High-performance component twisting-extruding forming device

A high-performance, extrusion-forming technology, applied in the field of metal plastic processing, which can solve problems such as difficulty in processing high-performance plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0040] The invention provides a twist-extrusion forming device for high-performance components.

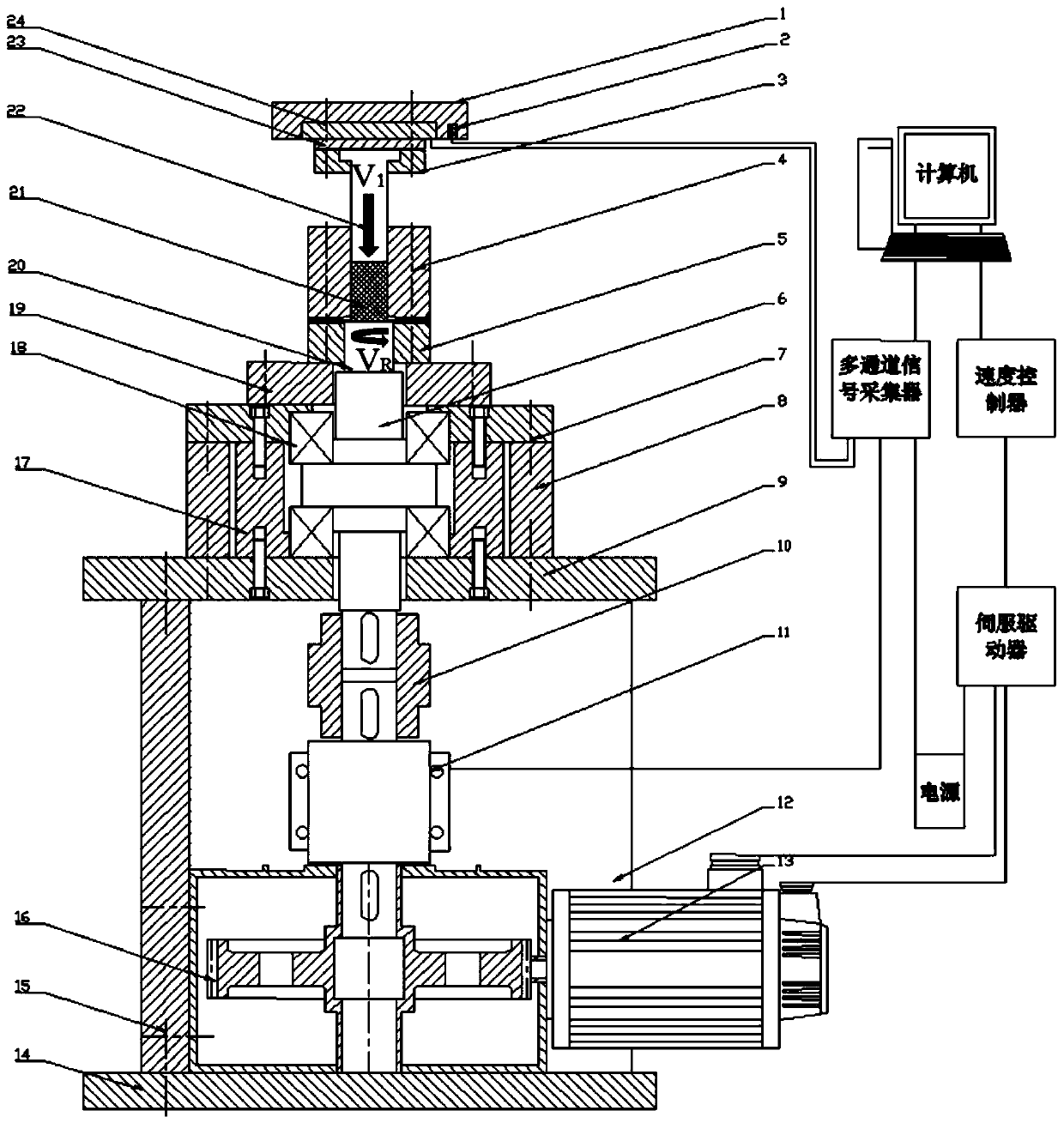

