Quick transverse cloth shearing system

A technology of transverse shearing and cloth, which is applied in the cutting of textile materials, textiles and papermaking, etc., which can solve the problems of mechanical movement that cannot carry out continuous and rapid conveying and cross-cutting, the original state of cloth conveying and staying, and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

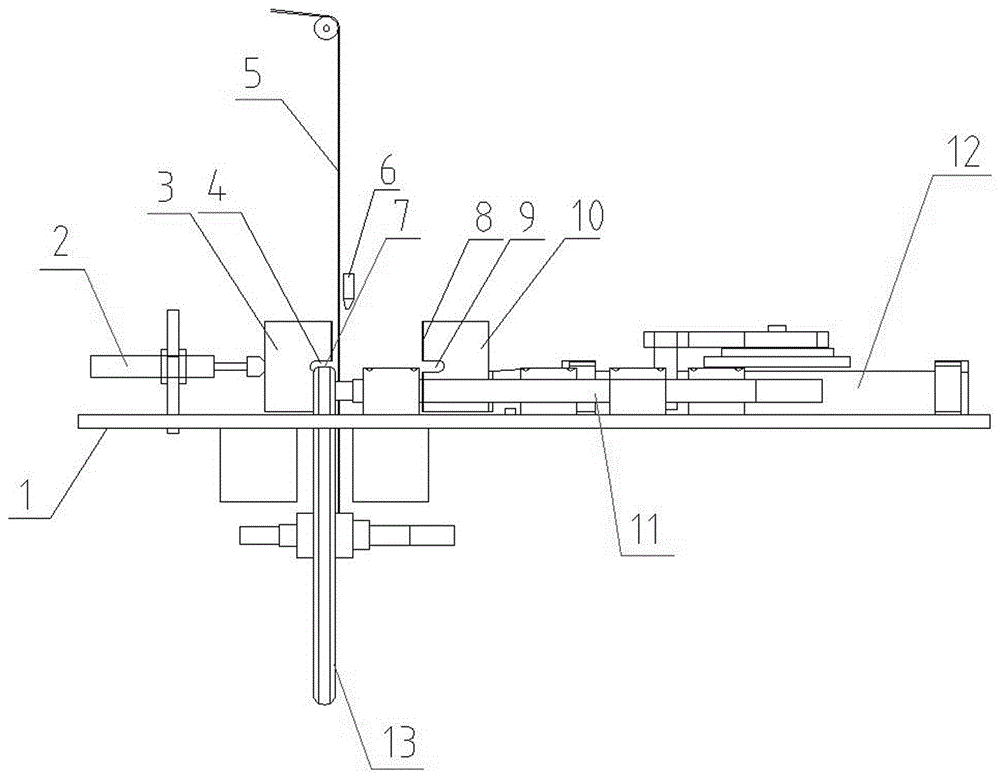

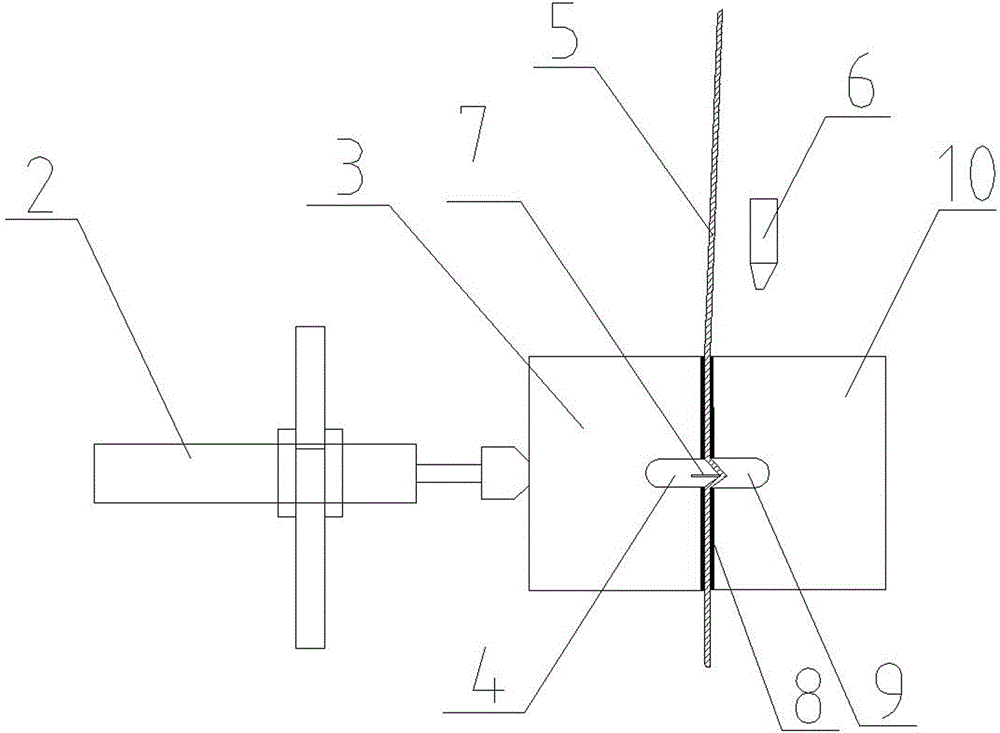

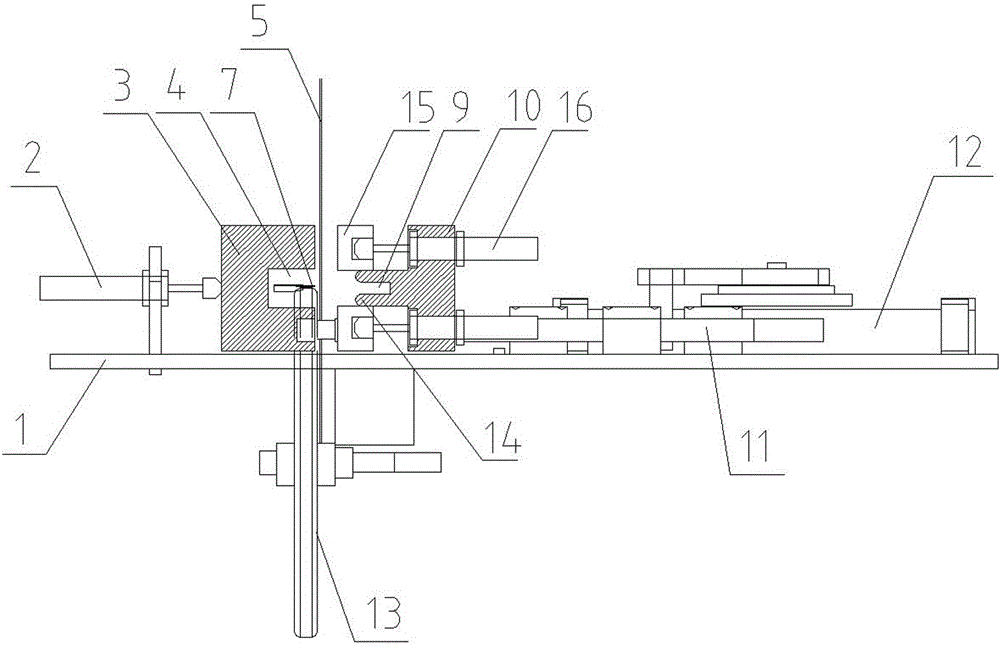

[0021] like figure 1 , 2 A kind of fast horizontal shearing system of cloth is shown, has frame 1, and the channel that cloth 5 vertically falls is arranged on described frame, and fixed knife block 3 is arranged on the frame of one side of described channel, and the back side of fixed knife block A first elastic support device 2 is provided, and the first elastic support device 2 is used as an oil pressure buffer. The corresponding cloth side of the fixed knife block 3 has a knife groove 4 that runs through horizontally, and the frame is provided with at least 2 or more than 2 ring cutter wheels 13, and an annular knife belt 7 is housed on the ring cutter wheel. The blade of the belt is wavy or serrated or straight. A straight section of the annular knife belt is located in the sipe 4, and the straight section of the annular knife belt in the groove is arranged at an acute angle with the cloth, and the two are in point-like contact with transverse cutting, and the annular k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com