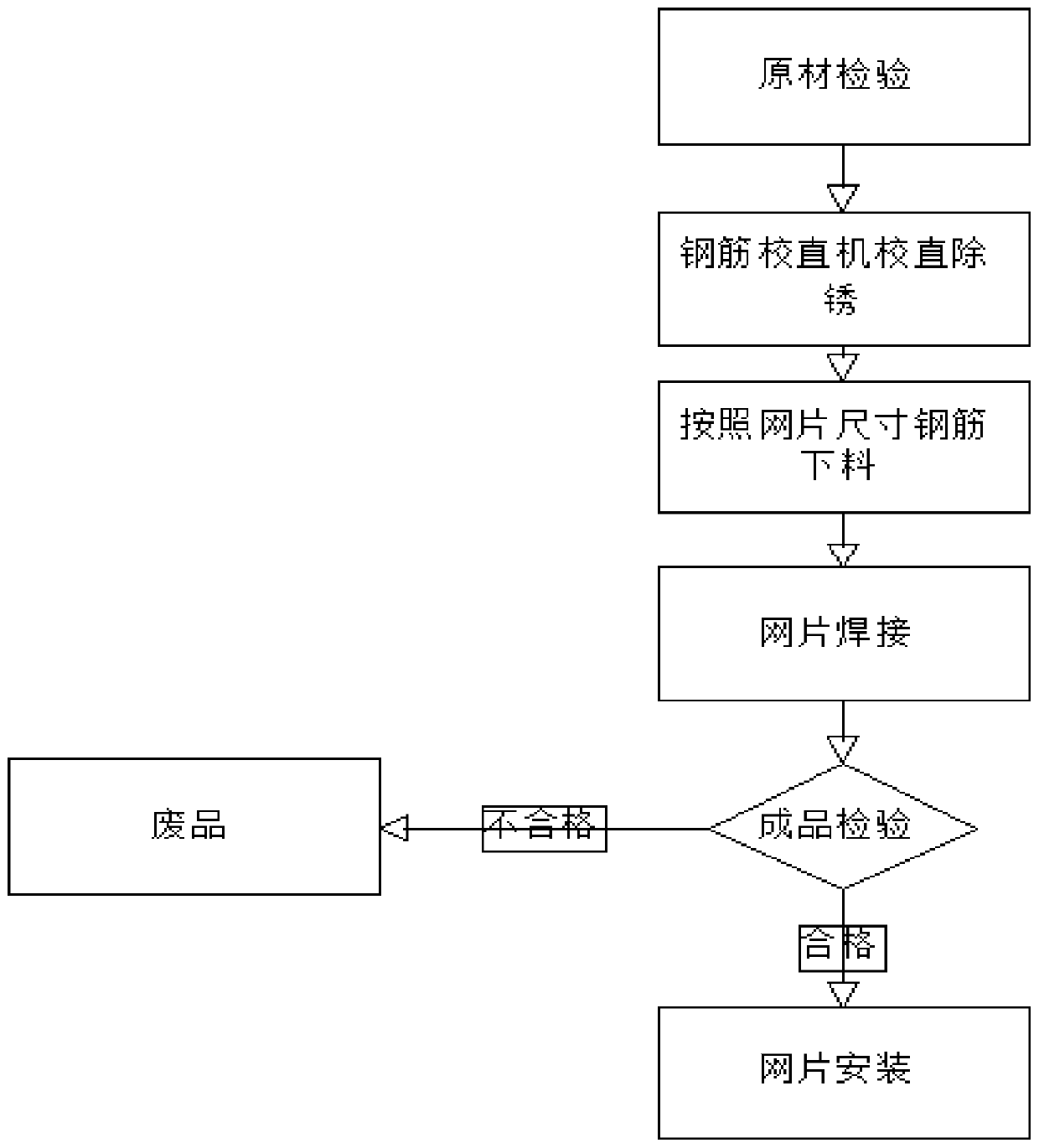

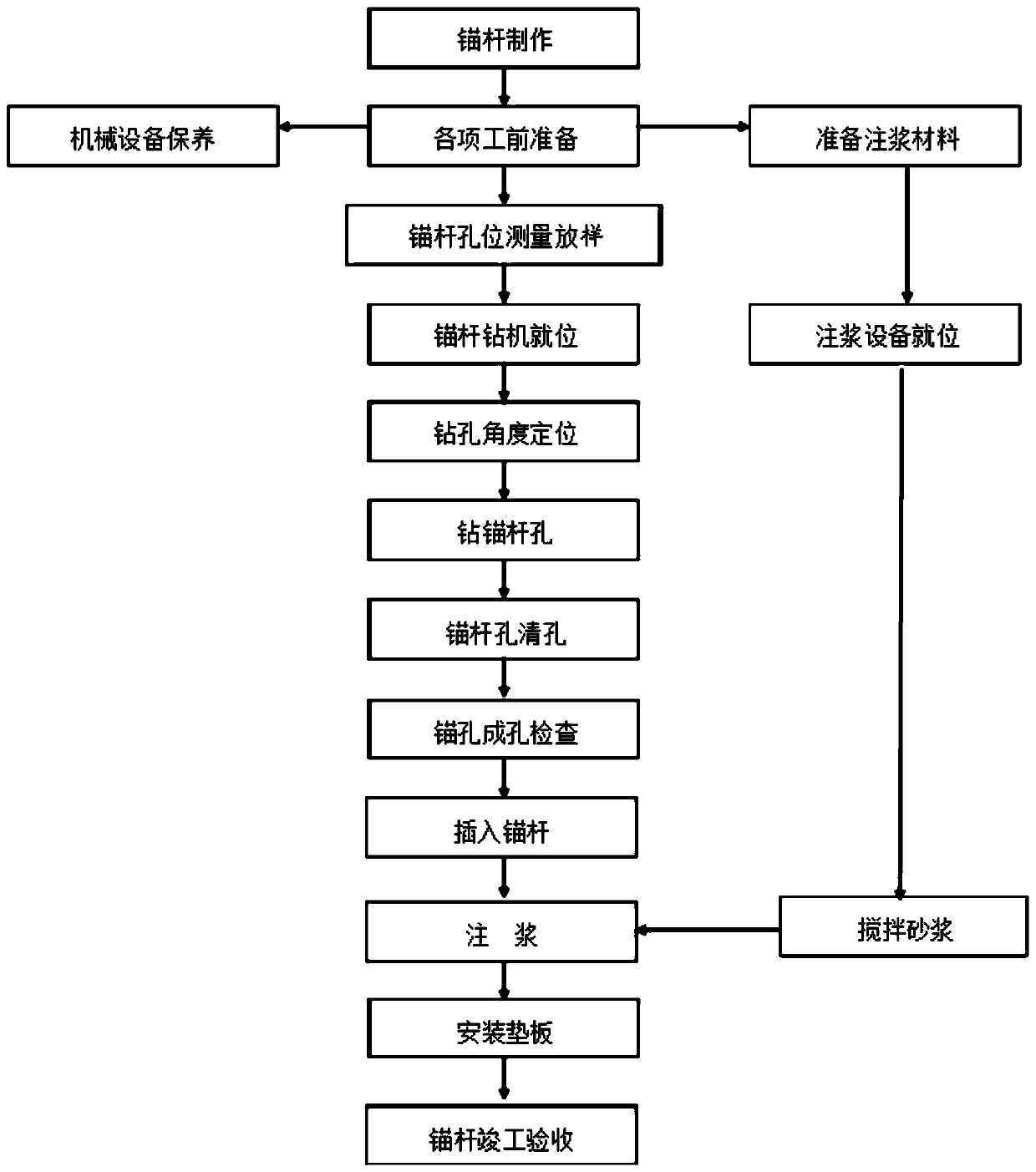

Construction technology for tunnel trunk primary support

ActiveCN110005435AConstrained deformationTo achieve the purpose of permanent supportUnderground chambersTunnel liningShotcreteRebar

The invention discloses a construction technology for tunnel trunk primary support. The construction technology for tunnel trunk primary support comprises the following steps of initial shotcrete, steel shotcrete installation, advanced support of a next cycle, reinforcing mesh installation, compound shotcrete and system anchor rod installation. When the step of initial shotcrete is carried out, awet spraying technology is adopted. The steel shotcrete installation process comprises the following steps of steel shotcrete manufacturing and steel shotcrete erection. Advanced small duct support iscarried out when the advanced support of the next cycle is carried out. The reinforcing mesh installation process comprises the steps of reinforcing mesh machining and reinforcing mesh installation pavement. When system anchor rod installation is carried out, a hollow grouting anchor rod is adopted according for a V-level surrounding rock segment. A cement mortar anchor rod is adopted for an IV-level surrounding rock segment. A cement mortar anchor rod is adopted for an III-level surrounding rock segment. The system anchor rod installation process comprises the steps of anchor rod manufacturing, anchor rod drilling, grouting and anchor rod installation. The construction technology for tunnel trunk primary support can perform effective reinforcement processing on tunnel surrounding rock, tunnel deformation is rapidly restrained, and the purpose of tunnel permanent support is achieved.

