Construction technology for tunnel trunk primary support

A technology of primary support and construction technology, applied in tunnels, tunnel linings, shaft equipment, etc., can solve problems that affect the rapid construction and safe operation of tunnels, large deformation of surrounding rock extrusion and even landslides, and support structure instability, etc., to achieve The effects of eliminating potential safety hazards, stabilizing the foundation, and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

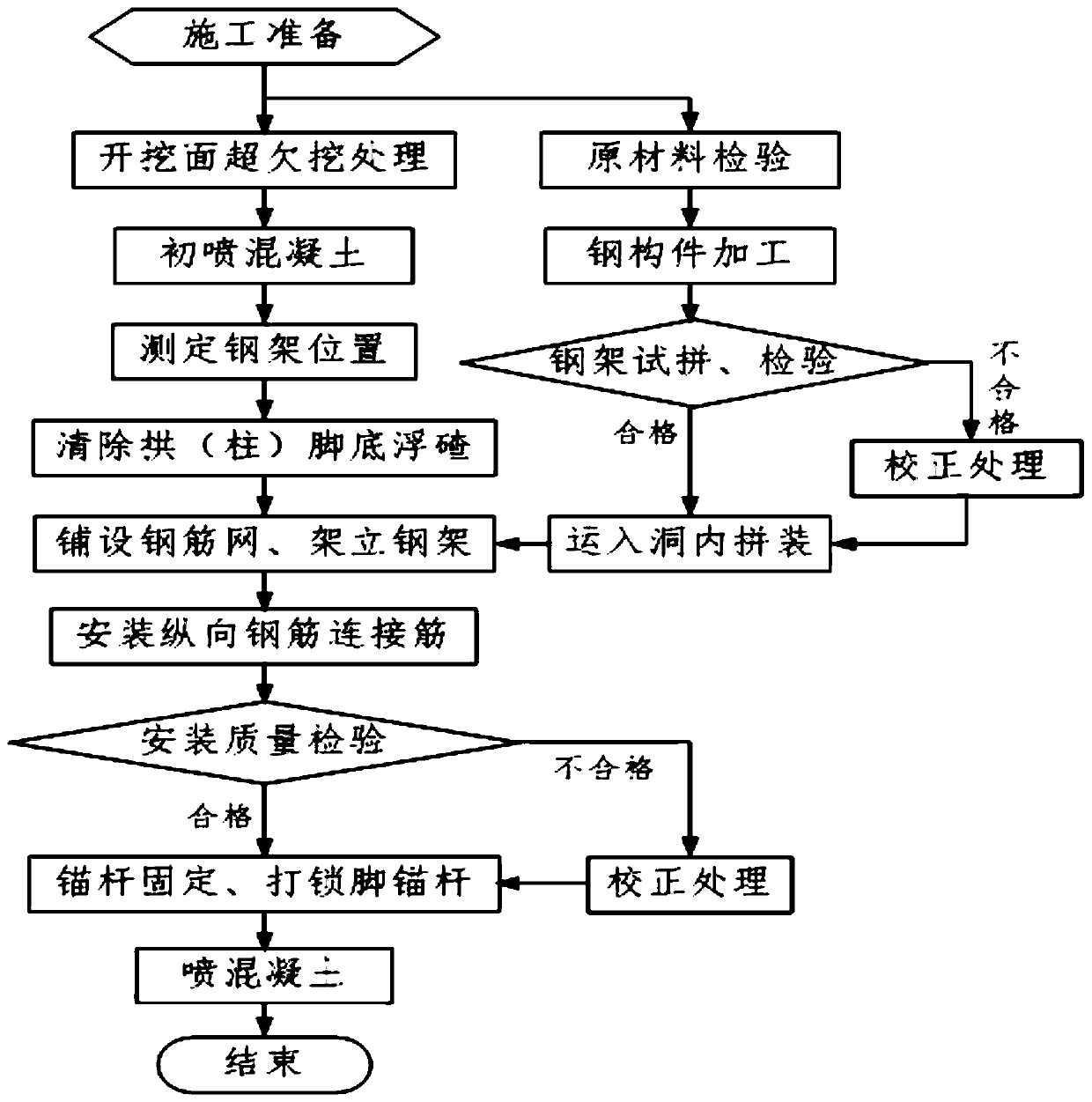

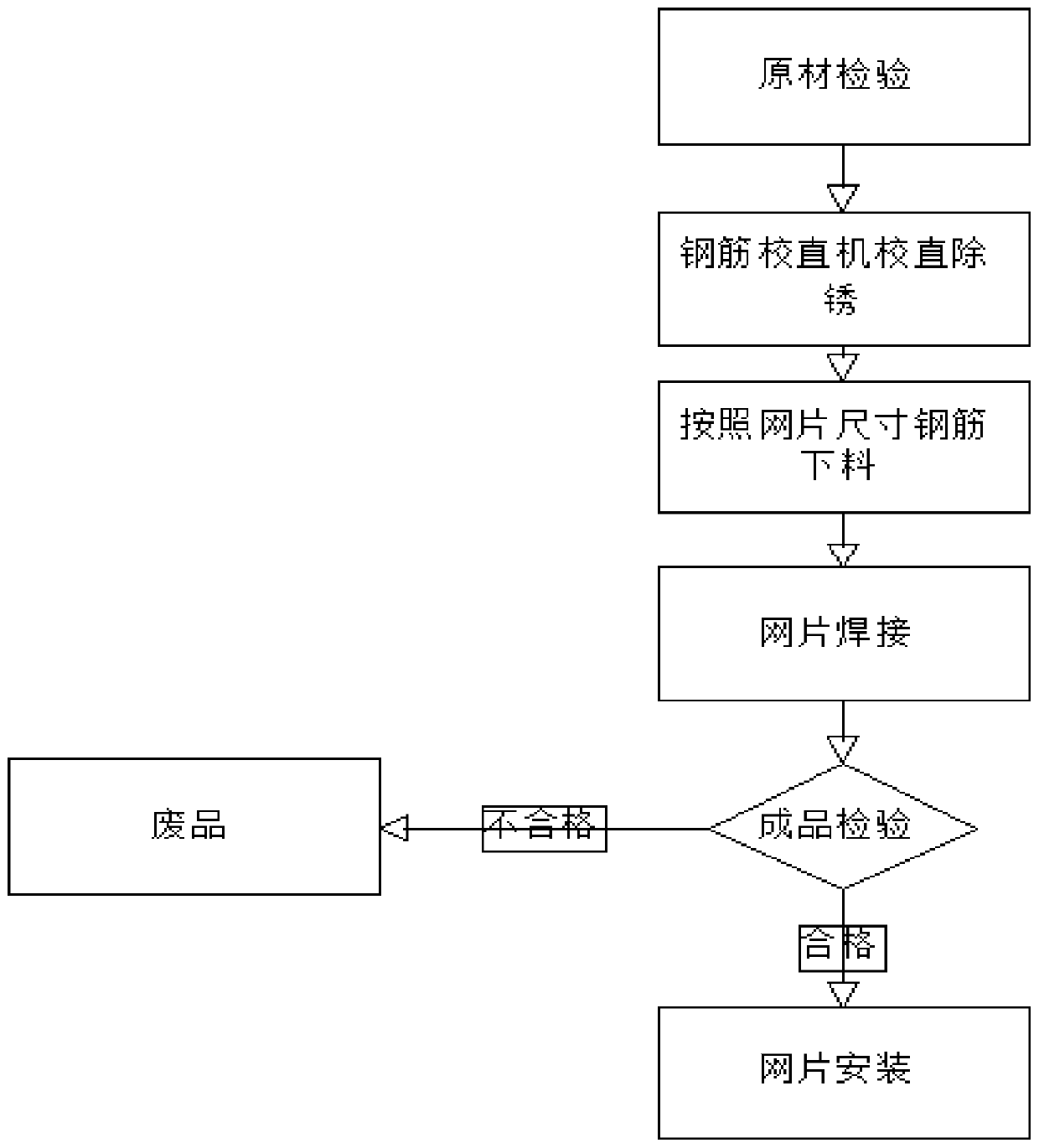

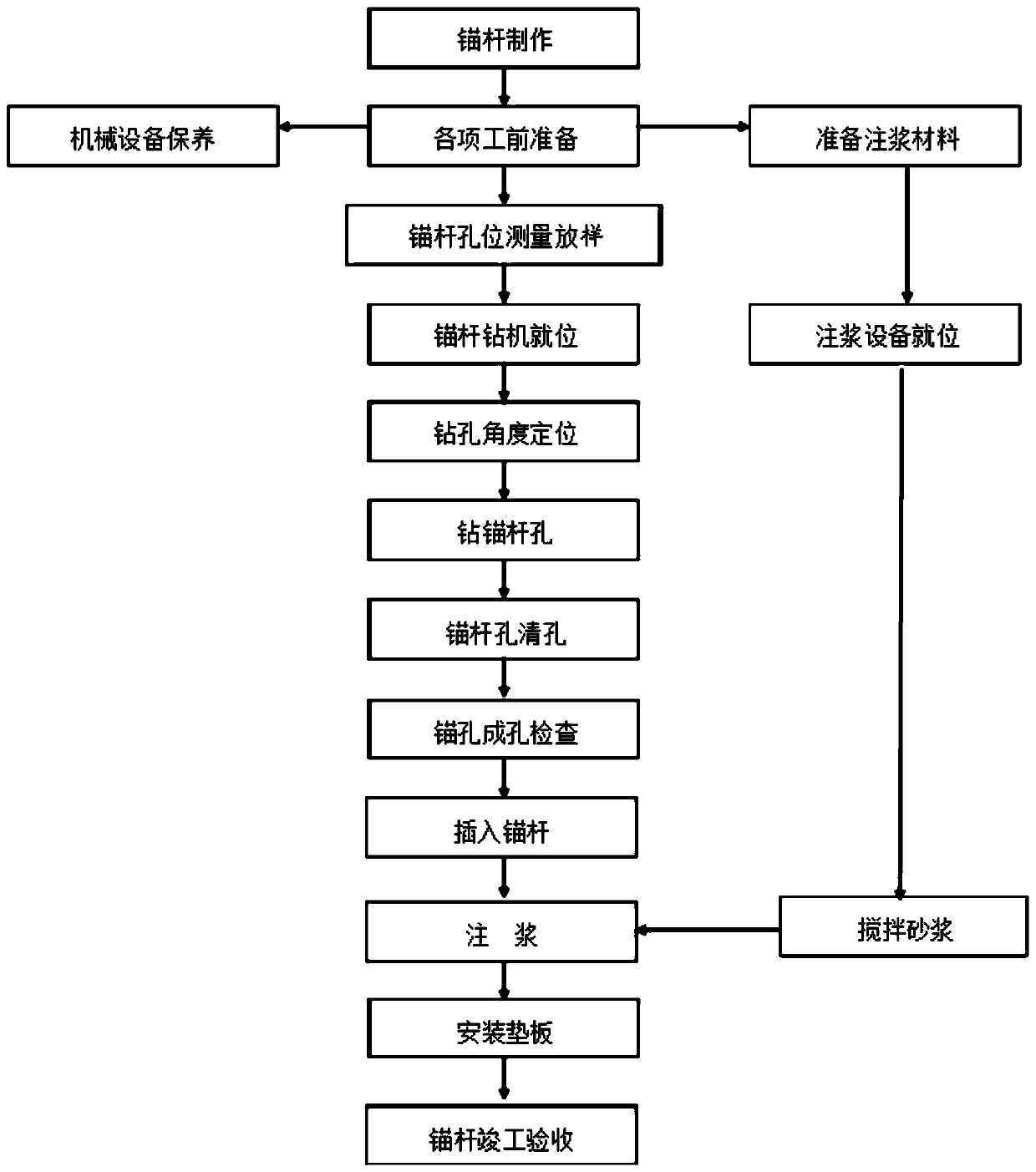

[0030] see Figure 1 to Figure 4 , the construction technology of the initial support of the tunnel body of the present invention includes the following processes: initial spraying of concrete, steel support installation, advance support of the next cycle, installation of steel mesh, re-spraying of concrete and installation of system anchor rods;

[0031]When carrying out the primary spraying concrete process, adopt the wet spraying process and include the concrete preparation step and the concrete spraying step;

[0032] When performing the concrete preparation step, the following materials are used to configure the concrete: cement, sand, crushed stone, quick-setting agent and water; the cement is ordinary Portland cement; the fineness modulus of the sand is greater than 2.5, and the moisture content is 5-7%; The maximum particle size of the crushed stone is not greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com