Inner geotextile bag sleeve valve pipe grouting construction method

A sleeve valve pipe grouting and construction method technology, which is applied in the field of geotechnical engineering grouting, can solve the problems of restricting cement diffusion space, complex construction technology, and easy occurrence of grouting, so as to improve engineering construction efficiency and reduce pipe jamming , The effect of simple construction method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Those skilled in the art can understand that, unless otherwise defined, all terms (including technical terms and scientific terms) used herein have the same meaning as commonly understood by those of ordinary skill in the art to which this invention belongs. It should also be understood that terms such as those defined in commonly used dictionaries should be understood to have a meaning consistent with the meaning in the context of the prior art, and will not be interpreted in an idealized or overly formal sense unless defined as herein explain.

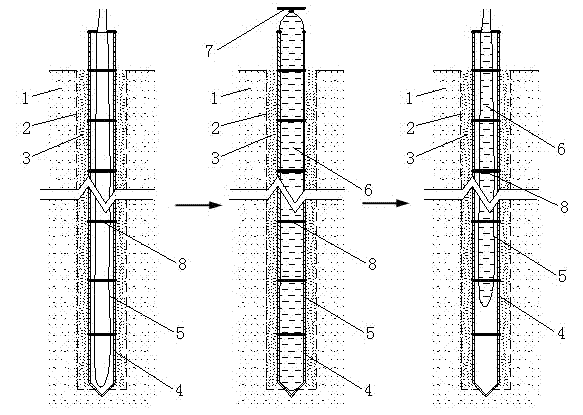

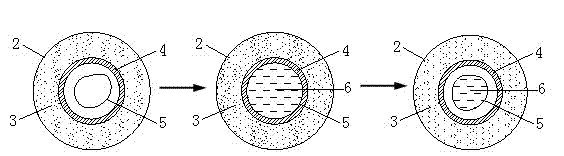

[0032] like figure 1 and 2 As shown, the geological drilling rig and other equipment are used to drill vertically in the foundation soil 1, and the mud retaining wall is formed into a hole with a diameter of 90-110 mm. After the drill hole 2 reaches the designed depth, the prepared casing material 3 is pumped to the The bottom of the hole is filled from bottom to top. After the casing material 3 is poured, immediately press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com