Owner:CCCC THIRD HARBOR ENG +2

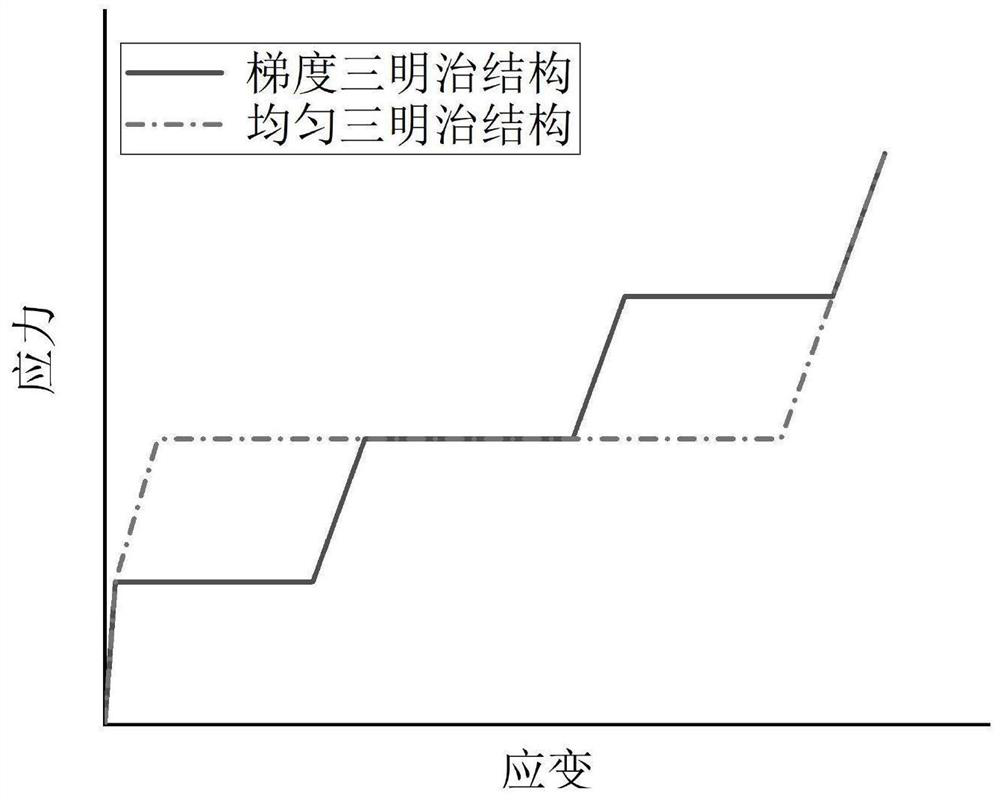

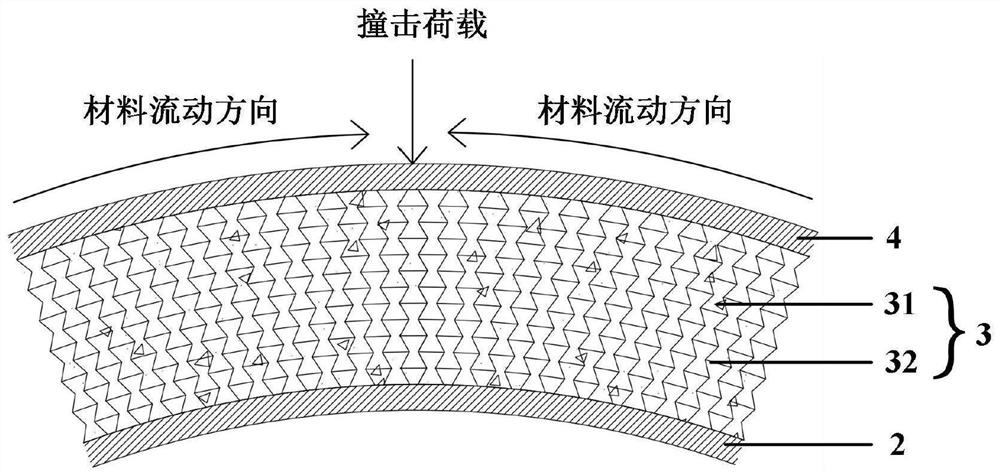

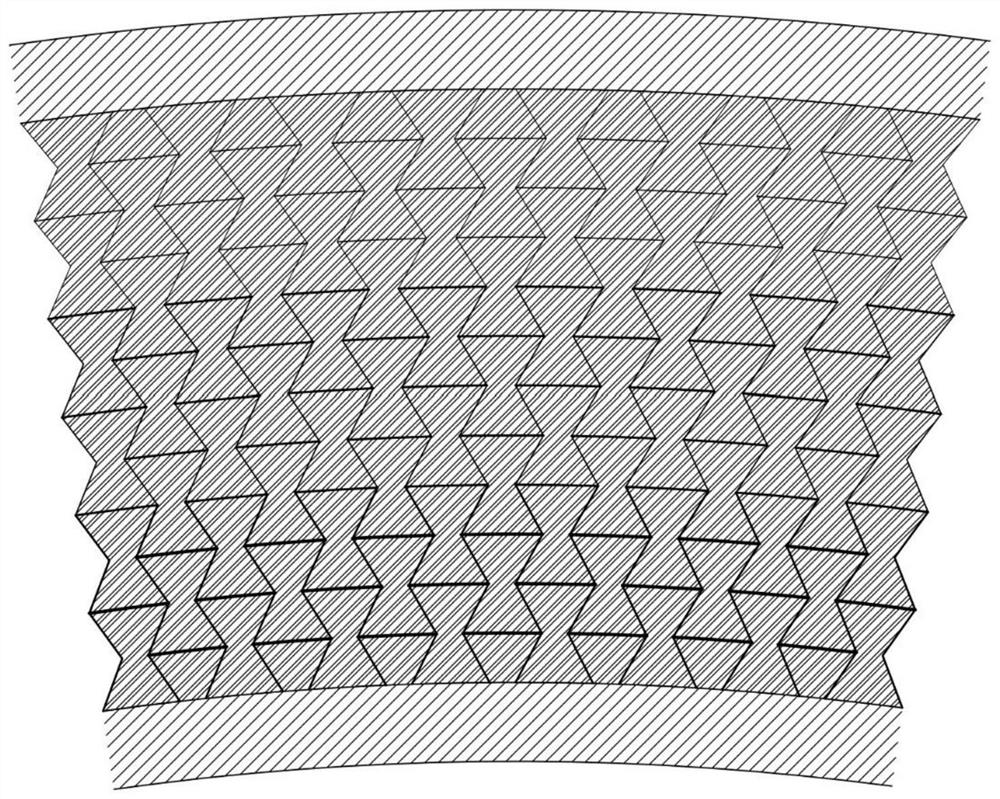

Layered gradient honeycomb filling pier anti-collision device with negative poisson ratio

InactiveCN112227187AAvoid YieldAvoid destructionClimate change adaptationBridge structural detailsEpoxyFoam concrete

The invention discloses a layered gradient honeycomb filling pier anti-collision device with a negative poisson ratio. The device comprises an outer-layer head-on collision panel, a layered gradient honeycomb filling sandwich layer and a steel plate inner anti-collision layer; the sandwich layer is composed of concave regular hexagon negative poisson ratio honeycomb framework and foam concrete materials filled in the honeycomb framework. All the components are formed by bonding epoxy resin glue, and the anti-collision sandwich structures are connected into a whole through I-shaped toggle clips. The device can achieve the effect of layered gradient through various forms such as cell wall thickness gradient, filler density gradient and cell element height gradient. Compared with a traditional anti-collision device, the device can absorb vehicle collision energy through plastic deformation and brittle deformation of materials, the energy absorption process can be controlled by changing the gradient form and the gradient coefficient, the vehicle collision force peak value is reduced, and the safety of piers and vehicles can be protected at the same time. The device is small in occupiedarea, convenient and fast to replace and small in adverse effect on traffic during replacement.

Owner:BEIJING UNIV OF TECH

Recyclable front-assembled supporting envelop enclosure and applying method thereof

The invention belongs to the technical field of foundation pit engineering and particularly relates to recyclable front-assembled supporting envelop enclosure and an applying method thereof. The recyclable front-assembled supporting envelop enclosure comprises a coping plate, at least two groups of steel tubes, a cemented soil wall, a front-assembled structural steel support frame, a pit bottom cushioning layer and a supporting buttress. The cemented soil wall is positioned below the coping plate and perpendicular to the coping plate, end portions of the two groups of steel tubes are connected and fixed with the coping plate, the inner group of steel tubes positioned on the inner side of the two