Electromagnetic blank holder method suitable for high-speed forming

A technology of edge blanking and high speed, which is applied in the field of electromagnetic blanking of high-speed forming, can solve the problems of large frictional resistance and unfavorable plastic flow of metal sheets, unfavorable deep drawing, and inability to effectively suppress wrinkling of sheets, etc., and is conducive to plastic flow. , the effect of reducing plastic flow resistance and contact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

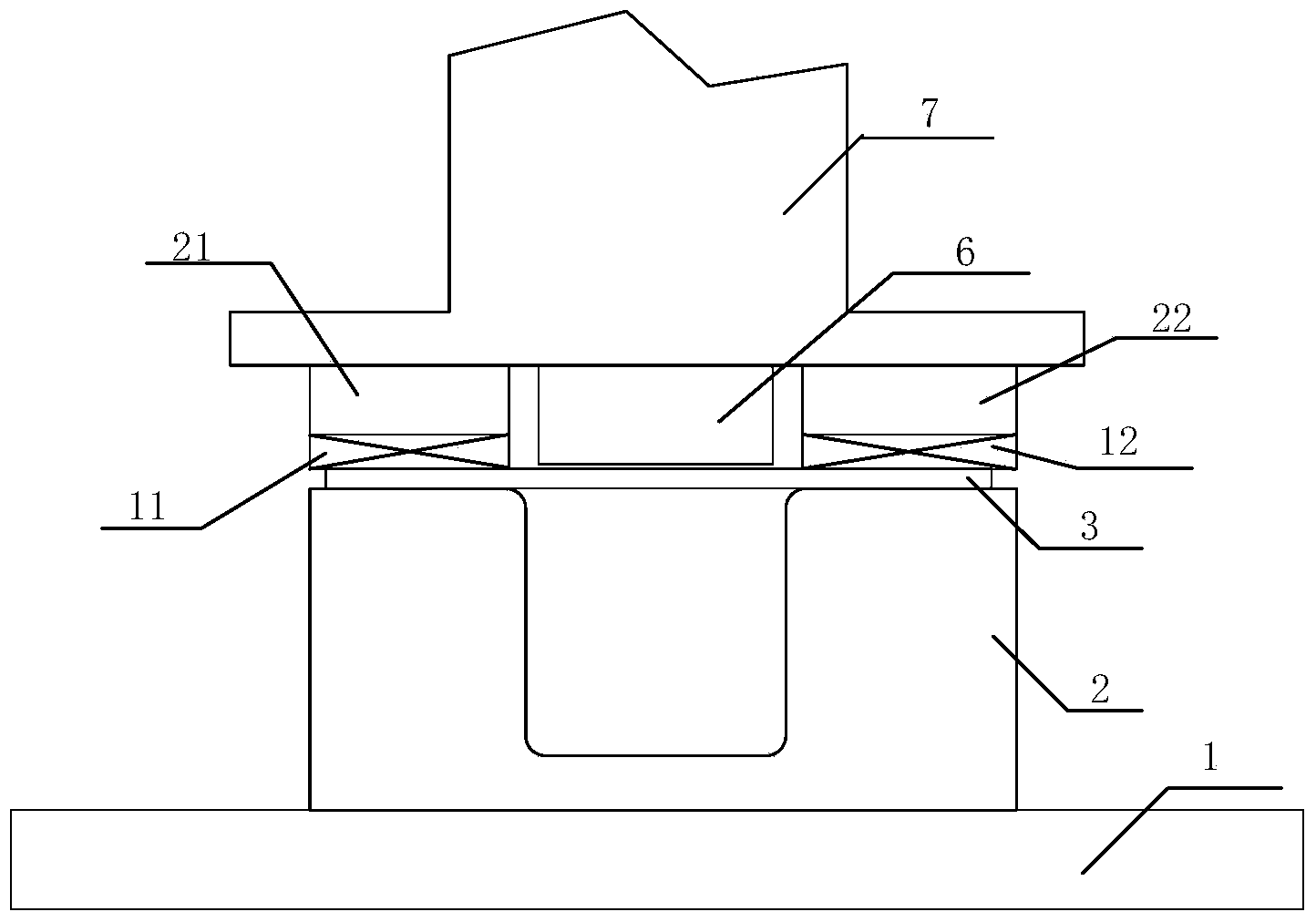

