Supporting device and method for loess tunnel

A support device and technology for loess tunnels, applied in tunnels, earthwork drilling, tunnel lining, etc., can solve problems such as instability, inappropriateness, and instability of loess water absorption, so as to prevent falling off, increase safety reserves, and facilitate stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

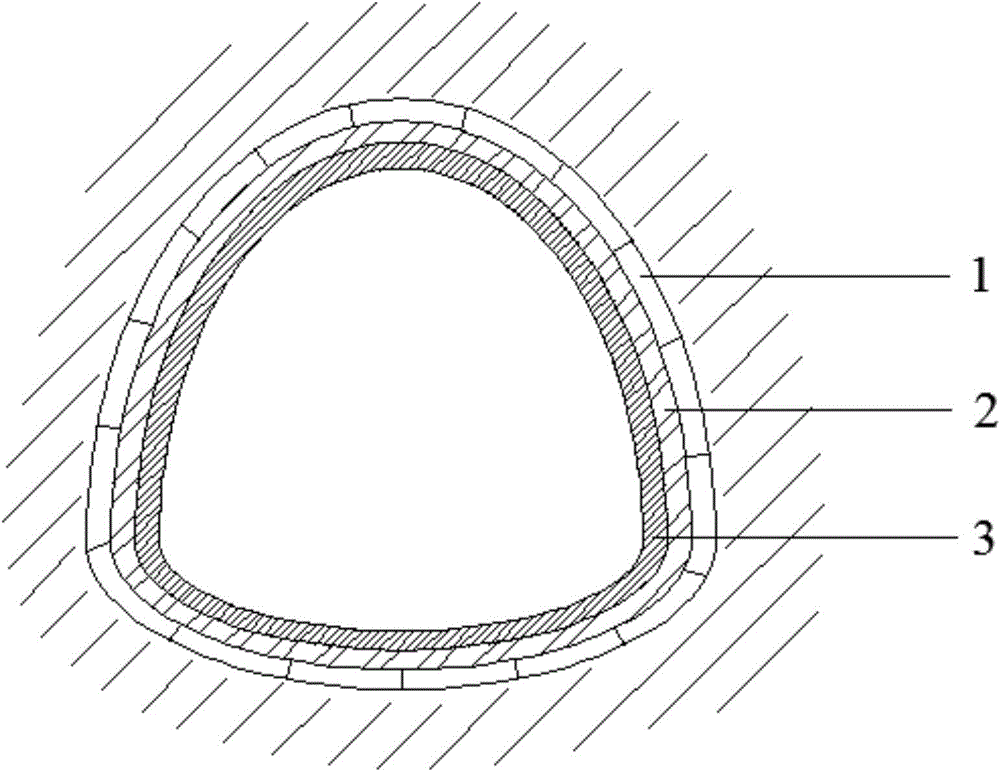

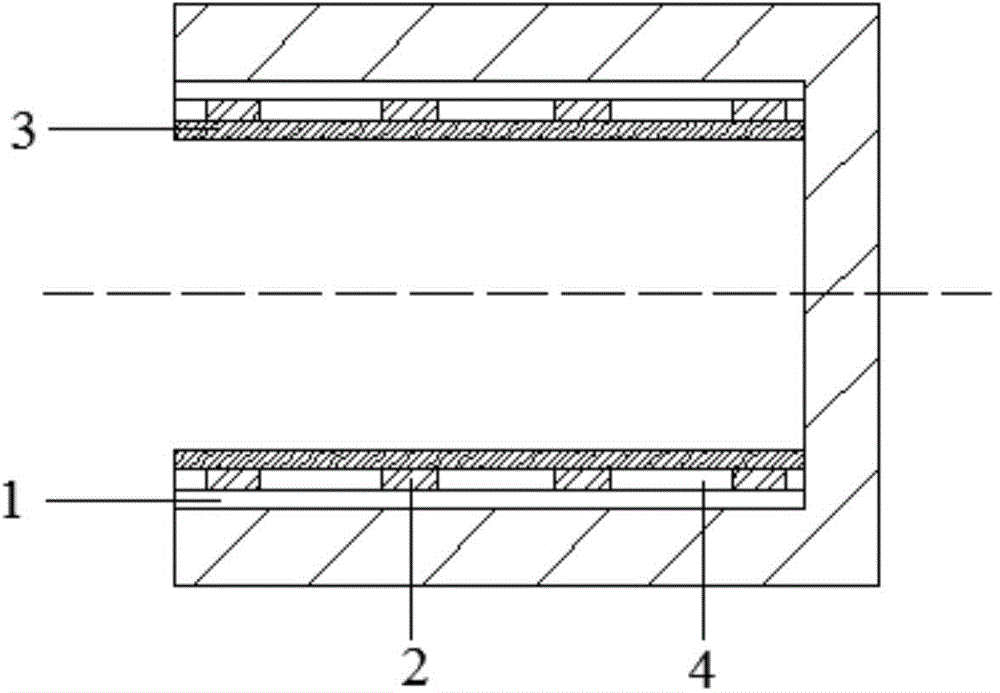

[0024] Such as figure 1 and figure 2 The support structure of a collapsible loess tunnel is shown, including: a wooden plank 1 used for tunnel support, a steel arch frame 2 used for tunnel support, prefabricated reinforced concrete segments 3 and two steel arches Wooden planks for padding between the shelves 24.

[0025] Tunnel support is divided into two supports, the inner one (near the cave wall) is called the first lining, the outer one is called the second lining, the first lining is the main force-bearing component, and the second lining also bears the force, and the second lining is mainly used as a safety reserve .

[0026] Wooden board 1 and steel arch 2 form a lining. Wooden board 1 surrounds the tunnel to prevent the soil from falling off the surface of the tunnel and form a load-bearing ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com