groups of steel tubes are perpendicular to the coping plate and positioned in the cemented soil wall, and an angle is formed between the other group of steel tubes and the inner group of steel tubes. The front-assembled structural steel support frame is arranged perpendicular to the middle of the cemented soil wall, and the pit bottom cushioning layer and the supporting buttress are both positioned below the cemented soil wall and are integrated. The recyclable front-assembled supporting envelop enclosure has the advantages of being easy to install and dismantle, convenient to construct, recyclable, friendly to the environment, low in manufacture cost and convenient to popularize.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST +1

Z-shaped steel pipe-steel framework recycled concrete combined pillar

InactiveCN104060763ASave energyImprove fire resistanceStrutsBuilding reinforcementsSheet steelSteel frame

The invention relates to a Z-shaped steel pipe-steel framework recycled concrete combined pillar. The Z-shaped steel pipe-steel framework recycled concrete combined pillar is composed of a steel framework, a steel pipe and recycled concrete, wherein the steel framework is formed by welding steel plates, the recycled concrete is located in the steel pipe and wraps the steel framework, the steel pipe surrounds the concrete and is shaped like a Z, the steel framework is welded to form a Z shape, is located in the center of the Z-shaped steel pipe and is coaxial with the Z-shaped steel pipe, the recycled concrete is arranged outside the steel frame, and an inner steel framework and the steel pipe are fixed to a base plate in a welding or bolt connection mode. The steel framework is located in the center of a Z-shaped pillar, and the stress performance of branch parts of the Z-shaped pillar is improved. The Z-shaped steel pipe is located outside, the concrete in the steel pipe is in a three-directional stressed state, and deformation of the concrete is restrained. The Z-shaped steel pipe-steel framework recycled concrete combined pillar is a main component of a framework structure in a high-rise and large-span building, and has the advantages of being high in bearing force, high in rigidity, light in weight, good in plasticity and tenacity, good in impact resistance and fatigue resistance, good in vibration resistance and good in durability, saving energy, protecting the environment and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