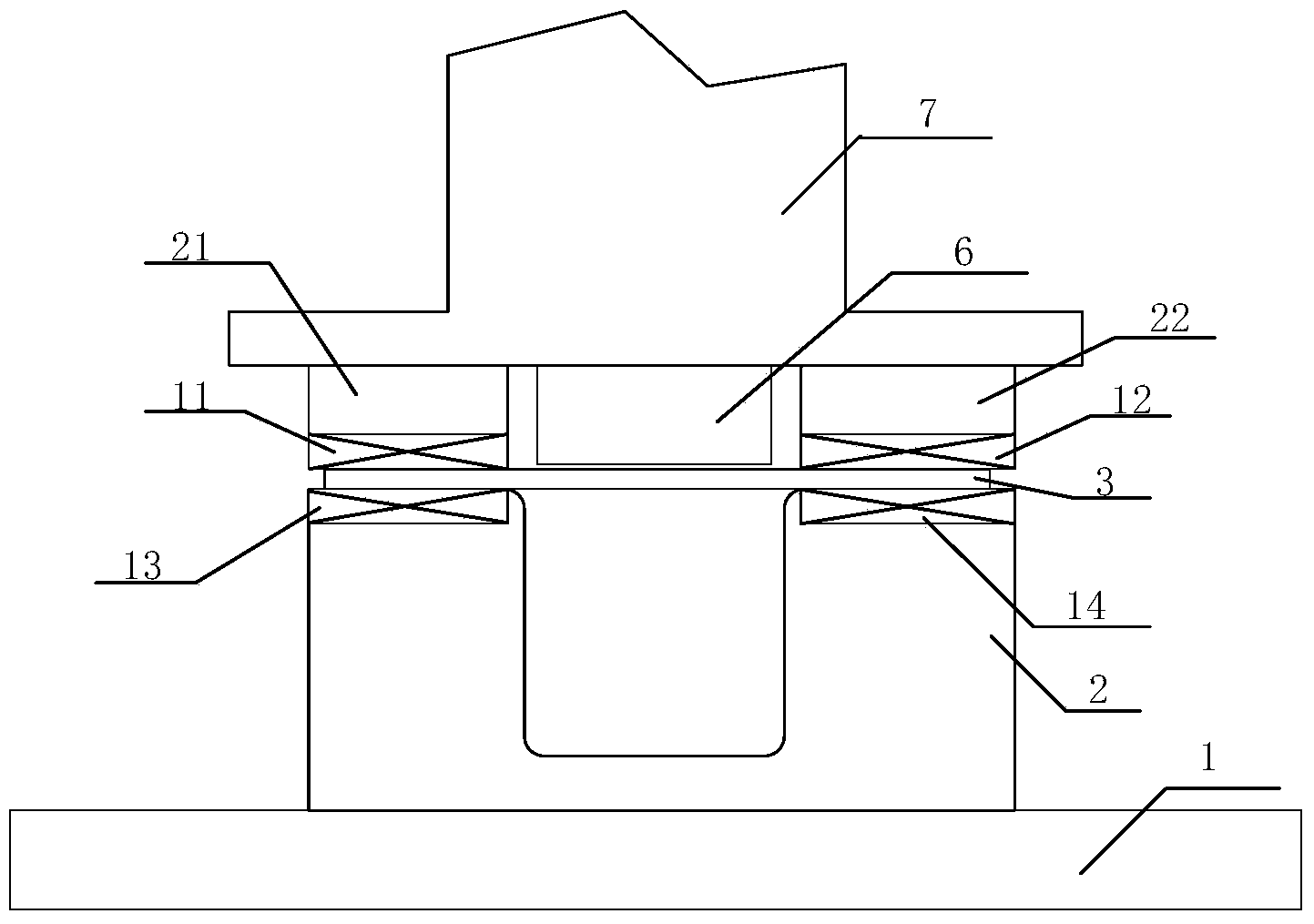

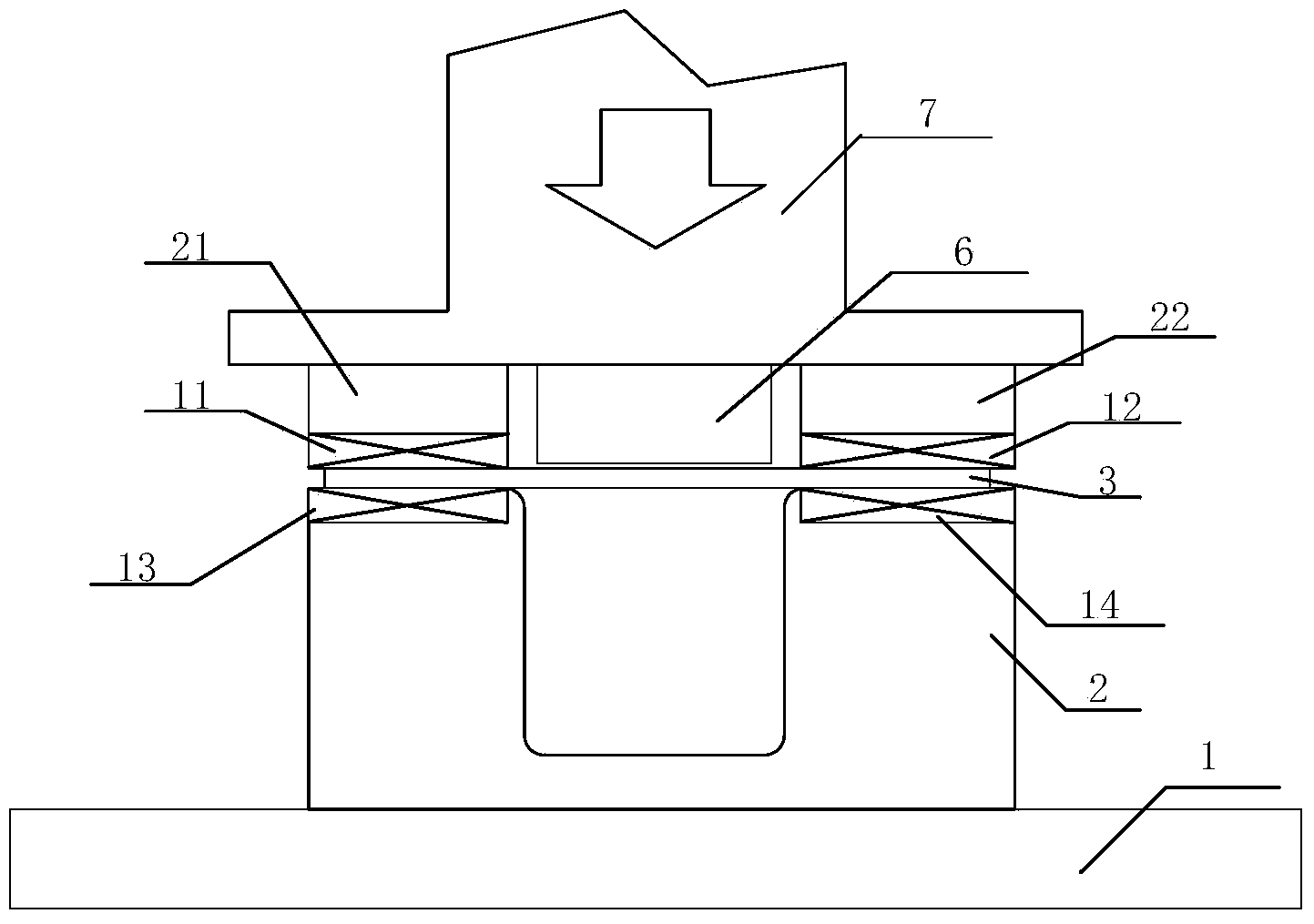

[0021] like figure 1 As shown, according to the first embodiment of the present invention, the electromagnetic blank-holding method suitable for high-speed forming of the present invention is applied in an electromagnetic forming system, which includes a base 1, a die 2, an electromagnetic forming coil 6, As well as the press motion platform 7, the method includes the following steps:

[0022] (1) Fixing the first crimping coil 11 and the second crimping coil 12 on the press motion platform 7 through the first tooling 21 and the second tooling 22 respectively;

[0023] (2) Control the motion platform 7 of the press so that the first crimping coil 11 and the second crimping coil 12 are in contact with the upper end surface of the metal plate 3, but no mechanical pressure is applied;

[0024] (3) During the electromagnetic forming process of the sheet metal part 3, the first blanking coil 11 and the second blanking coil 12 are supplied with pulse currents, which induce eddy cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com