Manufacturing method for shape follow-up supporting model for selective laser melting metal additive manufacturing

A selective laser melting and metal additive technology, which is applied in the field of metal additive manufacturing, can solve problems such as large internal stress, affecting the normal use of parts, and shape deviation of parts, so as to reduce thermal stress deformation, reduce temperature gradient, reduce The effect of internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Selected area laser melting metal additive manufacturing technology is based on the three-dimensional model data of the part, and the physical part is made by means of material accumulation through the forming equipment. The manufacturing method of the conformal support model of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that the drawings are only for illustration and should not be construed as limiting the present invention.

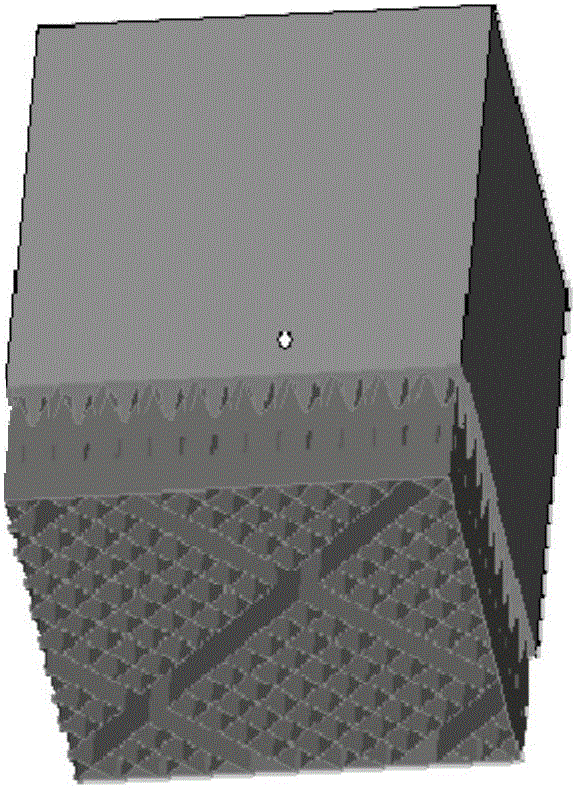

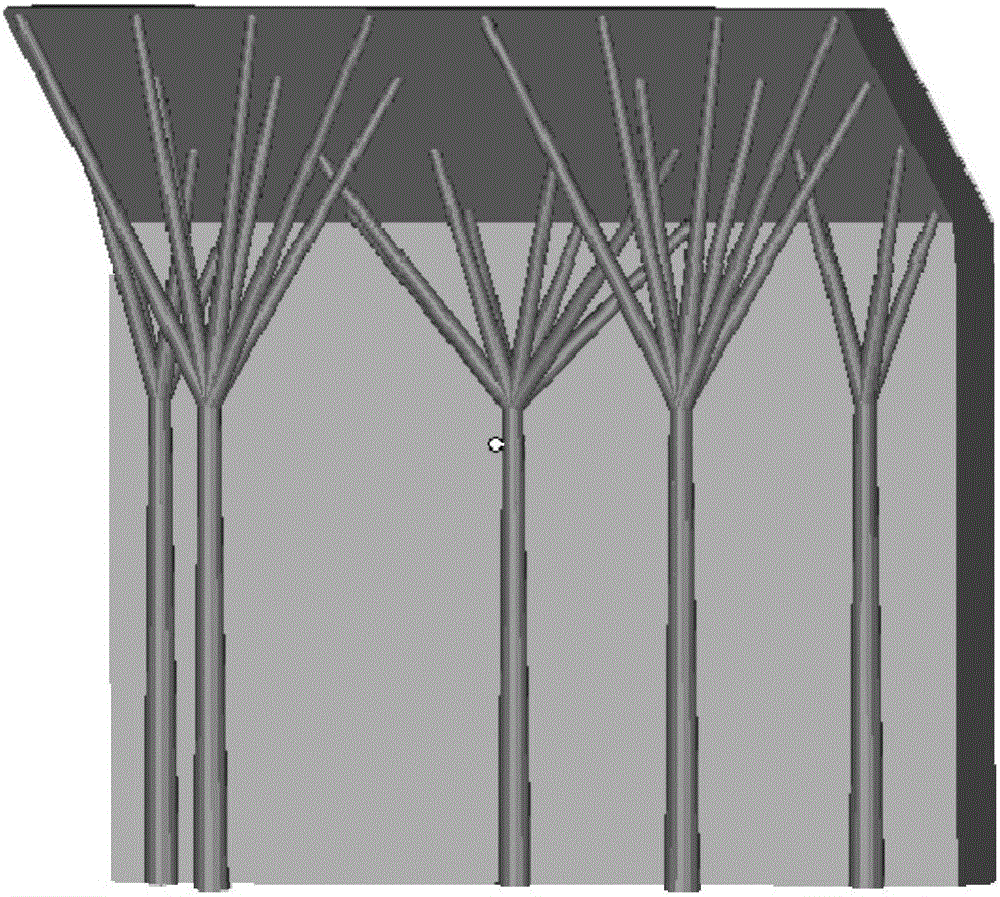

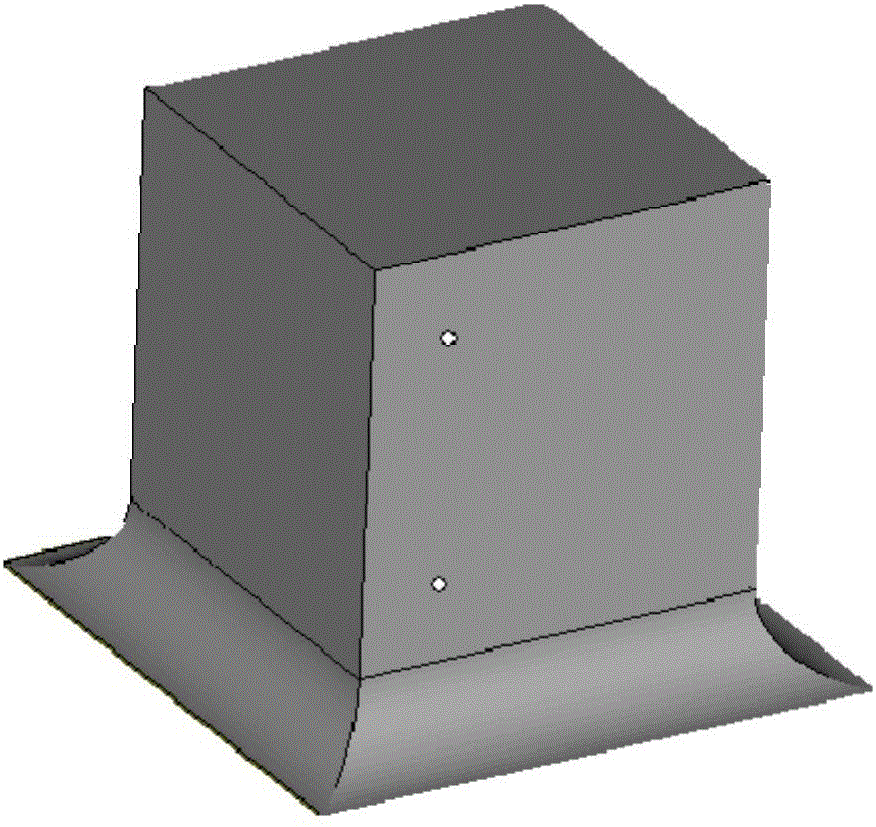

[0021] image 3 A flow chart of the manufacturing method of the conformal support model of the present invention is shown. In step S301, a three-dimensional part model is created by using three-dimensional drawing software. Specifically, the format of the 3D part model needs to be compatible with the drawing software. Open the 3D drawing software, load the 3D part model to be added with conformal support into the software, and then place the parts according to the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com