Magnesium-based spherical quasicrystal master alloy and preparation method thereof

The invention provides a magnesium-based spherical quasicrystal master alloy and a preparation method thereof, which relates to a magnesium-based alloy taking zinc as a secondary main component. The alloy is a Mg-Zn-Y-C quaternary magnesium-based icosahedral spherical quasicrystal master alloy comprising the following chemical components: 55.0 to 65.0 percent of Mg, 30.0 to 40.0 percent of Zn, 2.5 to 5.5 percent of Y, and 0.1 to 0.5 percent of C, wherein the diameter of spherical quasicrystals is 3 to 7 mu m; the average diameter of the spherical quasicrystals is 6 mu m; and the volume of the spherical quasicrystals accounts for 40 to 48 percent of the total volume of the alloy. The preparation method is characterized by adopting control over solidification rate, namely pouring molten alloy into a casting mold with cooling rate controllable and controlling the solidification rate in a range between 68.4 and 84.8 K / s. The alloy can improve the mechanical properties of alloy material better when a magnesium alloy matrix is reinforced, and has the advantages of simple process, not high demand for equipment, extensive sources of raw materials, convenience for realizing industrialized production and resource conservation.

Owner:HEBEI UNIV OF TECH

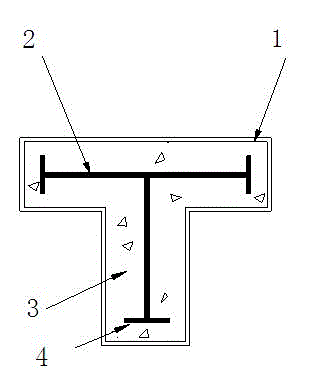

T-shaped steel pipe-steel rib recycled concrete combination column

The invention relates to a T-shaped steel pipe-steel rib recycled concrete combination column. The T-shaped steel pipe-steel rib recycled concrete combination column is composed of a steel rib, a steel pipe and recycled concrete, wherein the steel rib is formed by welding steel plates; the recycled concrete is located in the steel pipe; the concrete covers the steel rib; the steel pipe is in a T shape surrounding the concrete; the steel rib is welded to form the T shape and is distributed in the T shape; the steel rib which is distributed in the T shape is located at the center of the T-shaped steel pipe and is coaxial to the T-shaped steel pipe; the inner steel rib and the steel pipe are fixedly connected with a bottom plate through welding or bolt connection. The T-shaped steel pipe-steel rib recycled concrete combination column is good for improving the stress performance of a limb part of the T-shaped column; the concrete in the steel pipe is in a three-directional stressing state so that the deformation of the concrete is restricted and the application of fragile and high-strength concrete in the T-shaped column is accelerated; the T-shaped steel pipe-steel rib recycled concrete combination column is a main part of a framework structure in a high-rise and large-span building and has the characteristics of high bearing capability, high rigidity, light weight, good plasticity and toughness, good anti-impact and anti-fatigue performances, excellent anti-seismic property, good durability, energy conservation, environment friendliness and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

Inner geotextile bag sleeve valve pipe grouting construction method

InactiveCN103898913AAvoid pulping problemsSerum blocking effectFoundation engineeringSlurryMechanical engineering

The invention discloses an inner geotextile bag sleeve valve pipe grouting construction method. On the basis of a conventional sleeve valve pipe grouting technology, a geotextile bag which can be filled with water and made by sewing impermeable geotextile is applied. After a sleeve valve pipe is inserted or first-time grouting is ended, the geotextile bag slightly longer than the sleeve valve pipe is guided to the bottom of the sleeve valve pipe through a cavity in the sleeve valve pipe, and clean water is poured into the geotextile bag till the whole cavity of the sleeve valve pipe is filled with clean water; when first-time grouting on holes to be injected with slurry starts or before repeated second-time grouting on the holes to be injected with slurry starts, the geotextile bag is taken out, and the remaining steps are the same as a conventional sleeve valve pipe grouting construction method. With the method, not only are the advantages of the conventional sleeve valve pipe grouting kept, but also the problem that slurry enters the sleeve valve pipe because of slurry mixing in the grouting process and the problem that the sleeve valve pipe is blocked because of deformation are solved, and meanwhile remaining slurry in the sleeve valve pipe can be removed effectively. The applied geotextile bag is easy to manufacture, low in cost, convenient to construct and capable of being repeatedly used and thus has very good application prospects.

Owner:HOHAI UNIV

Design method for vertical type foundation pit supporting structure

The invention relates to the technical field of foundation pit engineering, in particular to a design method for a vertical type foundation pit supporting structure. The design method for the vertical type foundation pit supporting structure is characterized in that the supporting structure comprises a supporting pile and a supporting body. The design method specific to the double-row pile type supporting pile at least comprises the following steps that the supporting body is simplified into a supporting point of the foundation pit supporting structure according to the rigidity; the internal deformation force of the supporting pile and the supporting body under the soil pressure action is calculated; the resistance needed by the supporting body is calculated; and the included angle between the supporting body and the supporting pile and the length of the supporting body are calculated according to the resistance needed by the supporting body. The design method for the vertical type foundation pit supporting structure has the advantages that the vertical type foundation pit supporting structure has the multiple functions of reinforcement, soil blocking and water stopping, restrains deformation of a soil body, improves the stability of the wall of a foundation pit and realizes support-free or barrier-free construction in the pit; the related double-row pile soil pressure distribution theory research is disputed in the rock-soil field for a long time and no general agreement is achieved; monitoring data is the convincing measured data, the calculation mode is improved, and parameters are obtained through back calculation with the monitoring data, so that an effective way is provided to solve the problem.

