Recyclable front-assembled supporting envelop enclosure and applying method thereof

A technology of enclosure structure and application method, applied in basic structure engineering, excavation, construction, etc., can solve the problems of reducing construction cost, large grading and slope ratio requirements, and large impact on the surrounding environment, so as to reduce support construction time, reduce The effect of cement consumption and economical enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The features of the present invention and other relevant features are described in further detail below in conjunction with the accompanying drawings through the embodiments, so as to facilitate the understanding of those skilled in the art:

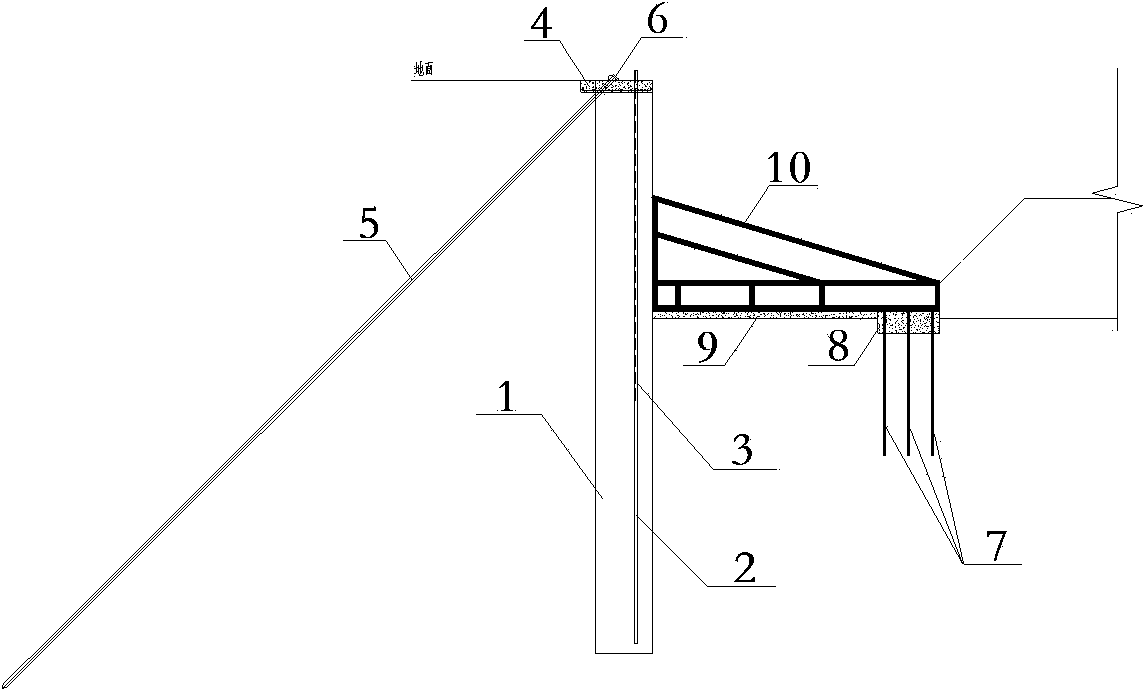

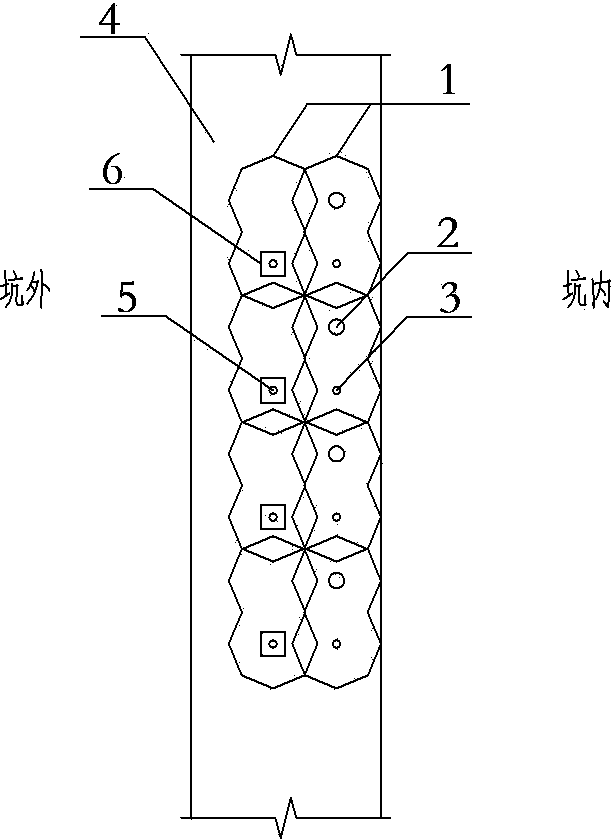

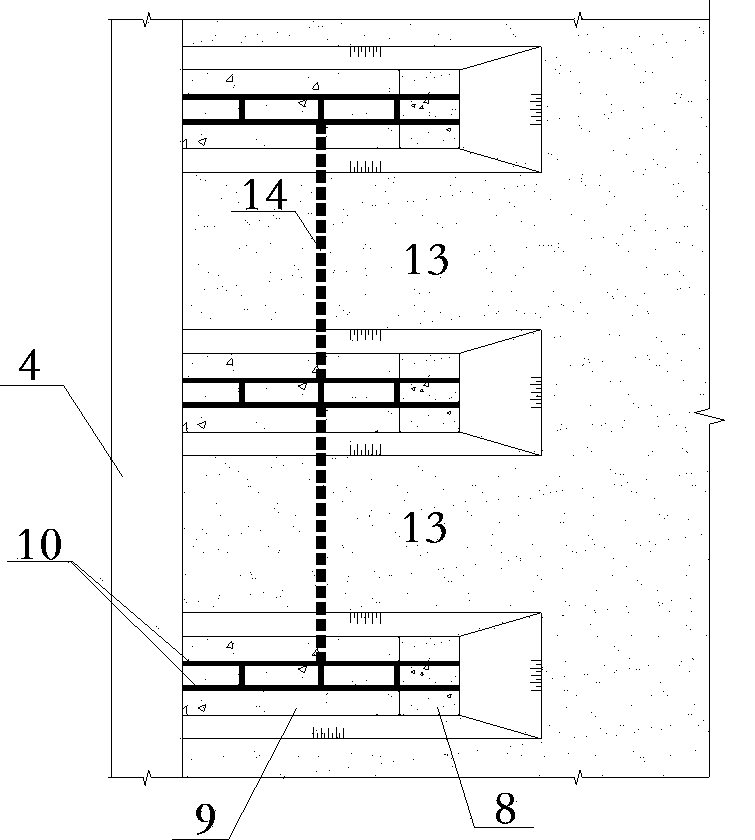

[0025] Such as Figure 1-4 , marks 1-14 in the figure are: cement soil wall 1, inner group long steel pipe 2, inner group short steel pipe 3, top plate 4, outer group steel pipe 5, bolts and pads 6, steel pipe 7, supporting pier 8, Pit bottom cushion 9, pre-assembled steel support frame 10, first layer of soil 11, soil 12, grading soil 13, connecting rod 14.

[0026] Example: such as figure 1 , 2 , 3, the present embodiment specifically relates to a recyclable prefabricated support enclosure for soft soil foundation pits and its application method. The inner group of short steel pipes 3, the pressure top plate 4, the outer group of steel pipes 5, the pre-assembled steel support frame 10, the pit bottom cushion 9 and the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com