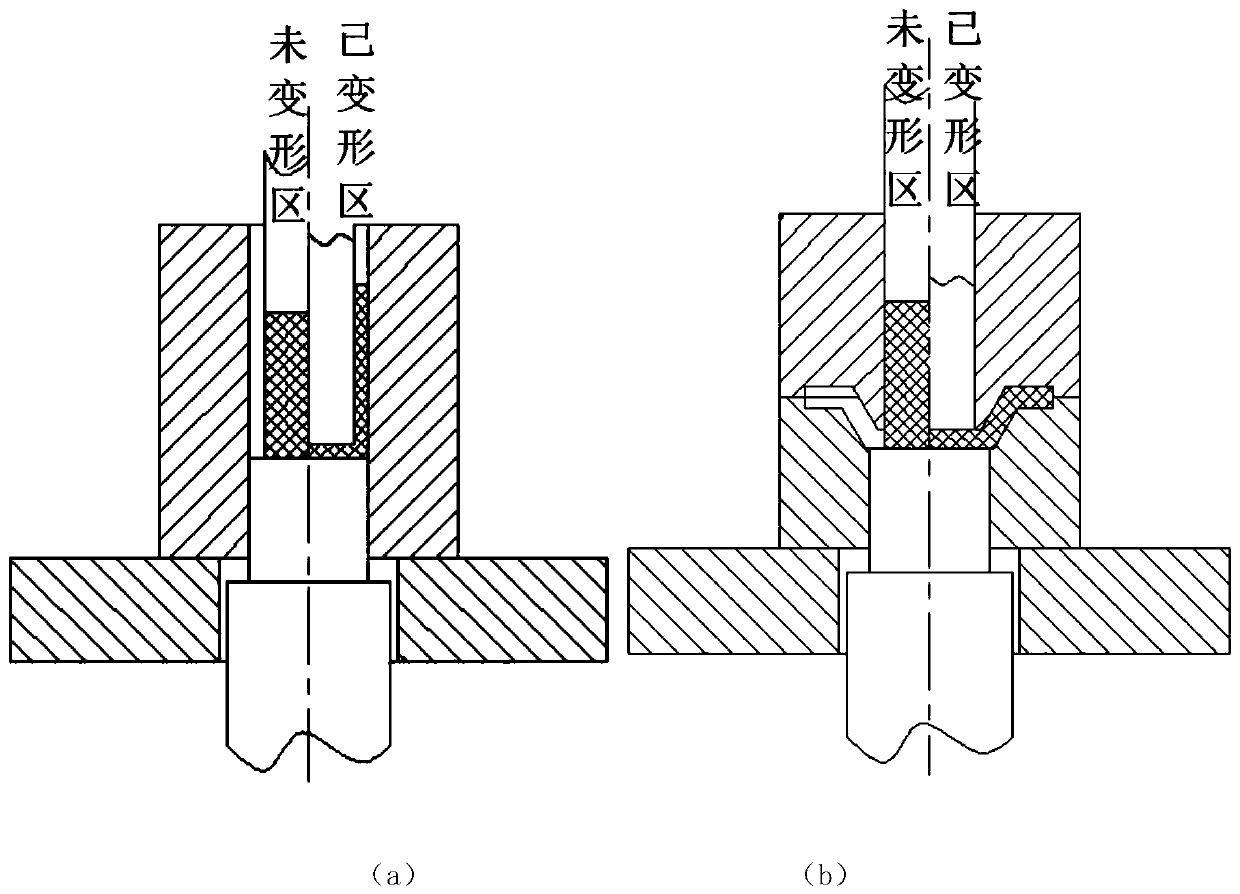

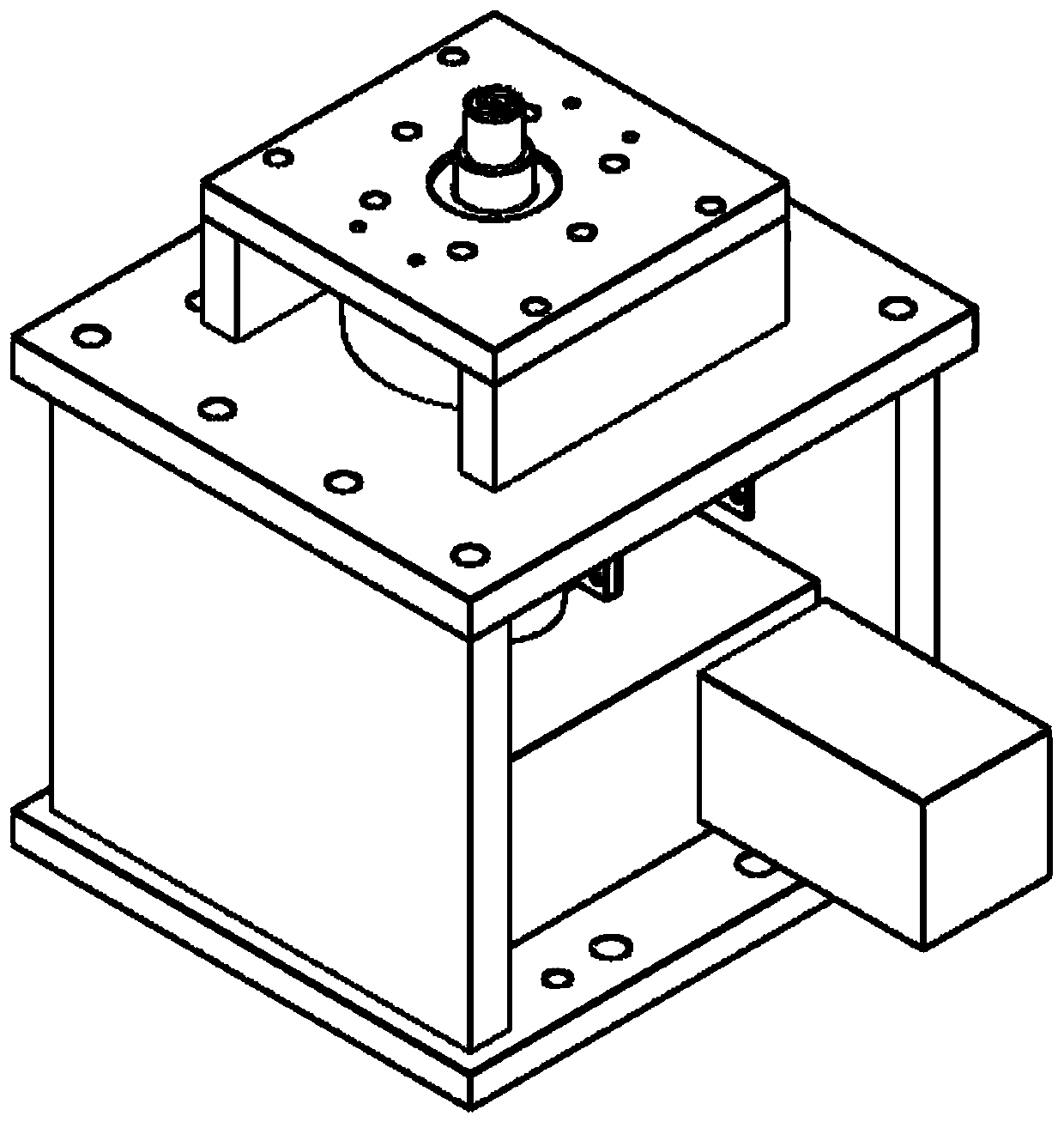

[0041] Such as figure 1As shown, the device includes an extrusion forming part, a torsional shearing part, a control part and a detection part. The extrusion forming part includes a punch 22, an extrusion cylinder 4, a mold 5, an upper die base 1, a backing plate 23, a baffle plate 3 and a lower die base 19, and the extrusion forming part is connected to the torsional shearing part by hexagon socket bolts; The torsional shear part includes torsion shaft 20, main shaft 6, thrust self-aligning roller bearing 18, bearing housing 17, bearing housing upper cover 7, bearing housing lower cover 9, bearing housing supporting plate 8, reducer supporting plate 12, R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com