Owner:SHANGHAI GEOTECHN INVESTIGATIONS & DESIGN INST

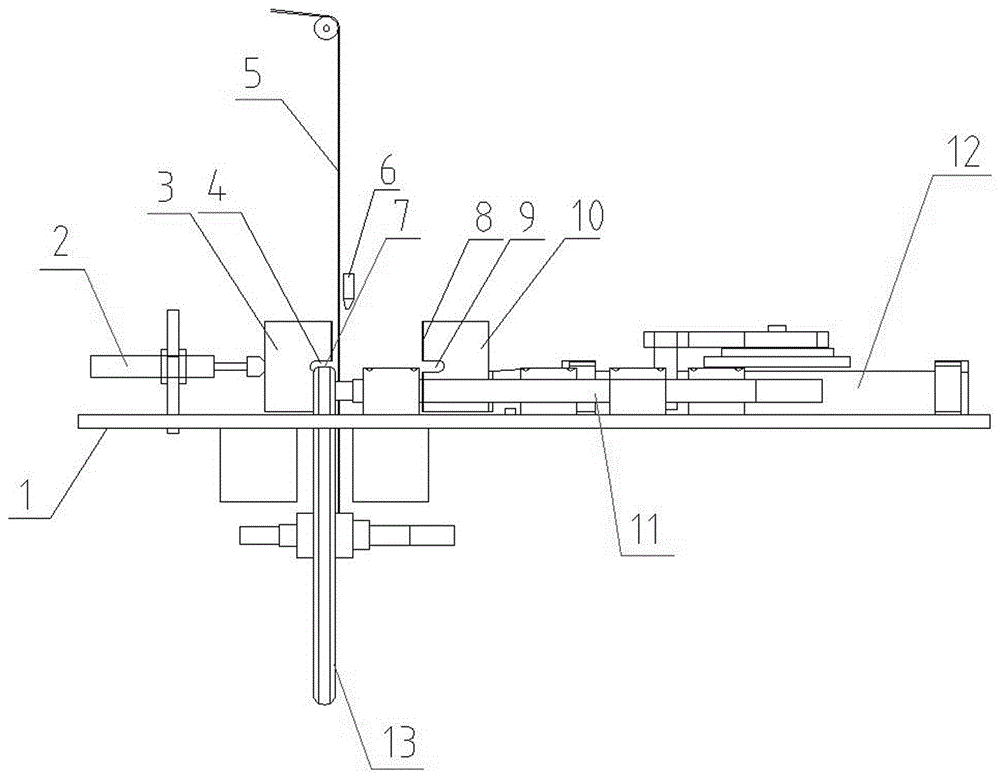

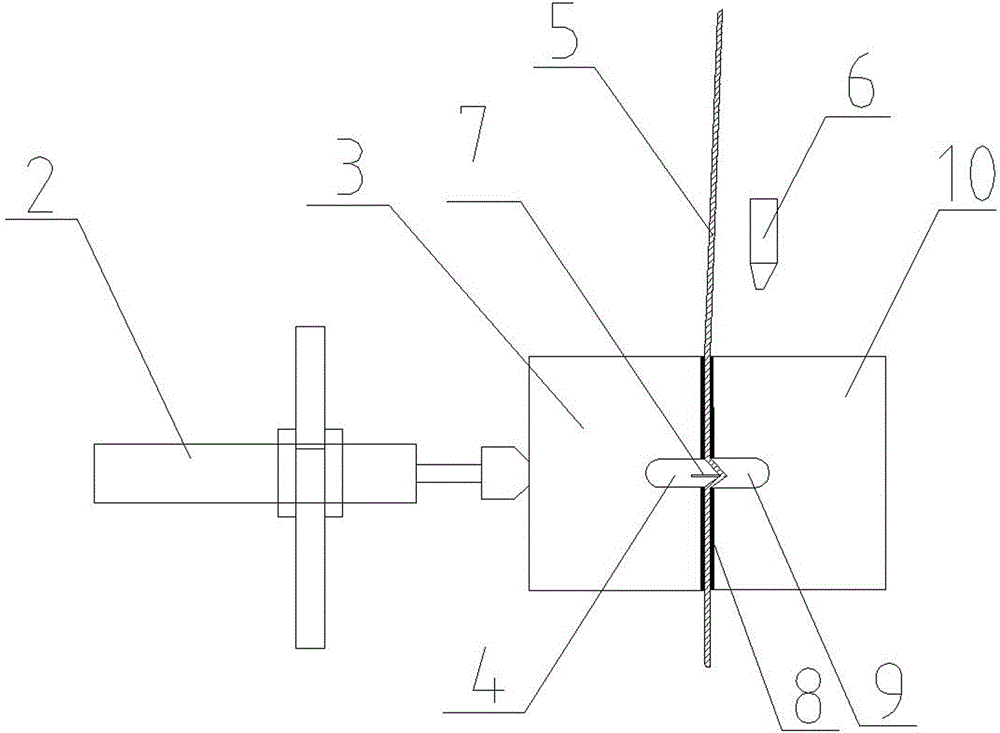

Quick transverse cloth shearing system

PendingCN105926265ASolve the problem of manual horizontal cuttingImprove work efficiencySevering textilesEngineeringMechanical engineering

The invention discloses a quick transverse cloth shearing system which is provided with a machine frame. The machine frame is provided with a cloth vertical falling channel. The machine frame on one side of the channel is provided with a fixed knife block, the back side of the fixed knife block is provided with a first elastic supporting device, the corresponding cloth side of the fixed knife block is provided with a knife groove, the machine frame is provided with two or more ring knife wheels, annular knife bands are installed on the ring knife wheels, and one straight section of each annular knife band is located in the knife groove. The machine frame on the other side of the channel is provided with a movable knife block, the movable knife block is connected with a high-speed reciprocating mechanism, and the movable knife block is guided by a guide rod and performs reciprocating linear movement under the effect of the high-speed reciprocating mechanism. Compared with the prior art, the quick transverse cloth shearing system is compact in structure and can quickly shear the cloth and adapt to shearing of cloth of different cloth widths, the cloth shearing linear speed can be 90 m / min at the highest, the working efficiency is improved, and the problem that an intermittent stopping transverse fabric cutting machine is not so quick as the manual cutting speed at present is solved.

Owner:孟周强

L-shaped steel pipe-steel framework recycled concrete combined pillar

InactiveCN104060762ASave energyConstrained deformationStrutsPillarsHigh strength concreteStressed state

The invention relates to a concrete component, in particular to an L-shaped combined pillar applied to civil engineering. The L-shaped steel pipe-steel framework recycled concrete combined pillar is composed of a steel framework, a steel pipe and recycled concrete, wherein the steel framework is located in the center of an L-shaped pillar and can improve the stress performance of branch parts of the L-shaped pillar; the L-shaped steel pipe is located outside, concrete in the steel pipe is in a three-directional stressed state, deformation of the concrete is restrained, and application of brittle high-strength concrete to the L-shaped pillar is facilitated; the recycled concrete can effectively improve the corrosion resistance of the pillar, resources are saved, and the environment is protected. The L-shaped steel pipe-steel framework recycled concrete combined pillar is a main component of a framework structure in a high-rise and large-span building, and has the advantages of being high in bearing force, high in rigidity, light in weight, good in plasticity and tenacity, good in impact resistance and fatigue resistance, good in vibration resistance and good in durability, saving energy, protecting the environment and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

Composite negative-poisson-ratio honeycomb vibration isolation and impact resistance device

ActiveCN106641088APlay the role of vibration isolation and shock resistanceExpand the field of structural applicationNon-rotating vibration suppressionMechanical equipmentVibration isolation

The invention provides a composite negative-poisson-ratio honeycomb vibration isolation and impact resistance device which comprises a composite panel (1), a negative-poisson-ratio honeycomb core (2), an outer sealing plate (3), an inner sealing plate (4) and a bottom sealing plate (5), and the overall device is formed in a welding manner. The bottom sealing plate of the device is connected with the floor through a bolt, and mechanical equipment is placed on the composite panel to be connected through a bolt. According to the composite negative-poisson-ratio honeycomb vibration isolation and impact resistance device, adjustable parameters are wide and include the composite laying manner, the inner and outer sealing plate thickness, the negative-poisson-ratio honeycomb core layer number and angle and the like; the impact resistance performance and low-frequency vibration isolation performance are both taken into consideration; the defects that a traditional equipment base is heavy and low in effect are overcome; and a new field is exploited for engineering application of the negative-poisson-ratio honeycomb structure.

Owner:SHANGHAI JIAO TONG UNIV

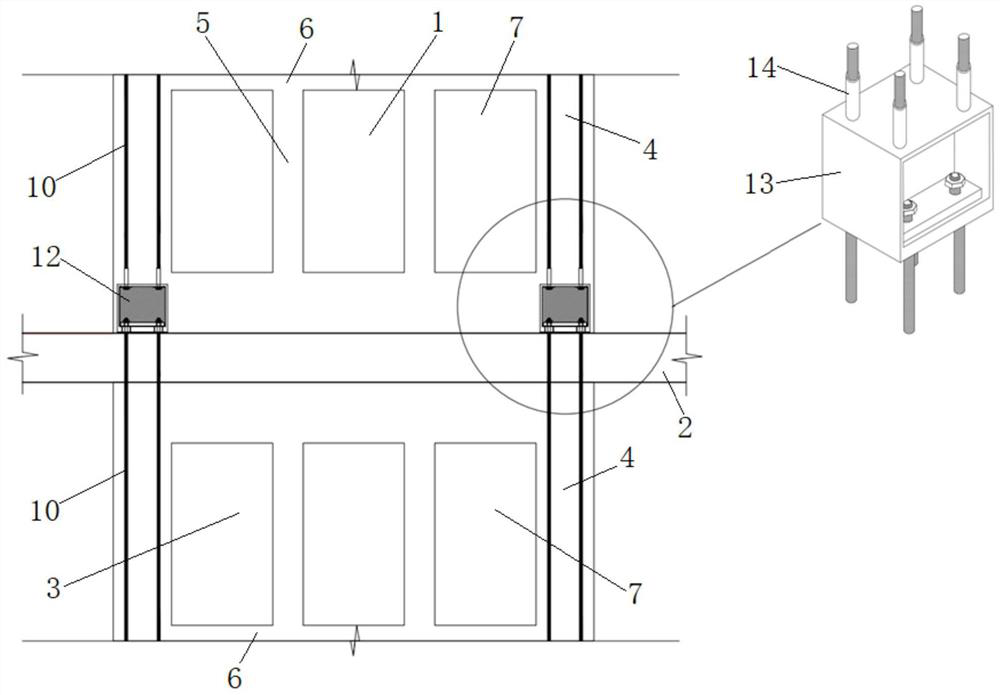

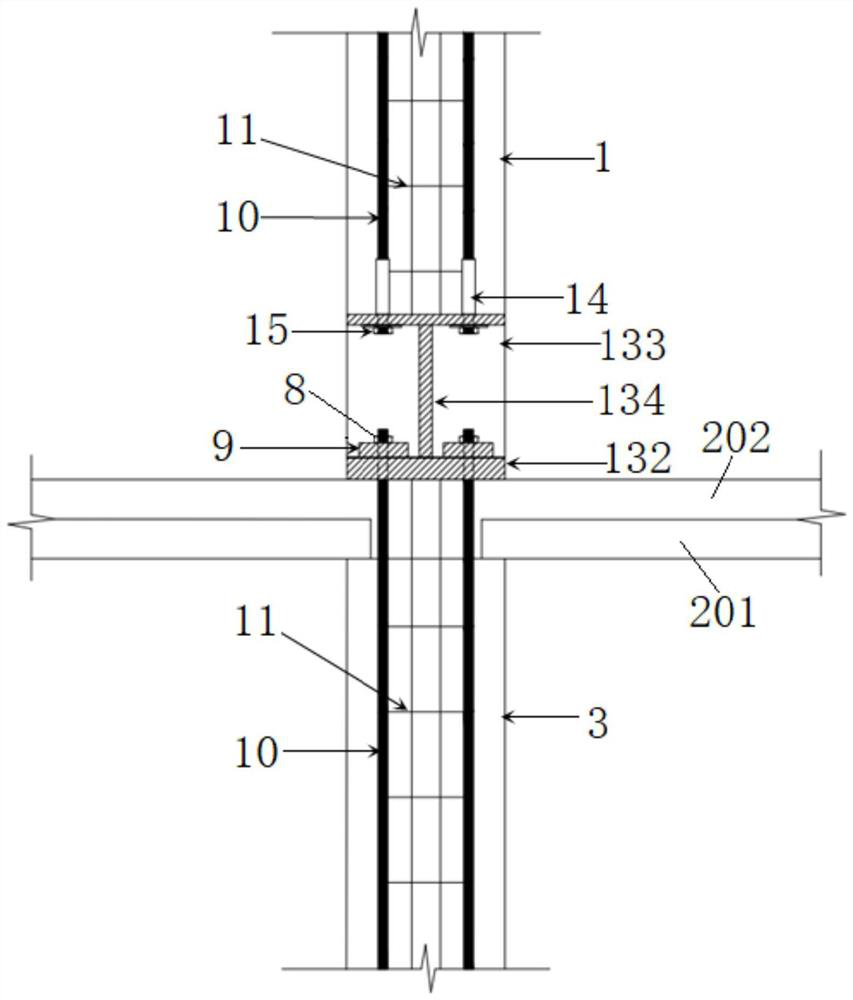

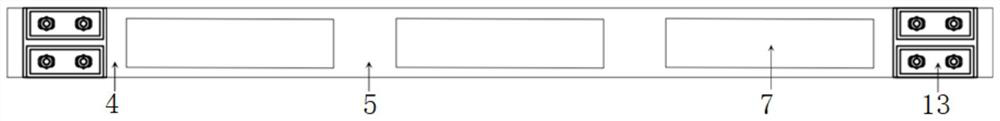

Ribbed box-based assembly type wall connecting structure and construction method thereof

PendingCN111663682APower transmission is clearGuaranteed efficient deliveryWallsProtective buildings/sheltersWall plateMechanical engineering

The invention discloses a ribbed box-based assembly type wall connecting structure and a construction method thereof. The structure comprises a prefabricated wall plate, wherein a through long longitudinal rib is arranged in the prefabricated wall plate, a ribbed connecting box is embedded at the bottom end of the prefabricated wall plate, the upper end of the longitudinal rib is exposed out of the top end of the prefabricated wall plate, the lower end of the longitudinal rib is fixedly connected with the ribbed connecting box, the ribbed connecting box comprises a ribbed box body and a threaded sleeve, wherein the ribbed box body is pre-buried on the two sides of the bottom end of the prefabricated wall plate, the threaded sleeve is vertically fixed at the top end of the ribbed box body,the lower end of the longitudinal rib in the prefabricated wall plate is fixedly arranged in the threaded sleeve in a penetrating mode, and the upper end of a longitudinal rib of a next layer of prefabricated wall plate extends into a ribbed connecting box of an upper layer of prefabricated wall plate. According to the structure, a vertical anchor rib is connected with the ribbed connecting box torealize assembly connection of upper and lower layer walls and floors, the vertical anchor rib is arranged in the prefabricated wall plate in a through long way, so that a stress of the prefabricatedwall plate can be accurately transmitted to a vertical adjacent wall body, force transmission is clear, the structural stability is good, and the assembling efficiency is high.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

An electromagnetic blank-holding method and device suitable for high-speed forming

The invention discloses an electromagnetic blank pressing method and device applicable to high-speed forming. The electromagnetic blank pressing method comprises the steps that (1) in the forming process of a metal plate, an upper blank pressing coil set and a lower blank pressing coil set are arranged on the end surface of an blank pressing part; each blank pressing coil set comprises two different-direction current coils, each blank pressing coil set is embedded in a framework made of high-strength materials, and the frameworks are encapsulated with epoxy resin and then connected into a whole through a high-strength bolt; a lead end of each coil is guided out of the corresponding framework through a copper bar; and (2) in the high-speed forming process, pulse current is led into the blank pressing coil sets, and the two coil sets generate big mutual attraction force; the attraction force is transmitted to the metal plate through the frameworks to carry out blank pressing, or transmitted to a blank holder through the frameworks to carry out blank pressing. By means of the electromagnetic blank pressing method and device applicable to high-speed forming, the problems that a traditional electromagnetic forming process needs a press or a mechanical tool, and existing workpiece forming is limited by the size of a table surface of press equipment are solved, and the electromagnetic blank pressing method and device applicable to high-speed forming particularly meet the needs of large tonnage and a large table surface in a large-workpiece forming process.

Owner:HUAZHONG UNIV OF SCI & TECH

Anti-sliding structure

PendingCN111173010AImprove stabilityImprove the anti-slip effectCoastlines protectionExcavationsClassical mechanicsStructural engineering

Owner:POWER CHINA KUNMING ENG CORP LTD

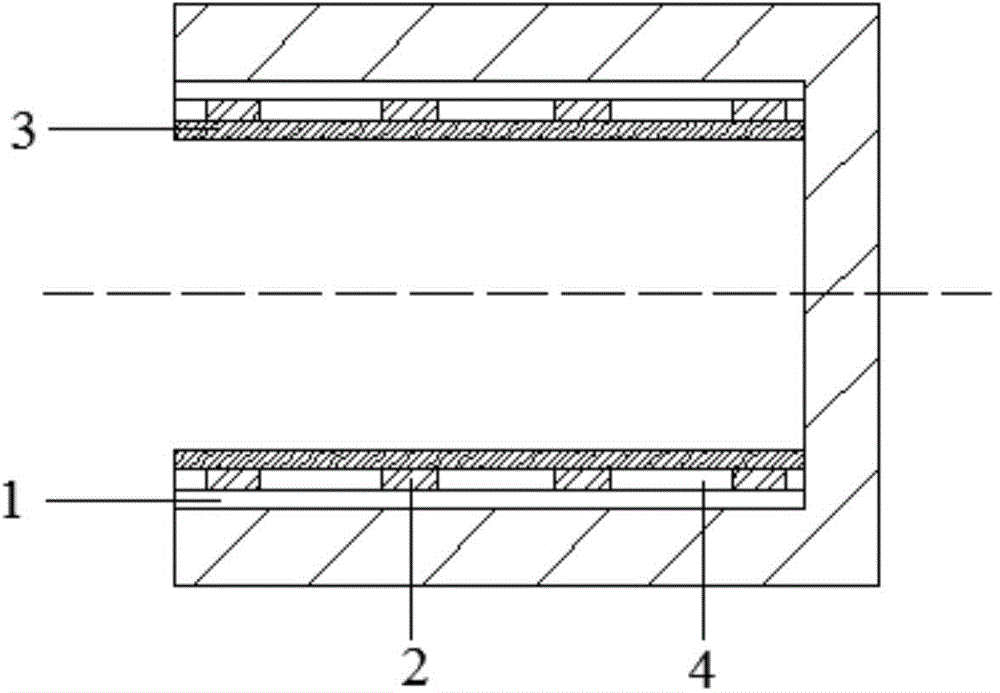

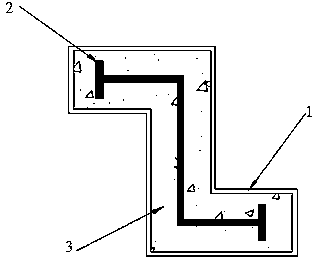

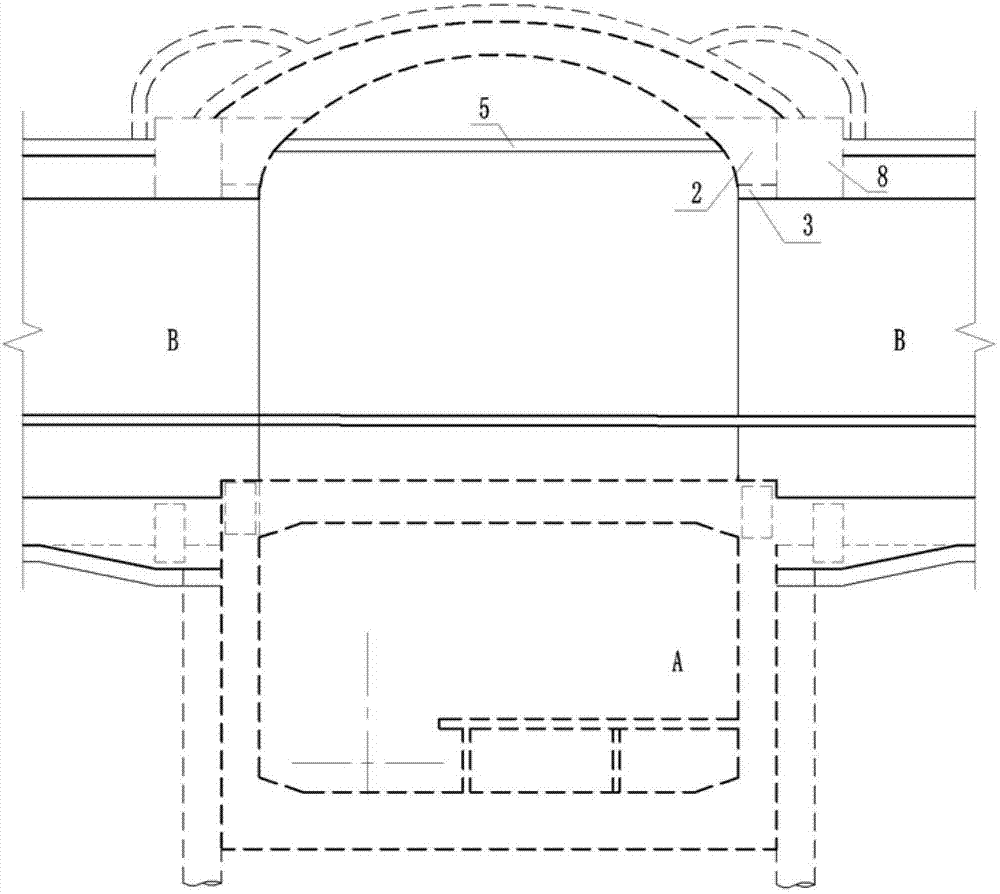

Arched subway station old and new building connection structure and construction method

ActiveCN102943678BIncrease stiffnessConstrained deformationUnderground chambersCompound (substance)Subway station

The invention relates to an arched subway station old and new building connection structure and a construction method. A profile steel pull rod is made of profile steel and divided into two sections which are connected, and a gap is reserved in the middle of the profile steel pull rod and is provided with a bolt fastening mechanism. A plurality of groups of chemical screws are oppositely arranged on the inner side of a bottom girder of an arched ceiling arranged in the range of an opening disposed on the lateral wall of an existing station, a plurality of profile steel pull rods with two ends respectively fixedly provided with wedge-shaped steel plates are fixedly connected with the corresponding chemical screws through the wedge-shaped steel plates, and the profile steel pull rods are connected between the bottom girders arranged on two sides of the arched ceilings and are fixed. The construction method is characterized in that firstly the profile steel pull rods are adopted to exert tensioning force on arched angle portions in advance, then a newly built structure is adopted to reinforce the supporting ceilings, and finally the old structure is demounted in segmented mode. Operation is easy, construction procedure is simple, and control on deformation and internal force conversion of the existing structure is benefited.

Owner:BEIJING GENERAL MUNICIPAL ENG DESIGN & RES INST

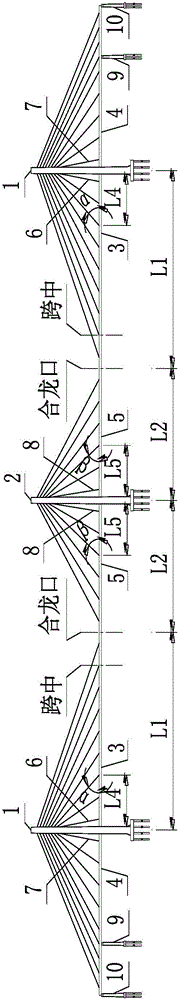

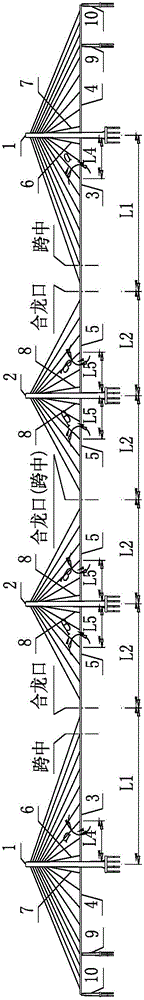

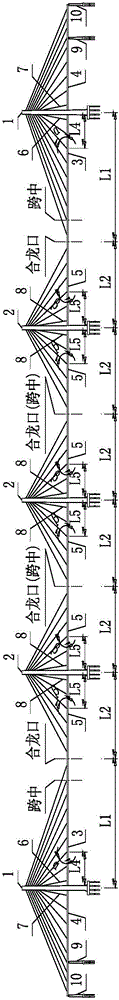

Multi-tower cable-stayed bridge and construction method thereof

ActiveCN105887654ASimple structureNice appearanceCable-stayed bridgeBridge structural detailsCable stayedTower

A multi-tower cable-stayed bridge comprises two big-umbrella-shaped structural systems on the two sides and a small-umbrella-shaped structural system in the middle. Each big-umbrella-shaped structural system comprises a side tower, a big-umbrella mid-span main beam, a side-span main beam, mid-span stay cables and side-span stay cables, wherein the big-umbrella mid-span / side-span stay cables are connected with the side tower and the mid-span / side-span main beam. The small-umbrella-shaped structural system comprises a middle tower, small-umbrella main beams and small-umbrella stay cables, wherein the small-umbrella stay cables are connected with the middle tower and the small-umbrella main beams. In the construction process, firstly, the side tower, the middle tower and the like are constructed first; then, the big-umbrella mid-span main beam and the side-span main beam are symmetrically constructed, wherein beam sections without supports like auxiliary piers are constructed with a cantilever construction method, and beam sections with supports like auxiliary piers are constructed with a support cast-in-place or hoisting method; finally, the main beams of the big-umbrella-shaped structural systems and the small-umbrella-shaped structural system are constructed to a final closure at the same time, and final closing is performed to achieve the finished bridge state. The multi-tower cable-stayed bridge has the advantages of being high in system rigidity, high in construction safety and the like.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com